1980Mooney

Basic Member-

Posts

3,249 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

@William A Here is a good thread earlier in the year on real maintenance costs of Turbo vs. Non-turbo

-

If "$150-200/hr in rental fees and having maintenance issues with the rentals 30% of the time" bothers you I hope you don't think owning a Mooney will reduce that cost. (and I assume $150-200/hr to rent a C-172 is "wet" including fuel). Your hourly cost of owning a J or K will likely be double that. Remember when it comes to airplane ownership some of the biggest lies by owners are related to the true cost of ownership. Why? - because we like to fly and have a passion for it. And it generally costs more than we plan or want to admit. As a "newbie" I bet your insurance on a Mooney (if you can get it) will be over $4,500/yr. You said you are in Ft. Worth and I see the smallest T-hangars at Meecham are $425/month and at Spinks $325/month. So you will be spending about $4,000 - 5,000/year just to park your plane. Your Annual with repairs will easily run $4,000/year - every now and then you will have the "Annual from Hell" that costs way more. The typical A&P in Texas has shop rates of $100/hour or more (and rising). Don't forget the cost of Databases and Subscriptions - Foreflight, Garmin, Jeppessen, etc. Depending on your avionics stack you could wind up spending another $1,000/year. So you could be spending $14,000/year in cash without even flying your Mooney one hour. If you fly 60 hr/year then that amortizes to $233/hr. There are a lot of unexpected maintenance issues when owning and flying (sometimes seems like 30% of the time!) so get ready to write $1,000-2,000 checks every now and then. And if you can average 11 gal./per hour with 100LL Avgas around Ft. Worth $6.50-7.00 then that will cost $70-77/hr. ($4,200 - 4,600/yr. @ 60 hrs/yr) So if you fly 60 hr/year your total cost will be about $300/hour. But you have nothing there for wear and tear and replacement over time. Engine overhaul $50,000 (and if you have a K with the 6 cylinder turbocharged Continental - although still 360 cu in. and only 210 HP it will cost you WAY MORE to overhaul than the Lycoming in the J) Prop overhaul - $2,500 - Replacement $10,000 Avionics upgrades $5,000 - 15,000 Paint - $13,000 Fuel Tank Reseal - $10,000 Interior - $5,000 That adds up to over $100,000 so if you can nurse 20 years out of each item then the average annual cost of replacement is $5,000/year. If you fly 60 hours per year that is another $83/hour to amortize. That gets you up to $380+/hour. And these costs come in big slugs. (some soon after you buy - hence the need for a good "pre-buy" inspection in case the previous owner had deferred a lot of needed repairs and had a lot of "pencil annuals".) Don't get me wrong - I also did the same thing as you with a young family of 4. I bought a J model Mooney when I had only 48 hours in a C-172 and 1 1/2 months before I got my Private. I had 2 instructors and I didn't tell the first instructor/flight school that I was flying a Mooney at the same time with a different instructor. And I did have insurance. Of course that was "last century". I still have the same Mooney although I added a 300 HP IO-550 to it. I also used the Mooney to train and get my Instrument ticket - which is something you will definitely want to do if you are flying your family in and out of Angel Fire.

-

I suspect that some don't realize the cut-out or the saddle on the base of the nutplate is where the fuel/water drains out. It is against the lower skin and at the lowest place in the tank. There was a SB 20-230 in 1986 and an AD because of sloppy tank sealant application that plugged the lower holes. Fuel/water would only exit when it built up high enough to exit through the valve at a point above the nutplate (like you reference regarding the Monroy idea above). As a result about 1/2 inch of water was always in the tank of the offending planes. https://mooney.com/wp-content/uploads/2020/12/SBM20-230A.pdf https://www.faasafety.gov/files/gslac/library/documents/2018/Jan/139912/Mooney M120J, Blocked Fuel Tank Drains, ATA 2810.pdf https://rgl.faa.gov/Regulatory_and_Guidance_Library/rgad.nsf/0/9C93312CAD9E7AAB86256A4D00490B41?OpenDocument

-

Since the nutplate will be exposed to water perhaps much of its life (especially if an unsumped tank sits for a long time), what is the proper material used in its construction? Brass? Stainless Steel? The nutplate in @Jim Peace picture above looks like it may be ferrous with considerable corrosion.

-

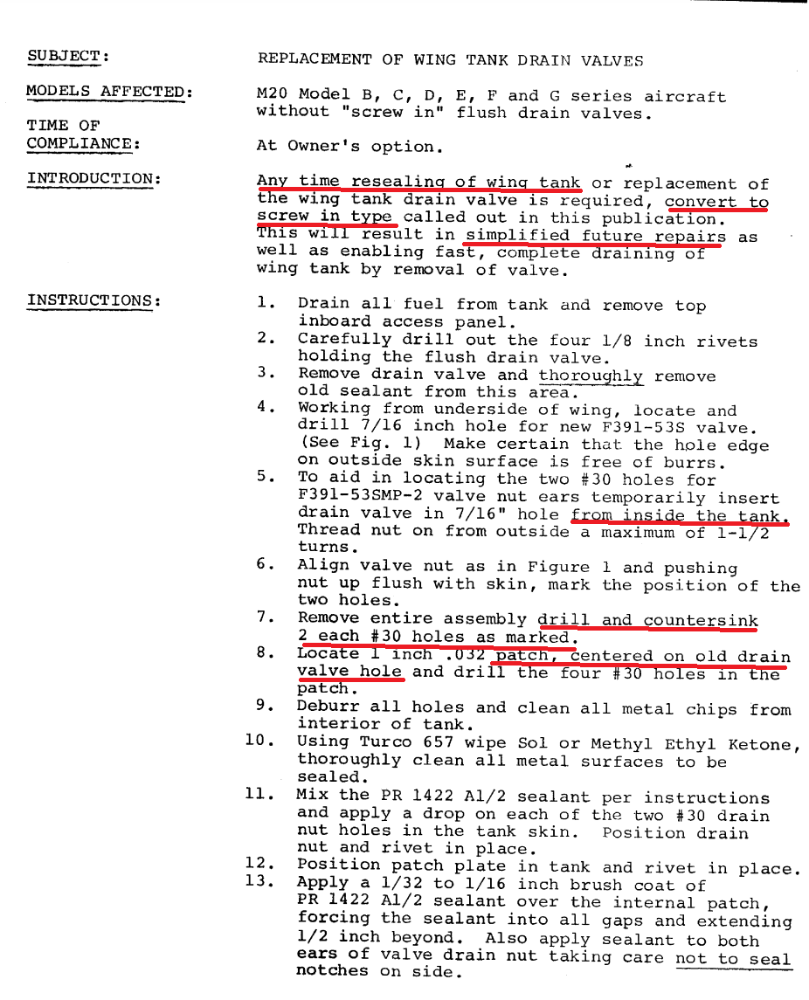

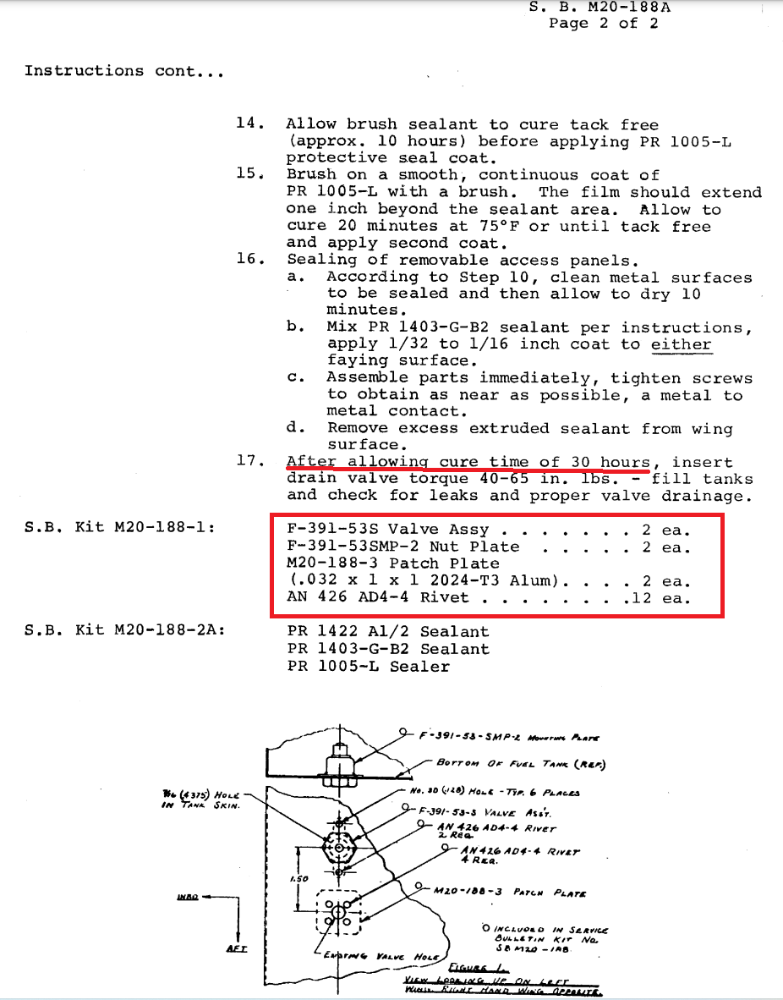

I think @M20Doc hit it on the head. Read Mooney S/B M20-188 and it is all self explanatory. The last thing you want to do is is wreck your $10,000 tank reseal because your 58 year old wing fuel tank drain ( also sometimes called "sump" or "dump") valves failed. The original valves are riveted in and then sealed. Mooney S/B M20-188 removes and patches the old drain hole and locates a new removable drain nearby. It looks like the parts are a small part of the cost - most of it is labor. Regardless $450/wing sounds like a bargain. If you leave to old riveted in drains in place and they fail after the reseal then you will have to open the wing up again and remove all the sealant around the old drain - disrupting the seal (and perhaps paint) on the wing fuel tank entry panels and potentially disrupting other sealant while cleaning the old sealant off to prepare for the patch. https://mooney.com/wp-content/uploads/2020/12/SBM20-188A.pdf

-

mechanic’s mistake - how to handle

1980Mooney replied to dominikos's topic in Miscellaneous Aviation Talk

I agree with @Clarence. I had a similar experience last year. I had to use a new A&P last year for Annual because my longtime A&P had a mechanic shortage and was prioritizing Cirrus customers and letting other customers go. The new A&P declared my plane unairworthy due to a fuel tank leak on one wing. The new A&P brought in a 3rd party, a supposedly reputable aviation service firm based at Hobby Airport, to find and seal my tank leak. This firm was trying to seal the leak from the outside rather than the inside. They tried twice and failed twice. Incredibly they admitted to me that they did not like to try to seal tank leaks (so why were they hired?!). The A&P billed me for the time and materials of this incompetent service company. I protested the bill with the A&P declaring I should pay nothing. We negotiated and the A&P ate most, but not all, of the fuel tank invoice. Make an unbiased neutral case to the avionics shop and A&P. Be factual. Try to come to a fair solution but if you don't get everything you want DONT GET UPSET. Get as much as you can, and then move forward. Last time I looked the number of A&P shops and qualified GA mechanics seems to be declining. I don't see any new ones entering the business. Don't destroy your relationships - you never know when you will be in a bind again at that same airport and will need help. -

1977 M20J Windshield shipping cost & shops

1980Mooney replied to Maxx's topic in Modern Mooney Discussion

One year ago I had to ship an engine mount for an IO550 from Houston to Spokane and back. It was crated in a wooden box nearly but not quite as large as one needed for shipping a windshield. With the box it weighed about 70 -80 lbs. The cost was $400-500 each way. As Clarence says there is no cheap shipping any more. And with the recent spike in diesel prices I am sure it would be more now. Sounds like you are getting a good price.....just add it to the absurd aviation product costs. -

I had the same problem last year on a Missile conversion (large 6 point mount for a TCM IO550). It cost me about the same but I spent another $900 in shipping expenses both ways combined. Because of its unique nature I had to send mine to Rocket Engineering in Spokane for repairs. The tubing is incredibly thin and oil filled. Minor corrosion quickly exceeds the 10% allowance and several tubes needed replacing. I recall that I had 3 tubes replaced and rewelded. The whole thing is powder coated. I thought it was outrageous at the time but now see it is the new norm.....outrageous costs for repairs and parts is just the new standard in GA. However the $6K quote seems really really unreasonable. (I assume that it is for a Lycoming IO360)

-

Mooney Factory Annual Inspection

1980Mooney replied to FAST FLIGHT OPTIONS LLC's topic in General Mooney Talk

The Refurb's that I was referencing involved replacing all the control cables (in the case of the Cessna's), bearings and hinges on the control surfaces, stripping and repriming everything (inside and out - early Cessna's were not primed internally), new glass, etc. In the case of the Mooney that sort of Refurb would include the removal of all control rods stripped, reprimed and new Heim bearings on every rod, New bearings on all the landing gear hinges and linkages, etc. And the tail would come off for bearings and hinges. Early J's would likely have the Lever throttle quadrant ripped out and replaced with push/pull vernier controls. and one piece belly installed, etc. In the case of an accident after such a factory refurb, I suspect the lawyers will be all over Mooney Int. Corp. In the case of an "interior refurbishment" I agree that a new interior by Aerocomfort, Jaeger or any number of shops including Mooney would not reset the liability clock, -

Mooney Factory Annual Inspection

1980Mooney replied to FAST FLIGHT OPTIONS LLC's topic in General Mooney Talk

I suspect that Mooney will never do it because of the General Aviation Revitalization Act of 1994. It limits manufacturer liability to 18 years even if it is proven that manufacturer negligence was involved. If the factory "refurbishes" a 30-50 year old Mooney then the 18 year Liability clock starts again for Mooney International Corporation. You are talking about planes many of which have been patched up or modified bespoke or with a no longer supported STC's and exposed to undocumented stresses/environment over its life. This is not like starting with new QCed materials and controlled manufacturing process. I can't imagine that there is enough money in it for the factory/corporation to take that kind of liability. You are more likely to see a separate smaller shop/legal entity undertake refurbishments many times partial rather than full refurb. In the past, many have tried full refurbs with the much larger population of Cessna C-172 and C-152 such as the Yingling Ascend 172, Redbird RedHawk, Sporty's 172LITE, and Aviat 152 Reimagined to name a few. Only a few were refurbished, all were failed ventures and have ceased. Additionally, if you are talking about interior and panel upgrades then there are plenty of established shops that already do that with lower overhead. -

"New design, new tooling...new construction techniques (composite)"...I am glad you mentioned it. No amount of automation or tooling will make frame welding and riveting of thousands of pieces of aluminum cost competitive. Mooney could bring a "me too" Cirrus SR20/22, Columbia/Cessna TTX, Diamond DA52RG, Pipistrel Panthera, etc that is late to market. But they already demonstrated that they are not very good at that sort of thing with the Chino M10T composite debacle. Comments on page one of this topic note that the capital wasted on Chino was highlighted and discussed at Mooney Max. Since Mooney is not first to market and they do not have a competitive advantage in composites, that history is not a great calling card for raising more capital.

-

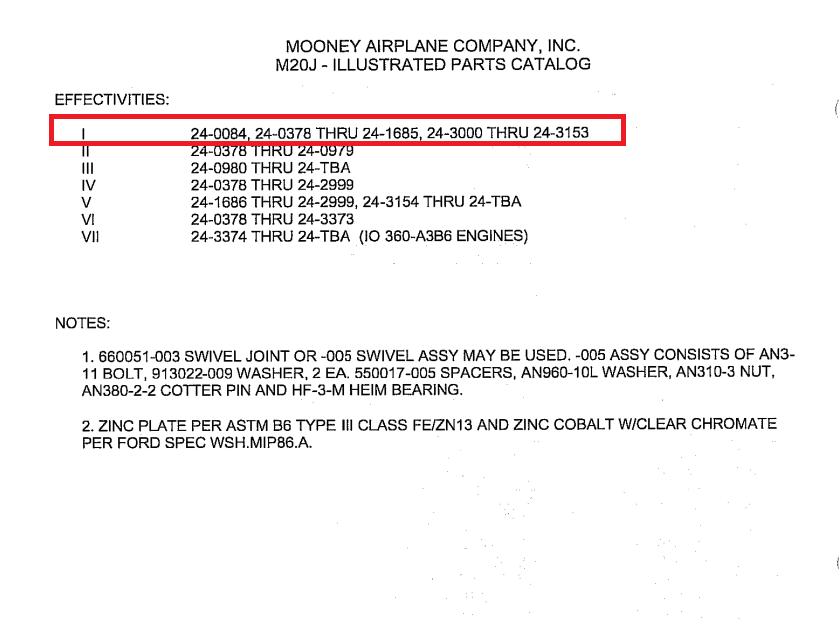

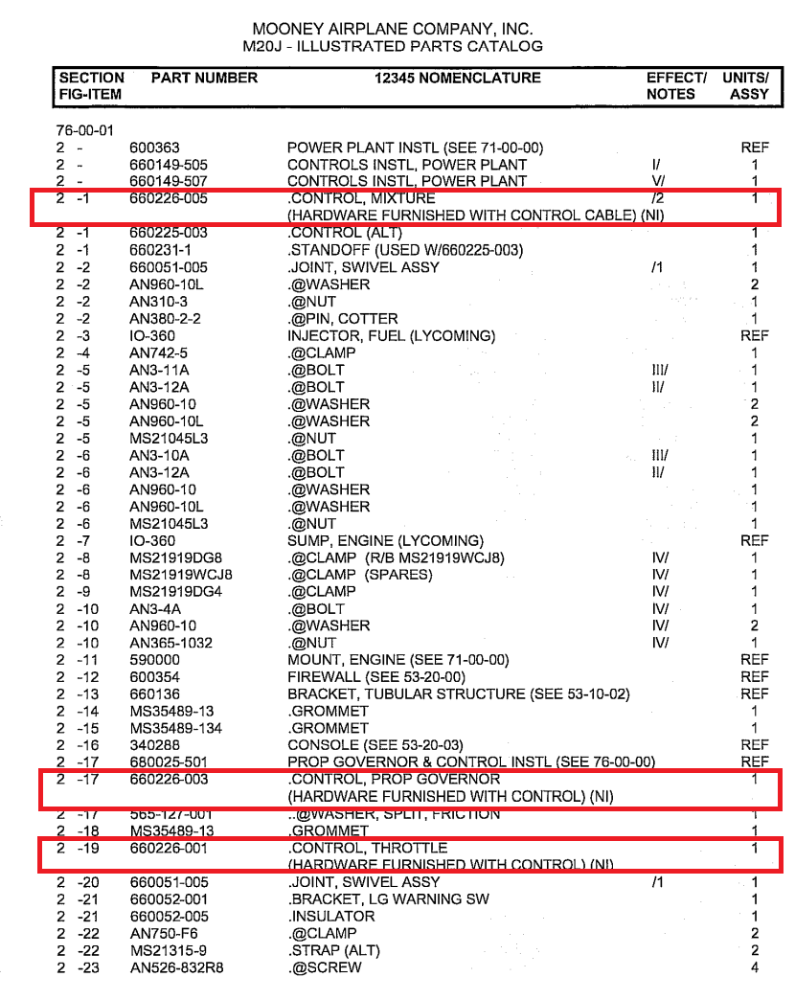

All J models from Serial #0378 and up to the end of production had "push-pull" controls with Vernier adjustment on Mixture and RPM. The Throttle "push-pull" had a screw friction adjustment. All J prior to Serial # 0378 (except 0084) had the lever controls. There are no "push-pull" Mixture and RPM controls without Vernier adjustment. Below is a pic of a 1978 M20J 201 panel clearly showing the Vernier controls on Mixture and RPM.

-

Yes but those were not speed mods. The engine cowling would crack from vibration - I know it happened to me. When you say "push pull controls" you mean the vernier control of mixture and RPM and push on throttle.

-

Per that same article in Flying Magazine again... "A published flight test evaluation made by the Mooney Aircraft Pilots Association (MAPA) produced 162 knots true airspeed at level flight at 7,000 feet with full throttle and 2,500 rpm, burning about 11.5 gph." First you should fly a box and average the four GPS speeds. If you are not getting book speed then you need to look at the engine, the prop and the rigging. Engine Compression, Spark plug condition, fuel metering (nozzles/injectors) can all effect your actual horsepower. Do you have an engine monitor to verify individual cylinder temps? Prop Are you able to get full book RPM on the prop? Rigging, During Annual, when your mechanic does the landing gear swing test you should observe the landing gear in the retracted position - ensure that the gear are fully retracted and that the doors fight flush and tight. Also make sure the nose gear doors are fully closed. Has the rigging of the flight control surfaces been checked ever since it left the factory?

-

-

The M20J is basically an "F" with all the speed mods that make economic sense. From Flying Magazine https://www.flyingmag.com/aircraft-pistons-magic-mooney-201/ "It all comes down to drag reduction. Mooney engineers had seen the potential for aerodynamic improvements of the M20F, but it wasn’t until Roy LoPresti joined the company in 1973 that the ball got rolling. “It was the first thing Roy did when he got there,” said Bill Wheat, who has thousands of hours in Mooneys and worked as a test pilot and engineer for Mooney for 53 years. Several key modifications contributed to the increase in speed. Wheat said the engine cowl redesign added about 8 mph, the sloped windshield also added about 8 mph, the inboard gear doors added about 5 mph, and the gap seals, flap hinge and empennage fairings added another 1 mph compared with the M20F. LoPresti also fitted the M20J with new sculpted wingtips in 1981, although no speed improvement was seen with this modification. However, Wheat said the square wingtip design of prior M20 models produced turbulence at the outboard 10 to 12 inches of the ailerons. LoPresti’s wingtip design made a “noticeable improvement in the handling” by making the airflow over the ailerons smoother, which reduced the control wheel loads and created a faster roll rate, Wheat said."

-

I think you are right. If you search the WATs site for Mooney products the only thing that they offer for Mooney now are lighting mods and replacements. They still carry speed mods for Piper but not Mooney. https://flywat.com/collections/cowl-aircraft-mods?sort_by=title-ascending Piper Only Speed MODS - COWLS, SPEED SPATS, SPEED SEAL, SPEED SLIPPER, SPEED SPLITTERS, WHEEL PANTS, Ironically it appears that they placed no value on the Mooney LoPresti speed mods when they acquired LoPresti and have discontinued them. Mooney speed mods at WATs/LoPresti are DOA (except for Hubba Caps which are sold out anyway). https://flywat.com/collections/mooney-products From a business standpoint it makes sense - Piper is a larger fleet and it is an airplane manufacturing company still in business. Mooney is a smaller shrinking fleet and a company that is struggling to be a parts supplier that will most likely never manufacture another plane. There is just no profit future in occasionally making a few Mooney parts. This also is an indication that modifying an existing Mooney doesn't make much economic sense. More and more STC's are being abandoned. Third party suppliers are seeing less incentive to continue to supply. Highly modified Mooney's are more likely to lose value and become abandoned over time due to lack of support and parts. You are better off sticking with a stock Mooney - salvaging parts as the fleet shrinks and buying parts when the factory produces. I had my J modified by Rocket Engineering over 20 years ago. Darwin Conrad is still there (in his 70's) and they still support the Rocket and Missile but I have no illusion that they will be in business in 10 years. At that time my J (Missile) will probably bring no more value (maybe less) than a plain unmodified J. I won't care because I won't be flying, will have gotten the life out of my plane and not trying to trade it on another plane.

-

Opinions on Turbonormalized M20J/Lycoming

1980Mooney replied to CoffeeCan's topic in Modern Mooney Discussion

FYI -

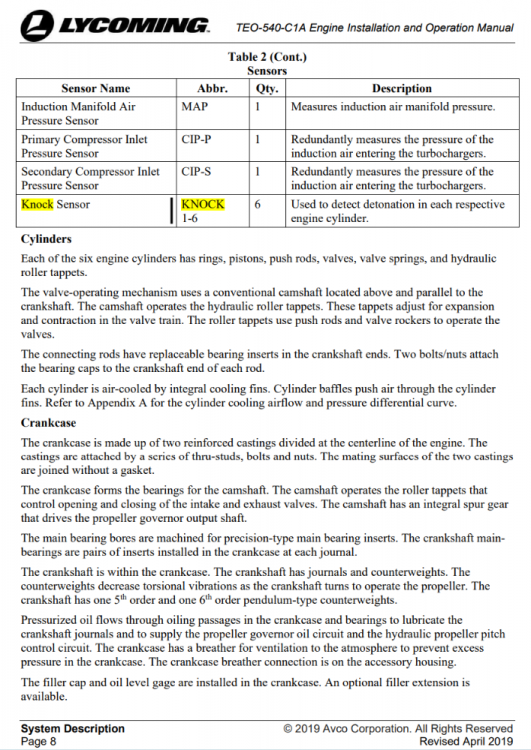

Except that knock sensors have been used on the Lycoming iE2 Integrated Electronic Engine (YTEO-540-B1A) that has been installed in Lancair Evo's for more than 10 years . (Lycoming announced the iE2 engine with acoustic knock sensors in 2008 - Textron Inc - Lycoming Engines Introduces the iE2 Integrated Electronic Engine Platform Lancair: Evolution and Revolution - FLYING Magazine Now it is being delivered this year on new Tecnam P2012 twin. The only difference is that the Evo setup is single lever control while the Tecnam application (TEO-540-C1A) allows for full feathering prop control . The iE2 engine has 6 knock sensors. As Aviation Consumer said way back in 2010 the technology is merely evolutionary and that the early problems with acoustic knock sensors in aircraft engines were solved back before 2010. "Acoustic knock detection has been a difficult nut to crack for air-cooled aircraft engines because their inherent vibration signatures make pinging difficult to extract from the hash of background noise. But knock sensors have gotten better and theres more processing horsepower available to separate the wheat of pinging from the chaff of banging valve trains and the whirr of gears. In any case, with individual cylinder knock detection, the IE2 suppresses detonation the same way it handles high CHTs-first with fueling, then with timing adjustments." Lycoming IE2: Incremental Technology - Aviation Consumer Lyco Manual 12 (lycoming.com) Tecnam Aircraft's P2012 Traveller: 11 Seater Twin Engine Plane for Sale

-

I use LPS2.

-

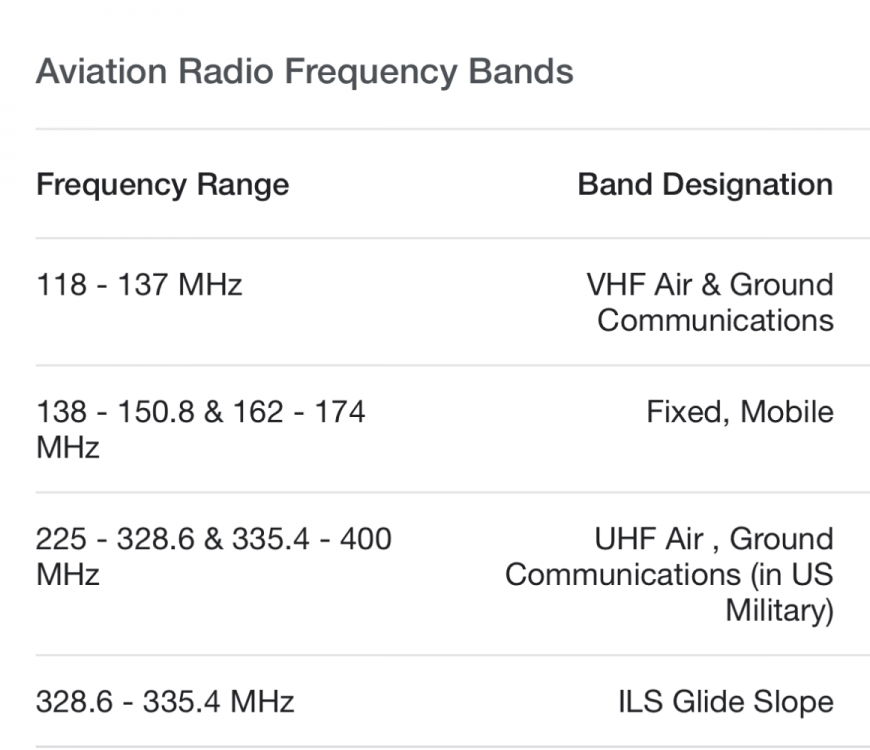

This for your VHF COM right?… I think you need DM C63-2 for the belly application. I have three COMs and the third antenna is on the belly. I think it is a DM C63-2

-

it is a COM antenna. “The DM C63 series antennas are VHF communication antennas designed for high mechanical strength with machine tapered aluminum alloy radiating elements. These vertically polarized antennas cover the frequency range of 118-137 or 138-174 MHz for both transmitting and receiving applications. The DM C63-1/A and DM C63-4/A are designed for mounting on top of the fuselage. The DM C63-2 and DM C63-3/A are low profile "bentback" radiating element designs for mounting on the bottom of the fuselage. They are well suited for helicopter installations.” https://www.dallasavionics.com/cgi-bin/products.cgi?master=avionics&category=antennas&man=edo&url=dmc63-3a.html

-

Low time pilot - intimidated by Mooney

1980Mooney replied to 40_Year_Dream's topic in General Mooney Talk

First and foremost a "property owner" in the Washoe County can't give permission for anyone to land an airplane on their property without first having an approved "Personal Landing Field" (Sect. 110.306.45 Washoe County Development Code). Among other things it imposes a 300 ft. limit from any structure, 65 db sound limit and the owner of the property must have a $1,000,000 general liability policy on the landing field., approval by the County Engineer, etc. Obviously the owner at 300 Desert Sun Ln. , Reno NV did not possess any of those requirements. The "landing strip" was a makeshift dirt racetrack with berms. Palmer eventually admitted that he didn't land because even he thought the berms to be too dangerous. Let's remember that it was a local resident in the County, a neighbor, that complained about this clearly illegal behavior at the County level. The only incompetence here is listening to Palmer or his attorney ignore the obvious egregious facts of his illegal activity while picking at irrelevant side issues as justification or listening to people trying to conflate this into only some Federal overreach conspiracy. The County creates laws to protect the majority general population from the actions of those that they believe are endangering others or behavior that is deemed unacceptable to the majority population. At every level, Cities, Counties, States and the Federal Government create laws to protect the well being of the majority general population. General Aviation Pilots are a tiny, tiny minority. We have no special rights and we will lose every time if we pick a fight with the local population, city, county, state or Federal officials. We need to go out of our way to build goodwill with the community. If we, as GA Pilots, choose to act like arrogant cowboys (Palmer) then we should not be surprised to see communities banning night flight, banning 100 LL fuel sales, creating tough noise ordinances and just closing down airports in general. And the Palmer case has nothing to do with Touch and Goes. Landing or Buzzing? Know CFR 91.119 - Aviation Ideas and Discussion! (safeblog.org) -

@MikeOH posted his M20F Vx table above, It shows 94 mph as constant Vx from sea level all the way to 16,000 ft. - no change. And yes Vy decreases.