1980Mooney

Basic Member-

Posts

3,340 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

I have a Missile also. It looks both bent inward on the leading edge (bent towards centerline) and buckled inward in the center and pushed back ( like stepping on a beer can). The hinge is probably bent. If you retract it the leading edge will contact well before it closes. The gear mechanism might force it closed but you run the risk of damaging the gear motor mechanism as well as jamming the gear. I would remove it and fly on.

-

There is no "airport 'authority'" in Texas. The state is indifferent regarding General Aviation which gives airport operators wide leeway as well as makes it easy for them to sell out to developers without any interference from governing bodies or "airport authorities". Airport operators give themselves exclusive rights. And yes there is only one FBO at either IWS or SGR (only one FBO and one fuel vendor at most GA airports in SE Texas - Galveston, Pearland, Gulf Coast Regional, College Station, even the newest western Houston GA airport Houston Executive KTME as well as the majority of GA airports in Texas) so I guess you would be mad being based here.

-

You didn’t identify which model of Mooney that you have. I find that a yoke mounted RAM Claw clamp with an XGrip and a short extension works perfect in a J model. It sits horizontally along the top of my yoke. I can still see all my primary instruments and twin Aspens easily. Get the 7” X Grip for iPad mini https://www.sportys.com/ram-x-grip-claw-yoke-mount.html?mrkgadid=&mrkgen=27&utm_source=google&utm_medium=cpc&utm_campaign=Smart_Shopping&creative={AdId}&device=m&matchtype=&mrkgcl=596&acctid=700000001999345&dskeywordid=92700067107255414&lid=92700067107255414&ds_s_kwgid=58700007109433166&ds_s_inventory_feed_id=97700000007407630&dsproductgroupid=961638435786&product_id=2160A&merchid=2857566&prodctry=US&prodlang=en&channel=online&storeid=&device=m&network=u&matchtype=&locationid=9027781&creative=524093874389&targetid=pla-961638435786&campaignid=13261768744&adgroupid=122815601677&gclid=EAIaIQobChMIiL-6yNOA9QIVjBPUAR2UHgbREAQYAiABEgLkpPD_BwE&gclsrc=aw.ds

-

Smear job? KSGR did not flood in the same event. There was no need to move anything at KSGR including tugs or tools. But you are right we should compare facts in order to understand why "IWS is almost $200 more than SGR a month if you can believe it," (per @jacenbourne). The runway at KSGR is more than twice as long as IWS and 25 ft wider, SGR has an ILS (in addition to both RNAV(GPS)) and IWS does not, SGR is Towered and IWS is not, per numerous sites AVGAS 100LL is $0.04 cheaper at SGR vs IWS, Ramp fee at SGR is half the cost of IWS ($10 vs $10 for SEP), SGR is under the 4000 ft Class B layer while IWS is under the 3000 ft layer and north of IWS is almost immediately under the 2000 layer of Class B, all the hangars at SGR have motorized electric bifold doors, the SGR Hangars have their own Pilot's Lounge with showers attached to the hangars, every other hangar building has an airconditioned bathroom at SGR - I know there was nothing at the IWS T-Covers when I was there - no idea about the IWS hangars. And SGR did not flood like it did to the many (most?) at IWS that did not get out ahead of the "weather it was predictable". An airport is just a place to take off and land and a hangar or T-cover is just a place to reasonably protect the plane from the elements. You may say "I don't need all those things at SGR, that runway capability at SGR and I don't want to talk to or deal with a tower". Fair enough. Both SGR and IWS are on the west side of the Greater Houston Metropolitan Area and both will support and tie-down/hangar any Mooney but that doesn't explain why IWS costs a premium over SGR. It should be at a discount. Isn't it just like the cost of Mooney's?... A J may do the job just fine - you may not need all the added performance/features of an Acclaim. Just like IWS will do just fine - you may not want all the features or capabilities of SRG. But would you pay a premium for a J? - or would you expect it to be at a discount?

-

I was just at KIWS today to meet with a CFII. He said that West Houston charges you to pull out any plane. He said he used to have his Baron under the T-Covers at IWS and they charged him $25 every time to pull it out. He said he got tired of the cost and moved out to Ellington. IWS seems to charge for everything. They wanted to charge me a $20 landing fee today when I pulled up to the terminal - and they are not even a towered airport. They waived the fee if would agree to purchase fuel at $5.54/gal. Here is a picture of the T-Covers and T-Hangars at IWS in August 2017. I had my Mooney at IWS under those very T-Covers back in 2004. Seems like they should offer a discount to keep your plane there......

-

The early J's had the box end wings with a 35 ft wingspan. The later J's, K's, all long body and any Mooney modified with wingtips/winglets are 36 ft. 1 inch. That ONE FooT bumps you up into the C/D hangars. They will not yield on this - trust me.

-

Have you contacted this person? I think he owns the STC and he is actively online on MS. https://mooneyspace.com/profile/16702-tomgo2/

-

RayJay (TALCO Aviation Corp. dba RAJAY Turbo Products) has the STC's for Mooney: SA 3555 WE for M20J (there is a typo in the number on the Rayjay page) SA 1156 WE Installation of Roto-Master turbocharged Lycoming IO-360-A1A or O360-A1D engine on Mooney M20A, M20B, M20C, M20D, M20G (held by ModWorks but RayJay says they can install) https://rajay.aero/pages/list-of-stcs Both searchable on the FAA site. But you show that you own an M20F so I think you are SOL.

-

Without the written consent of the STC holder you cannot legally install/modify the parts that comprise an STC. You can physically do it but it means that your plane will have an illegal modification and will never be certified Airworthy every again. The FAA states on their site that if you cannot locate the owner the FAA through the "ACO" can issue the STC but I would not hold your breath. It seems like a huge liability that the FAA has no incentive to take. - And I have never heard of them doing it.

-

Help With Power Settings For Upcoming X-Country

1980Mooney replied to GeneralT001's topic in General Mooney Talk

STC for Serial # 24-1686 and above only. Mooney increased the thickness of one of the tubulars in the steel frame from that serial number and up. M20J-Gross-Weight-Increase-SL92-1-1.pdf (mooney.com) -

Help With Power Settings For Upcoming X-Country

1980Mooney replied to GeneralT001's topic in General Mooney Talk

It is actually easier than that. Because of the various Mooney bankruptcies and owners, the POH, Parts Manuals and Service and Maintenance Manual for the J and K are in the public domain. POH 1977 Rev, 1984 https://www.nqac.com.au/wp-content/uploads/2016/12/M20J-POH.pdf POH 1996 Rev, 1997 https://pilotage.e-monsite.com/medias/files/m20j-poh3203b.pdf Parts Manual 2003 http://mooney.free.fr/Manuels M20J/M20J/Mooney M20J Illustrated Parts Catalog.pdf Service Manual 1998 http://mooney.free.fr/Manuels M20J/M20J/Mooney Service Manuel M20J Vol. 1 of 2.pdf Service Manual Electrical Diagrams http://mooney.free.fr/Manuels M20J/M20J/Mooney Service Manuel M20J Vol. 2 of 2.pdf also https://www.scribd.com/document/328319136/Mooney-Service-Manuel-M20J-Vol-2-of-2 -

Help With Power Settings For Upcoming X-Country

1980Mooney replied to GeneralT001's topic in General Mooney Talk

GeneralT001 will get a little boost from the cold temperatures in Canada which I assume will be less than Standard on his trip. It is just the opposite down here in Houston were it is currently 83 F and setting a new record again almost every day this week. -

Help With Power Settings For Upcoming X-Country

1980Mooney replied to GeneralT001's topic in General Mooney Talk

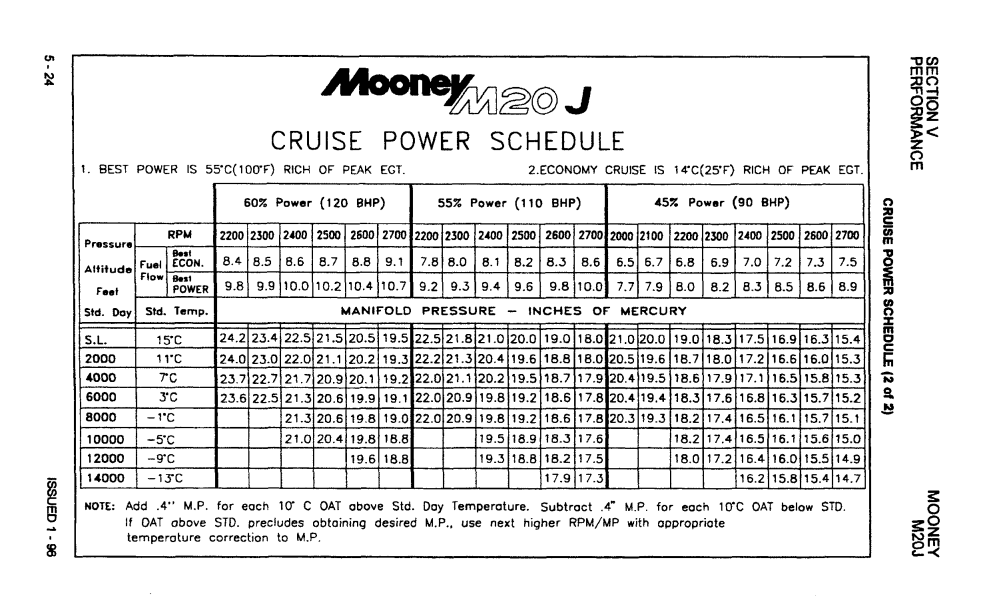

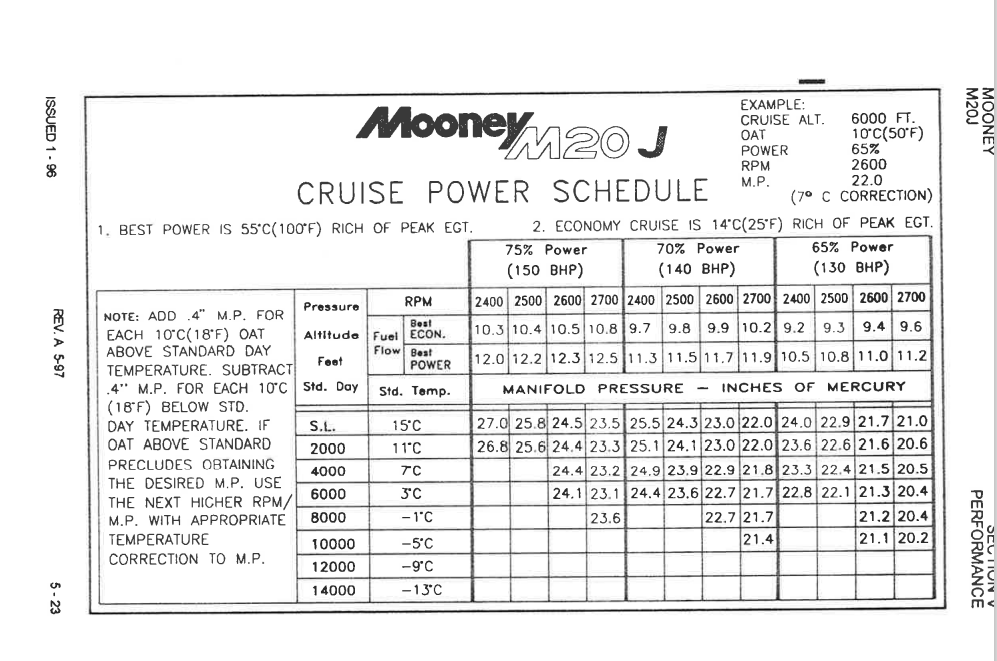

Exactly You are not going to get 75% power above 2000 ft. at 2500 RPM. You will need 2600 RPM or more. -

Help With Power Settings For Upcoming X-Country

1980Mooney replied to GeneralT001's topic in General Mooney Talk

True. In your very first post you said, "Before I get out there the aircraft is to be test flown to ensure that all is well with the engine/prop." If the shop test flies it for several hours before you arrive then they will have conducted the initial and most aggressive break-in of the engine. Everyone seems to be losing their minds with the idea of flying a newly overhauled engine on a cross-country. Think about it - what do you think the odds are that a newly overhauled Lycoming IO360 engine from a reputable shop will throw metal apart and fail in flight? Now compare it to the odds of a 15 year old Lycoming that may have been sitting outside for some time with more than a thousand hours - Which do you think is more likely to fail on a long cross country? We don't have the data but I bet it is safer to fly the newly overhauled engine. People have noted here that they have purchased "new to them" airplanes and flown them home cross country. The engines may seem ok on paper and in the prebuy but you never really know. At least with the overhauled engine from a reputable shop everything has been done to a higher level of consistency than an engine maintained in the field. -

Help With Power Settings For Upcoming X-Country

1980Mooney replied to GeneralT001's topic in General Mooney Talk

How would "all that break-in metal" be circulating through any just overhauled engine? Have you heard of an oil filter? This is not a 1965 VW Beatle 1500 or lawnmower engine with either no filter or only a screen. Let's not lose touch with reality here. It does not "circulate" - it makes one trip to the filter. -

Help With Power Settings For Upcoming X-Country

1980Mooney replied to GeneralT001's topic in General Mooney Talk

Is anyone going to answer his original question? Per Mike Busch: Mike Busch, author of “the big book on piston engines,” explains why engines need to be run hard for a few initial hours and then offers a concrete procedure: Break in the engine by running it as close to maximum continuous power as possible without allowing any CHT to exceed 420F for Continental cylinders or 440F for Lycoming cylinders. Run it this hard for an hour or two until you see the CHTs come down noticeably , indicating that the lion’s share of the break-in is complete. This requires running at nearly full throttle at a low altitude (the engine won’t generate more than about 75 percent power after climbing to an ordinary cruising altitude of 6,000 or 7,000′ due to the lower density of air molecules up there). -

They may be able to diagnose and do some repair but I doubt that they are certified by Garmin to do repair. Garmin does not release repair documentation since all their products are engineered as LRU's - Line replaceable units. Without documentation, its not legal for anyone to work on them; especially for a repair station. Although you may not care that any repair wouldn't be documented, most repair station wouldn't want to take the risk. Theses guys probably don’t care. Also some parts are no longer manufactured and but Garmin has some inventory. If theses guys work on it but lack parts then Garmin won’t touch it later.

-

This is what it looks like when the screen fails internally. Those are not cracks in the surface of the screen.

-

Garmin's flat price for IRAN of a GNS430W is now $1,850 plus shipping. I just had mine repaired. I don't see the value in spending about $13,000-14,000 for a GTN650 installed as a replacement which doesn't really add any material capability over the GNS430W. My avionics shop said that Garmin is running out of major parts like the screen.

-

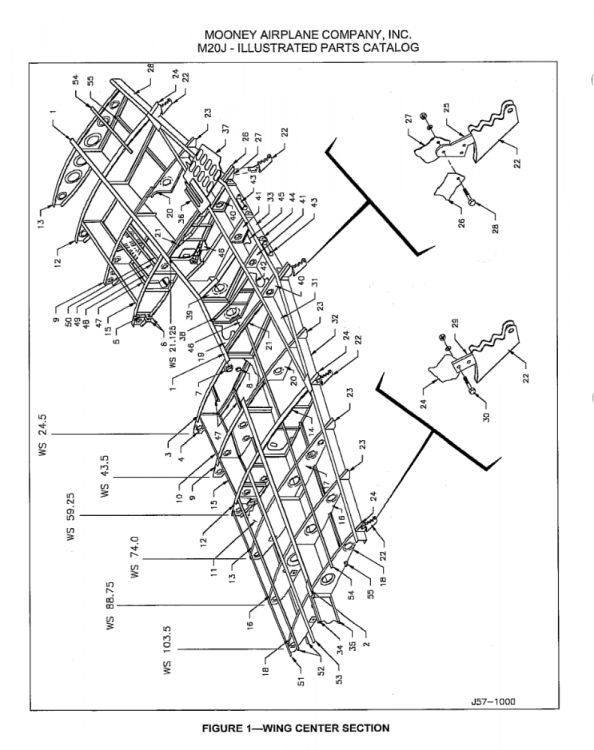

Good question. Isn't the K standard fuel capacity 75 gal vs. 64 in the J? Something internal is slightly different. I believe the external dimensions of both wings are the same as well as the internal structural components.

-

-

Sick + Single Pilot IFR + Trapped above ice

1980Mooney replied to hais's topic in Mooney Safety & Accident Discussion

Glad that you landed safely. It sounds like you came perilously close to becoming a statistic and a subject of "Safety & Accident" discussion for a different reason. I think it highlights how risky flying is, especially single pilot IFR. It also highlights how we tend to normalize that risk. In your first paragraph it doesn't sound like flying over fully cloud obscured Rockies is an impediment or show stopper for your flight planning. I am curious if this event changes any of your planning for risk mitigation. - either when flying alone or with passengers. -

All Mooney's come from the factory with "wet wing" fuel tanks. Bladders are only seen as a retrofit solution. This article is from 2009. Double the prices mentioned in the article for a more accurate estimate of today's costs. https://www.knr-inc.com/25-shoptalk/24-200910-ribs-wet-or-dry I just had the left wing in a J model patched. It has Monroy extended range tanks added but they only found leaks in the main (original) tank - 4 leaks in total. The cost of repair was $3,000.

-

I read the logs. I have not looked at the Mooney Value Guide here on Mooneyspace because the plane is worth what someone else will pay for it regardless of what the Value Guide says. If you look at the hour accumulations and the "100 hour" inspections and search the past owners in AviationDB you will see that the plane has been used most of its life for flight school training. That is not necessarily a bad thing. A flown plane is better than one that sits. It got a lot of inspection and the total hours are not too high. There was some corrosion repair and the plane was repainted in 1997 Engine overhauled first time October 1997 Tanks were resealed in 2001 Repainted again and interior/upholstery in 2005 Left main shock discs replaced in 2010 Repair/reseal right tank in late 2015 Nose gear shock discs replaced in late 2015 Right main shock discs replaced in 2017 The gearup was in January 2020 Kathryn's Report: Mooney M20J, N1077U: Incident occurred January 21, 2020 at Pompano Beach Airpark (KPMP), Broward County, Florida (kathrynsreport.com) The engine was shipped for overhaul to Pinnacle and looks like they got it overhauled and back July 2020 Also noted that the exhaust was sent out for some overhaul work in July 2020 The prop is new Repairs and painting completed November 11, 2021. So it took over 21 months to get the plane repaired. It could be both insurance and supply chain issues. A gearup in a Mooney can be repaired as good as new. I have a friend that did it twice in the same J - and he is still flying it nearly 20 years later. Now I noticed that they used the existing engine shock mounts when reinstalling the overhauled engine - that is really cheap.( after all the engine was out ) Also changing shock discs on the landing gear on one side of the plane is cheap too - should do both sides. Regarding the stain on the wing - either Mooney's currently leak fuel or they will eventually leak. It is just a matter of time and money - the curse of the wet wing. The plane is just new enough to be eligible for the GW increase to 2,900 lbs which is a plus. M20J-Gross-Weight-Increase-SL92-1-1.pdf (mooney.com) The gear up doesn't scare me but you need a good look at it during the prebuy inspection. Also a good test of rigging - control surfaces and landing gear.