-

Posts

9,507 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

Do this in the proper order 1. Get it rigged correctly 2. Remove any excessive control friction 3. Make sure there are no static leaks 4. Then if there are still issues try the new gains. If you do this first, you may be masking other issues.

-

Part number is for a 50A bridge rectifier. I cannot see all the wires in the picture, but it looks like Mooney just wired it to use one diode. Clever way to get a high current diode with a mounting means.

- 22 replies

-

- 1

-

-

- electric heat

- pitot

-

(and 2 more)

Tagged with:

-

Because I am a curious sort, I called Rochester Sensors (current company name for Rochester Gauges) and spoke with Cheryl Manning who told me that Rochester doesn't sell retail and I would need to contact one of the companies on a list which she then sent me (attached). Next, I called Air Dallas and the gentleman there told me that he thought that this part was discontinued, but to be certain he would need the part number. Apparently, the 5- number on the dial is not the actual part number. The actual part number is much longer and located on the back of the dial. So, if anyone has a removed or new dial, perhaps you could look on the back and find the part number and determine if it is possible to order these. Referral List.pdf

-

If you are calling around asking about parts, be sure to ask for the right thing. The nose gear has three main components. The truss attaches to the airframe, the leg attaches to the truss, and the spindle attaches to the leg. When oversteered, a tube on the leg hits a tube on the truss but the truss tube is beefier than the leg tube, so it is usually the leg that gets damaged, not the truss.

-

I own a 2009 Subaru Outback. It has a seeping power steering hose. Subaru no longer makes the part and there are no aftermarket replacements. Last I checked, Subaru was a going concern. When Clarence used to post here, he pointed out that some Cirrus parts have very long lead times. Beechcraft owners waited years to finally get some magnesium control surfaces made. I was pleased that Mooney could provide me with a new nose gear leg when an FBO damaged mine. Personally, I can live without a redundant fuel gauge. I understand that some of you cannot.

-

If you call Frank Crawford at Mooney, he can look up the drawing and tell you if there is anything special about it. Mooney sometimes modifies standard AN fittings (for example to add a flow restriction for instrument connections or to make a right angle sniffle valve). I don’t see why a mod would be needed here, but the drawing will tell.

-

Had a friend that had a Mercedes 300 SL. It needed a new fuel injector body. Mercedes agreed to allow Bosch to sell directly to owners. Bosch agreed to build a minimum order of ten for $10K each. That was 40 years ago, so $10K then would be about $30K today. My friend got 9 others together and they bought the parts. So it’s possible to do this sort of thing, but it might be expensive. How many Mooneys have the wing gauges and how many would buy spares and at what price?

-

I know for a fact that Mooney manufactured ten nose gear legs a little over a year ago, so they are making more than just sheet metal. Custom parts made outside likely have a minimum order and perhaps a setup charge and that ties up cash needed for things that are more immediately important like payroll, taxes, rent. Also, the previous owners may have left some unpaid bills which vendors will want paid before accepting new orders. Another cash drain. Been there. It's a tough situation.

-

There is nothing wrong with 5606 and it has the advantage of being universally available. However, it does thicken with age and especially heat from the brakes. I still use it, but I drain some from the wheel cylinder bleeders every year until the discolored fluid is running pure red. Then I top off the reservoir.

-

Landing gear bushing/bearing alloy

PT20J replied to Hradec's topic in Vintage Mooneys (pre-J models)

I would consult with Frank Crawrord at Mooney to see how the factory would advise making such a repair. He could tell you how much you can ream the leg and you’d have documentation from the factory for the acceptable method of repairing the leg which whoever signs it off might want. The gear legs are heat treated. -

It’s because the airplane sits on the ground at a positive angle of attack, so it’s light on the gear at landing speed. The flaps increase the effective angle of attack and exacerbate the effect. That’s why a lot of us raise the flaps after touchdown.

-

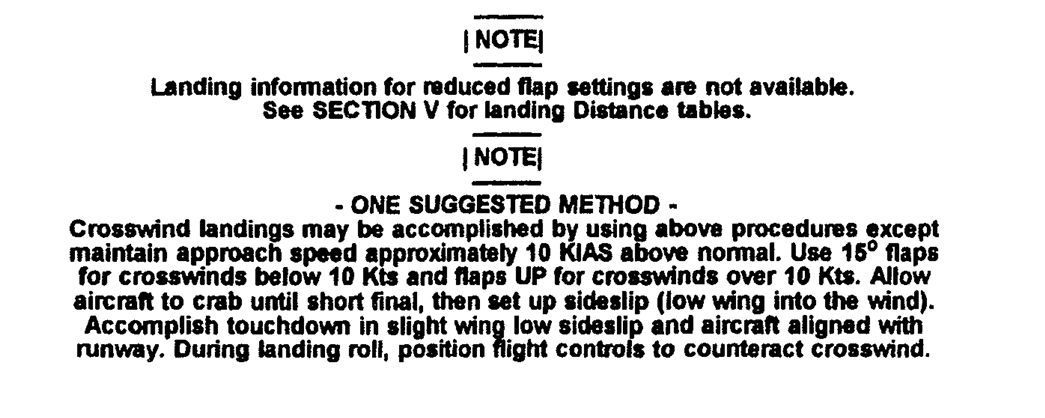

The certification basis for the M20 series is Civil Aviation Regulation 3 which states “There shall be no uncontrollable looping tendency in 90-degree cross winds up to a velocity equal to 0.2 Vso at any speed at which the aircraft may be expected to be operated upon the ground or water.” Aircraft delivered after 1975 generarally come with a Pilot’s Operating Handbook (POH). The POH is non-regulatory (except for the FAA-approved limitations chapter). There will not be a cross wind limitation. Instead there will be a maximum demonstrated crosswind velocity defined in the General Aviation Manufacturers Assoc. specification 1 (which defines the contents and structure of the POH) as “The demonstrated crosswind velocity is the velocity of the crosswind component for which adequate control of the airplane during takeoff and landing was actually demonstrated during certification tests. The value shown may or may not be limiting. (Whether or not the value shown is limiting should be stated.)” The M20J POH lists a relatively low demonstrated cross wind velocity of 11 kts. I asked Bob Kromer (former Mooney test pilot) and he said that he had personally tested a M20J to a 18 kt, 90 degree cross wind. But, Mooney has always been conservative to account for the skill level of the average pilot. Most pilots don’t practice crosswinds often and Mooneys tend to float. Higher approach speeds to perhaps compensate for gusts increase the float and it is during the float that the inexperienced pilot has ample opportunity to lose control. The 1996 M20J POH contains the following advice

-

KFC200 Trim Switch Needed - And Cost Reality Check

PT20J replied to PeteMc's topic in General Mooney Talk

The Cygnet switch works with the GFC 500. The BK switch can also be used with the GFC 500 with some rewiring. The Cygnet switch will not work with a BK autopilot. -

Gear shock disc collar orientation

PT20J replied to Hradec's topic in Vintage Mooneys (pre-J models)

Why not just ask Frank Crawford at Mooney? -

It is not common practice to use non-aircraft materials in an airplane. And if the previous owner did this, I would be concerned about what other shortcuts may have been taken. This doesn’t even save money: NAPA Auto Parts sells Dexron III for $11.33/qt. Aircraft Spruce sells MIL-H-5606A for $12.50/qt.

-

No, it's not right. Aircraft 5606 hydraulic fluid is a mineral oil dyed red. Automatic transmission fluid (ATF) may be mineral oil dyed red, BUT there are several kinds of ATF and the newer ones have additive packages and some use a synthetic base stock rather than mineral oil. There will also be viscosity differences between 5606 and ATF. If this were my airplane, I would find out if the previous owner was using ATF in the hydraulic system. The problem is that there are a lot of o-rings in the system and o-rings are available in several materials and not all are compatible with all fluids. If a fluid was used that is not compatible with the o-rings, it can cause them to deteriorate and leak. If this is the case -- and I don't know if it is -- you might be faced with replacing all the o-rings in the system to prevent leaks and failures. That's why I'd want to find out what the airplane was serviced with.

-

Best cordless vaccuum to clean your interior?

PT20J replied to MisfitSELF's topic in General Mooney Talk

I use a corded shop vac in the hangar. At the museum we used a DeWalt canister vac. -

Maybe it is the pressure caused by air load on the flaps. Try putting the flaps down on the ground and pulling up on them to simulate the air load and see if that makes it leak.

-

It's certainly not mislabeled. But it could well be an obsolete part superseded by a newer part, or simply discontinued. This happens all the time especially with parts that are 41 years old.

-

How much current do you need? My Batteryminder puts out about 5A@ 28V and runs my glass panel with minimum battery discharge.

-

It looks like the current Chicago Miniature 28V bulbs are either a 7387 (3 mm pin spacing) or a 7839-2 (2.5 mm pin spacing). https://cml-it.com/us/products/lamps-signalisation/bi-pin/pin-abstand-254mm/ International Avionics makes the annunciator panel. You could call them to verify. https://www.internationalavionics.com

-

That should be a Sigma-Tek 169CL1-8 Volt / Amp Cluster Module. If no one here has one, you could watch eBay and the aircraft salvage places. You might have to buy a whole cluster, but it's probably only a few hundred dollars.

-

The description sounds like a damaged Saf-Air drain.

-

One other thought: When was the last time you checked the suction screen in the sump? There might be some carbon in there reducing the flow rate slightly that might have an effect on oil pressure. Draining the oil might have migrated some carbon to the sump where it was picked up in the screen. This is just a spitball thought, though.

-

https://www.saf-air.com/products/oil-valves/oil-valve-chart.html Not sure what you mean by stripped. If the threads are damaged in the sump, it might be a bigger issue. But this is unlikely unless it was removed and cross threaded.