-

Posts

10,047 -

Joined

-

Last visited

-

Days Won

227

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PT20J

-

Seems like a good question for @Jake@BevanAviation

-

GTX 345r pairing but not connecting via Bluetooth

PT20J replied to TGreen's topic in Avionics/Panel Discussion

Garmin makes a lot of equipment that can be assembled in a plethora of configurations. Some equipment features are redundant and so not everything works the same way in every configuration. In your case, the reason that the GTX 345 BT is disabled is because you elected to install Flight Stream which provides the BT connection. If you did not have FS, the GTX 345 BT would be enabled and it would be controlled by the GTN, not the GTX user interface. Flight Stream BT capabilities is a superset of the GTX 345 BT so there is no need for it if you have FS. In addition, FS 510 has the wider bandwidth WiFi interface to enable Database Concierge. -

GTX 345r pairing but not connecting via Bluetooth

PT20J replied to TGreen's topic in Avionics/Panel Discussion

I was responding to your post, not the OP’s, by pointing out that the GTN (or a G1000) provides the user interface to the GTX 345 BT, but does not disable it. If you have a panel mount GTX 345, the GTN connection only disables the GTX BT user interface because that is now remoted to the GTN. The OP has a G1000 which can also control the GTX BT. Apparently he was able to do that but could not get ADS-B data because Garmin only supports Garmin Pilot and ForeFlight and he was using a different app. -

GTX 345r pairing but not connecting via Bluetooth

PT20J replied to TGreen's topic in Avionics/Panel Discussion

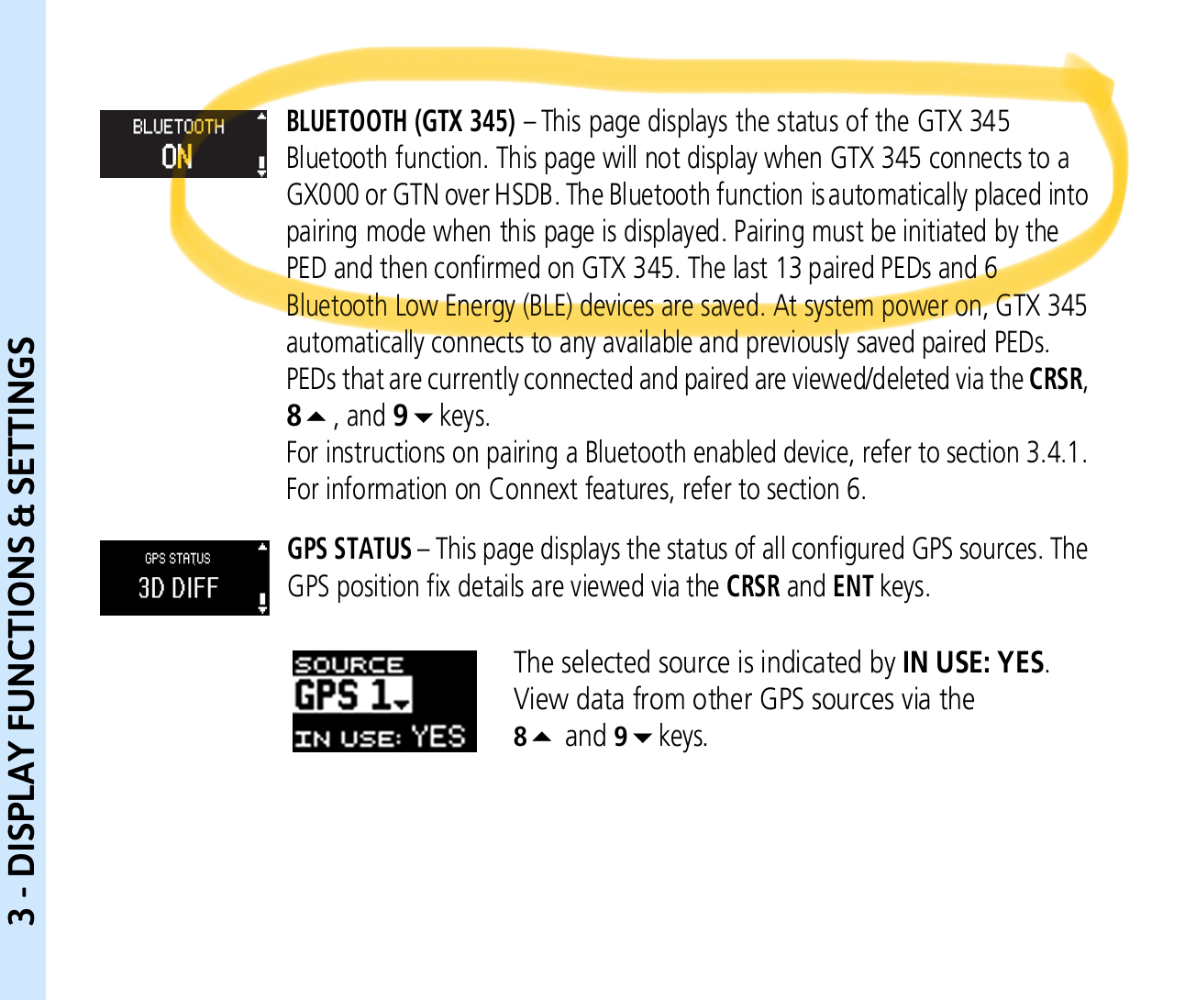

If it's wired correctly, a GTX 345 should be connected to the GTN via HSDB (Ethernet). In this case, the Bluetooth screen on the GTX is disabled. But the GTX Bluetooth is not disabled -- the setup is remoted to the GTN and you control it from there. -

GTX 345r pairing but not connecting via Bluetooth

PT20J replied to TGreen's topic in Avionics/Panel Discussion

And, we should have asked which app you were using. -

GTX 345r pairing but not connecting via Bluetooth

PT20J replied to TGreen's topic in Avionics/Panel Discussion

The BT is in the GTX, but the user interface to operate the BT has to be in either a G1000 or a GTN since the GTX 345R has no user interface. Garmin doesn’t explain this very well. (And, I'm right way less than 105%). -

GTX 345r pairing but not connecting via Bluetooth

PT20J replied to TGreen's topic in Avionics/Panel Discussion

If I understand correctly, you are trying to Bluetooth connect a phone and tablet to the GTX 345R using the built in Bluetooth in the GTX. Since the GTX is a remote unit the user interface for the GTX internal Bluetooth is remoted to the G1000. You must have found that, because you have been able to pair, but not connect to transfer ADS-B data to the iPad. What I think may be happening is that the pairing operation is not being fully completed at the tablet (and phone). When you select the GTX for pairing on the G1000, the GTX enters discovery mode. Then you have to select it on the tablet. Then you have to acknowledge it on the G1000. But, I believe that there is one more operation on the tablet to complete the pairing operation before it will show up as connected on the tablet and permit data transfer. -

GTX 345r pairing but not connecting via Bluetooth

PT20J replied to TGreen's topic in Avionics/Panel Discussion

If the GTX is connected to the G1000 via HSDB, then the Bluetooth connection is controlled from the G1000. If it pairs and doesn't connect it could be a signal strength issue and I would try removing the tailcone access panel and holding the phone near the GTX and seeing if that works. -

Hard to say. From what I understand, there is one G3X Touch code base. So, the 9.XX versions would be sequential from 9.00 (9.01, 9.02... 9.41). Since Garmin skips version numbers in its releases, some are likely versions cut for internal testing but not released to the field. Also, some versions in the sequence are released for certified and some for noncertified. The most current certified version is 9.17. There is no noncertified 9.17. The closest noncertified released versions were 9.14 and 9.22. Garmin's release notes are not very detailed and often say something like "General improvements to system operation" which likely means minor bug fixes. So, it's unclear what you would get with 9.41 running in certified mode. The biggest problem I see is that I don't know how Garmin does it's updates. It could be a complete reload or more likely it is a patch. Sometimes it can be problematic to back out a patch to get back to an earlier version, especially if several versions were skipped.

-

Sort of. When the lever is up the coil spring on the actuator engages the manual gear extension system. This will prevent the motor from turning and if you try to put the gear down electrically, the stalled motor will draw too much current and trip the Gear Actuator circuit breaker.

-

Did the D99 happen coincident with the AP Fail? If so, perhaps the GSU 25D is the problem rather than the autopilot. Without understanding the design, it's not possible to know, but maybe the "system" referred to in the failure message is the ADAHRS and not the autopilot. I could see the autopilot perhaps wanting to disengage if the ADAHRS was degrading but perhaps not degraded enough to cause a MISCOMP with the standby. Or maybe it is something external that affects both ADAHRS. Were the disconnects in different locations to rule out GPS interference in some location?

-

g3xpert mainly deals with the non-certified customers and the latest experimental version is 9.41 so perhaps this is something already addressed that hasn't made it to a certified release yet.

-

Resetting the AP circuit breaker would only reset the monitor AHRS in the GMC 507. This sounds more like an issue with the GSU 25D. You can look at the ADAHRS data in the log (column BQ I think). It should be XXXXXXXX N100 N100 where XXXXXXXX is a code. If the N numbers ever go to D it indicates a degraded status. The G5 can also log to an SD card and it might be interesting to compare G5 logs and G3X logs for the same event. I asked g3xpert what Fail / System not usable means and they said that Engineering has told them that the G3X software should be upgraded to the latest version if that occurs. EDIT: Trek once told me that since the ADAHRS uses GPS aiding, GPS interference can sometimes cause problems with the ADAHRS. A way to check is to look at GPS status in flight and see if you still have 3D DIFF NAV.

-

Possibly if it is a drift issue. But the failure was not logged as a monitor fault. What does the diagnostic log screen for the autopilot say?

-

There are two G3X log files. If you turn on data logging in configuration mode and keep an SD card in the GDU, it will log a .csv file for each flight (actually each time the G3X is powered up) with 1 sec updates. The G3X also keeps a internal log that can be exported as a .csv file that appears to have essentially the same data (I have not compared every field) but at finer time resolution. This is a single very large file (it takes several minutes to download to an SD card) and is ordered by date/time, not flights. Here are instructions for accessing it: Garmin_G3X_How_To_Export_Flight_Data.pdf In config mode there is a tile at the bottom right for Diagnostics and if you open this there is a section for Autopilot that will display a log of every error occurrence with a date-time stamp. I didn't see a way to export that, but you should be able to take a screen shot of it if G3X screen shots is enabled.

-

Nice. One suggestion: I mounted a USB power supply behind the panel (I used a Mid-Continent True Blue power cube, but there are probably others) and then ran a black braided-sheath USB cable from behind the panel underneath the yoke shaft to the iPad. It's out of sight and out of the way.

-

I'm not disagreeing with you guys, but we know that these things get damaged somehow and I don't know what the mechanism is. Perhaps someone that had one damaged would know what the failure mode is.

-

I doubt there is one. Trek told me that he was fielding about 150 emails a day. His primary job was to support the dealer network, plus his team was responsible for trade shows. He was trying to be helpful by showing a presence on the various user forums. That took on a life of its own and became time consuming and often not very productive because some members of the various forums mostly like to complain and rant. (check out the G3X thread on BeechTalk). I don't think anyone at Garmin has the time or inclination to get this involved with customers via the internet on a regular basis. They would much prefer that end users use aviation support or go through their dealer network. The best support I have gotten for the G3X/GFC 500 has come from g3xpert because they have the most experience with this equipment.

-

My airplane originally had a KAP 150. The previous owner had installed an Aspen without the autopilot interface to replace the attitude indicator so I still had the KG 258 in the panel. The Aspen HSI would interface to the autopilot and included GPSS, so the KI 525 and gyro were removed. It worked fine. Will the Dynon also work that way? Also, will the Dynon PFD display the KFC flight director? If not, you'd be giving up using the flight director.

-

The VEP switches are still manufactured. VEP is now a brand of World Magnetics (www.worldmagnetics.com). With a little calculating you could figure out the OEM part number. 654-switch-veproducts-aerospace-low-pressure-switches-specs-sheet.pdf

-

You could call Lycoming tech support. Since you have the old vernatherm, you could try swapping it and see if it makes a difference.

-

Contact Mooney if you really want to know. Mooney will have build records by serial number.

-

I take your point, but a number of people have reported damaged airspeed safety switches after the pitot-static tests. I’m not sure what the failure mode is. Just a week ago a local pilot related to me that he has the exact same problem after a test. He hasn’t taken it back to the shop yet, so we don’t know what the problem is. I suppose it could just screw up the adjustment which is the tension on a spring, but the kind of spring used would be fairly long with fairly soft coils in order to get linearity and it’s hard to see how it would take a set. But, I guess anything is possible.

-

IPC shows a 76510 gasket.

-

From my notes at the Lycoming factory class: #1 cause of excessive oil temperature is vernatherm. It should begin to expand at 150 degF and should be max expansion (>= 5/32") at 170 degF. Also check that Vernatherm doesn't have a break in the seal of the cone to the seat. Other causes: restrictions in oil cooler hoses, blocked airflow to oil cooler, oil cooler needs overhaul due to trapped contaminants.