-

Posts

9,515 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

Mooney Bravo accident, Victoria MN 8/7/21 NTSB final report

PT20J replied to jaylw314's topic in General Mooney Talk

All airplanes naturally have some roll-yaw coupling. I believe it was a certification requirement to be able to make turns using the rudder if the aileron control system failed. If the airplane doesn’t have enough coupling, interconnect springs (like on the Mooneys) are often added. This makes it possible to make small heading changes (less than 5 deg) using the rudder on a precision approach. Controlling pitch with trim is only an emergency maneuver because it is very easy to get behind the dynamics (i.e., phugoid) of the airplane and lose control. Skip -

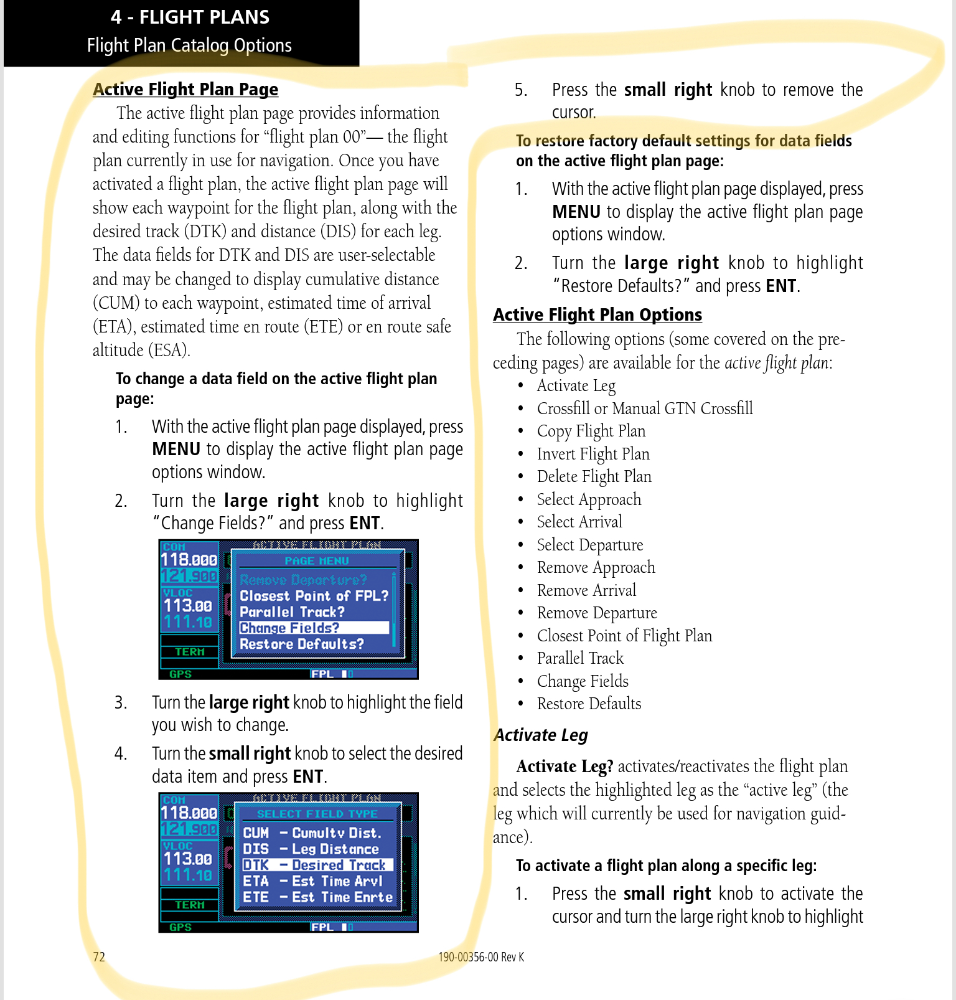

I’ve also found that the database manager sometimes won’t recognize an SD card when I plug it into the external card reader (even though it shows up in Windows explorer) but will if I unplug the reader with the card in it and replug the reader back into the same USB port. I always quick format the cards before updating just to be sure all the old stuff is cleared out. Shouldn’t be necessary, buy can’t hurt. Skip

-

Maybe Clarence @M20Doc still has some.

-

Mooney Bravo accident, Victoria MN 8/7/21 NTSB final report

PT20J replied to jaylw314's topic in General Mooney Talk

And, perhaps now we can dispense with the myth that the Mooney wing is unbreakable. -

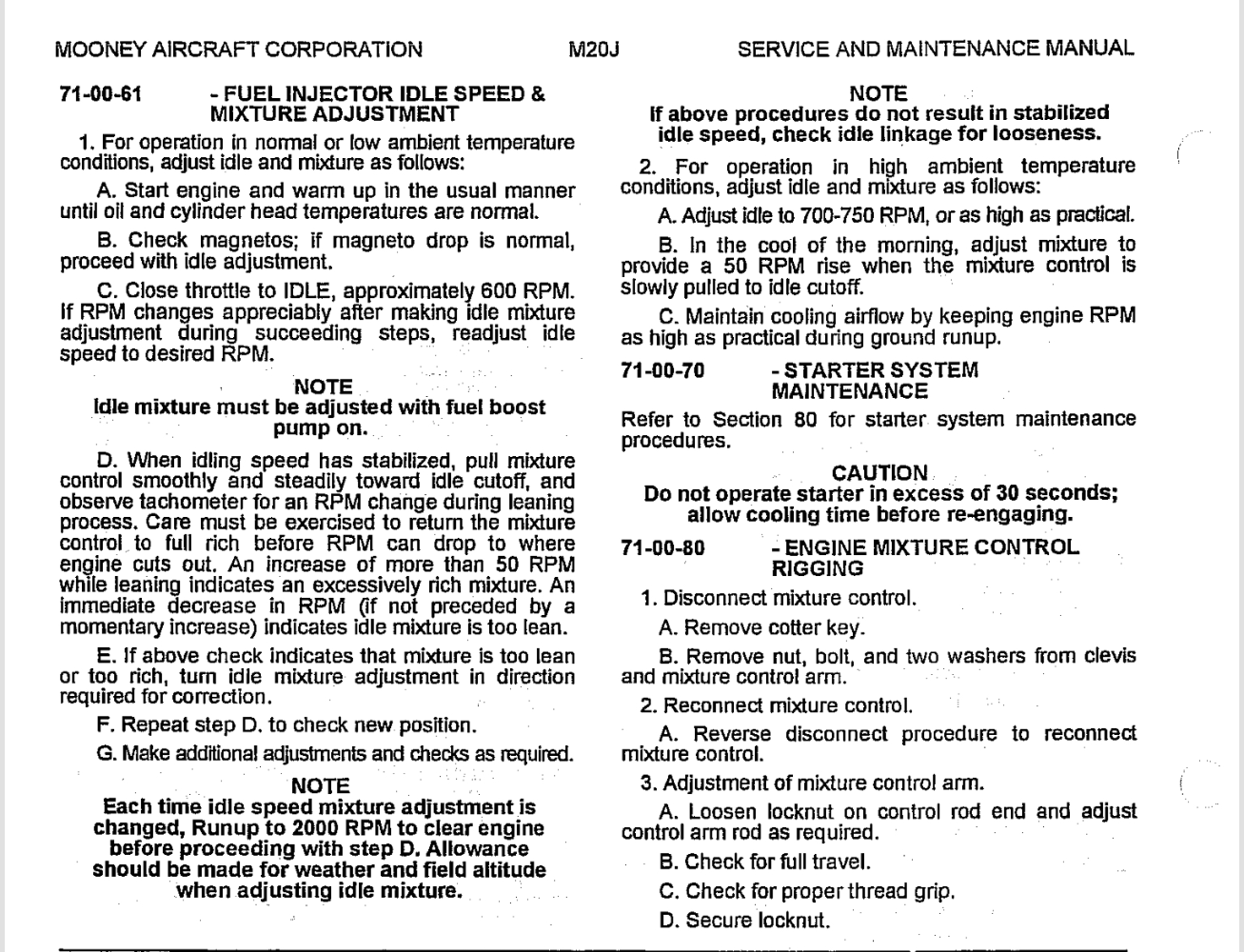

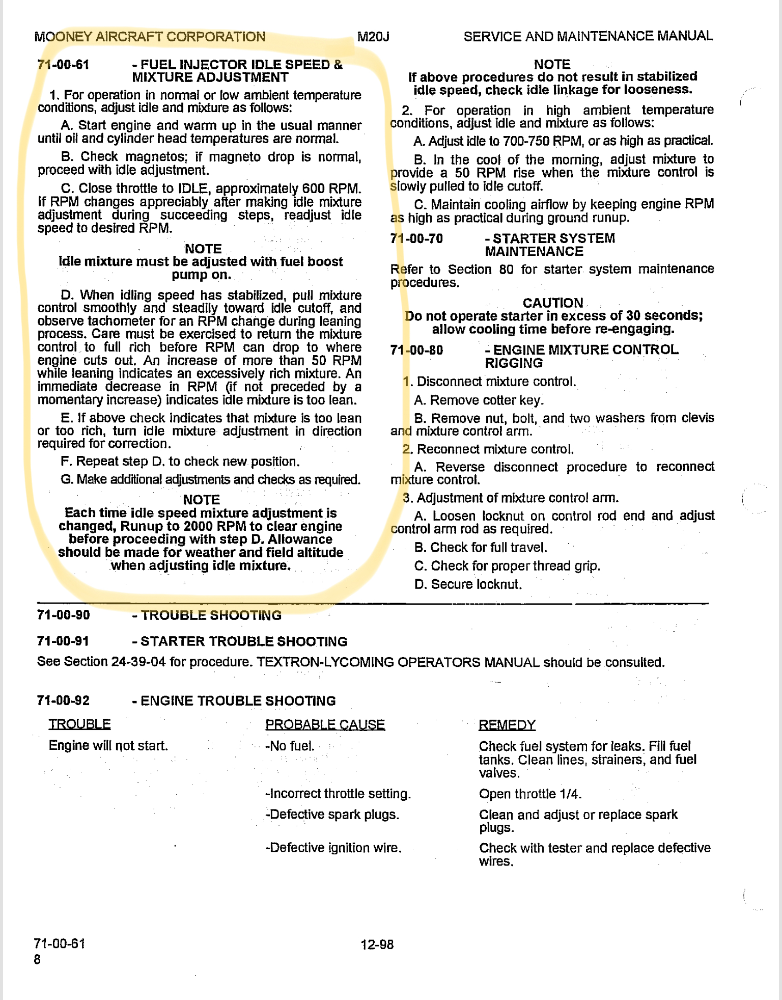

Some of us know our airplane very well. But for the average pilot, there is such a thing as too much of a good thing. For the IO-360, the RSA fuel injection system doesn’t meter fuel according to airflow at idle speeds because the airflow is too low to create enough pressure differential through the venturi and impact tubes to operate the metering diaphragms. Instead, a “constant head idle spring” internal to the fuel metering unit holds the ball valve slightly off its seat to provide idle fuel flow. This is why the idle mixture is so sensitive to idle speeds. If the idle speed is set very low at a standard day at sea level, it can be too low at higher density altitudes. Mooney recommends 600 rpm (700 rpm for hot temps). Personally, I’ve found my engine to be very stable at idle over a wide range of density altitudes when set to 650 rpm at sea level. But, each engine is a little different - this in 90 year old technology

-

-

There's a spec for that SI 1129D Alternator Belt Tension, Methods of Checking.pdf

-

The field voltage may be a bit less than bus voltage, but it should be fairly close. This is just a coarse test - you’re looking for gross errors like no voltage or a significantly low voltage.

-

Lycoming IO-360 Fuel Nozzle torque and "A" position

PT20J replied to redbaron1982's topic in General Mooney Talk

Did you check the idle mixture? Usually adjusting the idle speed requires a mixture change and adjusting the mixture usually changes the idle speed so it can take a few iterations. -

The first thing I would do is get out a DVM and measure the bus voltage with the master and alternator switches on (engine off) and compare it to the JPI to make sure that it's not an instrumentation error. If that's good, I would measure the voltage at the field terminal of the alternator and make sure it is near the bus voltage. Since the alternator is not putting out any voltage (the engine is off) the voltage regulator should be commanding maximum output from the alternator and it does this by applying max voltage available to the field. If that works, I'd suspect the alternator. The first thing to check would be the brushes if the alternator has a lot of time on it. Skip

-

It sounds like the installation isn't complete. Usually calibrating the magnetometer is done after everything else is complete. Database mismatches mean that the two GDUs don't have the same database. The RS-232 error could be that the navigator was turned off, or a misconfiguration or (less likely) a miswire. The installer should clear all this before releasing the airplane.

-

What issue are you seeing exactly? The G3X GDU uses RS-232 connections for everything except CAN Bus. In my case I have (port/protocol/connected device): RS-232 1 /MapMx /to GTN and G5 RS-232 2 /GTN Connext 2 /to GTN RS-232 3 /Connext 57600 baud /to GTX 345 RS-232 4 /Garmin Garmin Inst Data /to GEA 24 RS-232 5 /Garmin VHF Nav/Comm /to GNC 255A

-

Lycoming IO-360 Fuel Nozzle torque and "A" position

PT20J replied to redbaron1982's topic in General Mooney Talk

If you do decide to swap around nozzles between cylinders to improve balance, I'd keep the injector body and restrictor together and swap entire assemblies. When I was at the Precision Airmotive factory, Al Jesmer showed me how they don't actually measure flow on the nozzles but they do run each on the flow bench to make sure that the fuel streams out in a solid stream about the diameter of a #2 pencil lead. If not, they change restrictors until they get a combination that does. Skip -

Weight question came up today while weighing my plane

PT20J replied to hubcap's topic in General Mooney Talk

I believe that the proper technique according to the maintenance manual is to completely drain the tanks (by removing the sump drains) and then add back the unusable fuel to each tank. -

Lycoming IO-360 Fuel Nozzle torque and "A" position

PT20J replied to redbaron1982's topic in General Mooney Talk

You might try lubricating the threads with engine oil. See attached p177. Also, when torqueing into aluminum, turn the wrench slowly as aluminum has a tendency to gall which will cause you to reach the torque limit early. MM-IO-360-N1A - 3-31-2016 (1).pdf -

You could replace the bus bar with wire.

-

Weight question came up today while weighing my plane

PT20J replied to hubcap's topic in General Mooney Talk

Mine was right on accounting for the unuseable. Then there is the fact that Mooney’s weighing procedure calls for using a fuel density of 5.82 lb/gal. I was more interested in the CG than the weight. Because of the trailing link landing gear design which causes axel positions to vary, you have to make a lot of measurements to do it correctly. Skip -

Weight question came up today while weighing my plane

PT20J replied to hubcap's topic in General Mooney Talk

Probably a bunch of little things like cowl flap motors, split rear seats with headrests, articulated front seats, overhead wemacs, a tone generator and second overhead speaker for gear and stall warnings instead of sonalerts. But, my gross weight is 2900 so I still have 1000 lb. useful load. I’m pretty sure my 1978 J was a few knots faster, too. Skip -

Weight question came up today while weighing my plane

PT20J replied to hubcap's topic in General Mooney Talk

Those were the scale weights, but there were some adds and subtracts as it was weighed with full tanks and interior removed. Final empty weight was 1895 lb. Sorry, should have mentioned that. -

Weight question came up today while weighing my plane

PT20J replied to hubcap's topic in General Mooney Talk

Seems high. Mine was only 12 lbs heavier on the right. Left 788 Right 800 Nose 639 The engineer in me always suspects instrumentation and would swap the scales and repeat the measurement. Skip -

Does it matter? I think the manufacturer has a lot of latitude in specifying parts. Maintainers, not so much. Perhaps @A64Pilot has some insight.

-

The problem I see is as that @EricJ said, we only get to hear one side of the story and often the posts are made before final resolution and while the owner is angry. To be useful to the community as a pirep on a business, it would be better if the post were made after some resolution was reached and if it described the events matter of factly. There was a lengthy post about an engine overhaul gone bad a while back that I believe many found met this criteria.

-

Easier to flip toggles with those ugly nomex gloves

-

Looks like a candidate for an OPP