All Activity

- Past hour

-

toto started following Mystery oil pressure indicator switch

-

Wild guess is that it’s a remote mode selector for the engine monitor. But this doesn’t even look like an aircraft switch, and there’s no mounting screws in it - so it might be something like an input selector for your audio panel. No clue about the oil pressure fluctuation. If you hadn’t chased the wires, I would guess the oil pressure gauge is affected by interference from whatever that switch is controlling. Having a mysterious unlabeled switch that directly affects your factory oil pressure gauge is undesirable.

-

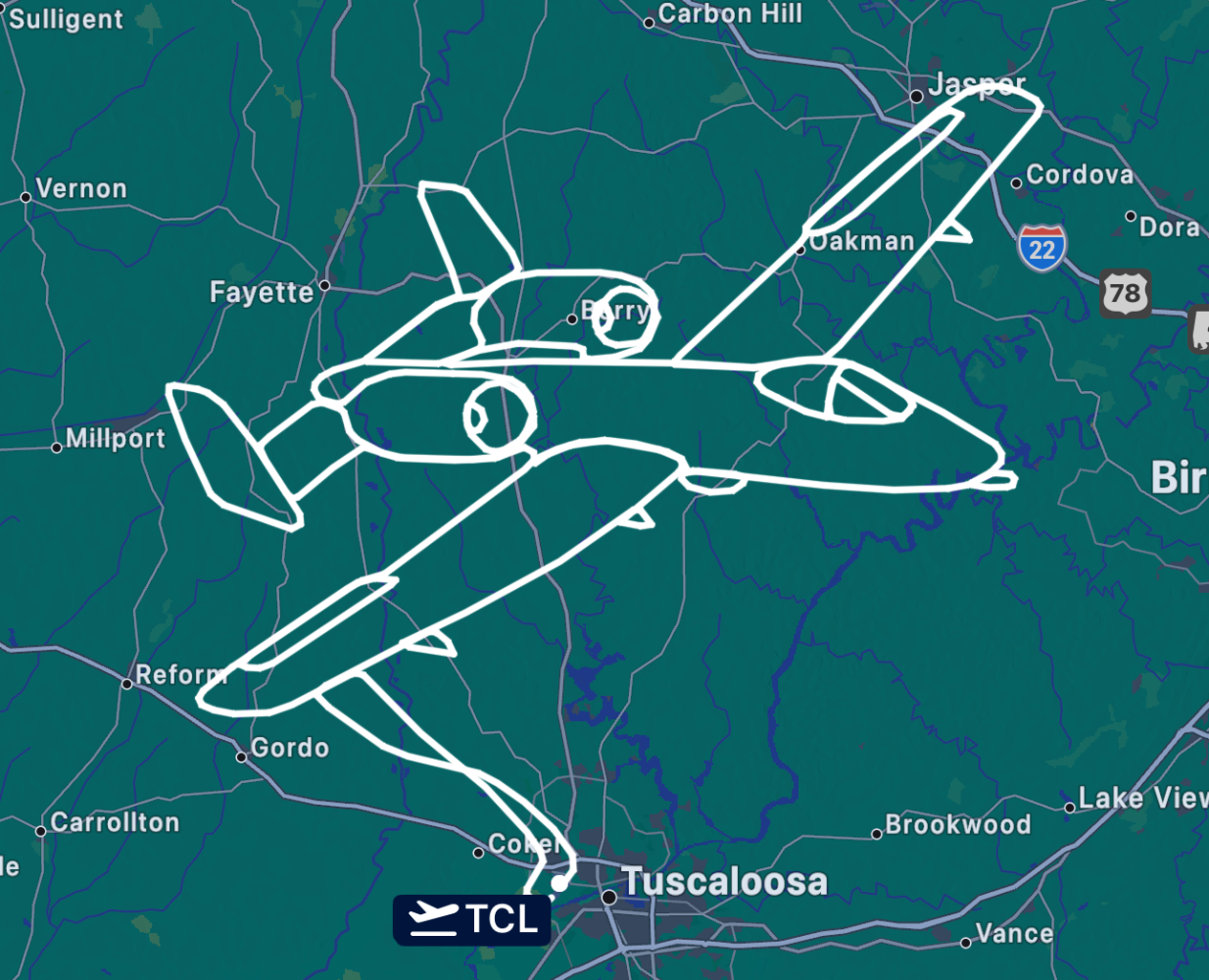

Ragsf15e started following Mooney pilot draws an A-10

-

Holy smokes! Excellent art! 4:30 hours! That took some serious effort!

-

IO-360 ‘warm engine’ start on M20J

Shadrach replied to Tiny18Driver's topic in Modern Mooney Discussion

I think that’s a sub-optimal approach. I have seen flooded engines catch fire at the pump. I’m kidding. Starting an engine simply requires a combustible mix of fuel and air. I have never had to flood a Lycoming engine to get it to start. -

Hello detectives. I have a new, beautiful M20J. It includes a mysterious, unlabeled switch. My pieces of evidence: 1) when toggling switch, only noticeable change is that the factory Mooney oil pressure gauge pegs high. Toggle switch back, it goes back to normal reading. 2) chasing wires of switch, it appears to be a 2 position switch that interfaced with the oil pressure gauge. The wires on the other end of the switch head towards RH side of panel but are disconnected and tied off. I would like to remove this switch one day, but am curious about what it may have done? Plane has a JPI700 and Fuel Scan 450. Any idea what instrument may have, presumably, ingested oil pressure data when the pilot flicked the switch?

-

Cruiser73 started following PC Wing Leveler help needed

- Today

-

And it was drawn by a Mooney!

-

toto started following Mooney pilot draws an A-10

-

Okay, this is pretty cool. https://flightaware.com/live/flight/N7132V/history/20251002/1530Z/KTCL/KTCL Saw the pilot post on Reddit, but thought this was more properly shared on MS Nicely done

-

IO-360 ‘warm engine’ start on M20J

Ragsf15e replied to Tiny18Driver's topic in Modern Mooney Discussion

Just be careful. If you have to flood it often because it won’t start hot/warm, you’re doing a lot more starts than needed with excessive fuel in the engine. It’s in the exhaust, maybe dripping down the intakes, etc. there’s maybe a slightly increased risk of fire. The engine should start pretty well if the ignition system is set up correctly and the plugs are good. Once in a great while, a flooded start happens, but shouldn’t become SOP. -

Upper cowl machine screw issue on '83 J

jetdriven replied to 0TreeLemur's topic in Modern Mooney Discussion

Stainless screws tend to gall and seize up in the nut plate and then break off and then you have one heck of a problem. We just started using more and more cad plates steel fasteners, which don’t do this nearly as often. Spinner screws in M20Js are another notable example. -

McMooney started following IO-360 ‘warm engine’ start on M20J

-

IO-360 ‘warm engine’ start on M20J

McMooney replied to Tiny18Driver's topic in Modern Mooney Discussion

i do exactly as you've been told, hot start, if that doesn't work, flood it. -

seeking current owner of N58016

N201MKTurbo replied to MKEgal's topic in Miscellaneous Aviation Talk

Your best bet is to send a letter to the PO Box. You could contact the local airports around Muskegon. -

IO-360 ‘warm engine’ start on M20J

GeeBee replied to Tiny18Driver's topic in Modern Mooney Discussion

That is correct. Lycoming and Continental require different approaches. -

toto started following seeking current owner of N58016

-

There’s no flight history on this a/c (or, at least, the last flight I see was in 2002). It seems to have a current registration, so presumably it’s still operational. The owner may have opted out of the commercial flight tracking databases. Maybe someone with a fancy adsbexchange subscription can see if it’s flying. The hive mind of MS is pretty good at these sorts of things, so I’m optimistic you’ll get in touch with the owner. Seems like a nice piece of aviation art that would be best kept with the plane. As mentioned elsewhere, you can almost certainly get in touch with the right contact if you go through the business records at the SoS office. But I understand that you’re short on time. Maybe someone here can provide a PM with contact info.

-

IO-360 ‘warm engine’ start on M20J

Shadrach replied to Tiny18Driver's topic in Modern Mooney Discussion

You would expect people to have different experiences, given the differences between the Bendix RSA style fuel system and the Continental fuel system. Lycoming’s have no return line from the servo as there is with the Continental. This means that you cannot circulate fuel through the servo. It’s a one-way street from the tank to the injectors. This does not mean that it is difficult to hot start an injected Lycoming engine, it just means that one must use procedures oriented towards the Bedix RSA style fuel system. Challenging hot starts are often related to ignition issues. These engines really aren’t that hard to start when hot. I’m proof that it doesn’t take a genius. -

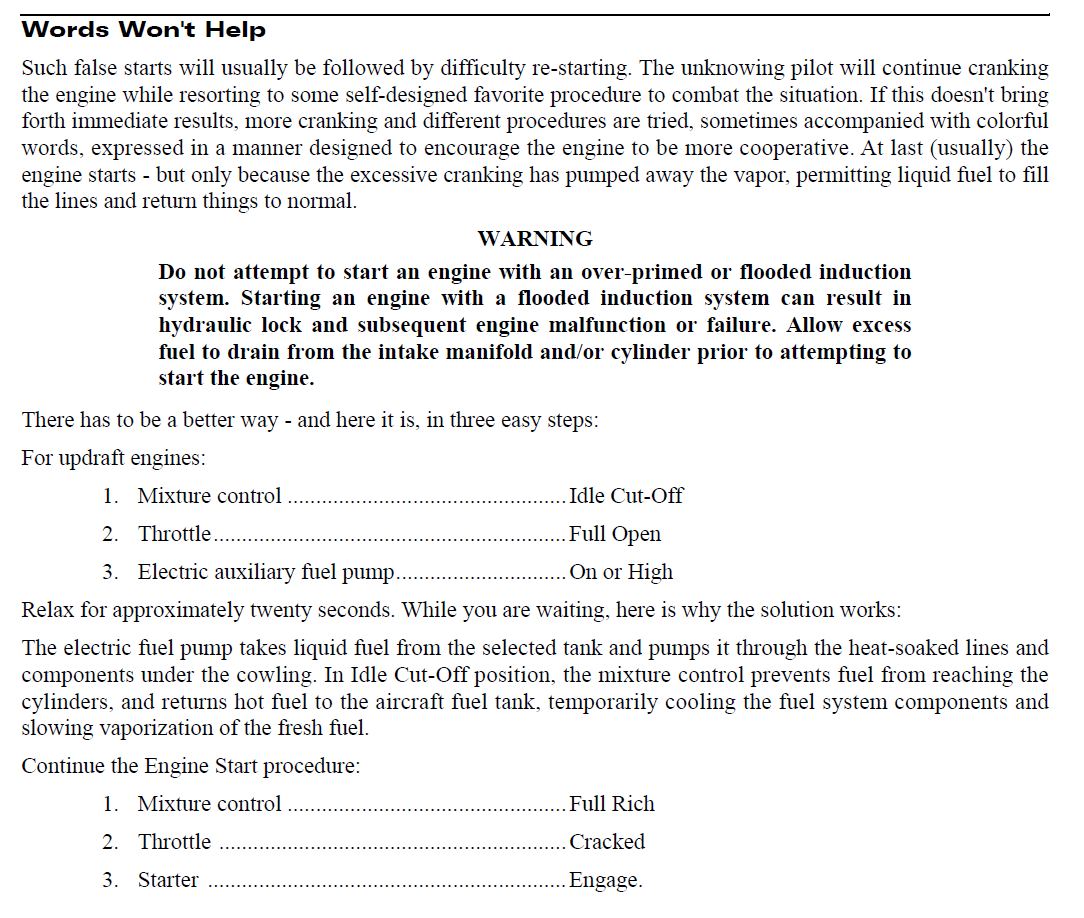

Here's how Continental says to do it, from their "Tips on Engine Care" publication. Works every time. Full documentation attached and worth the read. Lycoming people may have a different experience. Hot Start Procedures - Continental.pdf

-

MKEgal started following seeking current owner of N58016

-

https://imgur.com/gallery/28uFdLJ Several decades ago, my dad owned this plane. One Christmas, mom found a stained glass artist who made this panel, complete with tail number & the right color stripe. After dad died the plane was sold. Why we still have the stained glass, I don't know, but if the current owner can be found & wants it, s/he can either pick it up [SW Kansas City, KS area] or pay for packing & shipping. [This is about 12x24".] We only have about 2 weeks before this gets donated or sold by the estate sale company. I've found a current registered owner in Muskegon, MI but can't find his contact information.

-

For those of us that fly in the south where air is warm and humidity is high, our performance will not match our northern counterparts. I routinely see a 10 knot difference in TAS between flights in PA (where he is) and flights in FL. Our engines are not making rated HP in hot and moist air, if you want bragging rights, move to where it’s cold and dry.

-

favor534 joined the community

-

Upper cowl machine screw issue on '83 J

0TreeLemur replied to 0TreeLemur's topic in Modern Mooney Discussion

To answer my own question it is not a floating nut plate so alignment was not the issue. Running a tap in did clear the way. It seems odd to me that suddenly it developed a problem. I can't imagine what caused it to change. I suspect that nut plate is going to need replacing sooner rather than later by an A&P with the experience and tools, which I am not. -

IO-360 ‘warm engine’ start on M20J

0TreeLemur replied to Tiny18Driver's topic in Modern Mooney Discussion

This is what I do too. And it allmost always works. There is a video by Don Maxwell about hot-starting a Mooney that I really enjoyed and thought was educational. It's linked here on this site multiple places I'm sure. In that video he said "Lycoming engines always start flooded." I took that to heart and it relieved my stress about starting a hot or warm engine. -

IO-360 ‘warm engine’ start on M20J

MikeOH replied to Tiny18Driver's topic in Modern Mooney Discussion

For anything but a cold stat my technique is to leave the throttle where it was at shutdown (1100 rpm), NO boost pump, mixture ICO, start cranking and WAIT 2 to 3 seconds to see if it lights off...if not, then I SLOWLY start advancing mixture until it starts. This works for me for anything from a few minutes to a couple of hours after shutdown. -

1980 M20 K 231 with Merlyn and Turbo plus-- $147,900.00

Steve Dawson replied to Steve Dawson's topic in Aircraft Classifieds

Added new equipment including a 28 volt Robotow and Rosin sun shades- 16 replies

-

- 231

- m20k for sale

-

(and 1 more)

Tagged with:

-

This translates to approximately 147ktas which makes more sense. I honestly can’t tell you what the RPMS were but I normally cruise at 2400 even up high. I know that our little C models are amazing for the speed you get from 180hp but 160 knots does seem a bit questionable

-

He's showing just over 20" at 11,500; my C barely makes that at 10,000. And at 20"/2500 and 10,000 msl, I'm usually around 145-148 KTAS (indicating around 145 mph).

-

IO-360 ‘warm engine’ start on M20J

Joe Linnebur replied to Tiny18Driver's topic in Modern Mooney Discussion

Like Mooney in Oz said above, in those ‘intermediate’ situations I tend to go rich mixture, throttle full, then a few second burst of the fuel pump. Then I do a hot start technique (throttle open a little more than normal, mixture lean). Seems to light off within 10 blades. A little throttle “in and out action” sometimes is needed to get the air/fuel ratio right, but that might be our engine. -

Ragsf15e started following IO-360 ‘warm engine’ start on M20J

-

IO-360 ‘warm engine’ start on M20J

Ragsf15e replied to Tiny18Driver's topic in Modern Mooney Discussion

I generally did them in this order when warmish… 1. Hot start 2. Normal prime, normal start 3. Flood it, flooded start. Don’t remember getting to #3 more than once or twice in 10 years. Fyi, I always prime with throttle full open, mix full rich as that’s the most flow.