All Activity

- Past hour

-

Things moving along! Shop found a discrepancy in the roll servo arm length, needed to be shortened on my bird. Minor modification thankfully. Ill be heading out Monday for a review and were adding a second cigarette light socked for additional power for future items i may want to power up. Excited to see the panel update for the flat pack… -Don

-

In a Diamond DA20 during PPL training power idle was on downwind at the numbers with first flaps...

- Today

-

Better yet, is replacing the 10,000 plus belly panel screws !!!! ;-)

-

I'm told Vinyl paint will work; I'm suspicious as well which is why I ordered a sample. I plan to give it some overlap to address shrinkage since I'm installing in FL where it's HOT!

-

+1 @Ragsf15e 1. Cad machine screws. If the head shows any damage, replace it. 2. Put a small smear of anti seize (use a tooth pick) on each screw before installing. It’s time consuming, but once done, you don’t have to do it every year. 3. Hand install screws. Using a ratchet screwdriver helps. Do not use a battery operated drill-driver. Even the lowest torque setting is too tight. 4. Use a new (quality) apex bit to remove the screws. Worn bits strip out Phillips head screws. You’ll spend much less time removing stuck/stripped head screws.

-

Actually they do pre-punch parts. Maintenance wouldn’t be possible on some things without doing so such as for example the seat rails are pre-punched. You could never drill out all the holes under the floor panel, as it is you can’t get a bucking bar on some of the rivets. But you are very right about your factory and LASAR comments. The factory is pretty much over and LASAR is so cash poor that buying the raw materials for parts is a struggle. Sent from my iPhone using Tapatalk

-

kortopates started following Mooney Parts Rumor

-

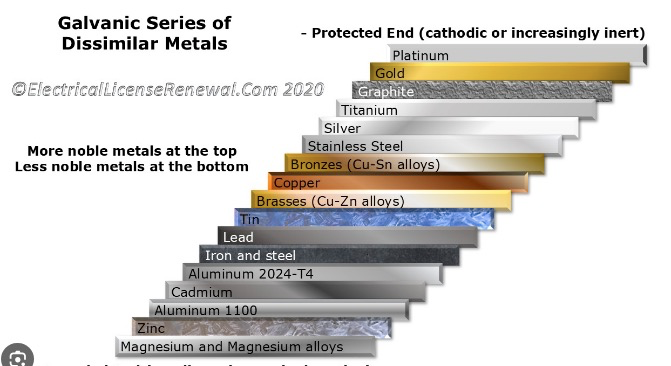

One other thing my mechanic and I noticed was how the stainless screws were much more likely to gall and stick in the nuts (machine screws at least). I haven’t had the same issue with cad screws. After watching my mechanic drilling out a ss screw (and cringing) and then replacing the nutplate as well, I just use the cad plated ones and throw them away as soon as I see them deteriorate or strip at all.

-

I'm no expert but if I remember correctly from my time with an Ocean Engineering group, stainless steel and aluminum were not great together. I think you are correct in your assessment (yet we use them anyway). Hopefully there's a materials expert on M/S that can offer an expert opinion. I think Cadmium has fallen out of favor due to its toxicity and carcinogenic characteristics. Cadmium corrosion (a white powdered dust) was a bad thing to inhale.

-

There are some of us who were around when this SB came out and remember the background of what actually happened. Even though it was only a couple of springs that went bad due to a bad heat treat in a batch of springs, the risk factor of the gear up landing if one was to break again (think lawyers) was high enough to make the 1000 hrs change out a reality. This would also preclude changing the SB to longer time limit today with today's litigious society. If it was an inherent problem with the design and wear factors of the spring itself we would have seen springs failing many times in the years before this SB came out. What changed? What have we done now when the springs were not available for years? We flew and didn't have spring failures. Many Mooneys would have had gear up landings because many Mooneys had more then 1000 hrs on the spring they came with before the SB. Fleet average might realistically be 1 or 2 gear operations per hour given 4000 hr airframes only 8000 operations over 40 or more years. Is there a limit to how long a god spring will last? We don't have those numbers so it seems reasonable to change the spring at some time down the road. I'm sure Al Mooney never figured his designs would be flying 60+ years after they left the factory. SB's are, after all, "optional" for Pt 91 airplanes (Australia aside :-) Your choice. Can anyone report on any Mooney gear failure due to a back up spring failure recently? Please provide the details so I can research the issue. Due to the very detailed SB requirements this is a prime place for "maintenance induced failures" if not done exactually like the SB proscribes. Being as esoteric as this particular maintenance action is it is not one to be attempted by just any A&P. Do I dare say "Johnson Bar" anyone :-)

-

I didn’t paint my bead trim. If you paint it before installation I don’t see how the paint withstands bending in the corners (or if it does, how it remains durable over time.). And if you paint it after it is installed then it gets “glued” into place and leaves a painting/ ridge if ever moved. I like to be able to remove it if I need to repair a panel. Another thing is that the beading will shrink due to the factors of time, heat and sunlight. Maybe you won’t keep your Mooney long enough for it to matter. Maybe the material has changed. But over 25 years of ownership, I replaced the beading once with factory material. It has always been hangared. The beading was installed perfectly with no gaps but now there is a gap and noticeable shrinkage.

-

ABS may be best but for the folks using epoxy, I used JB Weld Plastic Bonder (purchased from Lowes). Works great; no failures. It can be used for filling and can be easily sanded and painted. I've used it to glue steel adhesive ready nut plates to the back of the interior panels and I've used it to glue thin sheet aluminum to the back for reinforcement over damaged areas. Everything seems to stay stuck.

-

I have a sample coming in for paint from them. I've also stopped at a couple auto supply stores and not found anything that works. After more calls to Jeager, I was able to talk to someone. They no longer have a supply and have been working on trying to find a new supplier.

-

I'm sure Rich knows this, but if you try to straighten warped interior plastic pieces with a heat gun be aware that the temperature where the plastic gets soft enough to reshape is very near the temperature where it will get so soft that it completely loses its shape and wrinkles up. Like Lee, I find that ABS cement works well with glass cloth to repair areas that need to be flexible. I usually use two layers of cloth and have done that at every screw hole to reinforce the area. If an area does not need to be as flexible and needs more strength, I glue a piece of ABS to the back.

-

I am; the windlace is done and will be picked up from the upholstery shop today. I should be back in town tomorrow and my goal is to have the overheads back in. This weekend. Lots of small screws.

-

Christina joined the community

-

Mooney-Shiner started following Belly Screws - '67 F

-

Just bringing this thread back from the dead: Since I’ve been based at a coastal Florida airport (beautiful spot, but hot and humid) with my Mooney since 2020, I made a habit of replacing corroded or worn fasteners with stainless steel ones. The line for hangars are decade long and I'm on the outside tiedown. But the more I’ve read on this, the more I realize that cadmium-plated screws are actually less noble than stainless and closer to aluminum on the galvanic scale. Counterintuitive as it seems, that means cad-plated screws can promote less corrosion than stainless when installed in aluminum. Sure enough, I started noticing filiform corrosion forming around my fuel tank access panel after swapping the original screws for stainless steel ones. Does anyone have an experience with this?

-

You should definitely remove that strange avionics master setup regardless and return to a stock configuration. The legality of that switch install aside, it opens you up to a ton of issues, not the least of which are a complete avionics failure or back feeding into the main bus. Does that not concern you?

-

You sound/act like there are no and have never been any smart people anywhere working on this. Tell us why Thielert tried in 1999 and failed. Tell us why you have not mentioned DeltaHawk as a possible near term solution.

-

I would've kept the A220 if it fit in my new panel. It was a solid com radio. Never had an issue with it.

-

The hypothesis seemed to be .... IF the master relay is in fact off then the system is being back-fed via one of the attached components. But they would not have power if the relay was off without power supplied from somewhere before the master relay (because its open, right?). If true, pull each breaker in turn until voltage source is cut off.

-

So does the flaps….

-

The AUX and Avionics bus gets power from the Battery Bus which gets power from the Master (Battery) Relay. Do you have a problem with mice?

-

Yes, with one caveat- the KX-155 is well known for its reliability. Only time will tell if the Trig (or any of the very new radios, even Garmin) will match it going forward. My gut tells me the new designs will be as good or better than the older generation. The GNS-430 is now over 25 years old and still going strong.

-

Just like there are good and bad shops, there are good and bad customers. A good customer is engaged in the maintenance on their machine, without "standing over the shoulder" of the guy while he's working. He pays his invoices on time, and provides as much useful feedback to the shop as he can when an issue arises. I know there are lots of pilots (looking at you, Cirrus owners) who just toss the keys and say "fix it" but I try to work with my shop, as much as I can. Sure, there have been some invoices where I've questioned a couple of things, but it's either been cleared up by my shop, or they've given me a satisfactory explanation as to why something took a bit longer. That's the best approach moving forward I think. Just ask for 15 minutes of their time to sit down and go over your invoice, have them break it down line by line.

-

McMooney started following WTH -- seriously, is this what the algorithm thinks of me