All Activity

- Today

-

I have the flight enhancement step and am very happy with it. I removed the vaccum system several years ago and lashed the step in the retracted position; just didn't seem right so I finally sprung for the electric step. It's very lightweight, but sturdy and well-made. Many people have it hooked up to the beacon wire; I decided to install a toggle switch on the panel, matching the avionics master right next to it. That way it's kind of like the electric window control in a car (works only when the master is on). Here's a photo of the interior view. Outside it just looks like a normal Mooney step.

-

@M20Kid if you’re talking about the overhead electroluminescent panel if you have overhead light switches, this can be repaired by either Air Capitol Dial or Nimbus Aviation. If it’s warped and not working they can make it new with a new internal lamp. The overhead light switches should light up with your panel lighting rotary switch.

-

Thanks for your perspective. I truly haven’t flown in busy airspace enough to have experienced some of those issues, sounds like it definitely needs some improvement. Working as a controller in Canada is actually a pretty sweet career with good pay. You would think they could attract more talent! I was impressed with flight following in the US. Very helpful.

-

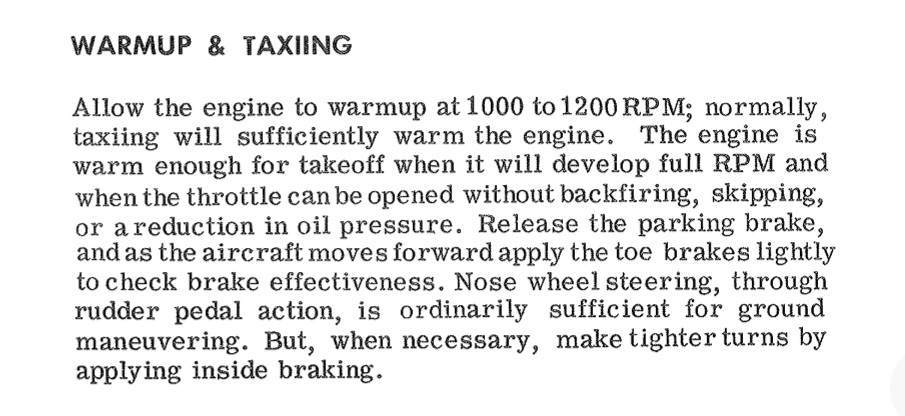

How long from start up to take off? (Normally aspirated)

Hank replied to NotarPilot's topic in General Mooney Talk

Back on topic: I've timed myself from engine start to 7500 msl, power set, mixture leaned. Fifteen minutes or less, even in WV winters. Obviously, I'm based at a non-towered field. -

How long from start up to take off? (Normally aspirated)

MikeOH replied to NotarPilot's topic in General Mooney Talk

If the oil temp needle is off the peg, I'll take off. Taxi and runup has always done that. -

McMaster Carr is a good source, if you don’t need 1 lb bags of each…

-

The fixed step has a different mounting configuration. The retractable step is more substantial. I suspect that a fairing would not do much. It has quite a bit of parasite drag and also induces drag because it puts the airplane out of trim. It would be up to your mechanic and IA to make a determination on a fairing.

-

How about acquiring a retractable step for a F, leaving it down all the time and making a teardrop fairing over the square tube? Would that be considered a minor modification that a mechanic could sign for?

-

Is the portion of the tube that goes inside the fuselage the same square dimension as the retractable square tube? In other words is it just a matter of installing it in the square bearing blocks? (which are still there on the aft bulkhead of my F, by the way)

-

Rght out of the gate? Seriously???

Echo replied to Freddb34's topic in Vintage Mooneys (pre-J models)

How did John Denver die? Hmmmmm. -

Rght out of the gate? Seriously???

Echo replied to Freddb34's topic in Vintage Mooneys (pre-J models)

I think not using your hand to feel the fuel selector,is absolutely wrong. relying on a tool is not a good way to go for safety of flight operation imo. Whether because it is to "hard" to move or because you are to gutenabled. Bad form. -

Talk to @AH-1 Cobra Pilot he's already mastered it

-

I have the electric step (was a vanguard installer) and it works perfect. The fixed step is installable as it is already used on Mooneys as a factory part. It does however need the rear bulkhead reinforcement plate that will unrivet from the donor airplane.

-

How long from start up to take off? (Normally aspirated)

N201MKTurbo replied to NotarPilot's topic in General Mooney Talk

When I was commuting, if I waited 10 minutes to takeoff. It made driving faster. - Yesterday

-

How long from start up to take off? (Normally aspirated)

201Mooniac replied to NotarPilot's topic in General Mooney Talk

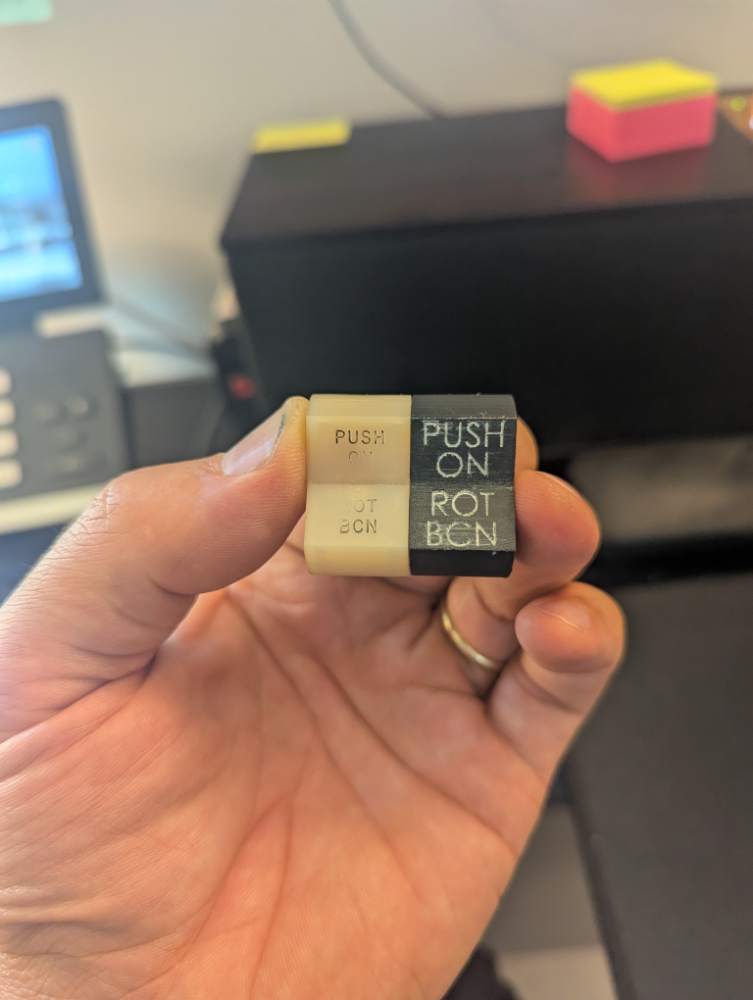

I'm not sure why but I wait for oil temp to get to 100F for the runup and 130F for takeoff, that usually doesn't take anymore than my normal taxi. -

How long from start up to take off? (Normally aspirated)

oisiaa replied to NotarPilot's topic in General Mooney Talk

Page 4-5: Seems to take roughly 10 minutes when below 50F for me. That's considerable ground time, but worthwhile if needed to prevent engine wear. -

How long from start up to take off? (Normally aspirated)

Hank replied to NotarPilot's topic in General Mooney Talk

Yep, in 18 years my C has not failed to run strong and hard when applying full throttle for takeoff, without bothering to sit and warm up. -

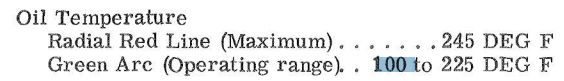

What switch covers are we talking about? I just reverse engineered one from my 201. Happy to share... Just need to do one more test fit.

-

Just bumping this thread. I need an overhead cover for my M20K and I don't have the tech skills to create it. I have a printer available if someone could design the part I need. I found software that you can just take multiple photos of the panel and it will make the file, but I haven't been able to even get that to install. Really, I am pretty tech savvy most of the time. Any suggestions for someone new to 3D printing?

-

How long from start up to take off? (Normally aspirated)

N201MKTurbo replied to NotarPilot's topic in General Mooney Talk

You will have oil temp in short order. You will be fine. -

Aerocomfort in San Antonio is the only option I would consider. all other routes are risky to me. Textile skills get rarer everyday. I took the risk with two people for my Aerostar and both ended poorly. when it was time for the Mooney I went and I will never experiment again. I will find a way for aerocomfort to be involved. Good value, great people and awesome quality.

-

How long from start up to take off? (Normally aspirated)

Hank replied to NotarPilot's topic in General Mooney Talk

This is what the Owners Manual for my 1970 C says, page 38, POH 1203: Where do you get 100° minimum temperature? I don’t see it anywhere. -

Most any of the foam that you buy really does not burn that well.

-

takair started following Fixed step on F model?

-

If you have questions about the electric conversion let me know. Over 400 kits sold to date. We have an occasional failure, but in many cases we trace it back to an alignment issue with the cable and step, and we have instructions on how to rectify that. Mooneys being hand built, there are small variations in each.

-

According to this SB: https://mooney.com/wp-content/uploads/2020/12/SBM20-231.pdf they are MS20426AD4-5 and -6