Search the Community

Showing results for tags 'Overhaul'.

-

Unfortunately we found that our camshaft on our 1986 M20J with the A3B6D was spalled and since it’s 1500SMOH, we elected to overhaul the engine. We have narrowed it down to Triad Aviation in NC or Watson Aero in Georgia. Any PIREPs of people who have used either would be much appreciated!

- 18 replies

-

- watson aero

- triad aviation

-

(and 3 more)

Tagged with:

-

Newbie question here. I have a 62 M20c, original A hub. 2 blade Hartzel. it was suggested during my recent oil change that it might be time to look at a prop overhaul. There has been some oil/grease seepage along the back side of the base of the propeller since i bought it 2 years ago. Not a lot but enough to be observable in the right lighting conditions. I've generally just wiped it off once a month or so. It's not really ever seemed to affect the operation of the propeller. My question is, what is usually involved with a prop overall? does it just look at the prop or do they get into all the workings in the spinner? Also, about how many AMU's does one usually go for? Thanks,

-

Well, we left N252AD in Smithville, TX in the capable hands of JD and Laura Casteel at SWTA. It's time for the big one. Her engine made it to 1830 hours on the original cylinders and turbo. But she's definitely tired. Only one cylinder was able to make compression over about 50. And her belly is just one long oil slick all the way to the tail skid. The governor is leaking oil as well, and the vacuum pump can't seem to muster enough power to deploy the speed brakes anymore. This year's annual will include an engine overhaul and Encore conversion. The engine, turbo, waste gate, governor, and fuel pump will all go to Jewell Aviation for overhaul and conversion from an MB to an SB engine. All of the other Encore parts are laid out and organized by Laura, ready for installation. This includes new double puck brakes and all the associated parts and pieces. New control surface counter weights, instrument remapping, and the engine stuff. We will also swap the vacuum speed brakes for electric and remove the remainder of the vacuum system. And finally swap the dangling compass for a panel mounted version. We're looking forward to a horse power increase and useful load in the 1100 lb range when it's all said and done. To say nothing of a clean belly. A big thanks to @Denver98 for picking us up in Smithville and giving us a ride back to Denver in a Cessna 421. A very nice ride.

- 113 replies

-

- 35

-

-

I have owned N1084L, a 1997 J for 10+ years. TTAE 1806. Oil consumption has gradually increased from 9 hrs/qt to 4. Regular oil analysis has never shown high metal levels. I changed oil after returning from flying in Caravan to KOSH, and found small metal flakes in filter for first time. With 20 year Lycoming limit for Rebuilt for Overhaul Price Proram coming up (June 2016) looks like it's time to go ahead & order rebuilt IO360A3B6. I haven't received latest oil report yet. Alan Millet

-

So I have a 1979 M20K, 75 hours into a new top end overhaul, the number 3 cylinder vibrates and broke 2 of the bolts holding it to the engine. After proper break-in procedure based at KSNA. I have done some research and from what I can find, it could of happened if the seal wasn’t prefect and over time the vibration cause the suds to break. The mechanic that did the top end doesn’t want to take any responsible and claims it’s because of the way I flew the plane LOP. He thinks all the cylinder could have been burnt up. He recommends doing an overhaul exchange at 1,000 hours it’s only $35,000. I feel like he just wants to wash his hands with everything, and cover his tracks.. Has anyone ran into similar problems? This is my first plane, and I really don’t know how to proceed....

- 15 replies

-

- top overhaul

- overhaul

-

(and 3 more)

Tagged with:

-

-

I am sure this subject has come up before, but I can't find the details needed. Many publications discuss the cost of an engine overhaul, different options, different suppliers, etc. Yet I would like to know how much more the aircraft owner has to put aside for the items typically not included. And numbers from within the last 5 or max 10 years are of course more interesting than older bills. Consider your IO-360 has lasted 30 years and never failed, and now it's time for major work. Engine accessories are almost always included or listed, but what about the following firewall forward items which aren't any younger : engine mount - inspection and repair, exhaust - new (if welding isn't economical), oil cooler, and the related cost of labor, shipping, taxes, etc. Anything one cannot simply postpone until it really requires replacement or overhaul because that would come even more expensive. Any real data / bills / experience on this very welcome. It is clear that the cost will vary a lot from case to case. Would could be a worst case ?

-

I had a low oil pressure indication in my Mooney Encore the other day and made a precautionary landing in Myrtle Beach, SC. There was debris in the oil pressure regulator causing it to fail and the shop there looked at the oil filter and found non-ferrous metal, indicating it's time for an overhaul. I had been seeing the oil blacken quickly so I knew this was coming. The engine is at about 1330 hours. Shop there quoted me $35,000 for an overhaul including magnetos, harness, spark plugs, turbocharger and new cylinders. They plan to reuse the starter, exhaust system and wastegate controller (was just overhauled a couple months ago). I've replaced a couple cylinders already and am pretty overwhelmed and beat up from spending money on this engine (welcome to airplane ownership, I know). Can anyone offer advice or a place to ship the engine for a better deal? The shop there says the next step is to take the engine apart to see what's really going on. Long story short, I'm not super familiar with the overhaul process and want to feel comfortable that I'm not getting a bad deal or doing work I don't need to do.

-

MooneySpacers, I just had my propellor overhauled after an annual inspection because it was throwing grease from the hub. I got two used blades because mine were no longer serviceable. After install, my engine tops out at 2550 RPMs. We looked at the governor and noticed that it was adjusted to its stop of high RPM. I had the governor flushed and tested by two shops and they both confirmed that the governor was good. I had it overhauled anyways because I cant tell when it was last done. Put it in and got the same 2550 with the governor adjusted to where it should be or adjusted out to the high rpm stop. I took the plane for a lap around the field and saw 2700 rpm on climb out and around 2685 on downwind. We had a prop strobe tach with us and it coincided with the tach in the plane. I'm having my A&P check the fuel pressure and fuel flow today. We also measured the blade angles and and they were within specs of the TCDS... Any advice on what I can check next would be great fully appreciated. Thanks much, Jon

-

looking for Continental IO550G cylinder needed for replacement.

-

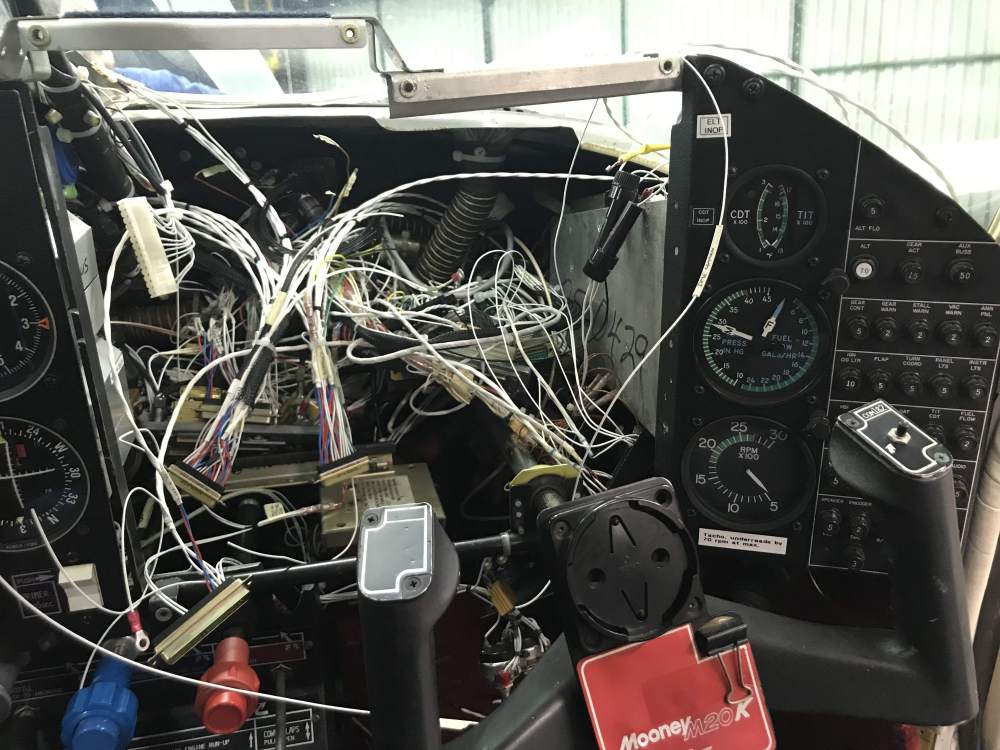

Has anyone else noticed how little information is available about the real cost of major maintenance? As I'm winding up my firewall-forward project, I'm considering releasing a line-by-line cost breakdown. Does anyone have any thoughts about why that might not be a good idea? If any non-flying spouses see this post, just tell them I got ripped off and you paid a lot less.. Or maybe we could play 'The Price Is Right' and let everyone guess. Here's an {almost} complete list of work performed: TSIO-520-NB Overhaul & Test Run by Certified Engines http://www.certifiedengines.com/ Magnetos & harness Starter Fuel injection system Oil cooler Intercoolers Turbocharger, controller, PRV, & waste gate Camshaft Crankshaft Prop overhaul by Palm Beach Propeller http://www.pbapi.com/ Prop governor overhaul prop blades overhaul new hub Millennium cylinders (new) Gami nozzles (new) Tempest fine wire spark plugs (new) Hoses (all new) Exhaust (overhaul by Rocket Engineering, replaced five sections, re-welded, polished) Engine Mount (overhaul by Rocket Engineering, replaced two tubes, re-welded, powder coated) Vibration mounts We definitely got in to the "while the engine is off, we might as well..." mode of thinking. That's what happens when you have access to a maintenance hanger and your -IA lets you do a lot of the grunt work. I've learned more about how everything works in the past three months than I did in the past twenty-five years of GA flying.

-

I got the pictures back from Triad today from my tear down and I must say that it's worse that I had hoped. Pics attached. The crack in the crankcase under #2 came as the biggest surprise....

-

So we’re into this year’s annual, and I have a cylinder (4) with a leaking at the exhaust valve 60/80 and it’s opposing partner (3) leaking at the intake valve 72/80. From my logs, these same two problem children were replaced in 2001 and 2000 respectively, so it seems they haven’t done too bad to make it nearly 13 years and 750hrs. (although 1 and 2 are mid 70s and haven’t been touched since shortly after last major in ’89). My IA and I are discussing the options, but basically at 1500hrs and 25yrs, I’m weighing my decision pretty heavily. Oil consumption Is pretty low – 1qt every 6-7 hours. That being said, topping the engine is a thought I’m having, but I’m curious to know if anyone can offer any insight with regard to the “Overhauled” cylinders I’m finding around the internet for around $350-$800each vs the “New” cylinders at $2300 each. The OH’ed cylinders come with 8130, so I don’t think we’re talking about buying some grey market garbage. My thought process would lead me to believe that if I had any thoughts of getting the latter cylinders, I would likely end up better getting one jug for now and a factory overhauled engine in the not so distant future. This is new territory to me, so I thought I’d solicit input accordingly . Any thoughts , constructive input, or things otherwise to be aware of? Thanks! ~Abe

-

This is a little follow up from my other post.http://mooneyspace.com/topic/10331-making-aluminum/?hl=%2Bmaking+%2Baluminum My overhauled cylinders from Ly-Con showed up and I thought a few of you would be interested in seeing them. Ly-con claims 4 to 5 additional HP per cylinder with their porting and flow balancing so I thought I would give it a shot. If you look at the intake and exhaust ports you can see the work is amazing. In the photo above you can also see the dental camera that I bought on Ebay to take the following pictures. This is a close up of intake port you can see the nice smooth surface. This is the cylinder wall and top of the piston. The cylinders where not installed so the piston is all the way to the base of the cylinder or you would see more of it. These are a couple of shots of the valves and seats. I was very impressed with the little $79 camera! It fits in pretty tight but I was able to get all the critical views I would want. After I get it all together I will give you all an update on the performance! Karson

-

This was preventable. It was a beautiful landing except that last part...then it got expensive. Where: San Antonio, Texas (KSAT). Runway 31L (The 8000 ft. one...) When: Saturday February 23, 2013, 11:15 a.m. What: Pilot Induced Gear Collapse. (beyond embarrassing) How: This is the interesting part and why I felt I should share the details of this event. The winds were calm so I decided that I would use full flaps. With 630 hours of flight time, 602 being in Mooneys flown on the coast of Texas, I have the partial flap landing pretty much figured out. (I seldom, if ever use runways less than 3000 ft.) Nonetheless, I developed the practice of moving the flaps on roll out to place more weight on the wheels and reduce float. On this unfortunate day, due to the perceived excessive float, as soon as I felt the tires touch the runway, I reached over to pull the flaps up...only..I didn't hit the flap switch...I pulled the gear switch out sufficient to unlock the gear, then apparently let it go---but too late. The 2004 Ovation2 set its belly on the runway gently and slid a couple hundred feet in a long arc to the right edge of 31L. The 3 blade scimitar prop came to a stop with one curled blade sticking straight up. I heard tower calmly request the aircraft holding short at 31L to turn 180 degrees, taxi via Alpha to Runway 4 and hold short. The plane came to rest pointing directly at the emergency response vehicles garage so when I saw the big green emergency vehicles coming at us, I snapped out of my 'oh crap' mode, turned to my wife and told her we needed to exit the plane so that they's know we we alright. Now, Iv'e told my daughter, as she has grown up, that the best thing to bring to a bad situation is a good attitude. I saw nothing but the best from KSAT airport operations from the moment they showed up to the point where we moved to plane to Cutter Aviation via a helicopter dolly and a large crane. The FAA investigator (FSDO), Mr. Richard Tarwater was the picture of thoroughness, courtesy and professionalism as I chewed up the lion's share of his afternoon.(He did his due diligence, as required, by checking all required pilot and plane certifications.) Because the gear was in the down position when the plane came to rest, I really wasn't sure that I had hit it or the flap switch. When Mr. Tarwater and I went back out to the plane (there was a 1.5 hr wait for the crane) to get some certification documentation, I noticed that the flap switch was still in the full down position and pointed that out to him. He noted that the gear breaker switch was out, even though the gear lever was down. Keeping an open mind, he said, "well, the FAA mechanics will sort it out." Nice guy, but I pretty much had it figured out: I pulled the gear switch out, but not up, at the point where the tires were barely touching (still in the full-flap float) but there was still enough airspeed going into the pito tube and insufficient weight on the mains to trigger these gear safety interlocks. In other words, there was a very narrow window of opportunity to screw things up, but I managed to do it with perfect timing. Hard lesson: I've seen other Mooney drivers comment on this site that taking flaps up reduces float and increases control. Unless your Johnson-bar equipped, I offer my unsolicited advice: don't touch any thing but power and radios until you come to a stop. Make landing practice to a full stop (rather than touch and go's). For reasons that even neuroscientists probably don't fully understand, my take-off sequence of gear-up-flaps-up crossed into my landing sequence. Maybe it won't happen to you. Maybe you can make a very strong argument that I made a boneheaded mistake and you won't, even with your similar practices. And you may be right to all of the above. I offer this only to those who can appreciate that my mistake caused serious property damage and it was entirely preventable. Phoenix Insurance and Dugosh will take it from here. ...now I've got to make some phone calls to engine rebuilders. Any suggestions?

- 43 replies

-

- flaps on landing

- overhaul

-

(and 3 more)

Tagged with:

-

So we finally got with our insurance to add the value of the new engine to the insured value of the aircraft. Just so you know if you are doing an overhaul, the terms of our policy, at least, is they will cover you for a 20% value increase temporarily (30 days) after a major modification before you have to report the new value to your company and pay a premium for a difference in insured value Anyway, our 20J was insured for $80k before the new engine. This was a bit overinsured for us, we had estimated the replacement value of the plane was about $70k-ish, but wanted to be free to go buy a new plane following a major totalling accident with minimum drama. After much discussion, we decided that with the new Lycoming overhaul we wanted to insured for $95k, which is probably still a bit over insured, but closer to the real value. Doing quick math, this represents an 18% increase in hull value. We just got the invoice from the insurance agent for the premium different: $1,618.00 New Hull Premium $1,118.00 Current Hull Premium Change = $ 500.00 $500.00 X .332 pro-rate Prorated amount due = $166.00 (Note that is not the total policy price, its nearly an additional $1000 for the liability portion of the policy, can't remember the exact value.) My math shows they are increasing the rate of our hull insurance by 44% ($500) to cover the 18% increase in hull value. I am a little appalled. Is this normal? We insure through Falcon - is this just a failure of my agent to negotiate with the insurance company? We are pretty locked into an insurance company because we have an open claim, and so all the other companies declined to quote this year - still we thought the rate we were paying was in family with what other people in our area was paying.