-

Posts

1,564 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by larryb

-

Resurrecting an old thread here. This has been a constant problem for me. The bracket was found cracked at the pre-buy when I bought 15 months ago. It was replaced by new at that time. A year later at the first annual it was cracked again, and my shop welded it. And I found it is cracked again today. Does anybody have a good solution for this? Has anybody actually gone the owner-produced route with a more robust material?

-

Thank you! It doesn’t match the IPC pic but it does look like what is on the plane.

-

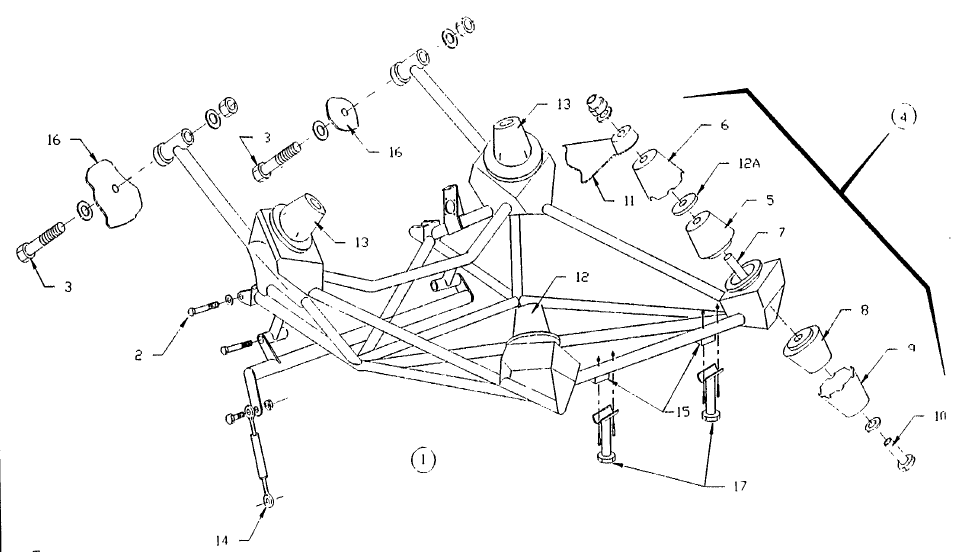

This is item 17 in the Mooney M20K IPC, shown below. It rests against the lower cowl. Mine are a bit deteriorated. 590026-501 BUMPER ASSEMBLY I'm looking for a convenient source. I know I can call my MSC, but I was hoping to just conveniently order online from a place like Spruce. Google hasn't helped me with this part number.

-

Digital LED display drivers multiplex the segments. That means they are switched on and off faster than the eye can see. But a digital camera does see this. So the display in this picture probably looks fine in person while the picture looks like it is failing.

-

Engine model? Edit. Never mind. I didn’t notice this was the bravo sub forum.

-

I visited Texas this year. I found it useful to displace the 130 degree air with nice cool 100 degree air.

-

Cylinder head/barrel separation at 14,500ft.

larryb replied to DanM20C's topic in General Mooney Talk

I had the same thing happen in my Lycoming IO360. Fortunately it was on the takeoff roll. Never left the ground. I also never figured out why. I could not reliably determine the history of the cylinder and how many total hours it may have had. I replaced it with new. I will never install a used overhauled cylinder. The one useful thing I did learn was it was probably cracked for a while and leaking exhaust. So now I carefully check the cylinder fins for exhaust residue any time the cowl is off. -

I am surprised nobody has mentioned the kool scoop vent. https://www.aircraftspruce.com/catalog/appages/koolscoop.php

-

The reason to take out old gauges is because, in some cases, the gauges are not maintainable. In my J the fuel pressure transducer was bad and there were none available. Even if maintainable the cost may be prohibitive. But all this depends on exactly which factory components you have.

-

I had a similar problem and it was a problem in the roll servo. The motor had become loose in its mounts. A trip for the servo to mid continent for repairs and reinstall by my avionics shop and all is well. Testing the AP on the ground showed an obvious problem in the servo. It sounded sick and moved sluggishly.

-

In my opinion to be successful in GA ownership you need to develop relationships. You cannot do this alone. You need a trusted A&P and avionics shop. If you install a 530 and then go looking for a shop to bless it things are not going to end well. If you are successful at this folks will go the extra mile to help you out.

-

Typical costs to install a JPI 830 or 900?

larryb replied to jemenake's topic in Avionics/Panel Discussion

In my J it was 40 hours labor at a well known MSC. -

The fact that it broke right after overhaul is certainly worthy of a conversation. The installing mechanic should have ensured the system was lubricated and working correctly. Perhaps it was and there was some other issue going on. There may be a warranty on the part you can take advantage of. I certainly felt somewhat uncomfortable in the first 50 hours of ownership in both of my Mooneys. At that time you just don't know what is normal and what is not. In my opinion, some of the linkages on these aircraft are poorly designed. Steel on steel with no bearing material at all. Even with proper lube they wear quickly. Carb linkages in old cars used to be like this, but no longer.

-

Next up, the question of why it broke in the first place? When I had my J with manual cowl flaps I could feel when the mechanism got stiff. A shot of tri-flow on each piece of linkage would fix it right up. Fast forward to my K with the electric system and there is no longer any tactile feedback. I did notice one day on a flight that the indicator was moving much slower than normal. Once again, tri-flow to the rescue. I carry a small can in my toolbox and did this on the ramp 1000 miles from home. So my point is, keep up on the lubrication of the cowl flap linkage. It seems to need lube pretty often, certainly more often than at annual time. Larry

-

Radios and antennas can be easily tested on the ground by a competent avionics shop. There should be no need for shotgun troubleshooting. Antenna and cable can be tested with an SWR meter. Radio can be bench checked with a service monitor. Outside interference, like the ignition harness mentioned, is more difficult.

-

I would say be flexible and let the route be dictated by the weather on the day of departure.

-

M20C Avionics Debate (failing NAV2..now what)

larryb replied to Boilermonkey's topic in Vintage Mooneys (pre-J models)

You mention neither nav is great. Perhaps the problem is not in the radio but instead in the antenna or splitter or cabling. This should be easy for an avionics shop to test. -

Tough Avionics and Plane Marketing Decision

larryb replied to MBDiagMan's topic in Avionics/Panel Discussion

It sounds like Don will move the gear as part of the deal with no or little cost to you? I’d do it. Move all of it. Buyers are cheap and don’t want to pay for anything. If you had to pay hourly shop rates to move it I probably would not. -

Please tell me more on how speedbrakes help crosswind landings.

-

Yes, it will cost you $100,000 all-in. Need a couple GTN's? Need new transponder? Audio panel? Engine monitor? It's like a kitchen remodel. You wouldn't replace your formica counter tops with granite but leave your old harvest gold appliances installed, would you?

-

I had this exact same problem in my 1997 Encore. Working with a local mechanic, I replaced both of the flap relays and the limit switches for the TakeOff position. I did not replace the limit switches for full up and down, which are on the screw assembly. Replacing both relays and the limit switches along with careful adjustment of the limit switches fixed the problem. I know that one of the switches was bad, the terminals were loose. The adjustment of the limit switch was poor, putting too much pressure on it. I think this over-pressure damaged the roller and switch. One of the switch terminals was also just a hair-width away from touching the mounting bracket. I did not have any evidence the relays were bad, but they were inexpensive and I just wanted to ensure the circuit was fixed. Replacing the relays requires soldering skill and a de-soldering tool. Below are some notes I took at the time. Larry ######################################################################################### Flap relays ######################################################################################### Theory: For TakeOff (TO) position, both Up and Dn circuits are actuated with cockpit switch. The system depends on Both of the TO limit switches being CLOSED at the TO position. Both relays will be energized. Bottom switch, controlling up relay, trips first when flaps transition from UP to TO. Alignment is critical Top switch controls TO position going Down Bot switch controls TO position going Up ################################# Relay on plane: JT1E-DC24V Alternate, found on Lasar site JTN1S-PA-F-DC24V https://www.alliedelec.com/panasonic-jtn1s-pa-f-dc24v/70158673/ The JT1E-DC24V relay has 2 common contact pins, one near the coil and one near the NO and NC contacts. The alternate relay does not have the common contact pin near the coil pins. The Mooney circuit board does not have a trace feeding the common contact pin of the alternate relay. Therefore, a jumper is needed on the board from the common contact pin near the coil pins to the actual ################################# take-off limit switch Honeywell V3-1 https://www.alliedelec.com/honeywell-v3-1/70119063/ roller lever: Honeywell JV-5 https://www.alliedelec.com/honeywell-jv-5/70120150/

-

BatteryMINDer and external power plug

larryb replied to JETmachine's topic in Miscellaneous Aviation Talk

Close. The little positive pin in the shore power connector activates a solenoid which connects the big positive pin to the battery. -

I spent the better part of a year getting my built-in o2 system to hold pressure. My system would leak down over several days when the valve was shut. Sometimes it would leak down to 600 psi and hold, other times 500 psi or 300 psi. There were several problems, and every time I found an fixed one I thought I had it, but did not. Broken push-pull cable at cabin knob. Leaky fitting at oxygen fill port. Old o-ring where fill port tube connects to regulator. Shutoff valve leak, valve did not fully shut off when the lever was in the shutoff position. #4 was finally fixed by a valve overhaul at c-l-aero in Redding. 1 week total turn-around including shipping, $600. Your system has 2 regulators. There is a combination first-stage regulator in the same body as the shutoff valve. This drops the tank pressure to 125 psi or so. Then there is the altitude compensating regulator as a 2nd stage regulator. If you send the whole tank/regulator setup to c-l-aero they will fully test it including putting the altitude compensating regulator in an altitude chamber and test that it meets specs at the range of altitudes. I found #2 in the list with the blue leak detector fluid mentioned above. Fixed with new Swaglok fitting. Somebody prior to me had over-tightened it and crushed the insides of the compression fitting. #3 was just done because the o-ring was old and cheap. I never did prove there was or was not a problem here. I found #4 when I had the idea to connect a temporary tube to the output of the altitude compensating regulator and put the other end in a water bottle. I saw steady bubbles coming out even when the valve was shut. My MSC didn't really believe me that this was the issue, having never seen that particular fail before. Jeff at c-l-aero wasn't sure either, but was willing to overhaul the valve. I was pretty confident in the test so sent the whole tank and regulator setup up to Redding. They verified my diagnosis (valve did not shut off fully) and the overhaul fixed it. I am now finally leak-free. This one drove me crazy because I could not find it with the leak detect fluid. In your case I would suspect one of the unused passenger o2 supply ports. And the altitude compensating regulator will have a higher pressure at altitude, so it is entirely possible that one of these ports will leak more at altitude than on the ground. Perhaps you could fly and have a passenger spray the leak detection fluid around at altitude? Or you could be correct that you have a leak when it is cold but not otherwise. Or, perhaps your pilot breathing setup is flowing way too much, more than you expect. Larry

-

BatteryMINDer and external power plug

larryb replied to JETmachine's topic in Miscellaneous Aviation Talk

My setup. -

BatteryMINDer and external power plug

larryb replied to JETmachine's topic in Miscellaneous Aviation Talk

You would have to wire this a bit differently. The way it is now will not work well. There is a solenoid with a pretty heavy draw that will mess with the battery minder logic. It is best to wire a little molex plug in parallel with the airplane battery. Don’t use the existing power plug and don’t use the parallel battery.