-

Posts

6,609 -

Joined

-

Last visited

-

Days Won

79

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by kortopates

-

Look at your Garmin AFMS for your GNS430W, it trumps the AIM and is required to be in your aircraft as a POH supplement - that's the authority for your GPS and trumps the AIM.

-

This is one of the biggest misunderstandings I come across concerning flying with expired navdata. The above is only true with regard to flying in the enroute environment. You must have unexpired navdata to legally fly rnav gps approaches. See your garmin AFMS concerning this, one paragraph references the enroute environment, the next one for approaches - they are different. In reality though, if the the intended approach has not been updated since before the navdata expired, you're data won't be wrong - but that's not the law. Just be aware.

-

I am not feeling a lot of respect for my brethren here But its very saddening to read there are instructors out there like @skydvrboy has had to endure. That's certainly a very legitimate complaint and not that many instructors know much about engine management but I wonder what are some of the others complaints you folks have. Hopefully its not arguing about what the ACS standards are these days.

-

HELP another STEC 30 altitude hold oscillation thread

kortopates replied to DXB's topic in Avionics/Panel Discussion

Definitely follow through with Chris' @Marauder advice on the Static line checks and the Alt hold sensor. If nothing shows up, before you pull servo's or any parts to send in for bench checking I highly recommend you take the time to make a flight to a shop that has full capabilities on working on your auto-pilot. I don't have any suggestions in your part of the country but you want someone that has both the expertise and equipment to diagnose the issue. Sending in one part pf after another gets very expensive without fixing it. You need the expertise of Stec AP specialist not an avionics tech. -

Walk over to Neal Aviation with a picture of your panel and ask Garett for ball park estimate. The fact is, installation cost vary widely based on the equipment that needs to be interfaced with and what other expectations you may have, local shop rates etc. What other folks have paid isn't very applicable unless it was based on exactly the same interfaces and starting point. The Avidyne would save you all install cost's except for the antenna and optional wiring to take advantage of things the Avidyne can do such as voice alerts. Sliding in a new Avidyne won't give you voice alerts without wiring it to your audio. You may want to have your WAAS GPS wired into your 335 now too etc. GPSS steering is for your autopilot, not the GPS. The KFC200, being an analog AP needs it, but it would come from an Aspen adapter, ($) to integrate with your Aspen and your GPS.

-

True, for here in the US too. But note this kind of SB from TCM is being submitted to the FAA for AD status. So we can all wait to see if the FAA agrees to make this an AD, but given the seriousness that TCM is giving this issue and what they say about the consequences in the SB I am really not concerned about the cost as much as I am about safety of flight; even with 15 years on my engine without issue. Sent from my iPhone using Tapatalk

-

Pricing a charitable sightseeing flight

kortopates replied to Robert C.'s topic in Miscellaneous Aviation Talk

That was subsidized as a marketing expense. You wouldn’t expect to pay that little for a true for profit sight seeing flight. Sent from my iPhone using Tapatalk -

Highly unlikely he got his pilots license already and as Chris@Marauder cites above, his mentor pilot friend would have been the first to hear if he did get it, but tells us he was operating under his student certificate. I find that very compelling. Sent from my iPhone using Tapatalk

-

You bet it’s not entirely accurate so maybe you too would benefit from reviewing all of the available reports and FAA records for yourself. Per previous post in the other thread on this he got “Student” license 5 months ago - October 2018 per the FAA pilot registry. Sent from my iPhone using Tapatalk

-

There is an unavoidable amount of infant mortality with new parts whether installed into new appliances or overhauled ones. The fact is I can overhaul an alternator for about 1/4 to 1/3 the cost of new; even replacing a rotor. So that’s a no brained for me. But with a vacuum pump there is very little difference in cost between new and overhaul. Sent from my iPhone using Tapatalk

-

I have always been of the opinion there is much to learn by ones attempt to understand what could have gone wrong and learning how we (or myself) might respond to avoid a similar mishap. Its not at all essential that we assume our speculation of what went wrong is entirely correct, because we are still motivated to learn from suspected possibilities - regardless of what ever the NTSB finding turns out to be. Less experienced pilots learn a great deal from the more experienced pilots as well. But its important to realize that its not about placing blame but about learning. Recall the long discussion of the older Mooney pilot whose plane went very nose up on takeoff till it stalled. That brought about a very informative discussion of how a seat may have slid back on the pilot - a great many people learned something from that about guarding themselves from pulling back on the yoke as well as taking preventative measures to avoid this. But as far as this specific accident goes the current facts we know now, without any speculation, just leaves me feeling angry. I take no solace in this young man's desire to live life large and enjoy his life to the fullest; even though I feel much the same. The facts are: 1) he was only a student pilot 3) the weather was not at all VFR; at the very least he went VMC into IMC; 2) he owned his plane for mere weeks. That's enough right there for me to feel angry about his negligence. I am glad no one else was hurt, but he could have taken out more people if an incident had occurred in a more populated area such as attempting to land. The learning here for us, rather than just to be pissed at his negligence, is to strive to learn to catch ourselves when we are about to push ourselves beyond what is reasonably safe, whether it be to talk to someone else more experienced or just talk to another pilot who knows us. We're human and need to learn to recognize our mistakes so we can correct them before they turn into really big mistakes like this young man's.

-

FWIW, Garmin Pilots interface for MOS data is not having a problem, so its definitely on the Foreflight side; probably for exactly the reasons Scott cites above. ah, duh, just saw Chris showed a screen print from GP.

-

The pilot has been identified as Chris de Bar http://www.kathrynsreport.com/2019/02/mooney-m20-fatal-accident-occurred-on.html Per the article, the plane went down Friday evening, and it wasn't till about 2:41pm Saturday that the burned plane was found at 1000' below the summit and reported by a hiker. And the most shocking part is that he is/was a brand new pilot. Perhaps he just got his private - or perhaps not. Either way it was no place for new pilot to be. So Sad. Personal Information CHRISTOPHER LAWRENCE DE BAR 8025 BOREN LN GRANITE BAY CA 95746-5877 County: PLACER Country: USA Medical Information: Medical Class: Third Medical Date: 10/2018 BasicMed Course Date: None BasicMed CMEC Date: None Certificates STUDENT PILOT Certificates Description Certificate: STUDENT PILOT Date of Issue: 10/24/2018 Limits: CARRYING PASSENGERS IS PROHIBITED.

-

I used to think that too, but the fact is all the best technology doesn't make up for complacency and a lack of flight planning. And not that many of the vintage Mooney's (not that we even know which model this was) have modern avionics, let alone piloted by people that really know how to utilize their avionics beyond the basics. Many years ago we saw 2 CAP pilots fly a new G1000 equipped C182 into Mt Potosi on a night VFR flight. Hard to fathom how that one happened too with 2 pilots onboard with such a panel.

-

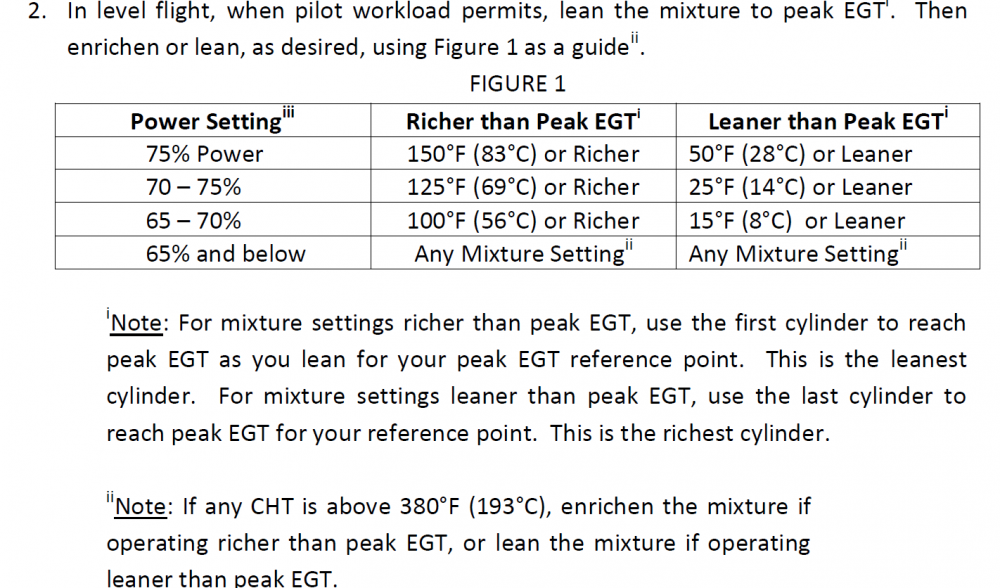

All very good responses above! As a professional that has reviewed a great amount of data on turbo engines I can also add what I see owners doing incorrectly that leads to harmful operations. With a normally aspirated engine flying at altitude most people can't hurt their engine since the max WOT power at altitude will quickly drop off to where it doesn't at all matter where you leave the mixture. You may not get the most efficiency but you can't hurt the engine once you get up there to where you are operating at less than 60-65% power. But with turbo's where we can operate at 100% power up into the flight levels engine management becomes much more critical; especially for those operating their engines aggressively at 70 and above % power. Its much safer and better to learn how to operate LOP at say 60% power than say 75% power but not everyone does so. The most common issue I see is that pilot owner believes he's operating LOP when in actually perhaps a couple of cylinders are LOP while half or more are on the ROP side squarely in what we refer to as the Red box at too high of a power setting. This happens because the pilot is trying to use a proxy for determining LOP before doing their due diligence to verify every cylinder is at least far enough LOP for % power setting being used. Gami publishes excellent conservative guidance on both how much ROP or LOP your cylinders need to be based on percent power. This will have you flying richer, if ROP, than the poor guidance given in the POH and give you very safe LOP targets as well. Its what I recommend to all of our Savvy clients when they have questions or clearly are operating outside of the boundaries. The most common misused proxy with the turbo's is using TIT. TIT can be a useful proxy, but one can't rely on say, leaning till 15 Lean of peak TIT at 65% power and expect every cylinder is at least 15F LOP. Till you do your homework to actually do the data analysis and find out where each cylinder really is you may be surprised to learn that only 1 or 2 cylinders are 15 LOP and the rest are at peak or ROP. You may learn that you need to be 30F or more lean of peak TIT to get all the cylinders to at least 15F LOP, which is why proper leaning for LOP is done from the last to peak or richest cylinder. Mike Busch is famous for recommending CHT as a proxy, but Mike knows his engine intimately well and operates his engine very conservatively in below 65% range where he doesn't need to be concerned about the red box is running LOP for max efficiency. None of this is too say that the cause for the OP's cylinder issues are due to engine miss-management since all the above issues are just as applicable, but if the turbo engine isn't being managed properly its much easier to abuse turbo's than the NA engines. For completeness the recommended mixture settings from Gami are: In addition to the CHT caveats I also recommend not exceeding a TIT of 1600F even if your max TIT is 1750F to maximize turbo and exhaust component longevity. Your exhaust system will thank you for it.

-

Very true! But most of our mooneyspacers don’t get out of the US to see lower flight levels. Sent from my iPhone using Tapatalk

-

How high are you planning? Much written about dogs at altitude here. They do fine into the upper teens without O2. Would not venture into the flight levels with a pet onboard. Sent from my iPhone using Tapatalk

-

Ironic you would post that example. I remember that accident very well, hard to believe it was back in 2005 since it seems much more recent. This was pretty heavily discussed on the Mooney list and perhaps Mooneyspace since the pilot had gotten his instrument rating by one of our well known Mooney instructors. I don’t know if we can call it good example of why climbing may not be a good strategy. I am of the opinion it depends on the circumstances. But IMO this is an excellent example of what happens when you do nothing till it’s too late and not having any options to get out of it. When he finally did take action, starting a climb already iced up not really knowing where the tops were sealed his fate. Sent from my iPhone using Tapatalk

-

There is always the possibility of losing GPS when in the vicinity of a GPS jamming device such as these devices: https://www.perfectjammer.com/gps-blockers-jammers.html Its been a few years, but there was one very sensationalized case of when a delivery truck driver was parked at Newark International with such a device in his truck to disable his employer's tracking device. The jammer brought down all the GPS approaches in use for several hours till they located the source of the jamming. As I recall it was an IFR day and it caused real havoc with approach traffic. Don't recall if the driver got prosecuted or to what extent. The above website implies its not illegal (so they can sell them) but it is most definitely is illegal to intentionally block, jam, or interfere with lawful communications, such as cell phone calls, text messages, GPS systems, and Wi-Fi networks (see https://www.gps.gov/spectrum/jamming/ )

-

I would bet on interference or jamming but at look at the satellite page would show if you just don't have an unobstructed view of the sky or your not getting any signal at all. Here is the article about military testing that is expected to shutdown GPS for many in the south east (but I assume to far south to effect KLNS) starting today: https://www.aopa.org/news-and-media/all-news/2019/february/05/gps-adsb-may-be-unavailable-in-southeast-during-interference-tests?fbclid=IwAR3bg-geSQOBNKqeASez_KrrsAfddnUZQ-iZj62elkkMCNKNWfd3VtSgy0Y

-

When this has happened to you both, what did you see on the satellite page? No satellites at all? If so I would suspect jamming when you otherwise always have great signal strength. Sent from my iPhone using Tapatalk

-

Thanks Clarence, after re-reading your post I realize now you were talking about an Ovation, but I misunderstood originally and thought this was a Seneca with a TSIO-360 with possibly a sniffle valve not up in the aluminium tubing. I understand you better now. I have also seen the aluminum tubing get chaffed through going to close to the engine where it comes down below it to the mate both sides just before the hose junction.

-

Is that just a single sniffle valve at #30 with the hose before it? If so, I imagine that engine was running really rough. Interesting though, as I thought all the TSIO-360 installations had the sniffle valve where the aluminum tubing joins the 3 cyls on each side.

-

It most certainly can take off at max gross weight, but I am a bit confused since the POH's (from memory) will refer to a maximum ramp weight which is 8-12 lbs more than max gross weight which enables you to taxi to the runway a bit overweight in order to takeoff at max gross weight.

-

Earlier ones were painted before they went to anodized at some point.