-

Posts

96 -

Joined

-

Last visited

About Bill_Pyles

- Birthday 09/08/1956

Profile Information

-

Gender

Male

-

Interests

In addition to flying, I race "shifter karts" all over the country on sports car tracks. Most shifter karts use an Italian tubular chassis and a 6-speed 125cc motorcycle engine such as a Honda CR125 or a dedicated kart engine such as Italian KZ. I run the Modena KK1 and KK2. We race at such varied courses as Firebird Raceway and Inde Motorsports here in AZ, Willow Springs, CA, Mid Ohio, Barber Motorsports, AL, Road America, WI, Summit Point, W VA to name a few.

-

Reg #

N239SW

-

Model

M20J

Bill_Pyles's Achievements

-

One of the mechanics did observe under the panel and did not detect any resistance or interference that would have caused the problem. Thanks, though. To "un-bind" the control wheel, I turn it slowly back to the right, change elevator position and turn it slowly to the left and it operates smoothly. There is something about moving the wheel quickly to the left that causes the singularity.

-

Yes, by binding I refer to a full stop bind. I did not try to force the the wheel to turn past the position where the wheel refused to turn. It's interesting that the full stop bind is dependent on the speed at which the wheel is turned AND the turn must be initiated from the full turn of the wheel to the right. If you just casually turn the wheel right and left without going all the way to the right against the stop, it doesn't bind. I did find the service bulletins that were mentioned by takair---thanks.

-

The plane was in the shop for the annual inspection for five months and I do not know specifically what was "touched/removed/adjusted" during the inspection or while the plane was sitting in the shop. I don't know what inspections or adjustments or lubrication the Mooney maintenance manual stipulates during a routine annual inspection.

-

I live in the Phoenix area of Arizona and I just got the keys and logbooks back for my 1980 M20J following the annual inspection. The plane has not been flown since the annual was completed. by a shop here in AZ. I went to the field today just to make sure the engine would start (not to fly it) since the battery is 2+ years old and the plane has not been started for at least a couple of months. Engine started normally. I performed a controls check as if I planned to fly the plane and found that at any elevator position, if I turned the control wheel fully to the right against the stop and then briskly turned the control wheel to the left, the control wheel would almost immediately stop after just a few degrees of rotation as if a control rod was binding up. If I neutralized the control wheel and then turned the wheel to full right and then slowly turned the wheel to the left, the control would not bind. I have been the sole owner of this plane for over 12 years and has never exhibited the aberration described. Performing the test by starting with full left aileron did not produce the binding, but the problem is 100% repeatable going from full right, rapidly to full left. I got three mechanics from the maintenance shop to look at the plane and they were also able to reproduce the problem, but none of them knew what the issue is, so the plane will have to be re-inspected by removing under wing access panels and the belly panel. The plane was in the shop for many months and there was nothing big that was wrong with the plane, and no long lead time items that were replaced (just a seat belt and an LED strobe). Has anyone experienced such an issue with the controls?

-

Leaking fuel tank. How much is too much?

Bill_Pyles replied to Bill_Pyles's topic in Modern Mooney Discussion

Eric: Expert might be a stretch, (Rich is the expert) but I learned a few things and wouldn't mind sharing what I learned. Niko: As far as how long the repair took, I didn't keep an exact record, but I estimate the actual work on the plane was around 10-12 hrs although I spent a number of hours corresponding with folks, researching and ordering (or borrowing) the scrapers and sealants (and special tools like the skin wedge and sealant applicator) and watching Youtube videos that related to the repair (there weren't many videos), so the actual work was less than half the total time I spent researching and agonizing over the possibility of flying the plane somewhere to have a professional do the job. -

Leaking fuel tank. How much is too much?

Bill_Pyles replied to Bill_Pyles's topic in Modern Mooney Discussion

I am pleased to report that, with the assistance and final approval of Rich, AKA N201MKTurbo, who is an A&P, I was able to detect and repair the leak in my left tank using the Mooney maintenance manual procedure. The basic steps were: 1) Drain the fuel from the tank 2) Remove the three fuel tank access panels. 3) Fabricate clear Lexan windows, for the access holes and one for the filler hole. 4) Position flashlights and mirrors inside the tank to enable a view of every nook and cranny and seam. 5) Squirt soap bubble solution along the seams inside the tank near the suspected leak location. 6) Install the Lexan windows with blue painters' masking tape. 7) Insert vacuum hose into a cutout in one of the Lexan panels and look for bubbles where outside air is being sucked through the leak. (I found one significant leak where the stringer passes through the outer tank wall) 8) Make note of the leak location and check the rest of the tank for leaks. (There was just the one leak). 9) Remove Lexan windows and completely remove old sealant from the leak area using MEK and plastic scrapers---no metal scrapers. This took a while. 10) Remove old sealant from the access panels and area inside the wing tank where the panels are mounted. 11) Thoroughly clean the tank with water and cloth that does not shed lint. 11) Using the Mooney Maintenance manual-prescribed sealants, I filled the leak area with filet sealant, brushable sealant and top coat. 12) Reinstall the access panels with panel sealant and new aircraft grade screws. 13) Fill both tanks with fuel and fly! 14) No leaking observed and depleted fuel is consistent with expected fuel burn rate. Thanks to EricJ for an early discussion and examination of the plane right after I noticed a leak, and thanks to Rich for guidance and encouragement throughout the repair project as well as assistance re-installing the access panels, which is easier with three hands. I had a great time working on the plane and it was one of those projects that I almost didn't want to end. "Almost" being the operative ;-) I am glad to be flying the plane again! -

Leaking fuel tank. How much is too much?

Bill_Pyles replied to Bill_Pyles's topic in Modern Mooney Discussion

Thanks everyone. Sounds like the tank is leaking into the dry part of the wing. For the past few years I have been going to Falcon Aviation Services at KFFZ and they are currently working with Southwest Airframe and Tank on another Mooney tank leak, and Falcon will speak to Southwest about my plane. -

Leaking fuel tank. How much is too much?

Bill_Pyles replied to Bill_Pyles's topic in Modern Mooney Discussion

-

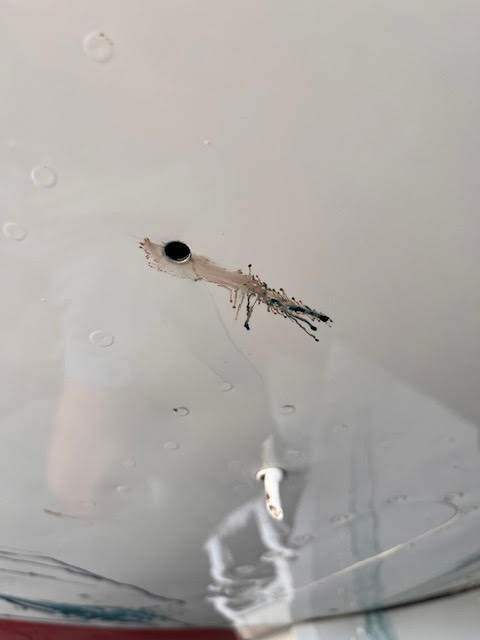

The left tank on my Mooney N239SW has developed leaks around two access panels on the underside of the left wing. The tanks were re-sealed 11 years ago by Weep No More which everyone says is the gold standard for tank repair but I am in AZ and they are in MN. I flew the plane for two hours using only the right tank and the leakage rate for the left tank is about a gallon per hour while in flight. However, while the plane is parked in my hangar, the leak rate for the left tank is about 6 gallons per week. How does this leak rate compare with your experience? Do leaks tend to get worse? Has anyone used Southwest Airframe and Tank Services to fix a leaky fuel tank on a Mooney? Can anyone recommend a tank repair expert in AZ? Thanks, Bill KDVT 408-717-2771

-

Traffic Display on GNS430W with Dual G5 and GTX-345

Bill_Pyles replied to glenv6's topic in Avionics/Panel Discussion

I have a 530W and GTX345 out/in and Century 21 AP in my M20J. (I know I will eventually have to upgrade the AP). I want to get dual G5s. 1) Will I get traffic on the 530W or have the same problem described above with the 430W? 2) Will I still need the vacuum pump for any reason? -

Thanks to all of you. Based on the information you've shared (and my own experience with car tires and racing tires) I will ask a mechanic to rotate the tires on the rims, hoping he/she won't object due to liability or fear. Attached are photos of my plane and tires in question. Obviously, I've flat-spotted the right one. --Bill