-

Posts

3,271 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 0TreeLemur

-

M20C Rudder Trim Adjustment

0TreeLemur replied to 0TreeLemur's topic in Vintage Mooneys (pre-J models)

While on a big trip out west in the summer of 2018 the left tank suddenly decided to stop weeping and start leaking. It would lose over 1 gallon overnight into bucket. For the most of that trip, I would use the left tank in its entirety first, then switch to the right. I didn't notice a big effect on the behavior of the aircraft in cruise. The PC system helped to compensate, and I was reliant on the relatively hard-to-read TC100 because had not yet installed the AV-20. I think the PC system masks a lot of behavior. The sensitivity of the AV-20 is what showed me that there was something amiss. -

M20C Rudder Trim Adjustment

0TreeLemur replied to 0TreeLemur's topic in Vintage Mooneys (pre-J models)

New panel installed in 2018 with new shock mounts. Both balls center during straight taxi and 30 psi in all tires. In cruise, trimmed for level flight with no rudder input, the tendency to climb after centering the ball indicates an increase in energy (speed). I think it is a rudder trim issue. -

M20C Rudder Trim Adjustment

0TreeLemur replied to 0TreeLemur's topic in Vintage Mooneys (pre-J models)

Thanks. Yes, it does have the trim tab riveted to the trailing edge of the rudder. -

Hi everyone. So far I've logged 400 hours flying our '67C since we acquired her 3 years ago. It's been a blast. In cruise the "ball" on the Brittain TC100 lies a little-bit off center to the right, but I ignored it, because the TC100 doesn't really seem that sensitive. However, since I installed the AV-20, when displaying the AI function I noticed that "ball" is about 1/3 out of center to the right in cruise and is quite sensitive. In cruising level flight trimmed with no rudder input, when I put in enough right rudder to center the ball, she starts to climb. This tells me that in normal cruising flight with no rudder input, the ship is out of trim. Looking at the S&MM, I see the procedure to bend the rudder tab to effect rudder trim. The tab on my aircraft is not bent, so it seems that none of the prior owners took this step. Looking at the rudder pedals, the right one is much more worn than the left, which causes me to suspect that pilots have kept some right rudder in for thousands of hours. Has anybody done this? The S&MM manual gives a maximum deflection of 0.08", but no procedure or steps. I'd like a procedure. Should I just try increments? I'd appreciate hearing from someone who has done this. Is 0.08" too much or just enough? Given the 0.08" limit, I'm thinking about trying 0.02" increments of bend to the left to impart a bit of right rudder force. Thoughts?

-

JPI EDM-900 C model installation thread

0TreeLemur replied to GWRatcliff's topic in Vintage Mooneys (pre-J models)

Here's what we did in our '67C. The EDM900 installed in the same place where the tach and mp/fp gauges used to live. -

That comment above about insurance rates mirrors my first thoughts.

-

Is this a doable flight in a M20F

0TreeLemur replied to Dream to fly's topic in Vintage Mooneys (pre-J models)

Looks like the heater in your C was as powerful as ours is! -

Is this a doable flight in a M20F

0TreeLemur replied to Dream to fly's topic in Vintage Mooneys (pre-J models)

Aha. Front range winter weather is _not_ Rocky Mountain winter weather. There's a reason the fish hang out behind rocks in a stream. The Rockies are littered with crunched up balls of aluminum that were once NA aircraft and most of them met their end in the winter. In the summer or fall, I completely agree that this trip is very doable in an F. I flew something similar a few years ago in a C, but in August. I lived over 30 years in Colorado and Wyoming. The front range and eastern plains are on average much nicer in the winter than in the Rockies when there is a decent pressure difference between SLC and DEN. Mountain passes become venturis, and can quickly become obscured. Intense updrafts/downdrafts form. Hydraulic jumps on the lee side of mountains cause huge and intense roller eddies. Lenticular clouds are plentiful. Severe turbulence. Terrible flying conditions at times, even the airliners avoid the Wyoming wind gap during those periods. -

Is this a doable flight in a M20F

0TreeLemur replied to Dream to fly's topic in Vintage Mooneys (pre-J models)

-

Is this a doable flight in a M20F

0TreeLemur replied to Dream to fly's topic in Vintage Mooneys (pre-J models)

I've got some experience in flying in western Colorado and Utah. Your route of flight avoids the tallest mountains. You'll still need to dodge some high terrain. and a few taller peaks. You'll want to fly at 10.5 and occasionally 12.5. In the summer/fall this trip would generally be easy in the absence of major frontal activity. In the winter that route presents some real challenges for NA aircraft. Here's the down side. You are going to fly right through the "Wyoming Wind Gap" between Casper, WY, and Craig, CO. In the winter this is one of the windiest, most turbulent atmospheric regions in the continental U.S. as the wind flows around the Colorado Rockies. Conditions are predicted using the the height difference of the 500 mb level between Casper to Craig. If this height difference exceeds 30 m, it can be bad. If it exceeds 50 m, turbulence can be severe. If it approaches or exceeds 70 m, then expect extreme conditions. Mountains and terrain are often obscured along that route by clouds. A much safer route for a NA Mooney, in the absence of significant weather caused by frontal passage, would be to fly south to Tucumcari or Clovis NM, then west around the mountains in New Mexico. There is a similar wind gap in New Mexico that occasionally experiences strong winds too. In general, flying in the Rockies in the winter in a NA aircraft is a bad idea, except for the occasional periods of dominant high pressure that rarely occur. <not a meteorologists> -

They should put a few oily rags underneath. Then add a plaque saying "That's not oil, that's sweat from all that horsepower." Love it.

-

Freezing rain. Atm. is saturated up to about the 650 mb level. If precipitation is produced, it will likely be mostly liquid because the temperature in most of the saturated near-surface layer is 0 to 2C. A strong temperature inversion exists with surface temperatures near 0C, and -5C at 850 mb (5k ft). That will supercool the rain falling through this air that is below 0C, yielding freezing rain at the surface. <not an atmospheric scientist>

-

Don't throw away your Generator!

0TreeLemur replied to moodychief's topic in Vintage Mooneys (pre-J models)

Followup: the bolt was bottoming out. In the absence of a shorter bolt, I added another washer and it tightened up nicely. Thanks again @RLCarter. -

Interesting article on a unique use of GA. Not a huge 'Tide' fan, but N1UA is hangared not far from my Mooney. https://www.nytimes.com/2020/10/21/sports/ncaafootball/saban-virus-tests-alabama.html?searchResultPosition=3

-

Great article. Our old airplanes have such history that we are only part of. I was recently contacted by the gentleman who owned my current charge back from 1970-1973. He lives not too far away. Once this COVID crap is under control, I plan to fly over and take him for a ride. He's in his 80's. When he owned her, she was poppy red. He's promised to give me photos. There might be a paint restoration in the future.

-

I looked at mine today. My '67 has a very different looking part. It has two slots that accommodate the end of the trim actuation tube, no Heim bearing. An AN bolt passes through the entire mount and the end of the trim tube, which provides four penetrations through the mount! No single failure path with this design. It does have a castellated nut and cotter pin. I took a photo but the iPhone focused on the wrong thing. @Sam Judd what year is your Mooney?

-

Aft stub spar replacement beginning

0TreeLemur replied to Hradec's topic in Vintage Mooneys (pre-J models)

Thanks for sharing. Looks like one heck of a job. Look forward to seeing photos of your progress! Kind of the surgical equivalent of a half pelvis replacement. -

Agreed. Much more susceptible to the observed failure mode that started this thread than the design using the stamped part. Requires careful inspection for fracture indications. Luckily this failure does not result in an unrecoverable situation in a J. I wonder how this failure would affect the pitch control in a short body? Anybody with a short body ever lived through this? There are aircraft in museums that are newer than my C. Next annual I'll spend extra time inspecting that little piece of extruded aluminum.

-

Ran into a Mooniac.. and realized the value of MooneySpace

0TreeLemur replied to Pasturepilot's topic in General Mooney Talk

http://www.google.com <search string> site:mooneyspace.com is your friend! -

I highly recommend the AV-20S timer, which includes a MEMS-based AI, if you have a 2-1/4" hole available in your panel. I have it showing the AI view all the time I'm in IMC, and so far it always agrees with the vacuum based AI. As a backup, I believe it will save your day and help with partial panel ops. The other thing that I really like about it is that when connected into the pitot-static system, it notes the time that you takeoff and starts a flight timer. Very useful for switching tanks. It has some negatives too. The TAS is not calculated correctly, the AOA sensor is worthless, and the G-meter is distracting. I have all those turned off in the setup. The timer functions are great. The backup AI is a winner. When the company sold to uAvionics, I contacted them about the TAS issue, and was told that a fix was in the works, but I haven't heard anything since then. I wish they would issue an improved firmware. Since it has an external temperature probe and pitot/static info, calculating TAS should be straightforward. Hell, they could even make it possible to enter a table to give calibration values to output CAS. I wish they would....

-

We flew Saturday from Tuscaloosa to near Grand Rapids, Michigan, to visit our son and family. On the way up, we flew around the rainy area associated with decaying tropical storm Delta. Returned this morning. The instrument rating made this flight possible, and our C is running great. Covered about 1300 nm and shot three instrument approaches, two to minimums. This photo was taken this morning as the sun rose over southern Michigan. Gorgeous day! Almost nobody flying between 6000-10000 ft along our route.

- 633 replies

-

- 14

-

-

Don't throw away your Generator!

0TreeLemur replied to moodychief's topic in Vintage Mooneys (pre-J models)

That is a great point. Now that you mention it, that might be happening. I'll give it a look. Thanks! -

Don't throw away your Generator!

0TreeLemur replied to moodychief's topic in Vintage Mooneys (pre-J models)

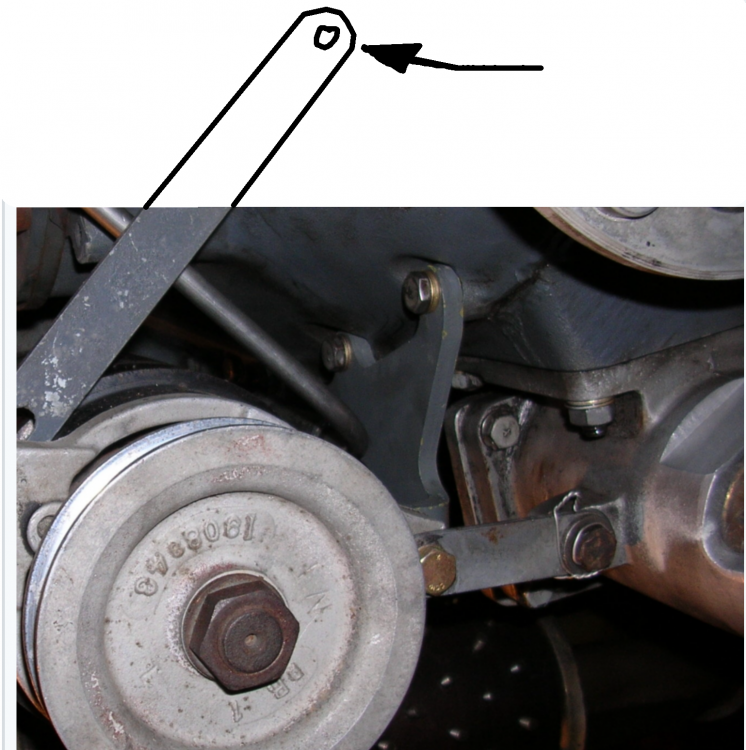

Let me clarify- it isn't one of the bolts on the bottom of the crankcase, it is the top one on the adjustment mount that seems to be a bit egged. Moves less than 1/32". This adjustment arm is the part I'm talking about, the same one that I think @Jerry 5TJ had the hole welded and re-drilled. -

Don't throw away your Generator!

0TreeLemur replied to moodychief's topic in Vintage Mooneys (pre-J models)

Since the prop replacement about 20 hours ago, I've noticed something new with the generator mount on my C. When I pull on the generator belt during pre-flight to check its tightness, I hear a new noise. Pull-thunk. Not loud. Looking closer, I see that the upper bracket where it bolts into the crankcase is slipping under the bolt head. I'm guessing that just like what @Jerry 5TJ observed, it must be egged. It wouldn't move otherwise. I guess the increased belt tension associated with removing and reinstalling the belt without loosening the generator mount probably loosened things up a bit. I think the sound is the generator housing making contact with the front air shield. This raises questions: 1. Anything urgent? It seems that a tiny bit of motion there doesn't likely represent a failure mode. 2. Aside from welding/re-drilling the hole, does someone sell that part? 3. What is the max. torque spec on that bolt that goes into the crankcase? I put a wrench on it and snugged it a bit, but don't want to go too far. Looked in the SMM and didn't find it. Thanks, Fred