-

Posts

3,251 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 0TreeLemur

-

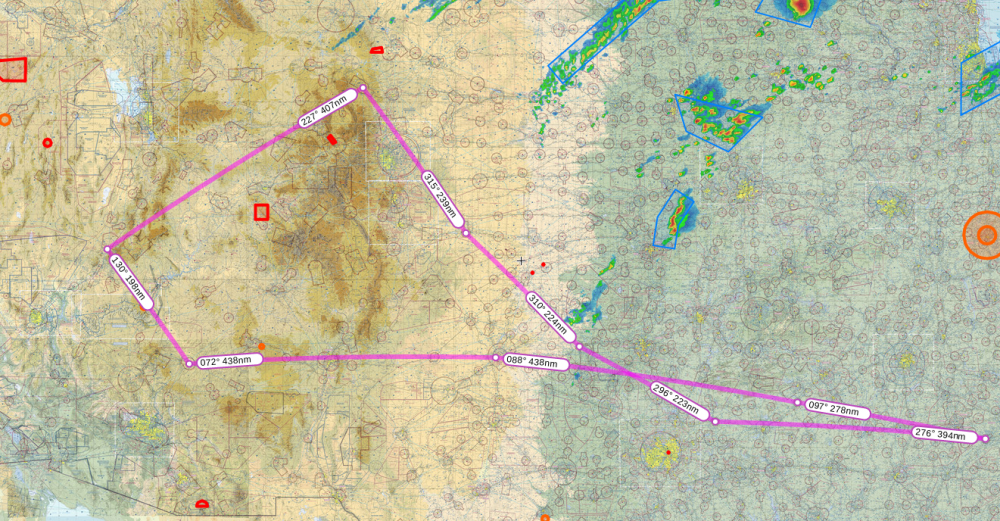

My co-pilot and I have gotten to know our 1967 M20C well since we acquired her last October. With the help and supervision of our A&P plus a good instrument shop, we took a tired example of a Mooney M20C and brought her panel up to modernity thanks in no small part to some advice given by MS members. She now has an 8-pack panel layout, JPI900 EDM, GNS430W, and Appareo transponder with ADS-B in/out. To celebrate we took her out on a "victory lap" around the Rockies in August, covering 2838 nm in 26.2 h flight time. We really spread her wings with max. cruise at 12,500, and 208 mph g.s. at top of descent approaching Amarillo thanks to some ridiculous winds. We faced headwinds more often than not, even on some eastbound legs! The haze from the numerous forest fires out west severely limited visibility particularly in the northern portion of our trip into Colorado front range and into southern Wyoming. We visited friends and family, plus toured Bryce Canyon Nat'l Park, Cedar Breaks, Nat.'l Mon., drove down the Moki Dugway and across Monument Valley, overflew the Grand Canyon N-S via the "Tuckup" VFR corridor at 10,500 ft., and orbited meteor crater near Winslow, AZ. "Little Sister" as we call her performed admirably.

- 11 replies

-

- 12

-

-

My maint/repair manual says 80 in-lb torque for the sump drains on the C model. That's not much. You should look up for your model if different. PP only. Not a mechanic.

-

I use the same slotted PVC but I glued a tee on the other end. The total length is 8". I velcro it to the top of the nose wheel well. It is happy as a clam there, always waiting for me next to might right calf, when I need it. Shown here.

-

Co-pilot and I cleaned square step shaft with brake cleaner, then applied dry teflon lube. The top half was pretty dry. We worked it manually several times, and the spring was well behaved. Seems better now. Thanks for the advice to all who replied.

-

The last few flights saw the vacuum actuated step on my '67C not fully descend after landing. The engineer in me thought "that needs lubed". An hour ago, I would have bet serious $$ that someone had previously discussed ad-infinitum how to do this on MooneySpace. I searched and much to my surprise it did not turn up as an issue... The maintenance manual says "Tri-Flow every 100 hours" but doesn't say how. Before I start spraying teflon-infused oil everywhere, can one of you experienced guys give a relative noob a clue? Thanks!

-

I had an empty 2-1/2" hole in my panel so I filled it with a GT-50 clock/timer/g-meter/voltmeter. I liked everything about it except one thing that drove me nuts. It has a low voltage warning mode that seems to be its #1 priority. Any time the voltage falls below about 12.7 for about 20 seconds, the thing becomes a blinking distraction. Getting ready to take off, I want to know the time, and it is blinking voltage! Doing my checklist, and runup, that thing is blinking voltage! I already have a voltmeter in my a/c. I took it out and replaced it with a good 'ol Davtron M811B. The AV-20-S will be on my Christmas list.

-

I agree- the plastic yield properties of aluminum are horrendous. Wrinkling of the wing skin suggests plastic deformation of the wing, possibly including the main spar. Normally structural aluminum behaves well. But, once aluminum yields and goes plastic it becomes an unpredictable and highly non-linear. Plus the load path changes under plastic conditions due to weakening of the parts that did yield. This means that extreme load may have traveled into connectors or parts of the wing far from the main spar. I'd think of it as an ill-tempered rattlesnake and steer clear.

-

Good idea getting sight gauges installed. My model C has them. We checked their accuracy when we calibrated the fuel sending units after adding the JPI EDM900. They are accurate to within 1 gal. They "run out of gas" so to speak and don't really measure anything below about 5 gal so they are not good for the FAA mission of telling you when your tank is empty. In flight we cross-check them with the JPI fuel totalizer and the fuel sending units. I really like them. Another source of data for fuel management.

-

Hi @PilotCoyote. Thanks for posting this. We'd all benefit from a picture if you can post one. I've never had that part of my a/c torn apart. Thanks!

-

The AV-20 looks pretty useful. Having a backup AI is appealing. This hits a pretty good price point.

-

WTB 40-200 mph airspeed indicator

0TreeLemur replied to 0TreeLemur's topic in Avionics / Parts Classifieds

Thanks for the photos. That looks like the original 1960's Garwin? The two shops I've talked to about re-screening both want to test/overhaul and warned me against sending them something that is obsolete. Do you know if parts can still be had for this AS indicator? I'd hate to buy something that turns out to be unserviceable. -

WTB 40-200 mph airspeed indicator

0TreeLemur replied to 0TreeLemur's topic in Avionics / Parts Classifieds

Thanks- can you send photos? -

Make sure to check your nose gear during preflight...

0TreeLemur replied to dtoelke's topic in General Mooney Talk

The prior owner of my C left me a little flag with velcro straps that says "DO NOT TOW". I strap it around the nose gear. -

Hi- I'm looking for a used working airspeed indicator with a range of 40-200 mph for my model C. I suspect there are some sitting on shelves because of glass panel upgrades. My plan is to have it checked/calibrated and re-screened so I need one from one of the 'major' manufacturers that would not be considered obsolete. TAS adjustment ring would be a great added feature. Please PM me if you have one that you would part with. Thx.

-

Hi- I'm looking for a used working airspeed indicator with a range of 40-200 mph. I suspect there are many out there made available by glass panel upgrades. My plan is to have it checked/calibrated and re-screened so I need one from one of the 'major' manufacturers that would not be considered obsolete. TAS adjustment ring would be a great added feature. Please PM me if you have one that you would part with. Thx.

-

Two weeks ago my A&P took the Lycoming governor off my a/c and I took it to a prop shop. When I handed it to the technician, the first thing he said was "That's an antique". Not a good sign. As was suggested by MS, the governor was in serious need of rebuild and had several ADs on it. The estimated cost of overhaul was hundreds of $$ more than the cost of a new PCU5000, so we installed the PCU5000. I changed out the studs under the supervision of my mechanic, which took the better part of two weekends working in a hot hangar to get done. Removal took de-greasing and triple-nutting to get the old ones out. I was slow and cautious because I was so worried about breaking them off. Yesterday we installed the new gov. and it works just as it should. I had a really nice test flight late yesterday after Tstorms cooled things down a bit.

-

M20C Panel Redo: EGT rotary switch too BIG.

0TreeLemur replied to 0TreeLemur's topic in Avionics/Panel Discussion

Thanks! We're really pleased. I'll finish my instrument rating with this setup. My motivation came from this group. -

M20C Panel Redo: EGT rotary switch too BIG.

0TreeLemur replied to 0TreeLemur's topic in Avionics/Panel Discussion

DONE. Finished installing labels/placards Sunday. Panels cut on water jet $120. Cerecote $50 and a twelve pack. The rest- way too much to mention. Now it is time for a victory lap around a good chunk of the north American continent. -

Wow, that looks like a lot of work. Irregular tetris at best. Question- some of the insulation in my a/c is coming unstuck. What are you using for adhesive?

-

I've got a similar story to @Skates97 A few weeks ago the governor in my C oversped on takeoff by about 100 rpm. I told my mechanic who adjusted it after a static runup. On the next takeoff it oversped again. Removed governor and took it to a nearby prop shop. They called the Hartzell H-1 an "antique" when they saw it (bad sign). In the test stand it demonstrated a lack of control at high rpm. They took it apart, found it had old flyweights with all kinds of ADs. Cost of rebuild estimated >> PCU5000. OUCH. Wasn't counting on that one. I'd like to FLY not FIX the airplane. New gov. arrived today. It is so tiny. Gotta be one of the most expensive parts of a M20C by weight? Anyway, my "co-owner" approves after I relayed some of the gov. failure horror stories I've read on MS. Hope to get it installed this weekend if A&P is available. I'm hoping that this is the big surprise for the year.

-

That's why I'm loving the Johnson bar.

-

Airspeed indicator in kts for C model?

0TreeLemur replied to 0TreeLemur's topic in Vintage Mooneys (pre-J models)

I don't think in terms of V/C. Just V (kts). -

The airspeed indicator in my C is like all others, outer ring in mph, inner ring in kts. I think in kts and would really prefer it the other way around. Does anyone know of a place that either can produce/silkscreen such a thing? Of course I'd like the Mooney logo on the dial. I searched before writing this post, and I saw that @Marauder sold one for an F model back in May. Something like that is what I want. See photo here. The problem stems from the fact that every other a/c I've ever flown has shown kts in the outer ring. Because 80 mph < 80 kts, it causes a distraction at a busy times that I could just avoid if the first outer number I saw was kts, and I didn't have to focus under the pointer. Any ideas?

-

Set screw needed, Terra TMA 230 Audio Panel

0TreeLemur replied to 0TreeLemur's topic in Avionics/Panel Discussion

Thx. Tried them already. When I applied the selection filter for shaft diameter, there was only one and it was too large. -

Set screw needed, Terra TMA 230 Audio Panel

0TreeLemur replied to 0TreeLemur's topic in Avionics/Panel Discussion

I tested a No. 4 and that seems to fit the hole in the knob. It is a short little bugga, the wall of the knob is only 0.1" thick. I'll try some parts stores around town tomorrow and see if anyone has a set screw collection. If not, I'll order from McM-C. @N201MKTurbo and @CaptRJM thanks for your input. It didn't occur to me that this would be a standard screw size being an "airplane" part.