-

Posts

669 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by larrynimmo

-

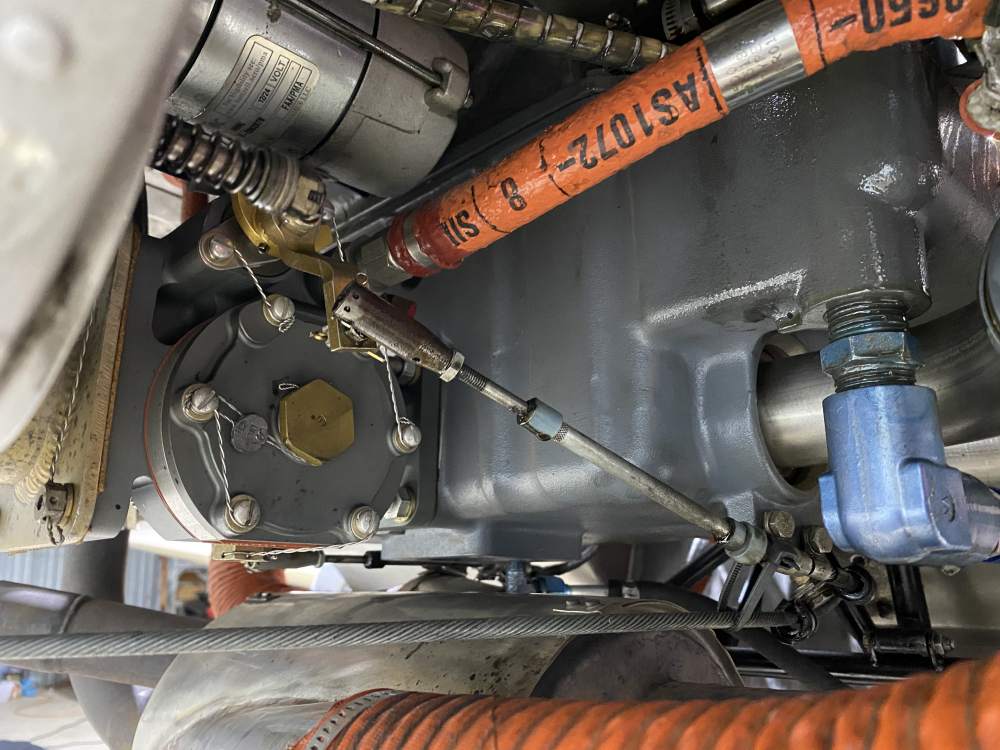

I bought my plane 6/2017...and there are no records ever of having the fuel servo rebuilt...and it functioned flawlessly. Then in 9/2018 I installed a Lycomming “rebuilt” engine which came with a freshly rebuilt servo. In April 2019 sent the servo back to get it repaired because the throttle became too stiff to operate....now after a 5 minute stop, I tried to restart the engine when the throttle wouldn’t move....and I ran the battery down enough to get a “hot shot” (first time ever). Eventually I got it started and flew it back to my home base and when I went to shut down I pulled out the mixture and it stayed running at 500 rpm...wouldn’t shut down...I shut the fuel selector to off and eventually no fuel to keep it running...tomorrow the servo is going to go somewhere!

-

Leather Covers for my Control Yokes

larrynimmo replied to Speed Merchant's topic in Modern Mooney Discussion

Another consideration that I chose was to simply repaint my yokes....I did it in place by taping up plastic sheeting everywhere and I painted the yokes black with propeller epoxy paint in a can...very satisfied with the results...at least for now -

Correction....I looked at it yesterday....no need to remove the cowl....simply undo the pilots cowl flap, and undo the fuel line at the firewall...then install a hose to pump out the fuel...

-

If I have it to do again....I would pull the lower cowl, undo fuel line and pump it dry...

-

Yes, I want one...what is the logic of having a 70’ one as opposed to 100’...please explain

-

Add LEDs to your glareshield...wire into the dimmer circuit. Shown is about 60% brightness, I fly with about 20% brightness... LED 12v strips are available on eBay in why ever color you want...my choice is cool white...

-

Gear ups and accidents are always a high cost for insurance companies...Mooneys have always had greater exposure than non Retract...my guess though is that insurance companies have somewhat “over reacted” and rates should now stabilize rather than spiraling out of control again. However...I don’t see the insurance becoming competitive again as there are now so few insurers out there....get used to paying what you pay or get out of flying...

-

My plane is hangered...I use the twin hornet 200w engine heater all winter long....what I like about it is that it keeps the upper end of the engine evenly warm....coldest spot is the oil pan in the bottom...this helps to avoid water vapor from condensing on the upper end of the engine. It turns on at about 67 degrees and off at about 70 degrees....and is explosion proof. To minimize its run time, engine cowling is covered by a thick black open sleeping bag (no zippers) for the interior I use a Honeywell (non glowing) heater on low to keep it above 60 degrees with the cord run through the slightly Ajar baggage door. when I pull the plane out...engine and cabin are always prewarmed...easy starting and coat off comfort in plane

-

Update....on the front MLG I used the grease buster device and when I hammered you could see liquid come out at the shaft...and while I did put some grease in, did not get the full transfer I was hoping for.. when I went to remove the grease fitting from the MLG zerk, the pressed in zerk actually pulled out...the bearing base appears to be a brass body, and I was able to tap the zerk back in...it stayed in...from now on I will be using the release lever type of grease fitting when I grease or bust these more delicate zerks

-

If you fly ifr, you would benefit by having a$299 subscription to the nav data...updates every 28 days...13 per year....also purchase FS510...that enables you to send & update flight plans back and forth between ipad and the 650. FS510 doesn’t require installation...it replaces you traditional SD card....plug in the FS510, and it is a Bluetooth device, wi-fi and a data card all in one. If you want terrain to work on your Garmin, you must load your current copy of terrain to the FS510 which needs to be done by a “powered” card reader (not part of most laptops) to wirelessly update the 650 you need garmin pilot (basic) about $70 a year, but is included for first year of the purchase of a 650. This gives you the ability to download the nav data to your iPad, then transfer it to you 650 wirelessly....if you go this route, let me know and I will tell you how to make the loading of the nav data to be seam less...

-

If you grab the elevator by the side, there is flex...a natural design characteristic...but in my plane there is no slop or free play from loose or worn bolt

-

When I ran at 2200 rpm, 25”MP I could get a true 20MPG (Statue miles) on my plane, but my fuselage rivets we’re failing. Much less vibration at 2500 RPM

-

Whelen LED tail strobe, rudder rebalance?

larrynimmo replied to bmcconnaha's topic in Modern Mooney Discussion

I changed out my tail beacon and I didn’t even think of rebalancing the rudder. The weight between the old and the new was reasonably close. the rudder performs exactly the same as it did before -

NO! On my M20J which should be the same, you can leave the riveted door strips in place and the carpet can sweep under and away as long as the copilots seat is removed...leave your drill and rivet gun in your tool box!

-

Airworthiness Directives; McCauley Propeller Systems

larrynimmo replied to Yetti's topic in Modern Mooney Discussion

With this notice...and being in annual.....I removed my affected McCauley prop governor and it actually cost me over $500 to get the bearing changed, and the shop essentially wanted to disassemble the unit and put all new gaskets in it. Mine was new 2 years and about 350 hours ago added to my then Lycomming factory rebuilt engine. I sent it to New England Propeller. i plan on going back to McCauley to see what I can glean back from them... -

201 High Low Volts Annunciator issue

larrynimmo replied to 1001001's topic in Modern Mooney Discussion

-

201 High Low Volts Annunciator issue

larrynimmo replied to 1001001's topic in Modern Mooney Discussion

In my 1981 m20J changing out the old Lamar VR to the zeftronics model took only minutes, and it is “Plug and play” with no wire swapping. New one holds 14.0v pretty steady. it is immediately accessible on co-pilot side with removing just two screw/ locknut fasteners. -

I am the opposite...I pass the machine vision tests without restriction. I drive with no restriction....when I went for my 3rd class medical I had to read a non illuminated chart in a dimly lit room where my eyes are at their worst...not that I would ever fly or drive with out glasses

-

My issue is with the front MLG....and my serial is 1189, and they are pressed in...I will tread carefully on experimentation and I will report back on success or failure.

-

Since I fly one bird...and only one bird, I keep my medical, and my ticket with the planes registration and airworthiness certificate

-

These pressed in zerks have no ball and I can press locking wire well through the oriface.... but still won’t take grease

-

FYI...I am going through annual now and I have 3 Zeek’s not taking grease....even with my mains in partial, and wiggling I am not getting any grease at the front main gear swing bearing...I have ordered a “Zerk buster” off of eBay and I will give it a try...thankfully none of these three bearing areas show any wear or play what so ever.

-

My AI missed this...but I didn’t...a 5/8” u joint from Mooney is $235 plus shipping this is for the trim, just before the jack shift

-

I spend one minute cleaning my front belly after every flight and I take about 20 minutes cleaning the entire bottom fuselage about every 12 hours. Just use the light blue aircraft wash/wax. an ounce of prevention is better than a pound of cure

-

Continuous Heater and Dehumidifier good or bad?

larrynimmo replied to J0nathan225's topic in General Mooney Talk

That is true, but are we talking about the dew point inside the engine or outside the engine. Almost no matter what, when an engine cools down after operating, water vapor that is in the engine atmosphere will condense on the relatively cooler metal parts and drip into the oil. Unless you circulate dry air through the engine, most of the time the cavity will hang in the 100% relative humidity state unless heat is applied after fully cooling off