mike20papa

Verified Member-

Posts

359 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by mike20papa

-

Trim Wheel Moves Nose Nown In Flight

mike20papa replied to lamont337's topic in Vintage Mooneys (pre-J models)

My first try - after I had read up on all the maintenance material - would be to tighten the chain. -

Did my first no flap landing

mike20papa replied to steingar's topic in Vintage Mooneys (pre-J models)

the Stearman I fly is an early model Navy N2S - check lists just coming into use. There is a place holder for one on the right side of the panel - 5 X 7 card. There is an aluminum box that you can "reach" between your feet labeled "aircraft data" but most of them have been removed. I keep FAA required paper work in it. And the seats ... they adjust up & down - not forward & back. Until you get time in one - you can't appreciate why. -

Did my first no flap landing

mike20papa replied to steingar's topic in Vintage Mooneys (pre-J models)

To the poor fellow with the 11 page check list .. tell him to go get some Stearman time - look for an old guy/instructor with 1000+ hours dusting .. that should cure him. -

In my A model I had the original two piece windshield. I decided to replace it with the 1/4" one piece unit. It improved the visibility and certainly upgrades the exterior appearance to get rid of the old vert. divider strip - in my opinion. Any noise reduction was not detected. Fitting the new, thicker windshield is a challenge and time consuming. Note the beveled edges in the attached photos. I would never consider installing a 201 style windshield and loose the ability to access/work behind the panel. I think the biggest decision is what type of sealant to use. I'll save that topic for later. Also, I dimpled the alumn. and counter sunk the glass enough to use flush head crews on final install. That was probably the best decision - cleaned up the over all appearance. Joe

- 12 replies

-

- 1

-

-

- 66e

- windsheild

-

(and 1 more)

Tagged with:

-

Yes, I agree with that statement. Having seen the patched up lower cowlings around the intake filter and the associated sheet metal around air filters beat up due to engine vibration. I have even seen the breeze clamps nearly chew a hole thru the bottom of the cowling air scoop due to vibration. It;s all a poor design. Actually, the rubber boot is great for axial/front to rear movement, but poor for lateral engine vibration movement. The fix I think about would allow for the lateral movement. Shut down can be especially cruel to all the bits connected.

-

Carb heat box and flex boot problems could be solved with an improved design the would effectively lengthen the heat box - forward.. The boot could be replaced with a metal duct the over lapped the inlet of the heat box with enough clearance to provide - engine vibration + round, flex sealant. I'm going to work on one.

-

I'm just saying the induction system for the 180 hp Mooneys is really a marginal design. The induction booty thing, the carb box, the carb heat flap & linkage. ... makes you wonder. The carb heat box usually cracks at the base of the carb heat inlet tube. The little needle bearings on the heat flap shake themselves to pieces - and the carb heat linkage geometry "was beat to fit". When I had a welder attempt to repair the crack - the alumn. had so much inter-granular (due to age) it was almost impossible to weld. Ended up cutting most of it away and forming a new piece of alumn. as a patch. The good think about this is that it created a "pocket" for the heat flap to swing up out of the way of the airflow. Also, look at MacFarlane for replacement "elastomeric" bearings to get rid of the old needle bearings on the air flap shaft. They are a great improvement - and won't be feeding needle bearings into your engine as they shake apart. Also, I think that Mooney put out a SB regarding the attachment of the heat flap to shaft. Once again - the photos are @%&?! inverted - Good luck. Joe

-

These came from the factory beat up junk. Re-work is the order of the day.

-

Checking Cam Lobe Condition

mike20papa replied to corn_flake's topic in Vintage Mooneys (pre-J models)

The lifters stay full of oil. If you ever change out a cyl. you have to fish out the lifters and release the oil pressure in each of the 2 lifters of you'll never be able to slip the rocker arm shaft back in place. The lifters have a ball type check valve that is released by inserting/pressing a small dia. brass wire into the oil tube. - When done, the lifter releases it's oil. Pretty cool. Also, when you have a cyl. off, you can use a small mirror and examine all lifters and cam. Here's s photo of one lobe at about 350 hr.s -

Did my first no flap landing

mike20papa replied to steingar's topic in Vintage Mooneys (pre-J models)

99.9% of my landings in my A model are done "no flaps" I can put that old bird down - nose high - the tires don't ever squawk or complain. walk it down the run way on just the mains - nothing (except landing a boeing A75N1) can compare. -

High CHT, 470 degrees +.

mike20papa replied to ragedracer1977's topic in Vintage Mooneys (pre-J models)

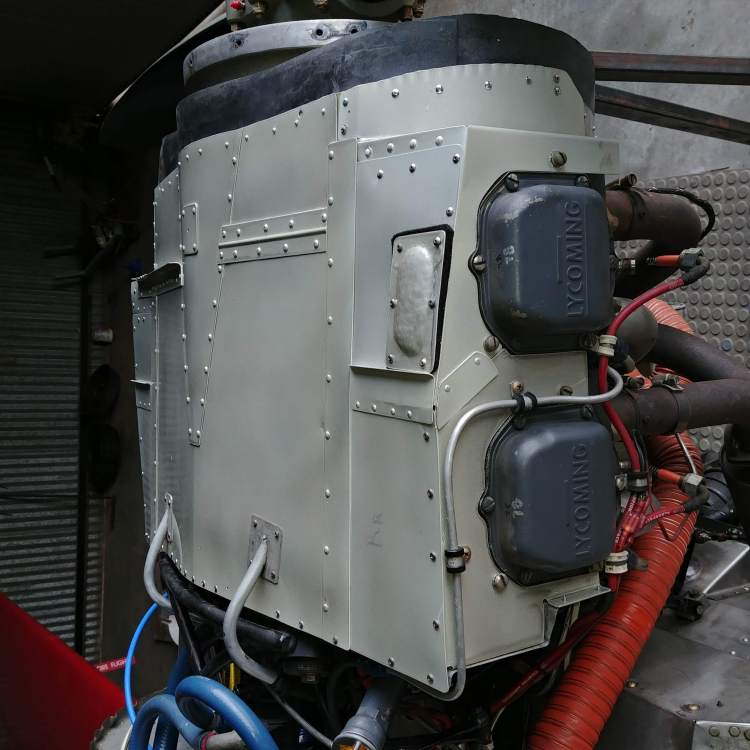

Is the 2" SCAT tube that feeds the heat muff coming from the back of your engines dog house - just above the #4 cyl.? Some 180 hp Mooneys are set up this way. -

High CHT, 470 degrees +.

mike20papa replied to ragedracer1977's topic in Vintage Mooneys (pre-J models)

Do you have the mod that closes off part of the cowling intake opening? Are you running the stock cowling opening? -

In annual I wouldn't offer half what is being asked, not a nickle more. That old bird (even if it glitters) will take you to the cleaners. I'd keep looking. Old radios, old motor .. no telling what else. Find a Mooney someone has adored, not abandoned. They're out there, especially now.

-

How Touchy is your Trim Wheel?

mike20papa replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

My old A model trims beautifully...just light pressure on the trim wheel does the trick in cruise. I still say the Mooney, because of it's laminar flow wing, is a trim sensitive AC. Always roll it back to the stop for landing and set appropriate for take off. A beast for flying touch & goes. In my Stearman, you can touch the trim wheel once in the spring - and forget about it. But it has a lifting tail. -

Here are a couple of images - my M20A, N8335E. Sorry for the inverted images, no matter what I upload - it's always inverted - even inverted photos ...!? The blue tape is a rubberized adhesive tape that seals water out of the rear spar area, under the aft tank.

-

I've owned my '59 A model N8335E for over 10 years. Just had it painted and now back in the air. Yes, there are some obvious vulnerable aspects of the wood wing, but it has many advantages, too. (like removable/serviceable fuel tanks) I need to post some updates photos. I found/bought an old A model wood vert stab - they have been so ridiculed & bad mouthed ... Anyway, I carefull removed all of the ply wood skin to examine the glue joints, wood members, etc. There was NOT ONE area of delaminated plywood, failed glue line, nothing! Joe

-

I have a '59 model and enjoy every minute I get to fly it. Nothing else in it's class can touch it! I'm getting mine painted right now - should have some photos under my profile. Joe

-

The "Real Rub" I found on my A model was on this fuel line .. where it comes from the fuel valve and turns into and up inside the wheel well to the gascolator - typical for all 180 hp models. I discovered it when overhauling my nose gear. You cannot see it unless you remove the tube - as it's turned away from view and gets rubbed during gear operation. I armed the replacement with section of nylon tubing. Joe

-

-

An engine guy explained to me how low power settings can reduce the ability of the rings to expand and seal sufficiently resulting in increased oil consumption and cyl. blow by. (it's during break in you need to run an engine "hard"). I use to lope around below 2400 and 20 in. but now I try to avoid it - in my M20A.

-

Trim position on take-off in a short body?

mike20papa replied to Prior owner's topic in Vintage Mooneys (pre-J models)

All I can add is that the position of the trim for take off can make a big difference in the way the AC handles during take off. Not enough up trim and it can be a handful .. I mean a feets full experience. Get the trim position set so that you don't have to hold back pressure on the yoke during take off to keep it from "over steering" - darting like a squirrel right/left and then it will climb out with little yoke effort, re-trimming. It took me a long time to finally get this just right. -

Gear won't retract after transponder install

mike20papa replied to Mike A's topic in Modern Mooney Discussion

Me and my butt simple A model have no idea what this subject "'tis about."