mike20papa

Basic Member-

Posts

359 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by mike20papa

-

If you are asking about the suction screen .. YES. Do not remove it from the sump or else you will have a gallon plus of oil let loose to deal with. If you are asking about the high, at the accessory case pressure screen - you can remove it with "minimal" oil leakage. But why?? This should be concurrent with the oil change - so just wait - unless you have oil pressure or other concerns - or just go ahead and drain/change the oil?!

-

O-360A1D Narrow Deck to Wide Deck Baffle Mods...

mike20papa replied to flyer7324's topic in Vintage Mooneys (pre-J models)

Finally, the answer. I think there is/was some confusion with this topic as some do not realize that "while all angle valve engines are wide deck engines - not all wide deck engines are angle valve engines." But at least you can rest easy knowing all eligible 180hp engines are parallel valve engines. Joe -

Mysterious water leak from speaker grille

mike20papa replied to Bob E's topic in Vintage Mooneys (pre-J models)

My A model has the speaker mounted thru the cabin roof with 2 - #10 screws. I see one #10 (?) screw about 6" forward of the GPS antenna. You might check it. -

O-360A1D Narrow Deck to Wide Deck Baffle Mods...

mike20papa replied to flyer7324's topic in Vintage Mooneys (pre-J models)

I've had experience with the light weight starter and alternator. The mods are in the front baffle - to close up the original larger holes for the smaller starter and alternator drives. I would imagine that you will also need new "inter cyl. baffles" that are mounted just below the cyl.s - but that is a Lycoming part. Google the parts manuals for the 2 engines and check the part numbers - or call Lycoming. I do not think the side baffles will require any thing. Again, I would call Lycoming and ask them if the bolt holes have different patterns. Hopefully not or else you will have to make new pieces there. The rest of the engine baffles should not be a problem. -

Need to repair air box

mike20papa replied to TravelVeteran's topic in Vintage Mooneys (pre-J models)

A few years back I rebuilt the airbox on my A model. I used these PMA'd bearings from McFarland, fabricated my own shaft, door, etc. Blessed by my A&P/IA I wrote it all up and sent in a 337. https://www.mcfarlaneaviation.com/products/product/MC955/ Of course, the photos (always) load inverted .. sorry. -

Mooneys are water resistant not water proof...

mike20papa replied to Trenta's topic in Vintage Mooneys (pre-J models)

I like this thread .. especially as a wood wing owner. I tell people to buy a wood wing mooney - back in the day - and leave it out on the ramp day in/day out - would be like buying a Steinway grand piano and leaving it out on the driveway and then bitching cause it won't stay in tune. -

Shock disks for 1965 m20c

mike20papa replied to TravelVeteran's topic in Vintage Mooneys (pre-J models)

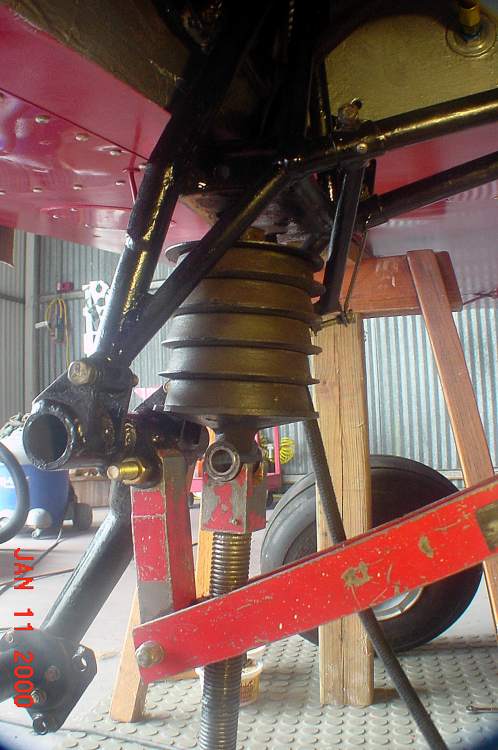

Notice the two notches or relieved sections in the disk flange on the shock tower? .. The retro fit to Lords does not take this dimensional interference into consideration .. in simple terms.. Do all the work as shown in the drawings and the gear will NOT retract and lock. You have to then (after all the swearing & cursing) relieve clearance around the link at the pivot bolt( what I chose to do .. or else remove the biscuits and accomplish the notches in the shock tower base plate. Also, I didn't rebore the new shock towers to size because I was looking to exercise my drill press .. Joe '59 A model.. First photo shows the tool I devised to remove the shock tower retaining collar. It was not a simple swap out - either. -

Shock disks for 1965 m20c

mike20papa replied to TravelVeteran's topic in Vintage Mooneys (pre-J models)

The "up grade" to Lords is a lot of work. The original Firestones were jewels that the whole gear system was designed around. When you do the conversion - you will understand that the Lords are a "retro fit". Some would call it a "beat to fit/paint to match" $$ affair. Joe -

Spark Plug Doghouse Interferance?

mike20papa replied to cctsurf's topic in Vintage Mooneys (pre-J models)

The solution involves a piece of annealed alum. hammered to accept the plug wire bend. I also added a piece of 1/4" wool felt to improve the clearance & seal. Joe -

How do I clean/change my oil screen?

mike20papa replied to TravelVeteran's topic in Vintage Mooneys (pre-J models)

Your engine has 2 "oil screens". One on the suction side of the pump in the oil sump and one on the pressure side of the pump mounted on the accessory case. Looks like what you have is the gasket to the housing that holds the pressure screen. Later with more info. -

M20A Brake Cylinder or push rod

mike20papa replied to Steve Smith's topic in Vintage Mooneys (pre-J models)

Steve, I rebuilt the master cly.s on my '59 A model a few years back and so looked at the record photos I take. Looks like you might be able to take a long an3 or 4 ( can't tell from the photos) and modify it to replace the actuating rod. I guess what your saying is the the seal is no longer tight around the rod diameter. Best of luck. Joe N8335E -

GILL LT 7035-28 SEALED BATTERY

mike20papa replied to MB65E's topic in Vintage Mooneys (pre-J models)

I bought one to put in my Stearman. Looks like a good battery for slightly less dough than the Concord. Looks like COMPLETELY DIFERENT battery from previous. -

Fabric Wings how long are they expected to last

mike20papa replied to Steve Smith's topic in Vintage Mooneys (pre-J models)

In the picture is the mahogany veneer (poplar core) plywood wing the "metal" aluminum colored portion is the Polyfiber coating "polyspray" an aluminized coating to block UV. The orange colored area is the "polybrush" a fabric glue/sealer (first applied before the polyspray. The only "sheet metal" covering on the wings is on the lower surfaces just fwd of the gear that enclose the main fuel tank bays. They are screwed in place with #8 MS's -

Fabric Wings how long are they expected to last

mike20papa replied to Steve Smith's topic in Vintage Mooneys (pre-J models)

SHEET METAL?! MERCY! Are you sure? The fabric is painted with aluminized dope - is that what you are seeing? As far as the "life expectancy" of dacron/synthetic coverings, UV exposure is the only variable. Keep it painted & hangar'd and it will out live the pilot. -

M20 short body guide, gotchas, and mission advice

mike20papa replied to DartMan's topic in Vintage Mooneys (pre-J models)

The back seat in my A model is one of the most comfortable rides I've ever experienced. 6 Ft and 185lbs. Go sit in one and find out. -

I'd be very suspect of that hose bend radius (both hoses). I bet you can go to the Parker web site and find out what the min. radius bend is, but common sense says ?!

-

When was the last time your oil cooler was flushed out. (probably never) The manual on these oil coolers require periodic flushing as a part of continued airworthiness.

-

#3 Cylinder runs very hot after overhaul

mike20papa replied to Greg Ellis's topic in Vintage Mooneys (pre-J models)

So, is the cyl. overhauled - not new, correct? And why an OH stud assembly as opposed to new? Was just oil consumption the problem? The piston is original, vs new? What you have changed is cyl. wall plating and rings - only. Did the cyl. shop do all of the work - clean /check the piston, fit the new rings, send you back a complete assembly? To me .. cleaning piston ring grooves is not worth the price of a new piston - they are the most reasonably priced piece of the whole assembly. Simply checking ring gaps by fitting a ring down in the cyl. then assembling on an old carboned up piston may be giving a false indication of fit. Did you fit the piston pins yourself? Did you put new pin plugs in? How did the pin feel in the rod end? Have you bore scoped the cyl? Checked to see if any scoring is going on. I'd be cautious with continued flying. -

Starter motor replacement- please advice

mike20papa replied to brndiar's topic in Vintage Mooneys (pre-J models)

Skytech 149NL has served me with out fail for over ten years. You will need to close the area in the front baffle around the smaller drive housing - or else wonder why you now have increased oil temps with a new starter. -

What is best way to start a flooded engine

mike20papa replied to rockydoc's topic in Vintage Mooneys (pre-J models)

The guy's question concerned starting a B model. Also it was NOT a hot start question. The B model with an O-360 - has no fuel servo, cause it has a carburetor. You are complicating things, here. -

What is best way to start a flooded engine

mike20papa replied to rockydoc's topic in Vintage Mooneys (pre-J models)

If you have not flown in months - there's a chance no fuel in the carb bowl. turn the master on, turn the aux. fuel pump on till you see a few pounds psi. turn it off. pump the throttle (acc. pump) about 4 full strokes. mixture rich, crack the throttle, make the left mag hot then hit the starter. good luck. Also, not a bad idea to pull the top plugs, spin the engine and pre-oil the motor. especially when it's been sitting for a while.