-

Posts

5,731 -

Joined

-

Last visited

-

Days Won

24

Everything posted by Andy95W

-

Flush side windows has anyone done it?

Andy95W replied to jetdriven's topic in Modern Mooney Discussion

Sounds like a huge waste of time, but I’m glad you own the shop that gets to do the work! I could almost understand doing that when installing the front windshield, but the side windows? What would that add, 1/10 of a knot? My question would regard other high performance aircraft. Does a 58 Baron have flush windows? A TBM? Citation? -

-

You were both rich kids compared to me… I was issued (forced to buy) my HP-15C my first year at West Point.

-

The first time I heard “Reverse Polish Notation” in 1984 with my HP-15C, I swore it had to be a joke. Excellent device, I doubt I could use it anymore!

-

Yet another newbie who posted one time (last Saturday) and hasn’t been back since.

-

So the big question for you and for everybody else is whether or not you’ll keep using Camguard? I’ve been alternating using AvBlend and Camguard every other oil change, but I’ll likely just change to only AvBlend. When the Aviation Consumer did a test on additives years ago, they found that AvBlend and Camguard had comparable results over straight weight oils and multi-weights. There has also been some evidence (probably apocryphal) that AvBlend might help with valve sticking. This post will probably give @jetdriven a conniption fit. (just kidding Byron)

-

@MikeOH- that is correct, at least for our CAR3 airplanes. I’m not familiar with everything GeeBee mentioned above. The actual CAR3 reg says that interior materials must be flash resistant in areas where smoking is not permitted, and flame resistant where adequate ash trays are provided. The only requirement for flash or flame resistance is that the materials conform to a nationally recognized standard. Cliffy and I posted data and references about 8-10 years ago, but all that was probably lost in the great MooneySpace knowledge purge.

-

You’re doing better than me, Lance. I doubt I would have even noticed that the last name was the same.

-

Switchblade: Kinda cool concept in progress

Andy95W replied to hammdo's topic in Miscellaneous Aviation Talk

That didn’t sound right to me, so I did a little digging. Other than a recommendation by the Consumer Product Safety Commission, I couldn’t find any “law” like you suggested. That CPSC recommendation was adopted by the Underwriters Laboratory. Reputable hot tub manufacturers follow that UL guidance- probably due to company lawyers wanting to avoid lawsuits. If you have specific information proving such a law exists, please post it. -

I used to own a Piper Aztec, N7HW. Practically every time I checked in to ATC for a clearance they would respond with, “say full N number”. It got annoying quickly.

-

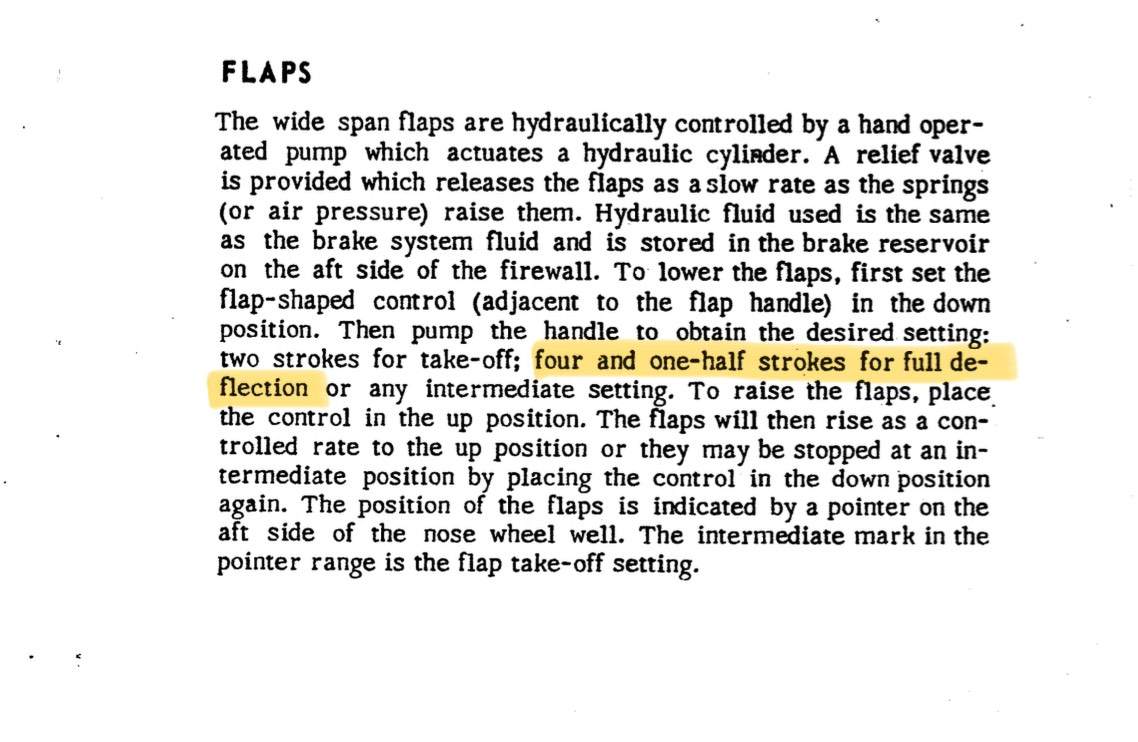

The factory probably wasn’t as diligent as you when they were bleeding the system. They probably got it pretty good and figured, “well, I guess it’s 4 and a half pumps…” I think we can agree that between 4 and 4 1/2 pumps is acceptable for airworthiness?

-

Ross knows more about Mooney hydraulic flaps than any A&P I know (myself included). But 4 and 1/2 pumps is perfectly acceptable, and was for both Mooneys I’ve owned as well as the Owners Manual:

-

Switchblade: Kinda cool concept in progress

Andy95W replied to hammdo's topic in Miscellaneous Aviation Talk

For all the naysayers who love to poo-poo on EVs and the associated technologies, take a look at the 1903 Wright Flyer. It was a crap airplane, but they kept at it and barely 10 years later the first scheduled airline service started (January 1, 1914.). Only 15 1/2 years after its invention, Alcock and Brown flew across the Atlantic Ocean (June 14, 1919). If the Wrights, Curtiss, Bleriot, etc. had listened to the naysayers and stopped pushing the technology forward, we never would have made it to the moon in 1969 and I certainly wouldn’t be flying my 1964 M20C. Or, as Benjamin Franklin said, “Asking what is useful about electricity is like asking what is useful about a newborn baby.” (I paraphrased.) -

I find it ironic that folks worry about single points of failure (such as the fuel valve or only one GPS) but have no problem flying over mountains, at night, or in low IMC in a single engine airplane.

-

I understand Wombat isn’t complaining, so I’m definitely not singling him out. His post highlights one of the problems with general aviation. I’ve worked in shops and done jobs exactly like he described. The work takes 90 minutes, but that seems excessive so the shop only charges the owner for 1 hour. The owner complains and says it’s only a 4” wire, that should only take 15 minutes! In order to keep a paying customer, the shop knocks it down to 1/2 hour labor. The shop is now out a full hours’ worth of work, and the jerk owner tells all of his buddies that the shop is a complete ripoff, and he had to talk them down to a reasonable price to do the work. (BTW, that same owner will gladly take his BMW to the dealership and just stroke a check for service.) Meanwhile, the shop owner gets offered $30/hour starting salary to work for the airlines, and he takes it so he doesn’t have to work for cheap bastard owners and he won’t have to pay $15,000 a year in liability insurance. Then, when he closes up shop, everyone complains that another greedy mechanic is leaving to work for the airlines and he’s the reason that General Aviation is dying. I don’t work on other people’s airplanes anymore.

-

⬆️⬆️⬆️ This. Please don’t kill another M20C while trying to gain experience. That’s what Piper Arrows are for.

-

Looking for a governor (H-1, PCU5000)

Andy95W replied to lithium366's topic in Vintage Mooneys (pre-J models)

Any proof of that, or just hearsay? -

I get FF free from my work, and I seriously dislike it. It is a royal pain in the ass.

-

Don’t know about no Cherokee. Both Mooneys I’ve owned flew straight regardless of passengers or unbalanced fuel. Didn’t matter.

-

Flying solo or burning one wing tank down should not affect flight characteristics in a noticeable fashion. If one wing is “heavy”, it is aerodynamic due to mis-rigging. (Note: this may be different for long range tanks.)

-

Just tell everyone you did it on purpose and the shop followed your instructions. They look great!

-

That’s like mine from 25 years ago. The FSDO quizzed me for about 2 hours to make sure I knew what I was talking about, then said, “well, if Sam says you’re okay, you’re probably okay.” Then they signed my authorization to take the tests.

-

But with the exception of the M20E that crashed (and that had been modified/repaired with duct tape), does anyone have credible information of any other failures that caused crashes?

-

Do You Leave Your Tow-Bar Connected While Parked?

Andy95W replied to PeteMc's topic in Miscellaneous Aviation Talk

I’ve been doing this as well for almost 30 years. -

Having “a few extremely small flecks of shiny metal” in the oil filter is very normal regardless of a recent top overhaul. The question is how many and how small. 5-10 flecks that are 1x2 mm or smaller is not a cause for concern, particularly considering your recent top.