All Activity

- Past hour

-

Retract Gear or Flaps First in a Go Around ?

1980Mooney replied to donkaye, MCFI's topic in Modern Mooney Discussion

Complicating this discussion is the fact that prior to 1987 (24-3000), M20J's did not have a "take-off" preselect on the flaps. I think it is the same with the M20K but have not looked at all the wiring diagrams. Late J's & K's and Long Bodies have the takeoff preselect. The POH states that if landing with full flaps deployed the pilot should Retract the flaps to "take-off" position before Retracting Landing Gear and then fully Retracting Flaps (from "take-off" position to 0 degrees). This means that the pilot has to look down at the indicator while toggling the flap switch and watch until it centers at the "take-off mark. This fumble farting around looking down can spell disaster when forced to execute a go-around while trying to land. @PT20J and others are right that full flaps deployed while landing can provide maximum landing performance (except in some conditions like strong winds, etc) but the lack of take-off flap preselect on most "modern" Mid-Bodies creates a sub-optimal (I would argue unsafe) situation to be dancing "flaps, gear, flaps" during a forced go-around. I think it better in Mooney's without a "takeoff" flap preselect to compromise and set up to land with "take-off" 15-degree flaps. That way you are set up to go around without thinking about it - without having to fumble/bumble looking down at a hard to see indicator (especially at night) to raise from Full Flaps to Take-off Flaps before raising Landing Gear. If set up with "take-off" flaps, once you break out or know the runway is clear, you can throw in the remaining flaps with a single press of the flap actuator switch (and not having to look) if you think it is needed. Everything in aviation is a compromise. Just my 2 cents. -

All, I've been the proud owner but not operator of an 84 J for 15 months. Since purchasing the plane it was ferry to Idaho and has sat at the mechanic since then with little to no work done, which is a much longer story. I've got Mooney Pros on the hook to help with transition training and relocation. I've got the A&P engaged and working on it now. Bottom line, we are trying to get this plane out of ID before winter hits, and the A&P is an amazing perfectionist . Hes trying to put in a new headliner (and all the other panels) from Vantage / Plane Plastics. He's running into a bit of an issue with the electrical pigtale in the headliner. I believe the previous headliner was removed and then the pigtale removed from the headliner and temporarily hung back in the plane. As such the A&P has reached out to Laser, who "has contacts at mooney" to find the electrical schematics for that headliner to know what goes where. The drawings in the manual are terrible, and the wire markings are no longer there/legible. Hes focused on finalizing the airworthiness for mechanical while we waits on Laser to get back to him, but said anything I could send could help in the mean time. I did not find a file section on here to see if they were here. I'm begging this community / 84J owners that might have the schematics digitally, or physically that could scan or picture them in high resolution for the headliner. Additionally, any 84J owners who could take some high resolution pics of their headliner of which lights/horns/etc go where would be hugely appreciated. Lastly, thank you all for your help in my desperation.

- Today

-

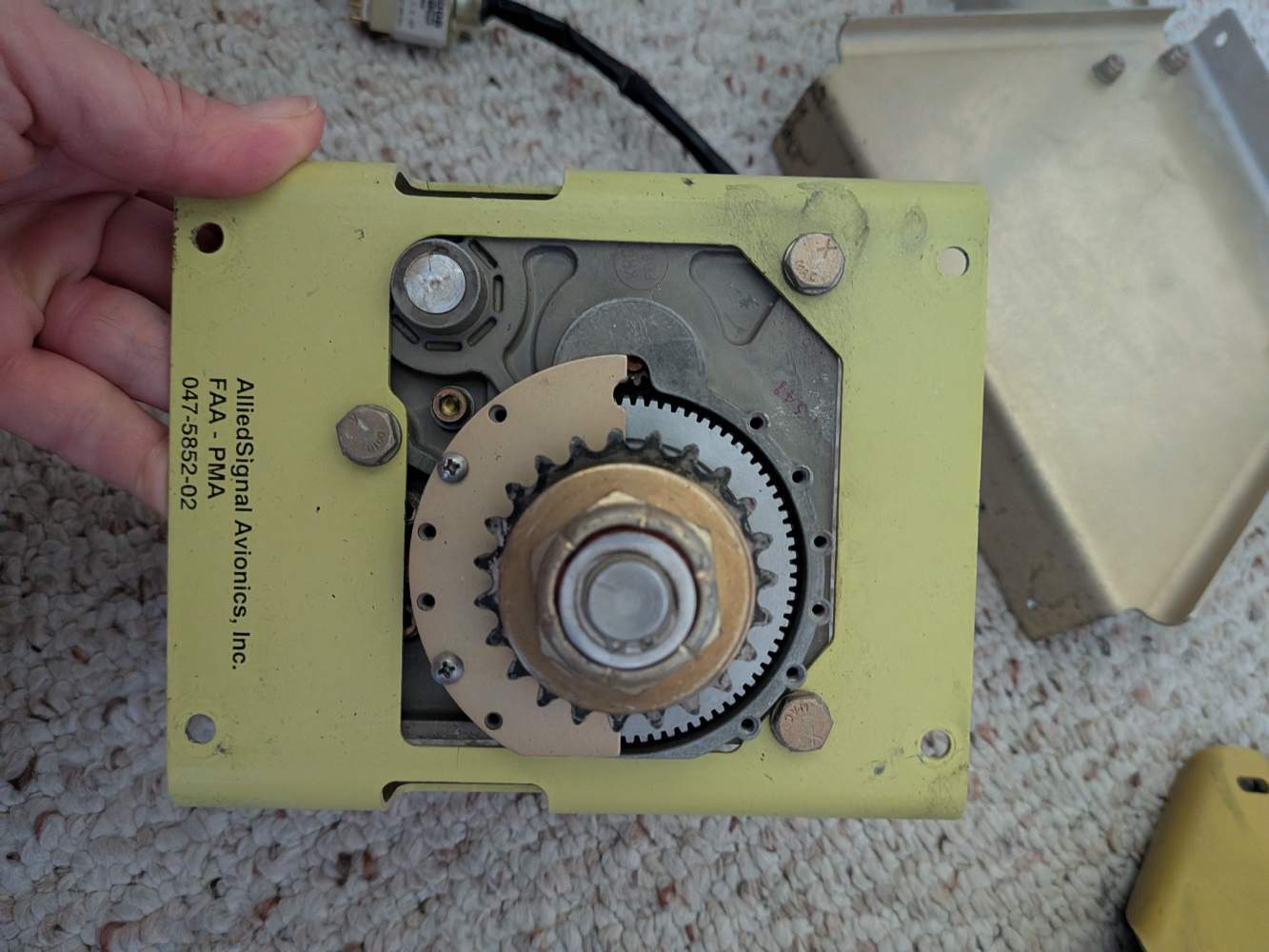

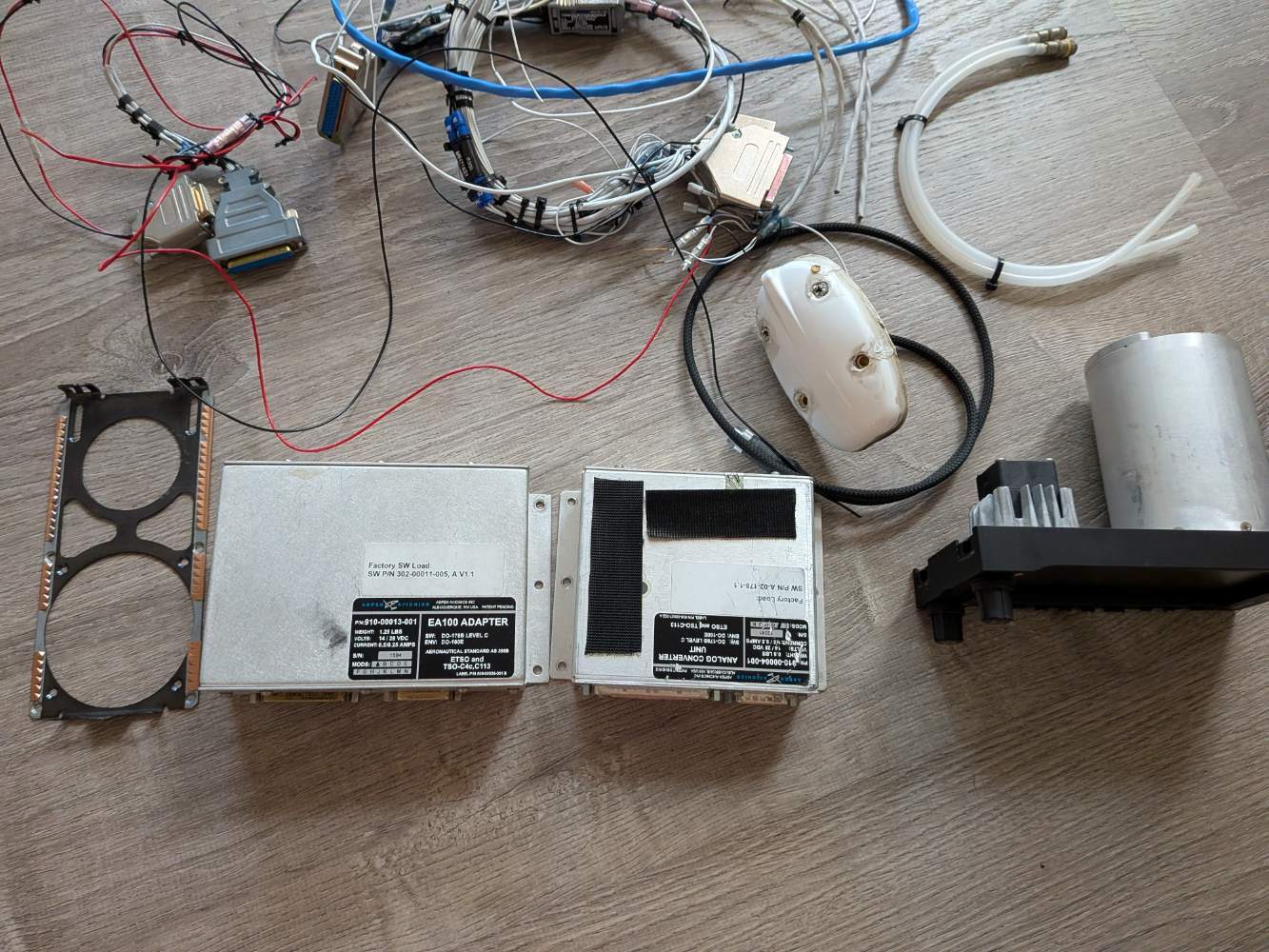

Selling a King KFC 150 Autopilot System and a Aspen EFD 1000. Both units were fully functional when removed from a 1995 Mooney Ovation M20R in May of this year for a Garmin GFC 500 autopilot upgrade.King KFC 150 Autopilot System King KFC 150 Autopilot System This complete system includes the King 150 autopilot computer, Bendix King mounting bracket, and all three servos (pitch, roll, and trim) with their mounting brackets. The system is in working condition, with all functions operating correctly, with the exception of the glideslope capture, which works intermittently. We had this issue looked at, and while it briefly improved, the intermittent nature of the glideslope capture returned. Additional components included: KAA Aural Alerter KAS 297B altitude preselect/vertical speed selector Mid-Continent DC-AC Inverter (Volts: 14-26) We prefer to sell the KFC 150 unit as a package, but are willing to sell individual parts if needed. Aspen EFD 1000 Pro This unit was in perfect working condition when it was pulled from the aircraft. The EFD 1000 was replaced with two GI-275 units for better integration with the new Garmin autopilot. Components included: Aspen EFD 1000 display EA 100 adapter Analog converter Remote sensor module (top mount) Prefer to sell the Aspen in its components as a package. But can sell individual parts if needed. Please contact us for more information or pricing. More pictures upon request Phone: 408-455-4031 Email: juliannechalupa@gmail.com

-

Is green or black positive on motor?

-

Don had me send a couple pics. A tiny screw was holding it on. Job done. Thanks Don!

-

takair started following No Back Spring Update

-

I know SB is not mandatory for part 91, but this shows up in at least some of the Maintenance Manuals… The Ovation manual shows it as mandatory. It’s not an AD, so I guess it may depend on the vintage of the aircraft if this manual applies to a specific airframe or not.

-

PSA for anyone coming to Tampa area

Grant_Waite replied to Grant_Waite's topic in General Mooney Talk

Yeah it’s a luxury to have that option these days. For a lot of us, we are forced into having to go elsewhere which is the worst thing unless you have a very good relationship with the shop. I always found that unless I was present, the work would take twice as long to get done. -

I learned big things air brakes in college driving the campus buses. There is an initial slow to make sure you still have brakes. The fun days with the fire truck are the driving course days. I pretty much have the go pedal on the floor most of the time. The key is when the rear tire passes the cone. going forwards or backwards. The steering wheel needs to be moving fast. They should figure it out when I tell everyone to strap in.

-

Pirep - Gee Bee Aeroproducts Baggage Door Seal

Gee Bee Aeroproducts replied to Z W's topic in General Mooney Talk

I will always answer the phone and questions if need be. Iam either in Jaco Costa Rica or in Hawaii. Cheers -

Pirep - Gee Bee Aeroproducts Baggage Door Seal

WilliamR replied to Z W's topic in General Mooney Talk

Thanks -

I’ve always found Guy to be very friendly and helpful on the phone.

-

That's the European racing school method. You can beat them by trail braking into the corner, although I don't think I'd advise that in a fire truck except as a last-ditch measure.

-

kortopates started following No Joy on Landing Gear Extension - J Model

-

G3X Touch + EIS Owners - How is your tach wired?

Ryan ORL replied to Ryan ORL's topic in Avionics/Panel Discussion

Thanks guys! That seems to be the most straightforward solution then... switch to the hall effect sensor for the G3X and ditch the P-lead pickups entirely (except for the R1). I think with that setup, there's no need for the Tach2. -

G3X Touch + EIS Owners - How is your tach wired?

PT20J replied to Ryan ORL's topic in Avionics/Panel Discussion

I used the the Hall effect sensor on my G3X also. -

Yesterday 2100 feet in non aggressive braking. No speed brakes. If I had braked earlier I could have not had to do a U turn for the 2000 foot turn off. Lht to variable winds. About 14 landings. The trick being to hold off a little longer which shortens the roll out.

-

No Joy on Landing Gear Extension - J Model

N201MKTurbo replied to Brent's topic in Modern Mooney Discussion

I’ve told this a few times. I think people think it is silly, but it is not. In your situation, if it is a contactor, they are mounted to the floor under the pilots seat. If the gear does nothing, stomping on the floor or bouncing on the seat may knock it loose and get the gear going. I also had this happen once and found one of the motor brushes fell out. -

No Joy on Landing Gear Extension - J Model

PT20J replied to Brent's topic in Modern Mooney Discussion

-

Pirep - Gee Bee Aeroproducts Baggage Door Seal

Andy95W replied to Z W's topic in General Mooney Talk

I wouldn’t worry about that too much, Guy (GeeBee) misunderstood my question also. I think he’s just very busy with multiple websites and a wide range of products. If you have a question about your payment you could message him directly, but it’s probably all squared away. -

Ragsf15e started following No Joy on Landing Gear Extension - J Model

-

No Joy on Landing Gear Extension - J Model

Ragsf15e replied to Brent's topic in Modern Mooney Discussion

There are the limit switches and the relays (which are near the actuator i think). Limit switches are exactly as you described- paddles on the rod. -

My pax seatbelt is always locked and stowed in a way that cant happen...dont ask why

-

Do all your braking before the corner. Apex the corner. The reason you accelerate out of the turn is to use engine torque to stand up the suspension. Now do it in a fire truck.

-

Pirep - Gee Bee Aeroproducts Baggage Door Seal

WilliamR replied to Z W's topic in General Mooney Talk

@Marc_B thanks for the very good detail. We are using the same seal. The tightness is on both doors. I don't think the top clamp is the problem on the cabin door as I can tell on both doors the pins are hard to engage in the holes. The doors are flush with the airframe as they were before. Now, just very tight. On an early fitting, I did notice the bulb was squishing out of the frame causing binding, but that was corrected. Also on an early fitting I came to the conclusion that as you noted, the seal for the baggage door near the hinge kind of straddles the door frame edge. The paper strip trick is a good idea and will do that. Looking again at your pics, my bulb is just about as close to the edge "unsquished" than yours that is "squished". So, maybe I need to go just a little further inboard on the doors. Let my try once more and will follow up with pics if I continue to have problems. Not sure where Gee Bee's comment is coming from as I'm not dissatisfied with what I received. I'm just trying to perfect the install. I paid at the time of my order. So, @Gee Bee Aeroproducts if there was some problem with my payment, please let me know and I can get my bank to find out what the problem is. You may contact me at the e-mail from which I placed my order to sort that out. Again, I appreciate the help. William -

Landing flap setting for "normal" landings in a J

76Srat replied to Ftrdave's topic in Modern Mooney Discussion

There are two words to solve all of this: Airspeed. Airspeed. Oh, and a third word goes with those two quite nicely: Airspeed. -

G3X Touch + EIS Owners - How is your tach wired?

jetdriven replied to Ryan ORL's topic in Avionics/Panel Discussion

We have the 275 EIS, but the JPI style Hall-effect magneto sensor works great with the system. It even reads Rpm with the key off.