-

Posts

790 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Z W

-

I set out this year to equip my hangar with the tools necessary to change a tire on the Mooney. It turned out pretty good so I thought I'd share what we did. I looked for tail stands available for purchase. None really seemed like a good option. We rent the hangar from the city, so drilling into their concrete to add a floor anchor was not something I wanted to do, and I wanted the tail stand to keep the tail from going up or down for ideal stability. Not looking to re-start any debates here on tying down the tail vs. lifting from the front. I'm fortunate to have a very smart and talented guy who works for me that's good at making things. I showed him a picture I'd seen on Mooneyspace, and asked if he could make one of those. He said sure. This is what he came up with: It's a large plastic tub and furniture moving dolly, both from Menards. He welded a T on the large piece of square tubing (no pics of that unfortunately) and set it in about 350lbs of bagged concrete. The smaller square tube has a number of holes drilled in it, and large nut welded on top. You can adjust the height by removing the pin at the bottom and raising or lowering the smaller square tube: T The shackle goes through the tail tie-down. It actually fits in the position shown in the first pic, so the stand is capable of going much taller than necessary for a Mooney. Once connected it's very secure, and the tail can't move hardly at all, either up or down. It rolls easily on the floor. It turned out very well and was probably less than $250.00 in materials. On to the jacks. I considered trying to make some, given the cost. I've seen designs posted here. I wanted a mechanical failsafe on them. I ultimately decided I was not really qualified to engineer a set I would trust not to fail and really damage some expensive equipment or hurt someone. To each their own. It was surprisingly hard to figure out what the options were to buy jacks that fit a Mooney. Most are too tall. We need the shortest ones made. After doing a lot of looking and comparing specs, I ended up ordering a set of these Model 324 Alpha Jacks from Aircraft Spruce for $858.00: https://www.aircraftspruce.com/catalog/topages/alphaJacks.php They fit perfectly and work great, and have a locking collar to mechanically hold them in place for extended periods of time. Very sturdy laterally. And they were half the price or less of some of the more professional options that were out there. Since I only plan to use these a few times per year at most, I went with the less expensive option. I'd buy them again. You don't need to also order the "wheel kit" that Spruce sells, by the way. Wheels are included. I ordered wheel kits initially and they called and asked if I really wanted them, luckily, and took the kits off the order. They show as "special order" on the website, but I got them in like a week. Mooneys look great with the gear up on jacks, like they're going 100 MPH sitting still: The setup is very stable for climbing in and out to swing the gear. Finally, if you're going to change a tire, you need a bead breaker. "Aviation" ones are very expensive. Picked this guy up from Harbor Freight for $93.16 shipped, and it works great on Mooney tires: https://www.harborfreight.com/bead-breaker-58769.html Pro tip - break both sides of the tire's beads before splitting and disassembling the wheel. Otherwise you'll probably have to bolt it back together to break the 2nd bead. All in all, it was a solid investment that will let us perform basic maintenance easier and on our schedule in the future. I hope someone else here might find it useful.

-

My TSIO-360 will read 1 quart higher before take-off than after landing / while hot. Very reliable. It's just a quart of oil up in the engine that takes quite a while to drain back down into the pan. E.G. 7 quarts before first flight of the day will read 6 if you check it at the fuel stop. I usually let it get down to 6.5 cold, then fill to 7.5. It holds 8 pretty well. After oil changes, however, it will drop 2 quarts after the first flight. Meaning I fill to 8, fly for a few hours, and it will drop to 6. Let it sit, it will settle a little under 7. I plan to add another quart before the next flight at that point, or pretty soon thereafter. The engine burns a quart maybe every 6-7 hours. I don't know where the extra oil goes after the oil change. Probably the filter and its lines? But since you noticed this after an oil change, I thought I'd share. I would be curious if you top it up and fly it for an hour if the problem repeats again.

-

You're right though, here it is in the Continental Installation and Operation manual for the TSIO-360-LB:

-

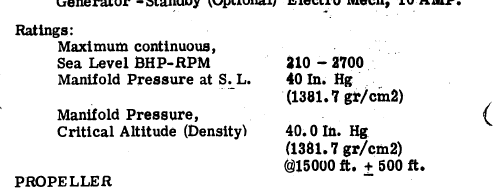

That's interesting. The POH I have, which was written for a TSIO-360-GB(4), does not contain that information, as best I can tell. All it has are these "Cruise Power Schedules" that seem to imply you can cruise at any RPM from 2200 to 2700.

-

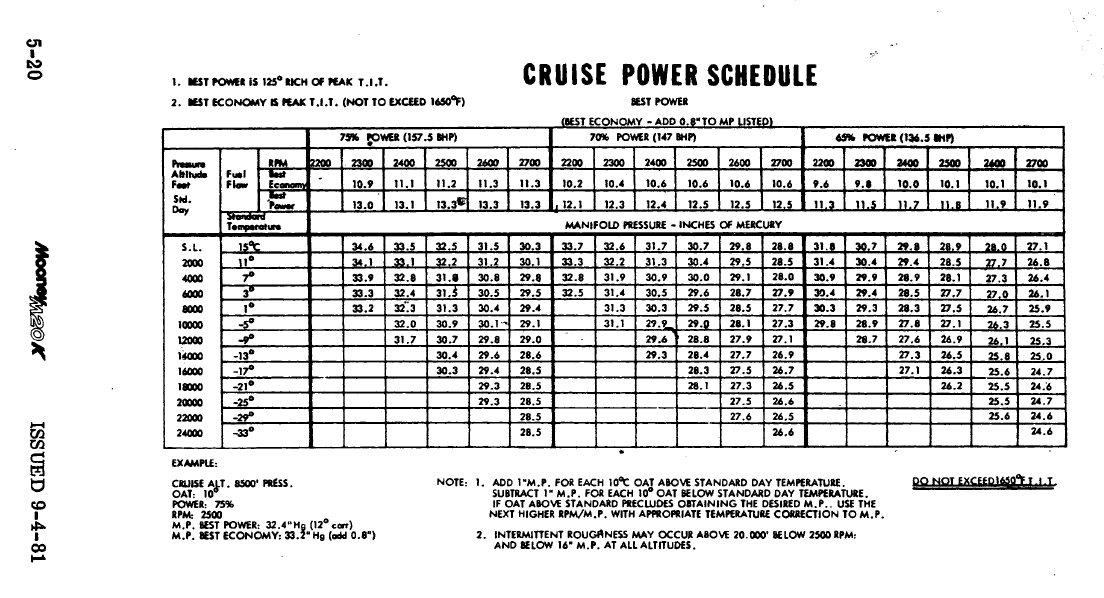

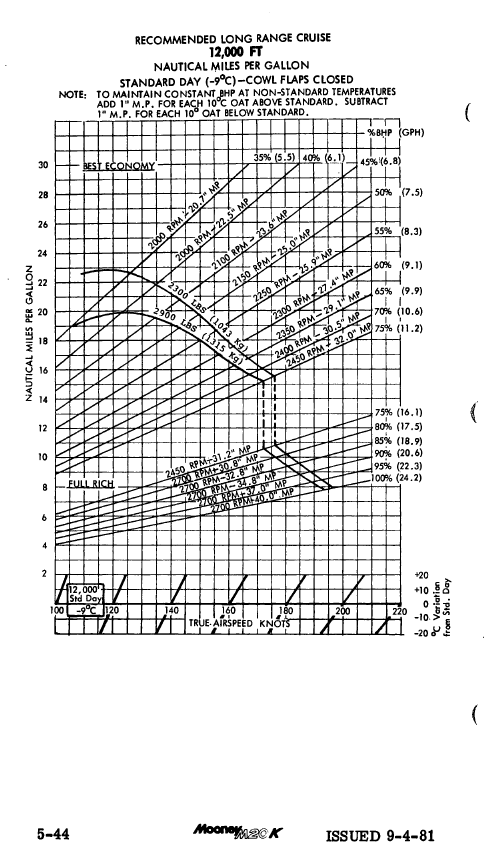

That's a bit of an odd power setting to get to 65%. The POH charts suggest you should be at 2350 RPM and 29.1" MP, 9.9 GPH (below). Personally, to get that flow, I find the engine is happier at 2500 RPM, 26" MP, and leaned to just under 10 GPH. Crack the cowl flaps as required to stay under 380 CHT which is very easy at the 65% setting. You'll get about 130 KIAS at that setting, and cruse 145-170 KTAS or so, depending on altitude. I've tried close to your setting as a recommended LOP cruise power setting. It's generally suggested online as 2500 RPM, 32" MP, and lean to 10-11 GPH (about a gallon higher than you're using). Never seen MP drop, but my engine has a noticeable intermittent stumble or burble you can feel in your feet, so I don't fly like that, even though the temperatures are good. I think you're just running too lean for your power setting, resulting in loss of turbo pressure. How many degrees lean of peak TIT are you when the power cuts out?

-

It would be very easy to keep a standard mask or cannula handy and if the O2D2 has any problems, just unplug its air tube and plug the standard cannula or mask into the outlet next to your elbow and put it on. Not a big deal in the teens but I would want something like that at FL240 for sure. And probably also a tube or two of Boost oxygen: https://www.amazon.com/Boost-Oxygen-Supplemental-All-Natural-Respiratory/dp/B094DY136X/ref=sr_1_6?keywords=Boost%2BOxygen&qid=1693743175&sr=8-6&th=1 Next time I'm at the hangar I'll take some pics of the O2D2 and oxygen transfill setups. There have been plenty of others posted here over the years but may as well add to the knowledge bank, and I'm pretty happy with how both turned out.

-

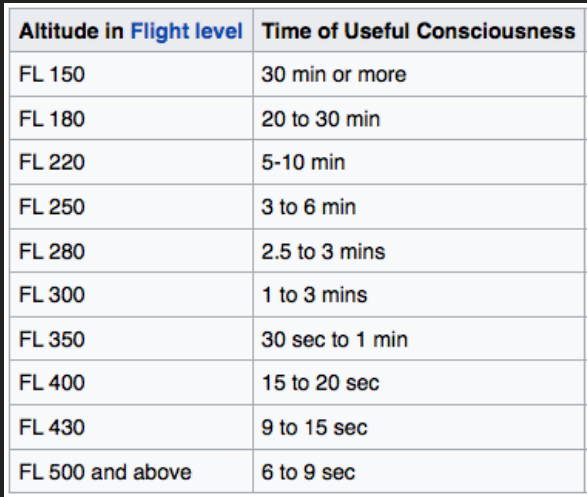

I use a Mountain High oxygen boom, paired with one of their O2D2 systems. Works great. Added a transfill setup in the hangar this year to have the option to fill the tank myself and always have O2. Should have done that years ago. My preferred altitudes are 15-17k. High enough for all the benefits of the turbo (speed, smooth air, above most weather, no traffic, no ATC restrictions, terrain clearance, glide distance for an engine failure), but plenty of useful time of consciousness if you or a passenger has an oxygen delivery problem. No need for a mask, and no requirement to be IFR, although I often am. This is the only real reason I don't go higher, except maybe for a short bit to cross the Rockies: In reality, seems like I get to the high teen altitudes about 1/3 of the time. Headwinds. Clouds. Flight too short to climb that high. On headwind flights, I'll climb until I'm out of the bumps, then stay as low as I can stand to minimize the headwind. I try to get up to at least 7k. Below 10k, once you're used to being higher, it feels like there's something wrong with the plane because you're going so slow and because the ground looks so close. Nice article, @Pinecone. I'm with you. They can pry the turbo from my cold, dead hands.

-

It's been a rough couple of years to be a piston aircraft owner. Parts and labor are both hard to come by when your plane needs something. Put the plane in for annual in 2022 and didn't get it back in the air for 6 months. Just got it out of annual for 2023. Took 8 weeks. Not the shop's fault. They fixed a lot of things, and there was quite a bit of waiting on parts. Had to go straight from there to the avionics shop for an autopilot servo. Got one of the bad early GFC500 ones, apparently. I've been reminding myself lately this is not the norm. Been flying for over 10 years and the last two have been the worst in the maintenance and parts department by far. It will get better. Sorry to hear you've had a bad introduction to airplane ownership. Hope it gets better for you too.

-

I have never flown a Rocket or a big engine long tail, so I have no idea. Just sharing my experience in a M20K 231 with a TSIO-360-MB installed via STC. I would probably experiment with different power settings and use the ones that result in lowest temperatures using modern engine instrumentation. As far as I know, most now agree that high heat is bad for engines, and the cooler you can keep things, the better. I believe some of the early recommendations from the 80's to decrease power for the climb were based on the idea of "reducing engine wear," "taking it easy on the engine," and "fuel efficiency", and that many of those ideas have been disproven. Remember these machines left the factory in the 80's with an analog single probe CHT gauge and no fuel flow meter. They were also designed to just replace a cylinder after it gets fried. But it's also airframe dependent. New or worn out baffling could change how your engine responds. I don't know what cowl flaps your Rocket has. My 262 has the infinitely adjustable ones controlled by an electric motor that were installed as part of the STC. 231's with different cowl flaps might do better at different power settings. Some do believe that RPM = wear, and that lowering RPM increases engine life. The idea is that the fewer revolutions the crankshaft makes, the less all the parts inside rub on each other. That makes sense to me. But in my plane, reducing RPM to 2500 for the climb results in significantly higher internal temperatures, so I usually do not do it.

-

I flew for long time with an old JPI 930. It developed some issues, so we swapped it for a G500Txi. All the readings changed significantly. Kept the stock RPM and MP gauges and it disagrees a lot more with them than the old JPI did. Still don't know which unit was more accurate, but on average, my true airspeed is lower if I trust the settings on the G500Txi and keep it within the limits we've been talking about than it used to be on the same settings with the JPI. All within a few inches or degrees, but enough to make me wonder how much good we all do trying to fine tune these engines.

-

I just meant maximum manifold pressure according to your POH. I believe with your setup, that requires you to set power at takeoff, and then slowly advance the throttle as you climb to maintain your maximum rated manifold pressure, as it will naturally decrease with altitude. Later models with the TSIO-360-MB and TSIO-360-SB got a fully automatic wastegate, which is what I fly, and we do in fact go throttle full forward to the firewall, and the wastegate holds it at 36" of MP all the way up. Maybe some modified TSIO-360-LB and TSIO-360-GB's are the same, I'm not sure. But the idea is to maintain maximum manifold pressure for best takeoff and climb performance. Never overboost your engine if it's one that's capable of doing that. Some pilots used to (and some still do) advocate a "cruise climb" power setting where they reduce power to something like 32" and 2500 RPM, and then pitch for 500 FPM in the climb. In my plane, that results in 1) higher CHTs due to increased angle of attack, decreased fuel flow, and decreased air flow, 2) longer climbs to altitude, 3) increased total fuel burn for the trip due to lost efficiency, and 4) higher overall trip times due to it taking forever to get to altitude. So while I started out flying that way, I no longer do. Full power and full rich mixture to top of climb, then reduce power and lean for cruise. If I'm at cruise altitude and have to go up say 2-3 thousand feet for some reason, I might use that cruise climb setting just to avoid drastic changes. It will quickly spike your CHT's if you watch it. If a larger altitude change than that is required I will go back to full power, full rich mixture, and cowl flaps open to help keep the engine cool and minimize the time in the climb. You can regain all that stored energy in the descent. Never lean in the climb, and never lean for takeoff. That's a naturally aspirated thing. Your turbo is always pushing full air, and so you always need full mixture. If you lean in those conditions, you will spike your temperatures, at best, and not be making full power, or even cause your engine to shutoff, at worst.

-

CHTs below 380. Easy to maintain even in climb if you climb full power and about 120 KIAS. Plenty of air and fuel to cool the cylinders. If one creeps up, I have an alert set in the panel at 380, and just level off for a moment. Climbs in the teens on warm days do sometimes result in temperatures creeping up towards 400. Open and close the cowl flaps as required to maintain CHTs under 380 in cruise. My plane's TIT runs hotter than most seem to post here, and it does not run smooth LOP. I keep it under 1625 TIT, as close to 1600 as I can get, which varies with ambient temperatures. Usually flying 27-28 MP, 2500 RPM, 12-13 GPH. Gives me 135-140 KIAS, which is 150-185 KTAS, depending on altitude. Somehow that's always 5-10 knots slower and 2 GPH higher than all the other posters with the same engines and airframes but I think the internet adds 10 knots and subtracts 2 GPH. Your experience may vary. Keep in mind also some are using the old factory TIT and CHT gauges, some are using modern glass panels and sensors of different varieties, and some are more sensitive to feeling or noticing LOP "roughness" than others. I think we each pick our own comfort zone and hope for the best.

-

Not that exact problem, but I would suspect the fuel pump settings. The TSIO-360 has a complicated engine set up procedure that must be performed after engine install and after fuel pump replacement that many shops are not familiar with. It requires some gauges and instrumentation and is very easy to get wrong. It also requires cowling and de-cowling the engine multiple times and is very tedious. It used to be called SID97-3G which is attached. That has now been replaced and superseded as a part of Continental's M0 maintenance manual, but as far as I can tell, it reads the same. Step #1 for me would be to have someone verify all the proper fuel pressures and flows are set per M0. I would also verify the air intake is unobstructed and properly connected. The engine sucks a lot of air with the turbo, through a very small intake plenum, and any restriction can cause odd behavior like this. Sounds like you have a fuel/air mixture ratio problem. SID97-3G - Continuous Flow Fuel Injection Systems Adjustment Specs and Instructions.pdf

-

Been replacing all the zip ties I can find on the plane with rubber-lined GripLock Ties designed for aviation: https://griplockties.com/ They're really nice and well worth the money. I use them in my cars, boats, heavy equipment, etc. now also. No real reason to use a regular zip tie when they exist.

-

Hah, I posted this exact same question back in May. It's something called a "Wraplock". Mine got replaced with some Grip-lock rubber-coated zip ties. Full discussion here:

-

I once had a flat nose tire after landing. Luckily went flat after I taxied off the runway, but was stuck on the ramp. A&P came out with a dolly and a couple of jacks. We jacked the wings up. I then pushed down on the tail to lift the nose wheel while he slid the dolly under it. Not ideal, but it wasn't exactly an ideal situation at the time. Tube had a hole in it and the tire wasn't holding pressure to move anywhere. It took most of my body weight (220 lbs or so) to lift the nose long enough to slide the dolly in. I wasn't hanging on the tail, but it also wasn't all that easy to just push it down like a 172 is. No damage to anything, it was fine, not that I'd want to do that on a regular basis. When we later built a tail stand, we used a large plastic tub and about 350lbs of concrete sitting on a furniture dolly. Wouldn't want any less weight back there while climbing around on the wings and raising and lowering the gear. I'll try to remember to snap some photos next time I'm at the hangar. It turned out very well. It's rock solid and seems to be about the right amount of weight.

-

Don't think I've ever seen a radar in a Mooney. Cool. Sounds like a plane with an interesting history. Glad you got it back up in the air. Good luck with the sale.

-

A tire potentially going flat on or before landing would be a serious safety concern to me. Could easily lead to a loss of control, a disabled plane on a runway, bent metal, or worse. I think for what a tube costs, any tube with any suspect issues would get swapped before my next flight.

-

Have had your same experience, many times. Also now doing as much as possible myself. It sounds good in theory to inspect the shop's work before takeoff. The reality is different. Removing and re-installing the lower cowl of a K-model is a 2-person job that takes some time. Asking them to leave it un-cowled and sitting in the shop until you can inspect it, then waiting while it's re-cowled, is inconvenient and requires you to be able to run down there on short notice and for them to stop working on another plane and go back to yours. And it's sitting in their shop taking up space after they're done working on it. With shops as busy as they can be, how long would they even put up with that? In short, you have to trust them. Many shops are short on help and have untrained people doing work "under supervision." It's a recipe for disaster that's going to kill some people. I don't have a short term answer, other than today I'm flying the plane 2 hours to a big name MSC for annual and taking that business away from a smaller local shop. Hoping for a better result. Long term, I would pay higher shop rates for good reliable work. I would do more work myself if it were legal, using proper maintenance manuals and techniques and parts. I would worry a lot about buying a certified plane another owner had been maintaining himself or herself. Not sure at all it's a good universal solution.

-

I've been in and out a few times over the last 3 years or so. Very cool airport. Like any mountain airport, best done with low winds, check winds aloft, over 15 knots or so at 12,000 feet may be a no-go. Flying early in the morning or near sunset helps. Be aware of the one-way-in and out nature of the place and the restricted area to the south. If you've never landed with a small (5 knots or less) tailwind component, you may want to go practice that at a flatland airport first on a nice day. It can be required here and I'm surprised how many pilots have never done it. I found the field to be unattended most of the time. Had to leave payment for tie-downs in an envelope drop box outside the FBO, on the honor system. Nice self-serve fuel at the upper end of the runway, except watch out, the ramp is very sloped there at the filling area, be careful how you park or you may need a friend to help you push the plane. Easy access to the FBO and ramp through a gate code. I had a friend who was also picking me up and dropping me off, so no idea how easy it is to get a car or ground transportation. It's a beautiful place to fly in and out of with the proper planning, knowledge, and precautions. Santa Fe does make a good alternative.

-

Had a '68 M20C with a three-blade Hartzell for several years. It took off very short, and more importantly, it slowed down really well at idle. Never flew it with a 2-blade to compare directly on the C, but compared to a M20K with a 2-blade, the 3-blade was a great short-field performer. Still cruised 140-ish.

-

Your engine has a complicated fuel pump that must be set up properly, as others have referenced, using specific steps and special gauges and lines. This is, as far as I know, unique to the TSIO-360's in the Mooney lineup. We recently replaced ours and the local A&P could not get it set up right, even after supposedly buying the gauges required. It did what you describe at first (die on roll-out). After another round of adjustments, it no longer does that, but is not idling properly until fully warmed up, it stalls if you lean at all on the ground, and the fuel pressure is over spec at full power and higher altitudes. Waiting to get it re-calibrated at annual in a couple weeks at a Mooney shop. Continental publishes the proper fuel set up. It's attached here as SID97-3G, which has technically been superseded by M0 (but seems to read the same), along with the parts of the Mooney service manual referencing how to do it. You need a good A&P to work through all this in order step-by-step and set it up properly. Note that when properly set up, the engine will "burble" and sound like it's going to die after landing when your roll-out speed drops enough for the engine to reach idle speed of 750 RPM, although it will not die. To keep from scaring passengers, I leave the mixture out slightly which is proper for taxi and makes it idle better anyways. Requires training on a go-around to always push mixture, prop, then throttle. SID97-3G - Continuous Flow Fuel Injection Systems Adjustment Specs and Instructions.pdf Mooney Service Manual - Fuel System Sections - 10.18.22.pdf

-

I also use only half flaps for approaches. Much easier on the go-around. If you have full flaps out, trimmed for 80-90 KIAS or so, and firewall the throttle, the plane will very strongly pitch up, requiring a lot of force to keep the proper climb attitude. It's distracting to the pilot and concerning to passengers. If I break out in time, I'll add full flaps before landing, but landing with only the half flaps is a non-event on any runway I'm shooting an approach to. I also find the plane feels much more stable on the approach at 80-90KIAS with half flaps than full.

-

Favorite Post Flight Wipe Down/Bug Remover Product

Z W replied to RoundTwo's topic in General Mooney Talk

An A&P tipped me off to Davies Klear to Land. Works really well, takes off grease / soot / other residues also, and is designed to be used on windshields and leave a film. I start at one wingtip and walk around the plane, spraying it on all the leading edges and windshield. By the time I'm back where I started, the bugs are softened up enough to come off with a quick wipe of a clean rag. Maybe a little pricy but the big 19oz can seems to last a long time. https://www.aircraftspruce.com/catalog/cspages/dwdavies08-12390.php?clickkey=3172559 -

Been there, done that, just finished changing a tire (although I think it was someone else this time). Very easy to scrape all that rubber off trying to brake while the plane is still almost flying. I'm going to work on using forward slips when high or fast on final. A recommendation from my CFI at the MAPA clinic this April. Always avoided those due to the POH warning about doing them with full flaps. Apparently with half flaps they're just fine, and maybe with full flaps too. We did some and nothing bad happened. Speed brakes are not very effective at all below 100 KIAS, they get blanked out at high angles of attack. Not a good landing tool, although supposedly they start working when the nose wheel touches down and the angle of attack lowers again. I'm also getting more comfortable flying final at 70-75 KIAS, especially when solo and light weight with light winds. There's a lot of float left in my plane at those speeds. And it really solves the runway length problem. Thanks for sharing.