-

Posts

12,444 -

Joined

-

Days Won

107

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by jetdriven

-

JPI FuelScan 450 erratic: ISSUE RESOLVED

jetdriven replied to PeytonM's topic in General Mooney Talk

I have seen a few of these installed, and what does work on NPT threads is Permatex Aviation sealer. It is non-hardening, and it does dissolve in fuel so it doesn’t find its way to some critical component and cause problems. Teflon tape is a big offender in this regard, it somehow finds its way into a fuel injector or into a main bearing passage, starving or for oil for oil, or the vacuum pump causing failure, either way it’s gotten a few people killed. If it doesn’t get you the first time, then shreds of it remain behind after reassembly the second time and that’s when it gets you, but either way the stuff is a time bomb. -

Redoing my J interior (continuous thread)

jetdriven replied to Oldguy's topic in Modern Mooney Discussion

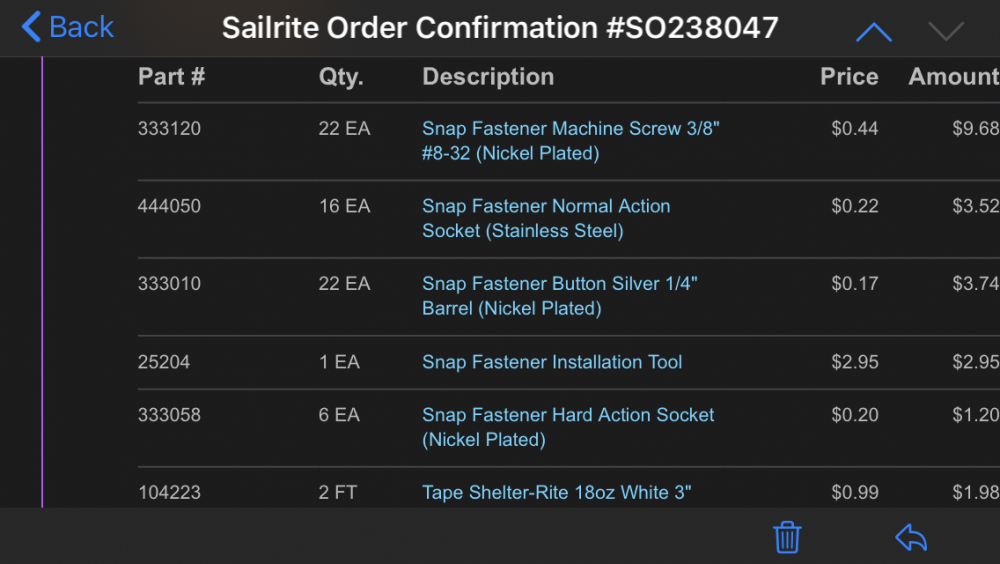

It’s easy, just drill through the floor, and if the drill bit snag something then shove a bunch of JB Weld in that hole and then drill in another place.;) seriously, doing it at the annual is easiest. But removing the belly panels doesnt take long. I put two at the rear edge of each strip of carpet so that is six that is forward of the spar. Then I have two snaps that hold the centerpiece, located just behind the nose well box. I’ve got 4 snaps underneath the front edge of the copilot seat and I think three on the Pilot side, and then one hard action snap between each rudder pedal. So you drill the holes from below. Poke a pick up through the hole through the carpet. Then install the snap in that hole. sailrite.com for the Snaps. I also stuck some reinforcing material on the back of the carpet to help hold the female snap on the carpet. The male snaps are screwed down with screws and nuts. -

Your aircraft should have two K—factors. One for the fuel flow into the servo, and one for the return line back to the tank. The number is engraved on the two fuel flow transducers.

-

New paint job... Before, during and after

jetdriven replied to Joe Larussa's topic in Modern Mooney Discussion

Looks great! Just needs some dead bugs on the windshield -

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

BDB8A271-1B46-409B-92A6-617AFEF25C79.MOV -

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

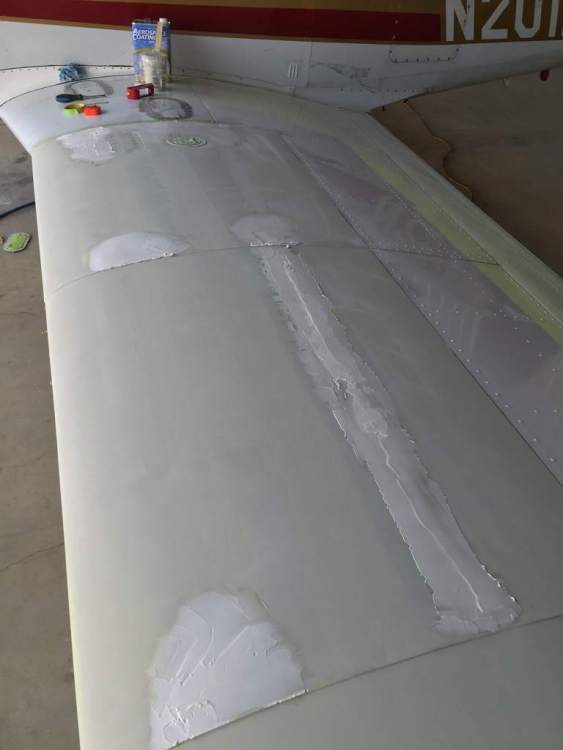

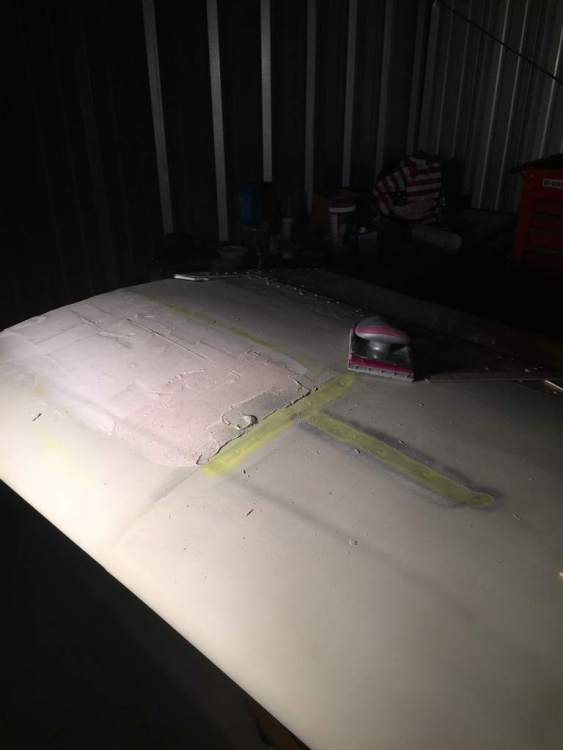

The skin was basically low over all of the stringers and it was very low over the spar. So instead of being the perfect shape that Al designed it’s kind of a series of high and low bands from front to back. The rivet dimples on the spar were .030” deep. The outboard wing skin was flat to the spar then kinked over it then flat behind it. We fixed all that. We use profilimeter to measure this, as long as the wing camber keeps getting flatter as you go back then the wing doesn’t have any low spots. Factory sprays something like Featherfill which is like Bondo out of a spray gun and they block it flat and paint it. But this is a cheap fast and not that really good way of doing this -

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

-

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

Minimal, 1kt maybe at the most. To get all the benefit you need to wet sand the wing and knock all the dust off of it so that it flows laminar. Right now it is not laminar at all. It’s ready, I just got to do it sometime -

The bladders in these airplanes are extremely thick and durable, it’s like 3/16 thick rubber. I don’t know if there’s anyway to quantify that if you crash the airplane and the wings get disassembled. You may possibly see less spillage. I do not think it would be more

-

Rolls Royce troubles do not end

jetdriven replied to Cargil48's topic in Miscellaneous Aviation Talk

The GE LEAP and Pratt Geared turbofan are also problematic. All of them had to come off the wing for major rework. -

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

I faired all of the ribs and stringer lines in the front half of the wing on my airplane. He probably used about a third of a gallon of a Epoxy and microballoons, which weighs about 5 pounds, and we sanded about 80%-90% of it off. And a gallon of Sherwin-Williams epoxy aircraft primer. So I would say there’s less than 5 pounds on the wings -

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

it would have ripped off in a similar manner. -

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

the Windecker Eagle, the first certified composite plane, is still airworthy and it flew in 1968. -

Shoulder belts need shortened. Any ideas?

jetdriven replied to 0TreeLemur's topic in Miscellaneous Aviation Talk

Sailboaters use something called a roping palm to force the heavy needle and strong thread through many layers of sailcloth. Sailrite has these. Also, boat canvas shops have the heavy duty machines to re-sew a seatbelt end. -

A full composite Mooney. Possible or not?

jetdriven replied to Cargil48's topic in General Mooney Talk

A steel truss covered by fabric (or aluminum) like this is prewar technology. The piper cub was built this way. So was the Meyers 200. Piper PA23. Not bad. Just obsolete design. But it is pretty tough. -

Safety wire or a test lead clipped to a long extension or a jack handle which is inserted into the gas can. Other end to the plane

-

I know for sure it’s in the 1977 M20J POH. Later versions deleted that note altogether. I thought it was in the Lycoming operators manual.

-

Later versions of the Lycoming operators manual says do not take off until the oil temperature is above 75°. That said, I like to see 250° CHT before I do the run-up and then after that, take off. Like John, I run the engine at 1200-1400 RPM on the ground. Multigrade oil helps greatly with cold starts. It pumps faster, and throws everywhere sooner since its pretty thin even when cold.

-

Not the 335 with GPS version. Garmin specifically sells this cash and carry.

-

Mooney M20F purchase....approaching Annual

jetdriven replied to Sheriff23's topic in General Mooney Talk

The plane we bought the annual was due in two months. We said well we would like you to do a fresh annual with sale or you can pay for it yourself next month. -

You can put the Tanis element on the top of the side of the oil pan. The heat makes it around to the oil. polygone will turn the rtv into goo that is easily removed

-

I get that part. What i dont get is the "in stock" note on the page, and after you buy it, it gets backordered and takes three weeks. Drop shipping is one thing, make to order by someone else is another.

-

It gets old when somebody tries to sell you something they don’t own. It says in stock, but after you hit buy it now or whatever then oh will get back with you with the shipping date and then three weeks pass

-

The 50W HID has 750k candlepower. That’s many multiples of what LED lights put out. Replace the Ballast for 110$ and roll on. lamps are cheap. Amazon.

-

I have a New red dragon. Email me. It’s on my profile