-

Posts

6,556 -

Joined

-

Last visited

-

Days Won

75

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by kortopates

-

Overhaul or IRAN on a mid-time engine?

kortopates replied to JamesMooney's topic in Vintage Mooneys (pre-J models)

If your planning to own in when the overhaul is required it makes little sense to overhaul now - but you really won't be able to fully decide till the engine has been torn down and fully inspected. Right now these are just good estimates. But at a 1000 hrs, IRAN is fine and depending what you do above the min you may get well past TBO hrs before it really needs an OH anyway. But if you do sell anytime soon after the IRAN, the IRAN cost won't have added to the resale value of the engine/plane - which is the only con IMO. -

Overhaul or IRAN on a mid-time engine?

kortopates replied to JamesMooney's topic in Vintage Mooneys (pre-J models)

Different Zero's, Zero time since major overhaul unless its rebuilt then zero time since new -

six gear collapses & gear ups in one week

kortopates replied to philiplane's topic in Mooney Safety & Accident Discussion

This thread has been quiet as of late, but not Mooney's having incindents. So far in March, we’ve had a C and a J gear up landing, plus a K model that "PRIOR TO LIFT, LOST ENGINE POWER AND SLID INTO THE MUD" - but no injuies in any of these. -

How long should it take to get a ferry permit?

kortopates replied to 0TreeLemur's topic in Miscellaneous Aviation Talk

These are special times due to the Pandemic. There is no telling since many FSDO are closed, you really need to know the status of the FSDO you're expecting to get a ferry permit from since you want to make sure there is someone to answer your request. The usual method of faxing a ferry permit may go unnoticed if no one is there. So you really want your mechanic to verify your contact information before sending blindly. Often we have choices between using a local FSDO or the one at our home base, and if one of those is open for business that's the one you'll be able to get fastest service. But typically it ranges between merely hours to a business day when the mechanic know whom to send it too and what documentation the inspector will be expecting. -

The best mixture guidance for both ROP and LOP is here: https://gami.com/gamijectors/AFMS - GAMIjectors Rev IR.pdf For TIT we don't like to see TIT being run continuously above 1600F and suggest 1600F as a cutoff to promote maximum exhaust component longevity. I personally target for 1580F max to give me a little buffer. Afterall Turbo OH's typically cost more than a couple cylinders and repacing thin or even cracked sections of exhaust gets expensive as well. Also whatch out for TIT probes that loose their accuracy over time. Both EGT and TIT probes suffer from tip erosion, literally from being torched by exhaust pulses. EVentually they'll become erratic and clearly signal a burnt out probe. But often they start to indicate progressively lower than actual before they become erattic so it good to periodically re-verify what peak really is - since its the degrees from Peak that important. Rocket Engineering even discusses a TIT probe calibration because they give mixture guidance on TIT temperature numbers. Personally I never thought that was good advice but all of the industry it seems, tries to over simply with simple proxies IMO without actually educating the pilot properly on how to manage their engines.

-

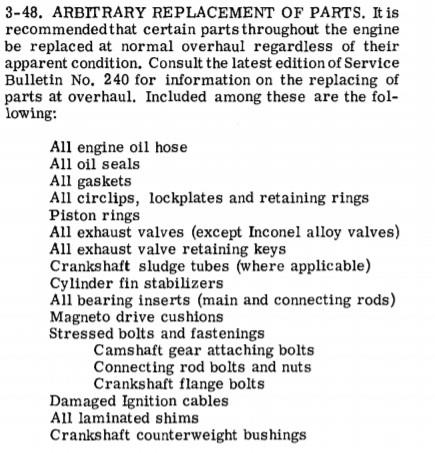

All agreeable points wrt to Service Bulletins. Sorry that it wasn't clear above as I'll add a couple more words to clarify the post above, but Mike is referring to all SB's referenced by the overhaul manual. You should find both Lycoming and TCM reference the list of mandatory replacement parts either directly by incorporating the text in the OH manual and/or by reference to the SB. Lycoming does exactly that in their 360 OH manual, notice both the list of parts and the reference to the latest version of their Mandatory Replacements parts SB 240: TCM does the same thing, here is an excerpt of a TCM OH manual, in this example they incorporated the text directly for the mandatory replacement parts and then referenced 2 additional SB's: 1-00-04 100% REPLACEMENT PARTS. It is recommended that the following parts be replaced 100 percent during the major overhaul of any Teledyne Continental Motor's aircraft engine regardless of conditions. Hydraulic Lifters Rubber Hoses Oil Seals Gaskets and Packings Circiips, Lock Plates & Retaining Rings Piston Rings Valve Keepers Bearings- Main and Rod Rubber Drive Bushings Exhaust Valves Piston Pins Rotocoils Needle Bearings Woodruff Keys Rocker Arm & Conn. Rod Bushings All Nuts - Self-locking Cotter Pins Pistons Springs - Oil Pressure Thrust Washers Generator Belts Spring - Starter Clutch Harnesses Oil Suction Screens with Small Openings Spark Plugs Washers - Locking Washers - Plain Exhaust Clamps, Turbo to Tailpipe Counterweight Bushings Intake Guide Seals If for any reason lifters are removed for inspection before the overhaul period has been reached, they must be placed back in the same location from which they were removed. CRANKCASES ALL MODELS Re-assembly with configuration as per Service Bulletin M76-10 and M83-10 Rev. 1 or current revision as applicable at the time major overhaul is recommended. I doubt you'll find any Lyc or TCM overhaul manual where the mandatory replacement parts SB isn't referenced in the OH in some fashion making it optional. Sorry though that the verbiage above implied any SB, I do agree that's a bit misleading and I'll add a few words to clarify that its any SB referenced in the OH manual rather than just any for part 91 operators.

-

Some of the new electronic/digitial tachs/RPM isntruments use resistor isolators to dampen the signal going into the unit - like the Electronics International R1 and MVP-50 - buts thats because they pick up their signal off the p-lead at the ignition switch. Replacing the Bendix Key ignition switch to the Electroaire switch isn't going to change anything providing its wired identically the way it was to the Bendix Switch - just moving wires to new switch. Unless I am missing something I don't see any reason why one would need to make changes just for swapping out the ignition switch. ---- unless you are referring to the initial install of the electronic ignition with it connecting to a digitial tach like the EI R1 or MVP-50 - in which case yes, the isolator resistor values are likely going to need changing but this depends entirely on which electronic ignition and which tach and its best to call technical support guys for your tach - but often it requires some experimenting if it is a Surefly ignition.

-

Absolutely, it comes from ICAO - https://www.icao.int/EURNAT/Pages/FAQ/faq_radio_licence.aspx But of course our FAA dropped the requirement many years ago for the US and other countries never ask for it. Of course I say only the FCC cares because they're the only ones that benefit from us purchasing. It certainy doesn't hurt to have them, I went many years without them on my second plane since nobody cared when I had them on my first plane. But you can also email or call your ports of entry to verify if your destinations are firm. One improvement though is I recall the FCC licenses are automated now on their website - no longer have to wait for months to get them in the mail - you just print them out. But the fees are still crazy.

-

Anyone Know a Source for Lycoming DLC Tappets?

kortopates replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Spruce is a distributor too. But I would google the part # and see if you might find someone with them in their inventory - if you need them now. But given engine rebuilds takes months, if its a few weeks wait or even a month, that's not uncommon right now. -

Yep the station license is expensive, but I don't know how many pilots actually buy the FAA licenses since no one in North America or Central America will ask you for them, at least not Canada, nor Bahamas nor Mexico nor CENAM. Been traveling beyond our borders for over 20 years now and I am convinced only the FCC cares and nobody else.

-

Same here in California, Airport FBO provide N numbers of all aircraft hangarded or in tie-down on a date in Jan (Jan 1st? - I forget) and the county's use that list to put us on their annual use/property tax bills. Plus, If they also see they didn't collect sales tax, then they'll inquire to see if sales tax is due too and collect with penalty's/interest if overdue. An LLC won't help in CA for taxes either, as Tom said above. It only really helps with sheltering you from liability from your partners. It used to be that when a private GA owner bought a plane as a CA resident that they could avoid sales tax by not bringing the plane into CA for a period of time as low as 3 months as long as the plane never flew over or into CA; but those exemptions are no longer. I was able to take advantage of that 20+ years ago - when I bought my second plane from a broker. Didn't know enough when I bought my first plane from a private owner. These days I think it's only possible for business owners to get an exemption but they may need to keep the plane out of CA for 6 months - plus when I last looked into it, it wasn't going to work to be a business owner in name only based on the way they set it up. But best to consult with an aviation tax consultant if interested.

-

Here it is SIM20-88A.pdf

-

What is your icing strategy?

kortopates replied to Scott Dennstaedt, PhD's topic in Miscellaneous Aviation Talk

I agree and am also a ABS member as well as a Bonanza instructor and have done a lot with Tom. I will say though that the Mooney PPP are exactly tailored after the ABS PPP's and even one of our PPP instructor has gone over to the Bonanza side trading his Mooney for an A36 - he outgrew his Mooney. Ditto for Mooney Caravan formation training stemming from the Boanaza progarm. I know we have a lot of other Bonanza pilots here as well and lots of Mooneyspacers that frequent the Beechtalk too. We have a lot in common. -

Mooney Safety Foundation Training

kortopates replied to Aviator's topic in Mooney Safety & Accident Discussion

The PPP in Santa Fe, NM next month on April 22-25 is looking to be a go as the directors are moving forward with it. It looks like its going to be a big one by the number of instructors, myself included. Shoud be fun! -

Thanks for identifying yourself as another A&P/IA, that's great as we get a lot of maintenance related questions here. I am as well, and an employed by Mike Buch of Savvy Aviation as well as an independent Flight Instructor. Mike wrote an article that addresses this topic head on, discussing differences in requirements from overhaul vs IRAN and more, that I'll quote a coupe paragraphs below. But the key point is to documents that something is “overhauled” the mechanic is required by regulation to follow manufacturers guidance to the letter, and that includes complying with manufacturers overhaul manual and mandatory parts replacement list (as referenced by the OH manual, either by referencing the SB or incorportating the text of the SB into the OH or both). Here are a couple of the pertinent points from Mike's article: Overhauled means disassembled, cleaned, inspected, repaired as necessary, reassembled, and tested in accordance with the manufacturer’s approved technical data—normally the overhaul manual as supplemented by service bulletins. The word overhaul implies conformance to service limits—not necessarily new limits—so if you want new limits you have to specify a new-limits overhaul. A new-limits overhaul is essentially the same as rebuilt, except that it doesn’t have to be performed by the original manufacturer and doesn’t receive a new serial number or a zero-time logbook. Repaired means inspected and repaired as necessary (IRAN) to restore the inoperative component to proper working condition. This term implies nothing about fits and limits, because there is no requirement to measure anything when performing a repair. One could, for example, remove a cylinder, replace a burned exhaust valve and guide, and then reinstall the cylinder without measuring anything, and call it a repair. A repair differs from an overhaul primarily in that there’s no obligation to follow the fits, limits, mandatory parts replacements, and other procedures in the manufacturer’s overhaul manual. The FAA’s late, great Bill O’Brien—who long served as the agency’s top maintenance guru—used to drive this point home to mechanics who attended his IA renewal seminars by using this catchphrase: “If you used a micrometer, then it’s an overhaul; if you didn’t, then it’s a repair.” ..... The words overhauled and rebuilt”are defined in FAR 43.2 and have specific regulatory meanings. If a mechanic documents that something is “overhauled” and hasn’t complied with every last jot and tittle of the overhaul manual and other manufacturer guidance (as referenced by the OH manual), he can lose his A&P certificate. However, if he documents that something is “repaired,” he can do as much or little as he sees fit to do—as long as he is satisfied that his repair work was performed properly in accordance with acceptable methods, techniques, and practices (e.g., typically the manufactureres Maintenace manual or AC 43.13.1b in the absence of manufactturer guidance) In short, if you ask for a repair, you give the mechanic or technician considerable discretion to do only as much work as he believes needs to be done—and that’s usually a good thing, assuming the mechanic is competent and you trust his judgment. On the other hand, if you ask for an “overhaul,” you eliminate the mechanic’s discretion and require him to do everything precisely by the book as required for an Overhaul. --------------------------- I added the text in italics above to clarify we're talking about guidance from the OH manual or maintenance manual and not just any arbittrary SB which are all optional for part 91 operators until being referenced by the OH manual and a OH is being performed making they mandatory. The full article is available here: https://www.aopa.org/news-and-media/all-news/2016/january/pilot/pe_maintenance - although it uses a Continental example, there is no difference between Lycoming and Continental. On a personal note, as you know this is the month to renew your IA, and I am actually getting mine signed off in the next hour. But I hope you can do the interiew process with a FSDO inspector in lieu of re-taking the exam! I know mine is very undertanding of these covid times and bending over beakcwards to help the 157 IA's in my FSDO renewing this month.

-

Its a Lycoming vs Continental thing, based on differences between Lycoming fuel injection and TCM fuel injection which a good portion of TCM fuel injection is controlled by the fuel pump in Continental engines, where Lycoming used a much simpler diaphram pumpTCM has never called on using the boost pump to change tanks (more on that later below). So sounds like your transition CFI didn't have much Continental experience. So I hope you still got a good understanding of the differences and intended uses of your Low Boost Pump, High Boost pump and your Prime pump which used to be a diverter valve to pump fuel into the induction tubes but should have been changed by a critical SB to pump fuel directly into the cylinder induction ports (via injectors). There is actually only one electric pump used for these activities with a voltage dropping resistor to give it 2 modes of high vs low, prime switch uses low and is now no different than low boost pump. Probably out of fear of libability concerns, but recently TCM has now adopted Lycoming's stance to recommend using the low boost when switching tanks. You'll only see this on the later models POH's for the Acclaim & Utras etc.

-

If its only an issue in Turbulence I wouldn't worry. I woud never use it turbulent air, the pilot can do a far better job than the AP. If it must be used in turblent air, then it should be used only in Pitch mode rather than altitude hold since the AP will stress the wings and tail far more than necessary. But mine will hold altitude within 20' in reasonably smooth air. Trim lock ups are a serious problem with an easy fix - see SB20-325 and SIM20-88A in the tech pubs section on www.Mooney.com The parts for the SI are not expensive nor is the labor to install it, this issue totalled a K model during landing not that long ago discussed here on MS too. On your #3, make sure the elevator trim rocker CB is always on before turning on master and avionics and that should fix the sonalert going on.

-

Vents with extended tanks

kortopates replied to FlyingDude's topic in Vintage Mooneys (pre-J models)

I recal some (3/8"?) aluminium tubing connects the vent outlet of the main tank to the extended tank top. And yes, in order to fill the extened tanks, which are higher than main tanks, you have to have the main tank fuel cap in place or the fuel added to the extended tank will drain out the main tank filler neck hole. But without the vent line connected to the extended tank it would just trap air at the top of the main tank and prevent fuel from occupying the top of the main tank outboard. Or to put it another way, when you're filling both tanks the vent in the main tank gets filled with fuel rather than air till the fuel level comes down to below the top of the main tank. Even with the vent line interconnecting the tanks if still not easily able to get all the air out of the main tanks to fill with fuel - it takes some time and some burping. -

Vents with extended tanks

kortopates replied to FlyingDude's topic in Vintage Mooneys (pre-J models)

No, that would be a problem, the vent is connected to the extended tank which is vented. -

Its not that its too old to weld that, but an exhaust welding/repair shop would replace the entire bend section from the existing seam. If the straight portion behind that was worn to thin, then they would also replace that section as well, and you might well have a completely new section of exhaust. But these repairs are generally always cheaper than buying new exhaust sections. If you have time to ship it out, I suggest sending some picture to Clinton here at http://www.customaircraft.com/ he would really need to see the rest of the exhaust to be sure, but I haven't seen any job he couldn't do and is one of the best in the industry. But he can't give you an 8130-3 back with it, so your A&P or IA would have to bless the end result.

-

My favorite ski resort had me descending in well below freezing temps, perhaps not frequently to -20C. Its been years since I replaced the springs the biggest benefit or most improvement came from replacing the conduit and the bearing on one brake. I do recall I had to buy some really long needle nose pliers, made for springs, to change out the speed brake springs though.

-

Yes the case must be split to change out the tappets, but splitting the case doesn't make it an overhaul. A major overhaul is a FAA legal defintion that requires replacing all the parts listed by Lycoming. Anything short of that is only an IRAN and doesn't reset the hours for TSMOH.

-

Any tips on switching out the Lord mounts

kortopates replied to Niko182's topic in General Mooney Talk

no, it’s not a lycoming, it won’t tilt. watch out for all the wiring - i disconnect it all first. Sent from my iPhone using Tapatalk -

you can get springs from Precise. I have replaced most everything in mine except for the bellows. Even the sealed bearing can be replaced - but a lot of work. Sent from my iPhone using Tapatalk