-

Posts

596 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by testwest

-

True for some products. But Dupli-Color self etching primer can be topcoated without an additional step.

-

I stripped the shelf and primed it with Dupli-color self etching primer. It works great and is a little healthier to spray and more durable than zinc chromate or zinc phosphate. It is a dark green color but that does not show up well in the photo.

-

Also for WAFI, back in the battery area, make sure the bonding area for the battery ground strap to avionics shelf is corrosion free. I had corrosion in this area which reduced my starting voltage to the starter (under the high current conditions accompanying) by nearly a volt. 201JX was always a lazy starter no matter how good the battery was. I cleaned the attach point on the shelf with a stainless steel bonding brush and treated the bare metal with an alodine pen to keep any further corrosion from happening. And the starter motor spins it up quite nicely now. Before: After: Hope this helps!

-

Landing gear indicator (on the floor) 78' M20J

testwest replied to Mooney13's topic in Modern Mooney Discussion

Marauder is correct, N201JX is a 77 with the fuel selector in the forward left foot well. It just had a small metal retainer over the plastic. The later models have a royalite (Kydex) cover that needs to be removed. I will say the window clean up and LED bulb replacement are well worth the effort! -

Landing gear indicator (on the floor) 78' M20J

testwest replied to Mooney13's topic in Modern Mooney Discussion

Aha, sorry about that! It's much easier to just pull the seats out to do this work. -

Landing gear indicator (on the floor) 78' M20J

testwest replied to Mooney13's topic in Modern Mooney Discussion

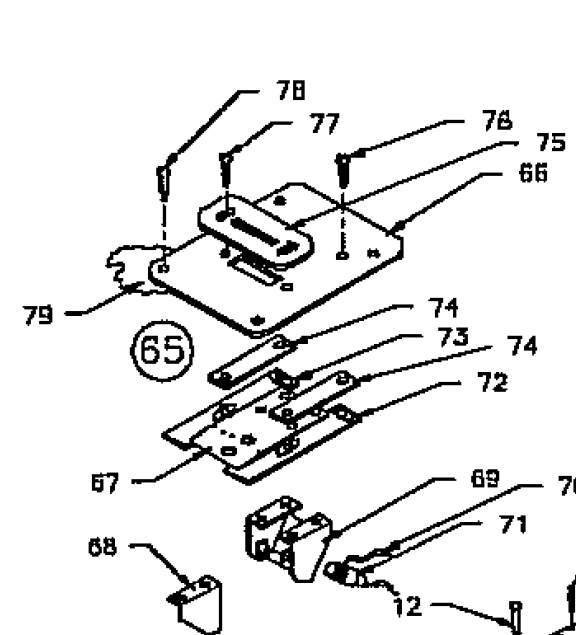

The plastic may be removed by removing the six screws from the indicator as shown here: This is from page 32-30-00 page 0 from the IPC. Remove the two screws #77 and four screws #78, but be careful to keep the shims and indicator slide in register. I did try using plastic polish initially just like 1980Mooney said, but the plastic was too far gone to polish out nicely. So the labor and cost to make a new one was a better choice personally. -

I sure do like the aesthetics of the installation. That was the primary motivation to be sure. And the tests have passed correctly each time I did them. It was interesting to see how the satellites picked up all the 406 information including the location and N-number after only about two sweeps which was a transmit time of a couple seconds. The 406test site had all the data. For me, that was a sufficient demonstration of RF performance. Sharp eyes will notice there are no antennas on this airplane forward of the baggage compartment. The accumulated drag reduction is noticeable, not so much for speed as for going the same speed on a little less fuel. A few little drag reduction mods do add up, even though they may not be individually discernible without an instrumented airplane and very stable atmospheric conditions. Again, I did have some people (not here) say that the under-dorsal installation would not work at all. Mooney's certified installations and my experience suggest otherwise! So, to directly answer the OP's original question: "have you added a 406 ELT to your plane", the answer is yes, yes I did! "And kept the antenna internal WITHOUT using the kit called out for in the service bulletin?" yes, to that too, and as a bonus the installation was signed off with no problems whatsoever, and the installation passes its operational and continued airworthiness tests. The pictures and cited SI show exactly how it was done and should be able to be duplicated by an A&P or even a motivated and sufficiently skilled owner-operator under A&P supervision. Note I did not build an angled doubler, just mounted the base to the skin and bent the antenna forward under the dorsal, it does come up vertically for a short bit before the bend.

-

We carefully weighed all of the old strobe/nav removed components versus the new LEDs. The weight savings and gain in useful load was 6 pounds, yes you read that correctly. I thought it would be a couple of pounds at best. Plus the new lights simply look cool.

-

I successfully did this very thing on N201JX and used SIM20-116 as the authority to do it. Tested the installed antenna for VSWR using the internal 406 ELT diagnostics and then ran the tests here: https://www.acrartex.com/406test/ . I ran about two sweeps as stipulated and the satellites reported back through the 406test system in under two minutes with good results, with the fairing clecoed back in place in case the tests did not work. Note the clecos were omitted in the area of the antenna so as not to corrupt the results. Of course with that caution the tests ran great! Anyone who says a 406 ELT won't work under a dorsal has no idea what they are talking about. Here is the dorsal removed and the detail of the ELT mounting hole. Note the diameter of the antenna base on the skin has been propped for electrical bonding and corrosion proofed with an Alodine pen. The ELT tested perfectly again under the new paint:

-

Speaking of useful load, N201JX shed about 80 lb as well, the UL is 990 lb now which is....well, it's useful!

-

Also very important, go ahead and replace the rubber hose couplers coming from your fuel tanks while the side panels are off. If they are original it is a big fuel leak waiting to happen. Mil-H-6000 hose, buy a foot of it from Aircraft Spruce for under $10: https://www.aircraftspruce.com/catalog/pnpages/6000-6.php Points if you cut the hose and install so the cure date shows to remind you when to replace it again:

-

I did the SEM Color Coat process on all the new interior panels on N201JX, they turned out great. Make SURE you follow the cleaning and prep process laid out by SEM exactly, don't skip steps or substitute materials.

-

Landing gear indicator (on the floor) 78' M20J

testwest replied to Mooney13's topic in Modern Mooney Discussion

I replaced that GE327 bulb with the Aerolites #330 in warm white on N201JX. I also replaced the clear plastic window as well (owner-produced part out of thin clear plexiglas the same thickness as the original)....and the visibility of the gear down placard is amazingly good now. Some labor but less than $20 in materials and is an easy owner-operator job. -

Hi everyone Up for sale is a red Whelen position light glass lens (dome) removed from a Twin Commander for upgrade. It has a small chip in the lens base, this is not visible when the lens is installed and resting on its gasket (Whelen p/n W1283, not included). Also needs a bit of scrubbing on the part that would be under the metal holder if you want. If you have ever dropped one of these you know what a significant emotional event it is. They are $89.95 each, new, from Aircraft Spruce. How about $29 for this one plus shipping. USPS Priority Flat Rate small box is $9.45 anywhere in the US. Paypal is good, thanks.

-

F391-53S Drain Valves for sale NOS - SOLD

testwest replied to testwest's topic in Avionics / Parts Classifieds

Sold! -

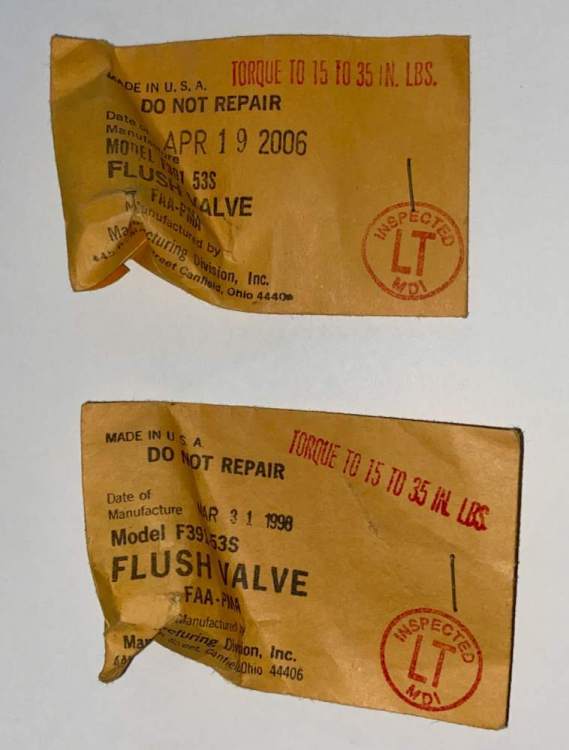

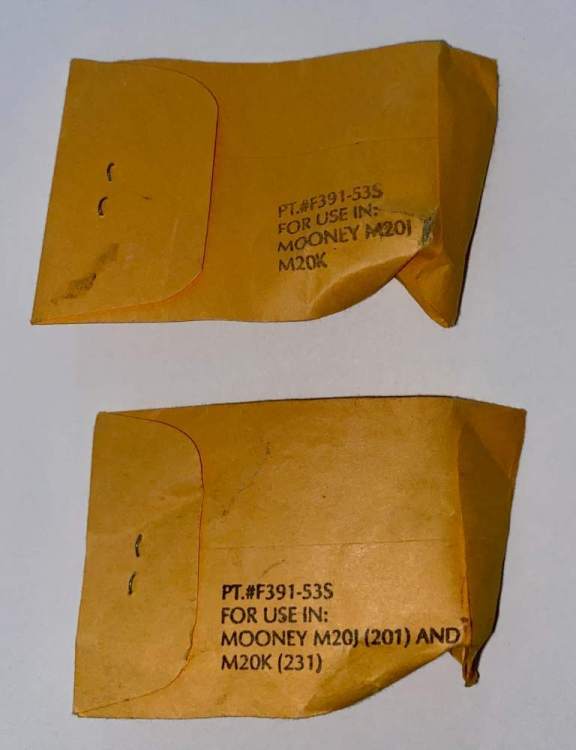

SOLD! Hi everyone Up for sale is a pair of MDI F391-53S fuel drain valves, new-old-stock in unopened packaging. These are about $34 each from Chief Aircraft, how about $25 for the pair plus shipping. Will likely use a USPS Priority Flat Rate Small Box, those are $9.45.

-

+1 for Clarence, I did that on our M20J, a new LED bulb and also fabricated a new little plexiglas window for the indicator. It is now highly visible even in daylight, while not being annoying at night.

-

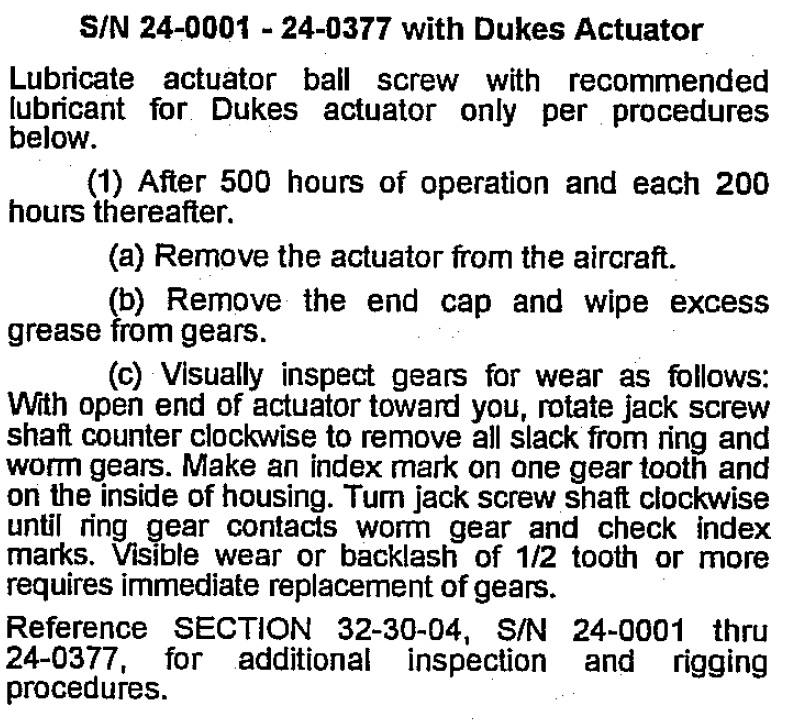

I had the same issue with our 1977 M20J and the Dukes 1057 actuator. It is very easy to shatter those old brush holders due to the epoxy on the caps. So folks are not pulling the brushes for inspection and they will eventually wear away completely, causing this: Luckily I was able to crank the gear down and land OK. After a LOT of research I was able to track down the original brush holder and brush manufacturers and had new engineering drawings created for these parts. There are minimum order quantities and so I went ahead and ordered to get N201JX back in the air. Kind of expensive but...... For 1977 M20J owners with serial numbers below 377, this may be interesting. The brushes, bearings, and wire necessary for the rebuild are all "standard parts" and would require no PMA or STC. The brush holders and caps are another story, for me personally they were "owner produced parts" and a "minor modification" (e.g. the method of safetying the brush caps). However, to have some of these parts available for others will require consultation with my local FAA MIDO. The threaded caps can be sealed on with tank sealant as others have suggested, but safety wiring the caps may be a better idea. That is still in work, as I said below. With the safety wire it will be very easy to inspect the brushes as an added part of the normal 200 hour inspection called out in the Mooney M20J Service Manual 5-20-06, Section 3, paragraph L: I would add: Inspect the gear actuator motor by removing the brush caps from the brush holders, remove and inspect the brushes. If the brushes are worn to a length of .25" or less (33% of original), replace the brushes. Now, that .25" (33%) is subject to review, I was balancing remaining wear versus spring tension in suggesting the criterion. Comments and suggestions welcome. Inspection and servicing of the gear motor bearings and commutator for the gear motor is not specifically addressed in the SM, but this level of work is outlined regarding the starter motor. So it should be doable by any A&P. LASAR used to send their Dukes gear motors to George's Electric in Sacramento for rebuild but he is closed down. Our 40:1 Dukes gears are still in great shape (proper maintenance, yay!) but replacing the unit with the $8500+ ITT actuator (if you can get it) versus rebuilding the electric motor and setting it up for continued easy inspection and service is kind of a no brainer.

-

Got 'em on our plane. Yes it seems like a lot of money. Aerotough material is not delrin or anything else off the shelf. A little research into the history and capability of Marsh Brothers Aviation will provide insight into this material. And the caps operate smoothly and easily like never before and like nothing else. These plus the MS25988/1 flourosilicone o-rings are a great improvement.

-

Mooney Summit VIII New Dates - October 22-24, 2021

testwest replied to Seth's topic in Mooney Summit

I still have my presentation in the hopper for the postponed Summit, I will be happy to present my talk this Fall. -

Mike I hope to see you at Sun n Fun this year!

-

How best to deal with malfunctioning vertical card compass

testwest replied to DXB's topic in General Mooney Talk

Seems I forgot to report on the results as I said I would earlier. Bottom line is I was able to get the VCC within 4 degrees or less on all 12 headings on the compass correction card. The interesting thing now is to watch it swing during an engine start. That #2 battery cable runs from left to right under the instrument panel to the starter contactor, then thru the firewall and back right to left along the engine mount to the starter. Lots of current, lots of steel, magnetar!! -

Nuke I hope this is one of the threads you looked at: https://mooneyspace.com/topic/36590-magnetic-compass-way-off/?tab=comments#comment-628292 It was my mounting bracket that was magnetized! I got my vertical card compass walked in finally, but it was much easier than before without that magnetized bracket. Still, if I get another failure I am going with the SIRS compass. The previous advice you received in this thread regarding that compass is well founded. Hope your PPL went well!

-

AFAIK all new Lycoming non-roller tappets come this way. See here https://www.lycoming.com/parts/tappets Lycoming spent a fortune developing the roller tappets and wants you to buy them, but roller tappets are 100% replace at overhaul. DLC tappets came later for the older engines, but they are so good it would knock down the market for the rollers. So Lycoming upgrades factory overhauled engines automatically to rollers, and really does not push the DLC at all. The layout of the web page above is testament to that, even with the DLC tappet pictured at the bottom of the page, there is still a roller pictured next to it. Having said that, the rollers do cut down rotational losses in these engines significantly, so much so that the cam grind had to be made a little “lazier” to make sure the engine did not make more than its rated power to a reasonable statistical probability.

-

OK, the coating you are looking for is called DLC, or diamond-like-carbon. Lycoming already offers this coating on their non-roller tappets, and it stops tappet spalling dead cold in its tracks. CMI, I don't think they do it yet but Ly-Con was working on an STC for the Continental tappets. I am amazed the knowledge of this process has not spread more widely among the GA community. Ly-Con says this problem is completely solved. They have a set of Lycoming DLC tappets now on their third TBO cycle in a traffic watch airplane and they still pass new limits criteria.