-

Posts

1,164 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Greg Ellis

-

These photos are work from AWM. The first two are my muffler inside and out with the loss of the flame tubes inside. The last two are the very nice work I got back from AWM. They also redid all the exhaust parts including the down tubes etc... DOn't have photos of those.

-

New Mooney owner thanks you all

Greg Ellis replied to Philip S's topic in Vintage Mooneys (pre-J models)

-

AWM did my exhaust last year and did a really nice job. Not sure about the prices because I had nothing to compare it to but they did really nice work.

-

Garmin GFC 500 Autopilot Flight Overview

Greg Ellis replied to Rmag's topic in Avionics/Panel Discussion

If what you are talking about is what I have circled in red then I think that is his compass deviation card taped to the side of his compass. I don't think it is electronic. It is taped over giving it a reflective quality but not electronic. -

305 Rocket & Oshkosh...

Greg Ellis replied to Austin305Rocket's topic in Mooney Safety & Accident Discussion

Very cool. Get to see the "new" plane. Awesome. -

305 Rocket & Oshkosh...

Greg Ellis replied to Austin305Rocket's topic in Mooney Safety & Accident Discussion

Well, I am taking the course in San Marcos this year. I am looking forward to it and flying into Oshkosh with the Caravan. I was supposed to do the clinic last year then Covid hit. I was also part of the Caravan XIII (The Phantom Caravan) during the 2010 Shloshkosh that was so wet and rainy the Caravan could not get in. -

305 Rocket & Oshkosh...

Greg Ellis replied to Austin305Rocket's topic in Mooney Safety & Accident Discussion

If you are considering the Caravan and have not done the formation clinic then you need to do that first before flying in the caravan. There is one in San Marcos, Tx the weekend of May14-16th. Go to www.mooneycaravan.com. It looks like the clinic in San Marcos has some spots left. -

Just for curiosity sake. In the photo that I attached, it looks like the area circled in red has been bent somehow allowing it not to seat flush and there seems to be a crack in the skin (area circled in blue) that possibly has been stop drilled at some point. Is that accurate or am I looking at the photo wrong?

-

I don't think anyone here will fault you for good, sound aeronautical decision making. With your three reasons given, any one of those would be satisfactory for me to cancel the flight. I think you are making a good decision.

-

Ok, what airplane WOULD you trade your Mooney for?

Greg Ellis replied to 201er's topic in General Mooney Talk

I think the kicker for me in this poll is the you have to pay all the expenses part of the poll. I really like the Piper M600. But I don't want anything to do with the expenses of inspections and maintenance on a turbo prop. So that wipes out all turbo props for me and really anything with a jet engine. I have heard of the number of zeros needed on the check to maintain these things and just can't do it. I have also seen first hand the fuel bill for a Premier Jet and that would wipe out any chance of flying again for months. So I think I would stick with my beloved Mooney product and maybe move up to an Acclaim Ultra which to me are just awesome. -

Ok, what airplane WOULD you trade your Mooney for?

Greg Ellis replied to 201er's topic in General Mooney Talk

I recall Bill Wheat talking about the Mooney twin. He flew it and said it flew like a dream. I would expect nothing less from a Mooney product though. -

There are two nice looking E-models for sale on controller.com and 4 available on trade-a-plane.com. Two places to get you started. You may also want to enquire with gmaxamericanaircraft.com and see what they may have. Let them know what you are looking for and see what they can do for you.

-

This could be possibly something to use. It is through the FAA. I think it is free unlike blocking at the user level on Flightaware which costs a minimum of $600/yr. LADD (faa.gov) They go through the requests monthly on the 1st Thursday of each month. So depending on when you submit your request, it could take a month to see it go into effect. A quote from the website: FAA Source With the FAA source option, your aircraft data is limited to FAA use only. No FAA flight data will be available to external vendors. If you are considering limiting data at FAA Source, FAA flight data on your aircraft will not be available to internet web sites.

-

-

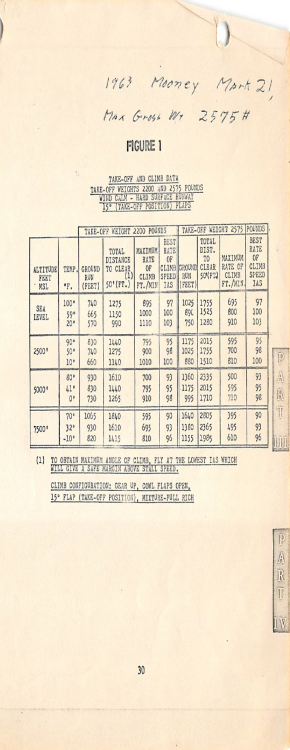

I have the takeoff data for my 1963 C model that is in the Airplane Flight Manual. It has data for 5000' and 7500' for takeoff and climb. I have also flown out of a couple of airports that were above 5000' as well. What is it that you are looking for?

-

Value in 2021 - M20C out of annual

Greg Ellis replied to Stephen Slate's topic in Vintage Mooneys (pre-J models)

Nothing in this reply tells me that you are dealing with an owner who loves his airplane. It sounds more like a guy who cannot afford the airplane now, or never could afford it, or circumstances changed where he cannot take care of it. This is not someone who loves this airplane. Someone who loves the plane would either do what it takes to keep the airplane in good condition (in annual, etc...) or sell it before it became "dirty and stinky with disaster lurking...." not someone that would fly with reckless abandon and fly out of annual etc... I may be wrong, never having met the owner, but it sounds like someone who just liked the idea of telling people..."yeah, I own a plane...." With other airplanes available that have been loved and cared for, I am not sure I would proceed with this one. As many have stated you will spend a fortune getting this airplane up to the point where you want it to be. Your pocketbook better be ready to handle the outlay of expenses it will take to get this plane up to par. You can take all that money and buy an airplane that is turnkey and ready to go. -

I have the POH for 1964 310. It does not specify the actual model (A, B, C....) Would that help or not? Its PDF format.

-

I replaced an O-ring and gained 10 knots!!!

Greg Ellis replied to SpamPilot's topic in General Mooney Talk

Something like this online calculator works well also....Takes the math out of it for you....unless you just like math. True Airspeed Calculator VIA GPS (csgnetwork.com) -

Fuel capacity/useable fuel in an F

Greg Ellis replied to warrenehc's topic in Vintage Mooneys (pre-J models)

Not to hijack this thread but 48 lbs of unusable fuel for certain K models? That is roughly 8 gals of unusable fuel? Seems like a lot. Nice to see that my little old C model only has about 1/2 gal of unusable fuel (3.4 lbs). -

@carusoamWhat do you do for a living? I want to create a post where you end your response with "As a matter of fact I am a ......" So far we have a nice long list of what you are not.

-

We all make a bad landing now and then ...

Greg Ellis replied to LANCECASPER's topic in General Mooney Talk

I saw this video posted elsewhere and the comment for it was "Should have pulled the chute" -

If you are flying into Destin, Florida and have not reviewed this Activities, Courses, Seminars & Webinars - ALC_Content - FAA - FAASTeam - FAASafety.gov Then you may want to. It explains the airspace around there and the proper way to navigate it especially if VFR. There are corridors that you must fly in order to get into Destin if VFR.

-

M20C elevator trim rolling forward in flight

Greg Ellis replied to dk580's topic in Vintage Mooneys (pre-J models)

I seem to recall a story told to me by the late, may he rest in peace, Bill Wheat during a Mooney fly-in about 15 years ago. He talked about a time when they loosened up the tail on an A model, I believe, to the point where it was just basically flopping around. When he flew it, he said it flew just as stable as it did when the tail was tight with no mobility. He was the most interesting Mooney guy to talk to. -

Glad I cancelled my flight...

Greg Ellis replied to Greg Ellis's topic in Miscellaneous Aviation Talk

Well, thanks for asking but not very well. He is a chihuahua. Lost function of his left hind leg. Chihuahua's are notorious for knee problems. We have one other that has had 3 surgeries on his hind legs for the equivalent of a torn ACL in a human and luxated patellas. Well, we thought that may be what was happening to this guy but no luck. He has cancer of the sacrum that is impinging on his sciatic nerve which caused the loss of function in his hind leg. Apparently we can put the dog through all kinds of grueling treatments including chemotherapy and radiation but it will only prolong the inevitable and make the dog miserable. So we have decided to enjoy the time we have with him while he is still happy and feeling ok. He is getting along on 3 legs quite well but eventually we will lose him. The one that had the three surgeries is running around wonderfully like nothing ever happened. In the photo, the dog on the left is the one that had the three knee surgeries and the dog on the right is the one with the recent cancer diagnosis. Great dogs both of them. They both love to fly with me and both run out to the end of the wing tip when we park and greet the linemen at the FBO's. Sad day indeed.

.thumb.jpg.ebbdc6804f65dbea99d3aab2e5d36700.jpg)