-

Posts

185 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Bob Weber

-

I can help you with this, I don't believe you have servo issues. There are some tests and questions that may help you, 616 822 1999 8am-8pm eastern time Bob Weber Autopilot consulting webairconsulting.com

-

A/P disconnect for Century 21 / M20K ?

Bob Weber replied to NicoN's topic in Modern Mooney Discussion

Yes it does, there is a service bulletin out about it. Give a call if you would like 616 822 1999 -

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

Replacing the fitting on the back of an ATT gyro is most certainly legal for an A/P to accomplish, just not disassembling an instrument. They cannot do that legally without maint man, ratings, and equipment. End of discussion. -

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

Perhaps a great first step would be to peruse the maintenance manual of a common altimeter, say a United Instruments 5934. -

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

Pretty sure there is language in there to follow manufacturers maintenance manual procedures, meaning you need the manufacturers maintenance manual. You may also read in that manual about the clean room that may be required. -

M20J Electric Clock ground wire

Bob Weber replied to allenawilson's topic in Modern Mooney Discussion

I can't recall mooneys, but others have an old school fuse holder close to the battery just for the clock. -

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

It's right here... Know it, love it, bla bla bla. Glad I'm retired!!! Bla Bla Bla.pdf -

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

"Popping" the front off an altimeter involves the Kollsman adjust mechanism, effecting the calibration. I would bet there was a ring of crap around the perimeter as well, that's decomposed gasket. An old crotchety inspector I have the utmost respect for had a saying I have always heard in my head "Folks, these are not lawn chairs we are working on here." There are far less critical areas to assist with, we have to keep in mind you are depending on these systems with your life and those with you. -

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

The feds I dealt with for the last four decades, thru countless restorations, repairs, and upgrades, would not turn a blind eye on opening flight instruments. In fact , I feel they're worse today than when I began by far. I never tore into an airspeed indicator, but I did open many altimeters and various other instruments. I worked in a shop with the appropriate ratings, manuals, and parts. My work was signed off by the instrument inspector as I did not have that rating. I had an airspeed fail on me (a bug), in VFR thank God, not the best of fun. I get a bit skittish when I see things like this. -

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

You might also keep in mind that opening those instruments renders them unairworthy until recertified and an 8130-3 is provided, legally speaking. Your mechanic is opening himself up to liability and a violation if he signs off that inspection knowing the elf was there, unless he has an instrument shop and the appropriate ratings. I speak up because this is an IFR aircraft(I assume), and you are talking about opening up arguably one of the most critical instruments in it. -

Matt I would be happy to give a quick rundown on operation, I talk faster than I type. Give a call 616 822 1999 8am-8pm eastern. Bob Weber Autopilot Consultant WebairConsulting.com

-

Panel Maintenance Question

Bob Weber replied to CharlesHuddleston's topic in Modern Mooney Discussion

Removing the airspeed indicator will be a blast for the elf, the glareshield will need to be removed to gain access to the connector and nut on the back of that post light. I doubt you want to dig deep enough into the panel to get it far enough aft to even see the nut much less get a wrench on it. Hopefully your elf has a pitot static test set to check for leaks in the instruments and the systems once it's reassembled. In an unpressurized aircraft, the static system is far less critical than the pitot system, I would be more concerned with the seals of the instruments myself. Bob Weber WebairConsulting.com -

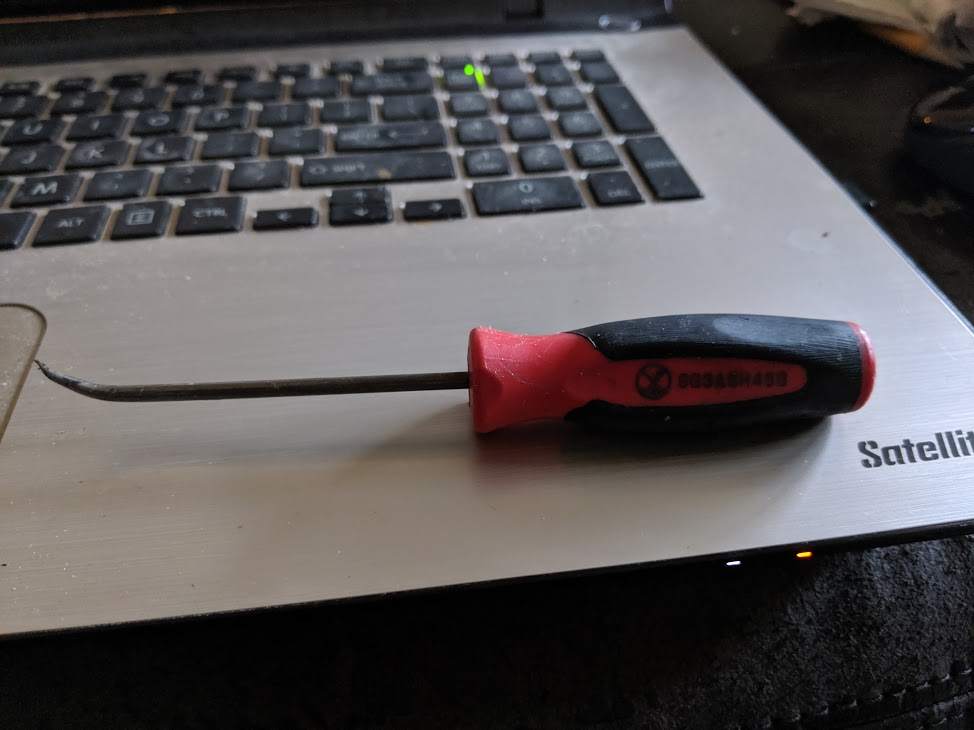

1 more for Jake, if you see engage voltage wiggle the connector while the system is engaged and watch for the solenoid to engage. Century Flight Systems has had a bulletin out for the little blue connectors for a long time, they told us about them when I was training there in 1989. My favorite weapon is a 45° snap on pick, slightly flatten one half of the socket to create more tension.

-

Jack I can give you some good insight, give a call if you would like 616 822 1999

-

I can't say I've heard this before, could there be a leak in the supply line to the TKS panel? Jake at Bevan will be the best place to send the servo. I can help with any questions about the autopilot, 616 822 1999. Bob Weber webairconsulting.com

-

I would go Garmin if available for your aircraft, the servo technology is far superior. I always preach the end game, what do you want to end up with for your dream panel. In today's world your entire avionics suite is software driven, one glitch in an update for one component of the suite can and will ground you. When mixing multiple manufacturers equipment, you now have the challenge of compatibility. I would go Garmin from top to bottom, if there is a glitch, it's their glitch. WebairConsulting.com 616 822 1999

-

Check and rebond all the engine to airframe grounds. You are describing a whine, not a tick, leave the ignition leads and plugs alone. I have a real good story about a Baron project, I built a radio package in it while the engine shop overhauled both engines. Lots of whine when we flew it. Mechanics were convinced it had to be my work because that's where we were hearing the problem. It turned out to be a finger tight bolt on one of the ground straps of the left engine, and I found it! Noise can weaken the strongest of knees, let me know if I can help you. WebairConsulting.com 616 822 1999

-

static drain for Instruments SI 20-43

Bob Weber replied to jamesm's topic in Vintage Mooneys (pre-J models)

James I can give you some good advice with this, a better understanding of the two systems and the connection between the two goes a long way. I would begin by obtaining an accurate diagram of them, and any modifications need to be assessed. Single, or additional static system for the G5's, this should be documented by the installer and included in the paperwork package required to be provided to you. Trivia question: what altitude change would be seen when opening the static drain in flight? Bob Weber WebairConsulting.com 616 822 1999 -

That is the switch that is marked slave/free in Cessna installations. You will see the slaving meter react when it is actuated. Give a call if you would like, I have been working with these systems for a long time and can offer some insight. Bob Weber WebairConsulting.com 616 822 1999

-

I can help you with this. WebairConsulting.com 616 822 1999

-

The KC 290 and the KC 192 are two completely different animals. There is around a quarter mile of wiring and many switches and connections that must function properly to keep either of these systems engaged. When the lever fails in the KC 290, it generally will not latch due to the failure of the tangs holding the iron plate on the cheesy lever. Rarely, if ever, would it be intermittent. Bob Weber WebairConsulting.com 616 822 1999

-

Earlier versions of the KFC 200 had no audible disengage alert, The -01 KC 290 brought the option later on. Bob Weber WebairConsulting.com

-

Mark I'm very familiar with that system, I've installed many of them. I can probably get you up to speed with a phone call. WebairConsulting.com 616 822 1999

-

I have not seen many failures of the engage latch assembly. I would be more interested in the wiring and switches in the yoke. I can help guide your mechanic thru troubleshooting this. WebairConsulting.com 616 822 1999