-

Posts

185 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Bob Weber

-

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Nope, but both airframes deal with a jack screw, as well as just about every other airframe out there. Wear happens, those that have learned to recognize and react are who I want to be around. -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Alaskan airlines ring a bell? I have lived this and guided multiple people thru dealing with this on several different manufacturers of aircraft. I would love to see your experience and data to back up this claim..... -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

I've watched some of the finest pilots manage a malfunctioning aircraft, justifying some pretty crazy "approaches" to "manage" a malfunction. It's the little things you should be paying attention to. A 30 or 40 year old aircraft will have "new and improved" problems, we need to focus towards this concept... And react accordingly. Fly Safe and Healthy Bob Weber Autopilot Consulting webairconsulting.com -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

As an aging airframe wears, we find different effects of this wear. Every airframe I flew always settled into a pitch attitude other than neutral if you were to measure it with an inclineometer. The point here is that the trim tab will always deflect to put the aircraft in a balanced pitch attitude to fly level. Over the years/hours of flying in this configuration, wear occurs on the pressure side of the threads of the jack screw creating a considerable disparity of friction between adjusting for nose up trim vs nose down trim in the range of flight neutral, with a wind load on the tab. Being immersed in autoflight for so many years I found myself dissecting even the most subtle of command errors out of "my stuff" and realized this disparity becomes much more important as it progresses. Thankfully, with Mooney's, we use a chain and sprockets to tie into the trim system instead of "V"belt technology, but we do move the entire empennage rather than a little tab.. We still have to balance the friction of the trim system with the clutch setting of the servo. In flight, at cruise speed, hand adjust the trim a bit up, and a bit down. If it feels pretty much the same you are probably fine, if not, look a little closer. The challenges and responsibilities of maintaining an aged aircraft... -

After takeoff in an old T210 from 17 out of GRR I was right seat and not running the radios against what I always insisted on. I heard the chatter of an approaching aircraft on 26L just before I heard the instruction to make a 180° turn to the left and contact departure. I looked at the pilot as well as out to the east and told him not to turn. delayed responses from both of us resulted it the controller yelling at us for not turning quick enough. The call was made and the controller walked off the job. Situational awareness... Today we have amazing amounts of information available, begging to be managed safely. Fly Safe, Bob Weber webairconsulting.com

-

Replacing these should be elementary as indicated above. I would be more concerned about where the loss occurred. If they failed when removed or reinstalled, and not "lost", replacement should be routine. It's when they're lost and floating around the belly of an aircraft among components that don't react well with things like this.. These are one of the most common things I found while cleaning bellies, I was a stickler for "debris free under the floor" and often presented the client with a bag of such that "people behind me" had missed during their work. The older and more sloppy maintained aircraft can get pretty scary when dug real deep into. Fly Safe Bob Weber webairconsulting.com

-

Glass fiber insulation replacement

Bob Weber replied to emilpemil's topic in Modern Mooney Discussion

During a big project I was involved in at Weststar Aviation a few years ago, they offered "Super Soundproofing". The theory was to change the resonant frequency in the areas of the skin of the aircraft that spans any structure. I remember minimal weight increase, and enough of a result that the C441's for sale today still boast the upgrade. There are strict burn test requirements that would be insane not to follow as well. Fly Safe Bob Weber webairconsulting.com -

Elevator Trim C/B trapped - any idea?

Bob Weber replied to NicoN's topic in Modern Mooney Discussion

There is an alloyed metal "spring" sized and alloyed to heat and release, over the decades this spring will lose tension. The biggest culprit I have seen over the years to cause this was corrosion and arc slag causing a resistance across the contacts which then becomes a little heating element. Under normal conditions, for a surprising length of time, the system will function correctly until the long term Annealing process reduces the over center friction as stated above. Not only is this working against us, but it also reduces the temp needed to trip the breaker causing it to trip at a lower current.. I'm working on an article for the Mooney Flyer trying to cover things like this, watch for it "The challenges and responsibilities of maintaining an aged aircraft". The most neglected component The one "component" of an aging aircraft, and arguably the most critical, is the wiring harness, it acts as the central nervous system of your aircraft. Our "new and improved problems" reach new levels with this component. There are multiple fronts of battle with maintaining and troubleshooting it as well. Fly Safe Bob Weber webairconsulting.com -

Elevator Trim C/B trapped - any idea?

Bob Weber replied to NicoN's topic in Modern Mooney Discussion

Castellated nuts, designed primarily to have a cotter pin installed to lock it. https://www.albanycountyfasteners.com/Brass-Castle-Nuts-p/129000-002.htm -

Nav light on - autopilot shutoff problem

Bob Weber replied to JohnB's topic in Avionics/Panel Discussion

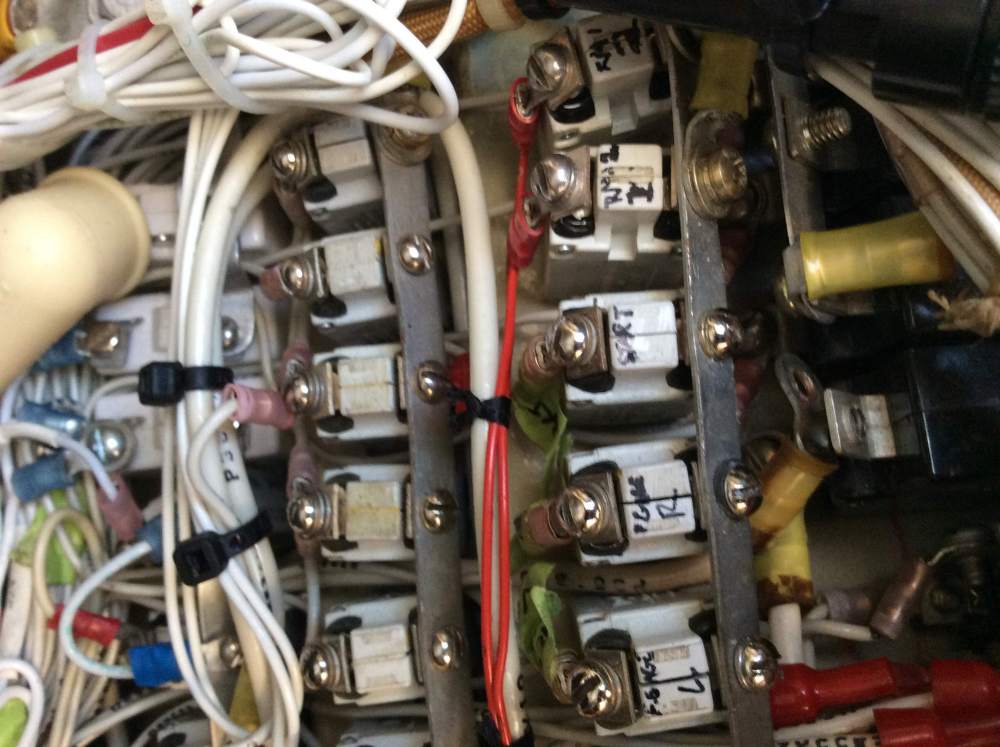

The screw was more visible in another shot, it was lodged a row below and close to the buss. It was located within an hour or two of the initial evaluation call, from Australia... Bob Weber Autopilot Consulting webairconsulting.com -

Nav light on - autopilot shutoff problem

Bob Weber replied to JohnB's topic in Avionics/Panel Discussion

Each of these types of problems have their unique causes, I call them "new and improved". I doubt we will find anything this severe with this issue, but we can locate it with a voltmeter quicker than a checkbook. Cheaper too! How much was that disconnect switch? Did anyone troubleshoot, or just shotgun parts? Bob Weber Autopilot consulting webairconsulting.com -

Nav light on - autopilot shutoff problem

Bob Weber replied to JohnB's topic in Avionics/Panel Discussion

-

Nav light on - autopilot shutoff problem

Bob Weber replied to JohnB's topic in Avionics/Panel Discussion

I have dealt with multiple issues like this. Bob Weber Autopilot Consulting webairconsulting.com -

Options for removing the Vacuum Pump w/ KAP 150

Bob Weber replied to MisfitSELF's topic in General Mooney Talk

I believe that interface allows for both. I'm certain about the approaches, and have flown many KFC 150/Aspen upgrades that flew very well in the ALT preselect capture mode. The beauty of this upgrade is to in fact, eliminate the very costly KAS 297/ KEA 130 components. The thing I noticed, was how crisp the system would fly when everything was working properly. Pilots would remark how it was flying the ALT modes differently, I would tell them it is finally flying them accurately! Bob Weber webairconsulting.com -

On the way back to Grand Junction from Moab during a certification flight for a shiny new KNS 80 installation I did in a T210, I noticed the gear trailing when I made my last enroute check at a railroad tunnel. I immediately looked and saw the gear handle in the up position, and the gear breaker was out. I questioned the pilot and he just started resetting the breaker. I told him to stop and pulled the POH out. I pumped like crazy until the mains looked right but the nose in the mirror couldn't be verified. As we approached GJT, we were instructed to do a low, slow flyby down the main runway's taxiway to verify that nosegear. By this time all of the Weststar aviation personnel were on the ramp waiting for the show. I was talking to the mechanic with the hand held when he verified the nosegear looked good just as the pilot cranked that aircraft into a steep climbing turn, gear out, flaps on approach, going slow into terrain that climbed thousands of feet above us. He said "hey they were looking for a show" I never flew with him again, he was fired later for lighting off a King Air with all the plugs still in it.

-

I used to fly with a grumpy older than me pilot that would scold me when I waved my three fingers at the gear lights multiple times prior to touchdown, he claimed it was a waste of time.

-

I got to watch a Lady put a Navajo on the ground gear up, she even bumped the starter on one of the engines hoping to minimize damage. I shook her hand. Thankfully I have never been involved with an unintentional gear up landing, I can only imagine surprised realization.. I did however experience the the long anticipation, and unknown outcome of a nosegear failure in a C310, after scuffing up two centerline stripes, and minimal damage, the owner pilot told me he wants me there if this ever happens again.. The pitot tube resides in my office today!

-

The challenges and responsibilities of flying an aged aircraft.. Stay tuned. Phil this is going to be fun! webairconsulting.com

-

Like many of my tools, it is nearly worn out from dancing. Still accurate though.

-

OK I could not help myself. Every bit of knowledge I attempt to share comes with a tongue in cheek smile. Here is a near forty year old stripper on an expensive pole.

-

The stripper is probably close to 40 years old, it was all I could do to not bring a pole into this conversation...

-

I found it best to not drop them, I pride myself to wear out tools by using them rather than abusing them. Those tools are well over ten and twenty years old.

-

-

-

I would do a solder splice as I have outlined earlier and call it good. Crimp it if you want..