-

Posts

185 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Bob Weber

-

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

The terminal and screw on that 15 amp breaker looks discolored as though it had gotten hot. Was it the one that was loose? -

KFC 150 Wiring Schematic for Long Body

Bob Weber replied to alextstone's topic in Avionics/Panel Discussion

I think I can get a copy of the installation manual. What does it do when it fails, light flashing, sonalert beeping? I can help you and your shop with this and save you time and money with both troubleshooting and any repair's. webairconsulting.com -

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

Imagine the cost of that if you just started sending boxes out for repair. We were able to find this problem and correct it with minimal time and materials. -

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

Good Eye! It took several pictures before I was able to spot it, that can be a pretty overwhelming area to inspect and make sense of. I was able to help my Client spot it, from 9,200 miles away! Look at the insulator on the terminal of the white wire, it is discolored from heat as well. -

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

Welcome to the Hall of Flame! I would wager that connection contributed, at least in a small part, to the demise of the motor. A loose connection drops voltage just as a resistor, a motor draws more current when ran on lower voltage. The bright side here is an LED replacement!(no pun intended) -

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

Who can spot the missing screw? Much of what is in this area will not react very well to a loose screw... -

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

The last 3 or 4 inches of that wire got hot enough to anneal the copper as well as the terminal end, the breaker components, and even the terminal on the other connected wire. I recommended they replace all of it. -

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

Funny you should notice the color, It has been baking for a while due to a loose connection. You are not missing anything, good eye! We need to be watching for all forms of these issues with older aircraft. -

The hidden world of aircraft wiring

Bob Weber replied to Bob Weber's topic in Avionics/Panel Discussion

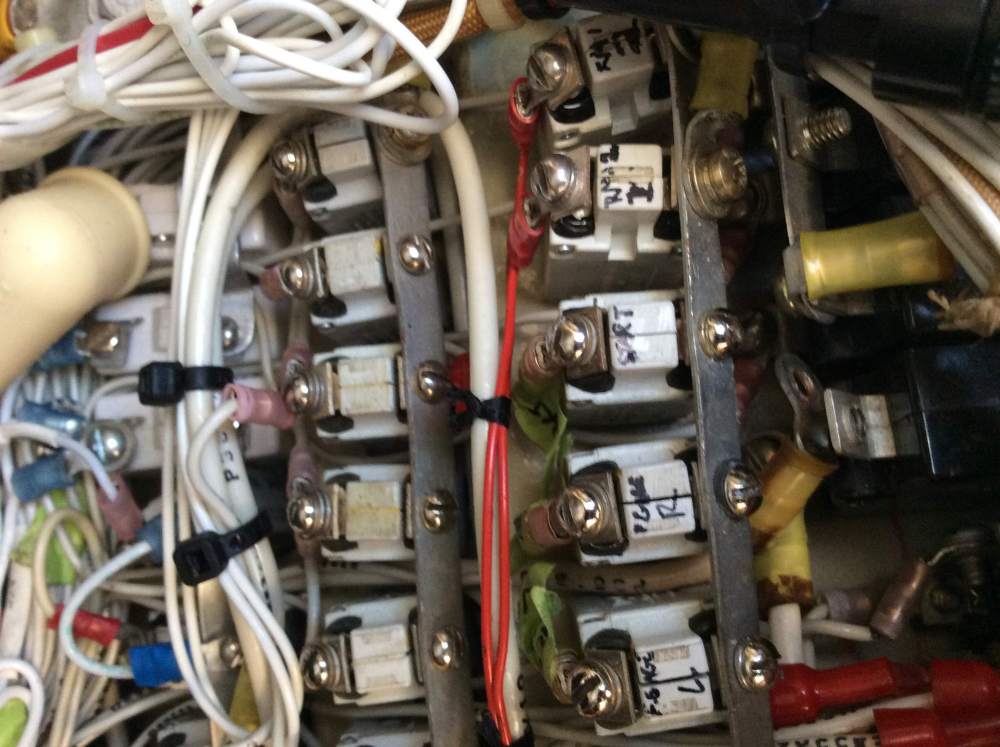

Just above and to the left of that big black tyrap is a loose ring terminal carrying the power to the avionics buss, or sort of carrying the power. Notice the discolored terminal and wire? -

Is there an avionics guy on here who can tell me why?

Bob Weber replied to Oldguy's topic in Avionics/Panel Discussion

I just started another thread, put some of these on there, show the coaxes that went to that antenna. Thank you for sharing these! -

I've started this one in an attempt to bring more awareness and understanding about arguably the most critical component of an aircraft. Your wiring. Also to minimize my hijack of another thread. This was a project I took on earlier this year, an autotrim issue causing a pretty good porpoise on autopilot. During a ground check over the phone, we detected and located this in less than an hour. My client was aware of the symptom, but had not recognized the severity of the situation. In this case the avionics would intermittently not power up when the avionics master breaker switch was flipped on. I told him we needed to begin there, I preach a simple rule, when you see a bug, stomp on it. Here is the bug we found, I hope to have everyone show a picture of the wiring maladies they have spent time and money on. Once we stomped on this bug, his autopilot problem was gone..

-

Is there an avionics guy on here who can tell me why?

Bob Weber replied to Oldguy's topic in Avionics/Panel Discussion

I'm trying to imagine what kind of antenna was mounted there, skywatch? Above the cabin? -

Is there an avionics guy on here who can tell me why?

Bob Weber replied to Oldguy's topic in Avionics/Panel Discussion

This is a 340A breaker panel, look middle right hand side at the loose ring terminal. That is the feed line to the avionics buss. On a routine ground check over the phone we were going thru the power up stage, when he hit the avionics master he hesitated and then said "it does this from time to time". I told him to power down and guided him to this in less than an hour, in Australia. He routinely flew in the soup with his family. I recommended he replace the heat damaged section of wire, and the breaker switch. I was amazed how well a high res picture can put my eyes half way around the world in near real time. look for the missing screw, things in this area of your aircraft do not react well with loose screws. Another thing to pay attention to is a few of the screw heads on the other breakers are discolored, check each screw for tight. We started this project looking for an autotrim induced pitch issue. I got to hear my favorite thing to hear, "It fly's better than ever now" Mate! Bob Weber webairconsulting.com -

Is there an avionics guy on here who can tell me why?

Bob Weber replied to Oldguy's topic in Avionics/Panel Discussion

All of the above comes to mind here, capped off with the unlabeled fuse holders indiscriminately tied up under there. Coming from a history of complete wire/rewire down to adding an aux power jack, as well as a much larger dose of troubleshooting and repair, I offer the following: I always pulled as much wire, connectors, fuses, etc... Every time, if I could, my rule to anyone was "if you can do it in 15 minutes, do it. Here is the rational, If we trim the unused harnesses as far as reasonably practical when we are deep in the panel during any upgrade, trim it,cap it with shrink. During the next inspection, generally the other ends are exposed and can receive the same treatment. Then when you deep dive into the interior (or what ever reason), much of the remainder is accessible. I've found clipping several era's of tyraps and removing the unused wiring can reveal some other potential issues as well. Know this from personal experience, be very careful with every wire you cut, I just helped a shop work thru this lesson.. A great deal of how I help people is with the aging harnesses, when a box fails, often times it is caused by something outside of it. The easier the wiring is to navigate, the easier, and cheaper, the aircraft is to maintain. I'm starting a new thread, Post some "up panel", and "exposed panel" shots of your aircraft. -

I have a few questions first, but I think I can help you. Those systems were a bit of a challenge when they were young, the same issues exist, as well as a few new and improved ones. I was factory trained on the 2000 in 1989 and have battled them down to the component level ever since, there is much to that system besides the computer. When they are working properly, they are a wonderful system, when the aren't, they can be a handful. In a ten minute call, I can tell you for sure if I can help you. Bob Weber webairconsulting.com 616 822 1999

-

I routinely used a green tag form soaked in IPA. Today I preach Stabilant 22, I will be trying the hundred dollar bill and report back!

-

When tuned to a localizer, the system is tracking a single, distinct, radio beam(forget the GS at this point). When tuned to a VOR, the system now needs to "resolve" which of the 360 radio beams to track. Unless the radio knows what radial to track, it will drop a flag. May I assume the HSI is a KI 525A? By all means try to swap the radios and check it, I'm curious what you will find with this one. Do you have NAV/GPS switching to that HSI, maybe an old MD 41?

-

It amazes me how hard it is to save people money, the first guy was beating me up for more info rather than listening to how to fix things. I helped the 310 guy with the switch in a 15 minute call, now he will have a system working better. More importantly, the extra hour he was gladly willing to spend brought him my "pocket full of tools".

-

WOW I just spoke with one person about the switch and received a call from another that offered more.. SOLD to the guy with a 310! it turns out it is an unused new old stock part.

-

I believe the King P/N is 031-0326-00, it would change (I think) to 031-00326-0000 in honeywell numbers. You may want to take a seat before asking the cost... Bob Weber webairconsulting.com 616 822 1999

-

I have a used one I can test, $100 + shipping if it looks good. Bob Weber webairconsulting.com 616 822 1999

-

The rigging should be checked as well, The Mooney's I've worked on have a bellcrank and a push/pull tube for the servo, if the Heim joints are worn they could be contributing to the issue. I always used a variable power supply and monitor voltage and current for the test. Slowly increase the voltage until the motor "breaks over", both directions. Record the readings, then run it for 30 minutes at full voltage (printed on the side of the motor) both directions. Recheck the break over. I've found at least 1/2 of the motors failed this test. The motors I used to build would break over at around 850mV drawing less than 250mA. Anything less than 1.5v and under 300mA after the burn in (full voltage runs), should perform correctly. That computer's threshold adjust is set around there, and, depending on the computer, is adjustable in flight. Once we get it back on rails, I would fly it in HDG, at cruise, with feet on the floor, and hands on your lap, for several minutes. We want to look critically for wings level flight, if it holds a wing low, indicating a skid, put a toe on the low wing peddle until it holds the wings level. At this point, check where the ball is, this is where it needs to be. I can't recall positively, but I don't think that aircraft has rudder trim, if it has a bendable trim tab, I would set it to hold it level in cruise. When an autopilot flies in even a slight skid, the computer is commanding the servo, the servo runs until stalled to hold the wing low. This can cook both the motor and the drive transistors, quite often shortening their lives.

-

SG3ASH45B Snap On part number for the probe. Stabilant 22 by all means on the connections. A health check of the servo motor should be done as well. Give a call if you would like, visit WebairConsulting.com then call 616 822 1999

-

I can get you the part number of the pick in the pic if you would like. What kind of oscillations are you seeing?

-

10 minutes with a volt meter and me on the phone