-

Posts

185 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Bob Weber

-

There are several things to check here that will narrow down the search. The install in your Ovation should have a small "B" nut for the static connection just above the copilots left toe. Does this failure act the same as leaving the trim master off? Give me a call if you would like 616 822 1999, and we can put this issue in the rear view mirror quickly. A couple pictures of your instrument panel with pilots yoke could tell me something, an hour or two guiding you or your maintenance shop with a volt meter will determine the likely culprit. Bob Weber Autopilot consultant webairconsulting.com

-

KAP/KFC 150 installation differences?

Bob Weber replied to Oldguy's topic in Avionics/Panel Discussion

Now... you can probably do it just for sport... I love this attitude, it reminds me of times decades ago. If memory serves, the KFC 150 has more ALT preselect functions with some of the new glass than the KFC 200. -

Thanks so much for the kind recommendation. Multiple thoughts and questions come to mind here, a quick ground check may reveal the deficiency. I'm sure we should be able to make quick work of this, if interested you can reach me at 616 822 1999. I can be available after 4pm eastern today, if that works, for a preliminary call to get more info and set up a ground check appointment. Let me know if I can help.

-

If you know your way around a voltmeter, I can help you troubleshoot this over the phone. I also work with shops that need a little guidance if your not comfortable yourself. 616 822 1999 Bob Weber Autopilot Consulting WebairConsulting.com

-

Glowing Hot Wire and Intermittent Panel Power Loss

Bob Weber replied to apenney's topic in Avionics/Panel Discussion

-

Glowing Hot Wire and Intermittent Panel Power Loss

Bob Weber replied to apenney's topic in Avionics/Panel Discussion

I helped a guy in Australia a year or so ago with the same issue 616 822 1999. We will need more information. -

Could you email a pic to bobweber@webairconsulting.com the bar on top is intriguing, sounds like a Century switch. You can also call me at 616 822 1999

-

Rebond the NAV antennas. Inspect the coax, probably RG 58. I generally found the "diplexer" for a blade or "towel bar" array in the tail. We would then use a splitter behind the panel to feed the NAV/GS inputs. I can guide you here if you would like 616 822 1999

-

I can fix this.. 616 822 1999. I will be available late afternoon Thursday if it works for you.

-

Did a 1980 M20K have an electrical trim?

Bob Weber replied to NicoN's topic in Modern Mooney Discussion

What roll autopilot does the 60PSS compliment. It was installed with options and sounds like you need some guidance to understand what you have. I installed scores of them tied into several different roll systems. Give a call 616 822 1999 -

Lance Thank You! I saw this earlier. This is a good example of "stepping into" a final dream suite. I look at an avionics package as three separate systems that are critically reliant on each other. Navigation/Communication, Flight instrumentation, and ultimately, Autoflight. The marriage of the final suite should be very much in mind. It can be made more difficult to continue a "peaceful" marriage with multiple manufacturers software. I would look toward two GI 275's, GFC 600, and run that 430W to feed them until upgraded as a final step. This being said, I can make that system 50 work again, an evaluation will give us an idea of the cost. The Aspen is a formidable piece that should have good value on the used market, and will make a good trade in toward the 275's. I will be available tomorrow before 11am if you would like to get some preliminary questions out of the way. Bob Weber 616 822 1999 8am-8pm eastern webairconsulting.com

-

Yep, give me a quick call, 616 822 1999 "I'm glad if I can help with a question or two, or perhaps some advice. If it gets more involved, you can decide to proceed at that time." An excerpt from my website... You have a simple issue, I guide people thru the easy ones in hopes they remember me when they encounter the hard ones! Bob Weber webairconsulting.com

-

If both the HDG bug and CDI track off the same direction, you are a good candidate for a simple roll centering adjust. Has something changed recently? Bob Weber Autopilot consultant webairconsulting.com

-

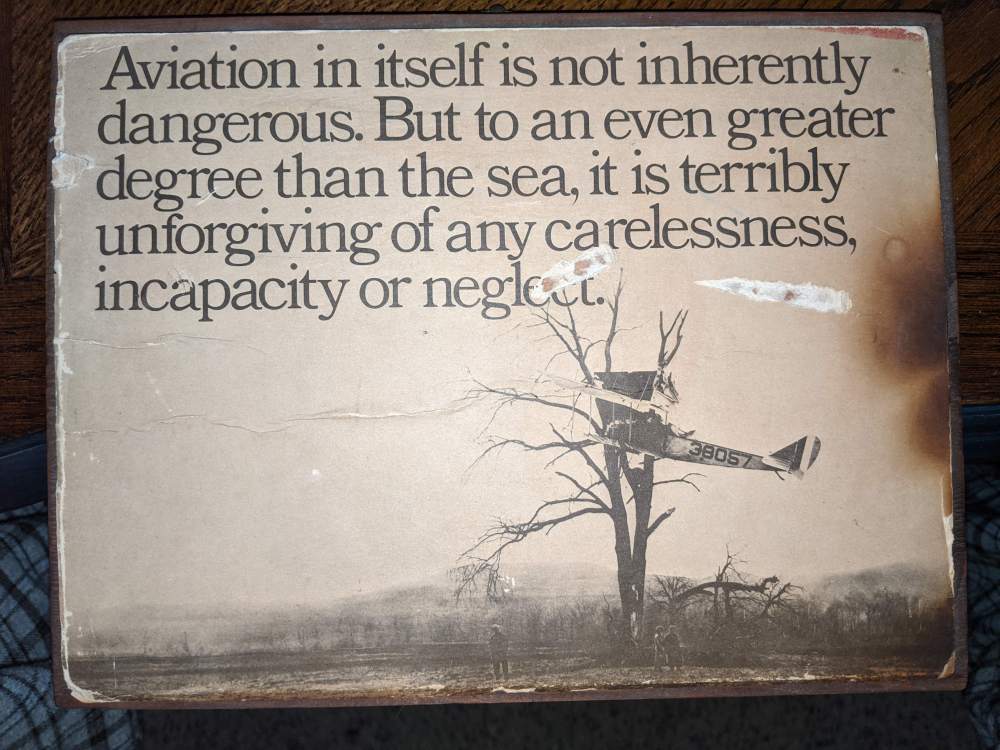

While the beatings occurred during training, the concept of the running engine and swinging prop guided me to never step even near the arc reach of a prop, it is always spinning.... We all could use an extra step or two of exercise, never ever think of walking thru where that prop can get you. It will save you a ding on the melon as well. This coming from a guy with the diamond shaped injury from a certain old Cessna flap... Bob Weber webairconsulting.com

-

Never, ever, treat an aircraft as though it is not running. This was beaten into me by multiple people much of my formidable years. An old, very worn out and abused little plaque with about 50 years of history in my family. It sits prominently above my desk today.

-

Paul I am very familiar with both the autopilot as well as the airframe, give a call if you would like 616 822 1999. 8am-8pm Michigan time. Autopilot Consultant webairconsulting.com

-

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Any anomaly in an aircraft needs to be attended to, quickly and correctly. Many of them are worthy of AOG until they are resolved. It is amazing the effect of seeing just how small of pieces an aircraft shreds into when it hits the ground after you have lived in and around them most of your life.. Especially multiple times, when there was an acquaintance, Friend, or work mate, lost. Fly Safe and Healthy Bob Weber webairconsulting.com -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

We need to be replacing the loose rod ends and be very sparingly on the dripping lube, it gathers dirt and grit that tends to accelerate wear. My biggest desire here is to get folks thinking about, and addressing, many issues we are now finding in older aircraft. I just spoke earlier today with a long time Colleague that found another elevator cable failing in a single Cessna. frayed and cut.. Waiting on pics, trying to determine the cause. Fly Safe and Healthy Bob Weber webairconsulting.com -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

I kept my boat in Holland right next to Heinz vinegar plant for a few years, you could smell it. The long time residents talked of pickles floating everywhere. Becoming aware and assertive in the early 1970's, I followed as the waterways were reported and then mitigated.. The Ohio river on fire was a pivotal sight. Today we get to celebrate the amazing reclamation of our waterways, just in our area alone, Muskegon Lake is being transformed from heavy industry to tourism and entertainment. These changes are having an enormously positive effect on all of our lakes as well as communities. After all we do have more shoreline than many.. We are really chomping at the bit, our launch and slip is 1/4 of a mile from us but can't touch.. Soon. "to internal combustion and wind in the face" -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Marie is well known in Freemont, Gerber was huge there. -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Back a few decades I suppose now, I read an FAA report of a Mooney crash. It was observed that the trim was at the stop, don't recall which one, but the determination was that it happened during the crash as the airframe exploded. Later theories were floated about runaway trim as the original cause. This was around the time an acquaintance/fellow Pilot died in a Seneca out in Utah running checks for the banks if memory serves, CIII runaway trim. The left wing and empennage departed the aircraft before it hit the ground. Much thought was put into continuing with these bleeping autopilots and having so many souls to feel responsible for when I received this news. I was not involved with the repairs or maintenance of the aircraft at the time, but had nightmares about what the guy that did must have been going thru. I chose to persevere with the notion of education, the more I can educate people, about the how and why, as well the why not, the safer we all will be. Fly Safe and Healthy Bob Weber webairconsulting.com -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Perhaps when we look a bit deeper into what caused this incident, we may have expanded insight on the problems we are facing today. -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

110 polo road, Graduated 1977. Jim Andre was my instructor. The "big D" was where I began to explore RC and became brutally aware of density altitude. My first research was at around 700' msl. A very close friend was well on his way to 80 days at sunlight this year until they closed it, that place and Aspen pretty much destroyed my wrists! Look up Skinny ridge Grand Junction, yet another source of chronic pain.. Far happier lookin at the lake than the mountain... -

How Touchy is your Trim Wheel?

Bob Weber replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

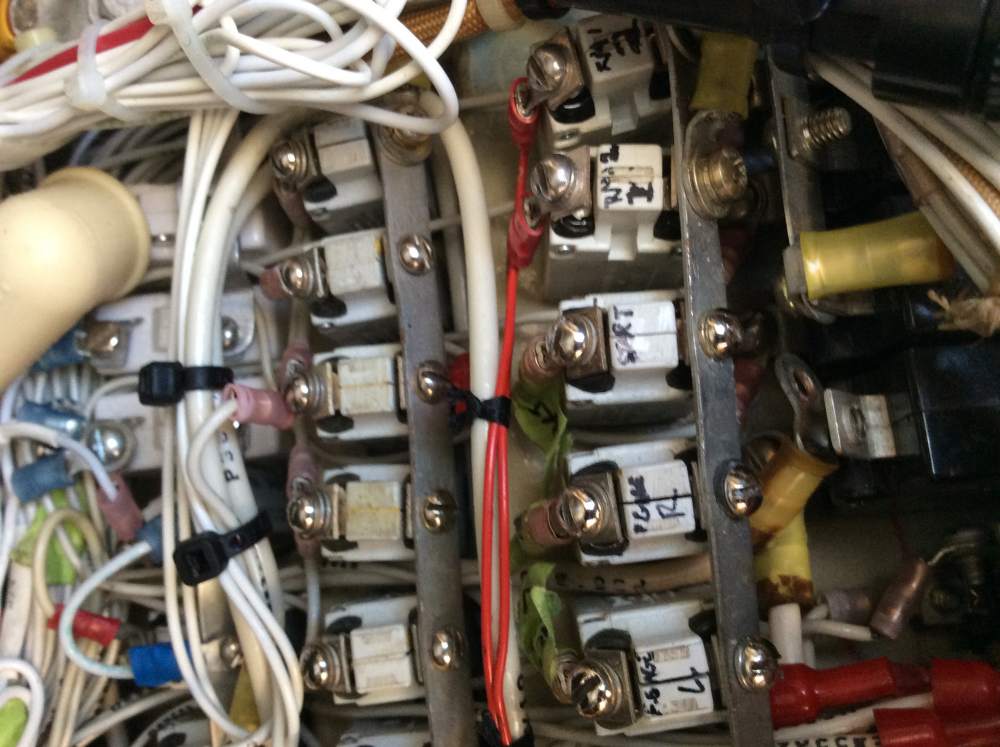

My autopilots have been a passion for 40 years, learning the different airframes and idiosyncrasies of them, though a challenge, I developed an understanding of the balance that must be achieved between an airframe, an autopilot design, and the pilot. The balance between the autopilot and the airframe has become the greater challenge lately due to age. During my racing days(the reason they will not let me anywhere near an aircraft engine), I preached blueprinting. Put it back the way the engineers designed it, as I'm still saying today. You are flying a 40 year old aircraft, with your family, in the bumpy soup. I Love old things, we just have to understand and respect them. I started flying models in my front yard at the age of 7, my first lesson was flying out of Glenwood Springs CO in 1975 and spent the rest of the time flying broken aircraft for troubleshooting and about a million cert. flights beginning with KN 74's. I still learn with every experience, anyone steeped in this stuff knows this as a life... Your really going to be mad when I bring up the wiring harness, the central nervous system.