-

Posts

9,514 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

Panel Planning with G3X...what would you do differently?

PT20J replied to KSMooniac's topic in Avionics/Panel Discussion

Nice glare shield lights! What did you use? -

My understanding is that the auto manufacturers got the EPA to mandate a minimum standard. Then they came up with Top Tier that gave gasoline suppliers an opportunity to market a more expensive (and higher margin) product that exceeded minimums.

-

I've got an ACK E-04 installed by the previous owner. It seems to be solid. I would check the cost of replacement batteries when comparing ELTs.

-

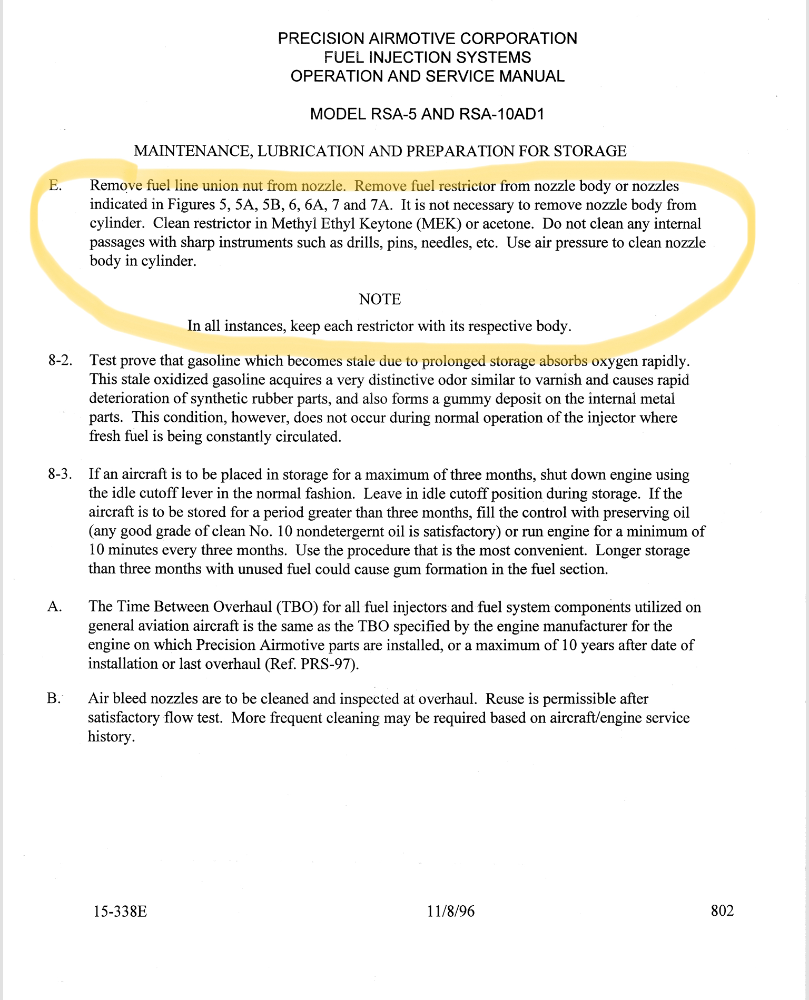

I use Hoppes #9 also. But it is interesting that apparently Lycoming is the only one that recommends it. It's not mentioned by Precision or Avstar in their service literature. I think Hoppes may be recommended because it removes lead deposits (it's a firearm cleaner) but I'm not sure, and I don't know if any lead will precipitate out of the TEL in avgas. The MSDS lists ammonium yydroxide as a component and that chemical will attack brass. One A&P at the Lycoming factory class said she left some injectors in Hoppes for an extended time (over a weekend? Don't remember) and it damaged them. I believe others have not seen this issue. I do note that the Lycoming SI says to only soak in Hoppes for 20 min whereas it says to soak in MEK or acetone for an hour. It also says to rinse with Stoddard solvent after soaking in Hoppes. Skip

-

If you want to minimize the chance of contamination, you can follow the RSA manual and just clean the restrictors.

-

Gasoline oxidizes when exposed to air and forms deposits. Remember back when cars had carburetors and we had to get the carburetor overhauled every so often? You would take it all apart and soak it in carburetor cleaner which would remove all the deposits. Because the deposits formed a yellowish coating on the aluminum parts, and because old fashioned wood varnishes yellowed with age, people got to calling these deposits varnish. When auto makers ditched carburetors for fuel injection, there were problems with injectors clogging and automakers lobbied the EPA to mandate minimum detergent standards for auto gas. I don't know what if any detergent is in avgas, but I'm pretty sure it is way less than auto gas. Skip

-

Parker’s suggestion for a low-cost bead breaker. Also easier if you spray the bead/wheel area with soapy water.

-

By the way, the BA-189-139 door seal specified in the IPC was the original and is thin rubber with a foam core. The foam compresses and loses elasticity and the thin covering tears. It is obsolete and the T-9088 is the replacement.

-

Floor light or annunciator panel light? The annunciator panel light dims when the nav lights are on. If it dims otherwise, there is likely a problem with the annunciator panel rather than the light bulb. The floor light should always be bright unless it's burned out.

-

The document you want is the schematic for your airplane which is part 2 of the service manual. The only way that a normally operating emergency gear extension system will blow a breaker is if you engage the handle fully and then try to operate the gear. The engagement will prevent the motor from turning which will cause the Gear Actuator breaker to pop -- not the Gear Control breaker. The Gear Control circuit supplies power through the various switches to the gear up and gear down relays which in turn operate the motor. So, the only load on this circuit is the relay coils. Assuming the wiring is sound, the usual suspect would be a gear relay or the flyback diode across the coil. However, since you experienced the problem during both extension and retraction, it is unlikely a relay because it would be improbable for both to fail simultaneously. So, it would have to be something common to both circuits, and probably the most likely component is the circuit breaker. Circuit breakers are pretty reliable. However, they really should be manually exercised occasionally or oxidation can build up in the contacts which can cause internal heating and lower their trip point. I exercise all mine once or twice every annual. If it were my airplane, I'd exercise the breaker a few times and see if it repeats before doing any additional troubleshooting. Skip

-

Mooney uses a Brown Aircraft T-9088 P seal. https://www.brownaircraft.com/aircraft-door-seals-s/59.htm Pull the old seal off the door. Scrape any remaining seal off with a plastic scraper. Use 3M General Purpose Adhesive Cleaner in the spray can to soak the old glue. Let it sit awhile to soften then use a rag to rub it off. Takes a lot of repetition and elbow grease especially if someone used too much glue before. Glue it back on with 3M yellow super weatherstrip and gasket adhesive applied to both surfaces and assembled when tacky. It will allow repositioning for a few minutes if you need to adjust the seal position. After application, close the door and let it sit overnight. It will seem tight at first, but the seal will eventually mold itself into the shape of the space between the frame and the door. The trickiest part is positioning the seal correctly. The center of the round part of the seal should lay on the door rivet line, NOT in the radius of the door edge. The bottom edge is tricky because the frame and door radii don't exactly match. I took out the right front seat and laid down inside so I could see along the bottom edge and closed the door without the seal in place and marked where the frame hits the door with a sharpie and then placed the seal outside that line so it would be compressed between the door and the frame. Skip

-

Most avionics should be on the avionics bus so that they are not powered during starting. The voltage drop during start can put a strain on power supplies. I would have the intercom checked to find out why it is squealing. A battery will appear to be good until it gets so worn out that it won't run the starter. But, the battery loses capacity long before it gets to that point. If you have older avionics, they will draw quite a bit of power and that means that if the charging system fails you might only have a few minutes of battery power available with a diminished battery. This is something to seriously consider if you fly IFR. The only way to know the condition of the battery is to have a capacity test done. Skip

-

I'm betting that there is something wrong with the power supply in the audio panel that causes the squeal at low voltage. A radio shop should be able to bench test it with a variable power supply. Also, how old is the battery? I would have it capacity tested if it's more than a couple of years old.

-

How does the bushing get lubricated? I wonder if the wear was due to a lack of lubrication. It takes a lot of grease every year to get grease to flow out of the bushings. I believe the steering horn is hollow. Somehow, the grease has to get through the bushing to lubricate the pin.

-

I presume that @PMcClure is referring to damage caused by exceeding the turn limit that could damage the stops and dent a tube on the nosewheel gear leg. https://www.mooney.com/wp-content/uploads/2020/12/SIM20-137.pdf Skip

-

You completely missed my point. I never mentioned who should pay for anything. That's entirely beside the point. I simply said that I would take it back to the shop that worked on it. They are in the best position to review what was done and why there is a problem. And, in solving the problem, they will learn something that they can apply perhaps in the future. That's how maintainers become experienced.

-

Glad it worked. Next time though, it's safer to use a NPT thread chaser to clean up threads.

-

That’s pretty much been my experience.

-

A drop or two of fuel might drip out after shutdown and you could get some blue dye stains when it evaporates. Frankly, I’ve never worried about it.

-

The injector nozzle bodies are brass and shouldn't gall. The bodies use a 1/8" NPT tapered pipe thread and the exact number of threads engaged will vary. The attached reference suggests a 1/4" engagement. I wouldn't worry about it if all the nozzles are all about the same and don't leak . If one were different that the others, I would investigate further. DixonCatalog1.Page525.pdf

-

It’s in the service and maintenance manual for the M20J and I presume others as well.

-

I’ve never had one of these apart to examine the mechanism, but from various documents and published descriptions, it seems clear that the spring performs two functions. First, it acts as a wrap spring brake to keep the wheels in the retracted position. Second, it acts as a wrap spring clutch to engage the motor with the ball screw to extend the gear. This is why the gear won’t extend if the spring breaks; the motor spins, but it is disconnected from the rest of the mechanism. There are really two preloads on the gear. The first is checked by slowly extending the gear with the emergency system just until the gear down light illuminates and then checking that the preloads are within the specified range. The second test is to cycle the gear electrically and check that a higher maximum preload is not exceeded. This is because momentum will cause the gear to keep moving a bit when the down limit switch cuts off power to the motor, and so the preload will be higher in this case. Skip

-

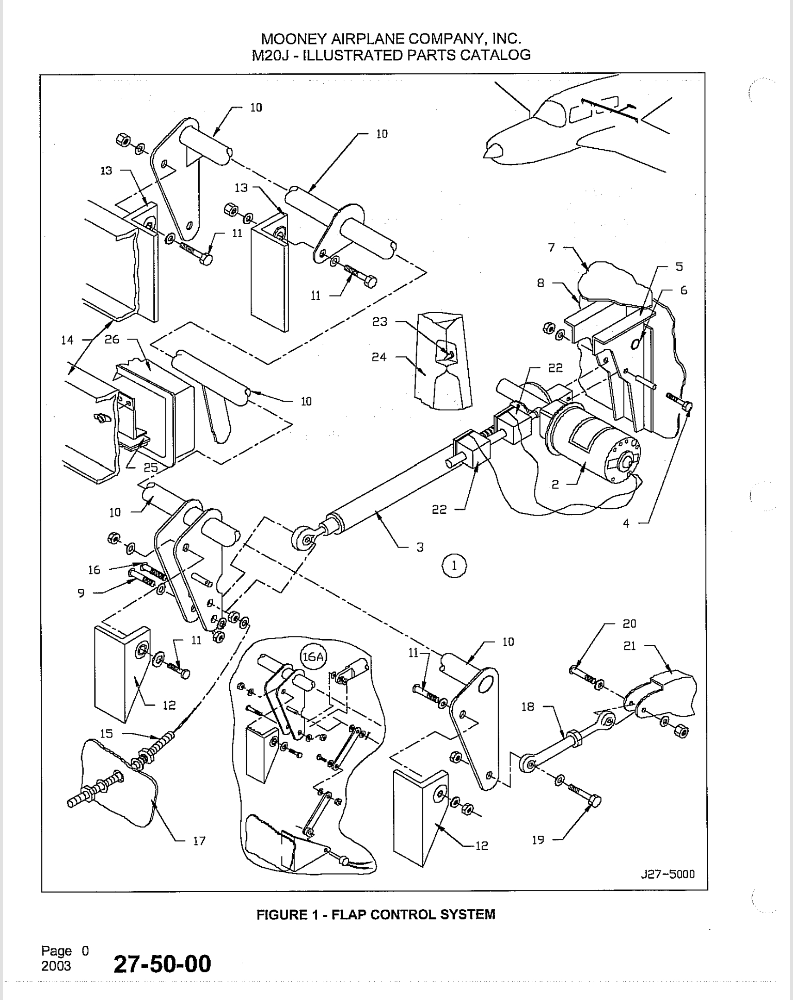

Here’s a drawing of the electric flap mechanism from my M20J IPC. There are no springs and the whole mechanism is rigidly connected.

-

Interior plastic repair at annual

PT20J replied to generalaviationguru's topic in Vintage Mooneys (pre-J models)

I’ve found that two layers of glass cloth works best. ABS dissolved in solvent dries softer than the original ABS sheet material and so it’s best to include some glass cloth for a stronger repair. I have melted ABS in solvent to make a paste. Legos work well. Both MEK and acetone will work; MEK gives a longer working time. It’s easier to just buy ABS cement at the hardware store which is ABS resin and solvent. If I really need to strengthen an area, I glue some sheet ABS to the back of the panel. SEM Color Coat is a professional automotive plastic paint and holds up well. It adheres better if you spray the panel with SEM Solve first to soften the plastic. Phantom White is the color I used. Skip -

Is it legal to fly with a front seat removed?

PT20J replied to FloridaMan's topic in General Mooney Talk

When I flew 135, we used an iPhone app to run a quick W&B and took a screen shot before each flight just in case. Seat isn’t on the required equipment list. Weigh it and subtract from the empty weight. What you choose for a moment arm is up for grabs since the seats move.