-

Posts

9,514 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

You can really get both. The smallest amount of paint that a paint store will custom mix is usually a pint which is 16 oz. A rattle can holds 4 oz. So you can have them fill three cans and still have around 4 oz left over. Mixing components is trivial if you can measure. You should only need reducer if you are going to spray it. Be very careful if you spray polyurethane. Overspray mist will stick to whatever it touches and dry hard as epoxy. You really need to mask everything.

-

Your wheels shouldn't be throwing a lot of grease. First, there is a felt seal that is supposed to keep the grease in, and water and dirt out of, the bearing. They are not the best seals. Parker now makes rubber ones that are better but expensive. The felt ones, can easily be replaced if they are worn out. Second, some people use way too much grease. The grease only goes in the bearing itself, and just enough to pack it. BTW, the recommended grease is now Mobil SHC 100. If you do put on hubcaps, take note of the screw size in the IPC. They are pretty short. If too long a screw is used, it will poke through the soft magnesium wheel rim into the tire. Skip

-

A Cautionary Tale to Prospective New Owners

PT20J replied to good2eat's topic in General Mooney Talk

-

Is it legal to fly with a front seat removed?

PT20J replied to FloridaMan's topic in General Mooney Talk

I believe that it has been well proven over the years that if the FAA wants to get you, they will find a way. I believe it has also been shown that the NTSB will back them up no matter how ridiculous the charge. -

Rocker Switch Cover Replacements - 3D Print your own

PT20J replied to freff's topic in Modern Mooney Discussion

Yes, but you still need to know which switch you have because the covers are not interchangeable. Someone posted this helpful photo a while back. -

Rocker Switch Cover Replacements - 3D Print your own

PT20J replied to freff's topic in Modern Mooney Discussion

Do you have Klixon or ETA switches? -

-

Any auto paint store should be able to color match and put polyurethane in 2K rattle cans. The cans hold 4 oz of paint and the catalyst is in the can released by punching a button on the bottom as @N201MKTurbo says. Once punched, the can is good for about a day before it hardens. (2K means two component, i.e., paint + catalyst. I believe the K is for komponente which is component in German). Don't confuse that with 2 stage paint which means basecoat + clearcoat more commonly used on autos. But, you only want the cans if you are going to paint an area. There are three ways to paint an area that I am aware of. 1) paint an entire panel if possible. 2) Mask it off so that the paint line just looks like another panel line. 3) Blend the new and old paint at the paint line mechanically (sanding and rubbing compound). Some people here have done the latter and posted pictures. It's a lot of work. I talked to a couple of paint shops and they don't do it because the polyurethanes have a minimum specified film thickness and they tell me that the blended edge will deteriorate and become visible over time. How long, I have no idea. Skip

-

I'm firmly in the camp of if it ain't broke, don't mess with it. I've looked into this a lot. Eaton never had a recommendation about maintenance on these as far as I can tell until they had a failure of a no-back spring that was probably due to a bad manufacturing lot of springs. That was many years ago. The 1000 hours seems to have come from Mooney and was due to the failure of two springs in Plessey actuators (different design) at a little under 1000 hours each. The 1000 hours is really meaningless. It's cycles that are important. Don Maxwell told me that the Eaton actuator is rated for 20,000 cycles. If you cycled the gear once per hour of flight time, that would be 20,000 hours. So, figuring that any bad springs have worked their way out of the installed base by now, I see no value in messing with it. I think about it this way: The only reason to mess with it is fear of failure. After I had it serviced, I would have to worry about a maintenance induced failure. Same difference -- I'd still have something to worry about and there is no objective means to tell which is better. By the way, when I asked Don about it he said not to mess with it unless it was making an unusual noise. Skip

-

It doesn't look like the steering horn has a bushing unlike the no-longer-available LASAR version. LASAR used to rebuild factory steering horns, so maybe someone still there knows what they used to do (I'd talk to Dan Riesland in parts because he's been around a while and most of the Prineville OR people are new. Dan's still in Lakeport working from home.) Personally, I don't think it looks that bad, but I would look into refurbishing or replacing the steering horn before messing with the pin. Skip

-

How you fix this depends on how picky you are. The way the pros do it is get some paint to match and then take a very fine tipped artist brush and carefully fill in the chip with primer and then with paint being careful to not paint outside the edge of the chip. Then buff it out when the paint has cured. It's pretty tedious, but if done correctly, the result will be nearly impossible to detect. There are videos on Youtube. Getting a good color match is the first step, but you will need to decide what kind of paint to use. Enamel is the easiest, but since the chips are on the leading edges you might want tougher paint in which case you would get a 2K polyurethane. This paint is mixed with a catalyst and dries very hard. It is the type of paint originally used on the airplane and on modern automobiles. Once mixed it has a working time or several hours, so you only mix a small amount at a time.

-

Panel Planning with G3X...what would you do differently?

PT20J replied to KSMooniac's topic in Avionics/Panel Discussion

I have a G3X, G5, GTN 650 Xi. I can load a flight plan from ForeFlight through the G3X to the GTN using the G3X Bluetooth connection. It also works in reverse. G3X flight plan is set to external. I have a GNC 255 for Nav/Com 2. The G3X will display and navigate on GPS1, VLOC 1 or VLOC2. The G5 is only connected to the GTN when used as a standby, so it will display and navigate on GPS or VLOC1 only. I like to display the approach plate on Foreflight because it is a larger display. With the yoke-mounted iPad and the G3X I've never felt the need for the larger screen GTN. This arrangement allowed everything to be in the panel in one stack. I chose the PMA 450B audio panel because I like the user interface and flightmate feature for aural alerts. The AV-20-S is a tie breaker in case the two Garmin instruments disagree. I kept the original annunciator panel because I still have Gear Down, Gear Unsafe, Speed Brake, Pitot Heat, Volts Hi/Lo, Start Power, and Boost Pump annunciations. But, I believe that someone here found out that the company that makes these (International Avionics, Inc) will make a custom version, and I might explore that if I were to do it over. Skip -

How loose is it? There is some play in the Mooney steering even when new. If it's not really bad, it might be better to just leave it alone. The bushing is softer than the steel pin. If it were mine, I'd replace the bushing and put it back together and see how it works. If I decided I really had to replace the pin, I'd have a machine shop reproduce the LASAR part. It doesn't look difficult to recreate. You'd have to talk to your mechanic about whether he'd consider it an OPP. Skip

-

If it leaks through the drain, it means that the seals are leaking internally and it needs to be overhauled

-

What audio panel do you have? Do you have a separate intercom? Do you know whether the noise comes from the intercom or the audio panel? I would do some trouble shooting to better understand the issue. 1. Pull the audio panel circuit breaker(s) and see if it still does it. This will tell you if the audio panel is wired to the main bus rather than the avionics bus. Do the same with the intercom if you have a separate intercom. 2. Since it only does this when starting and when the alternator is below cut-in rpm and doesn't do it after a flight, it seems voltage related. The battery voltage will be lower during and immediately after a start. After a flight, the battery will have been charging and voltage should be higher. This effect will be exacerbated if the battery is near the end of life, but it still shouldn't cause the avionics to make noise. Try starting with the alternator off (ALT switch off if it is separate from the master switch or pull the Field breaker). t. If that eliminates it, then I would investigate the alternator.

-

Since it is just worn and not broken, could you rebush the steering horn with a smaller ID bushing?

-

Slight engine egt/cht weirdness when leaning

PT20J replied to Ragsf15e's topic in General Mooney Talk

-

Pretty much the same for everything I've tried to order recently. They quoted me quite a bit more for a gear leg than I paid for one through another MSC (Neither had it in stock, so both would have ordered it from Mooney). Also the new owner told me they could repair gear legs, but they can't because they don't have FAA approval yet (at least as of a couple of months ago).

-

Help Troubleshooting Fluctuating Fuel Pressure

PT20J replied to Ragsf15e's topic in General Mooney Talk

A year or two ago, the Kavlico pressure sensors became scarce and Garmin approved an alternate GPT sensor. I believe the GPT is more expensive and I don't know who Garmin's vendor is. A possibility is to try the GPT sensor to see if it is less sensitive. However, I did ask Trek Lawler about it and he said that both sensors have the same specs. -

Lots of good info here https://www.goodyearaviation.com/resources/tiredatabook.html

-

Slight engine egt/cht weirdness when leaning

PT20J replied to Ragsf15e's topic in General Mooney Talk

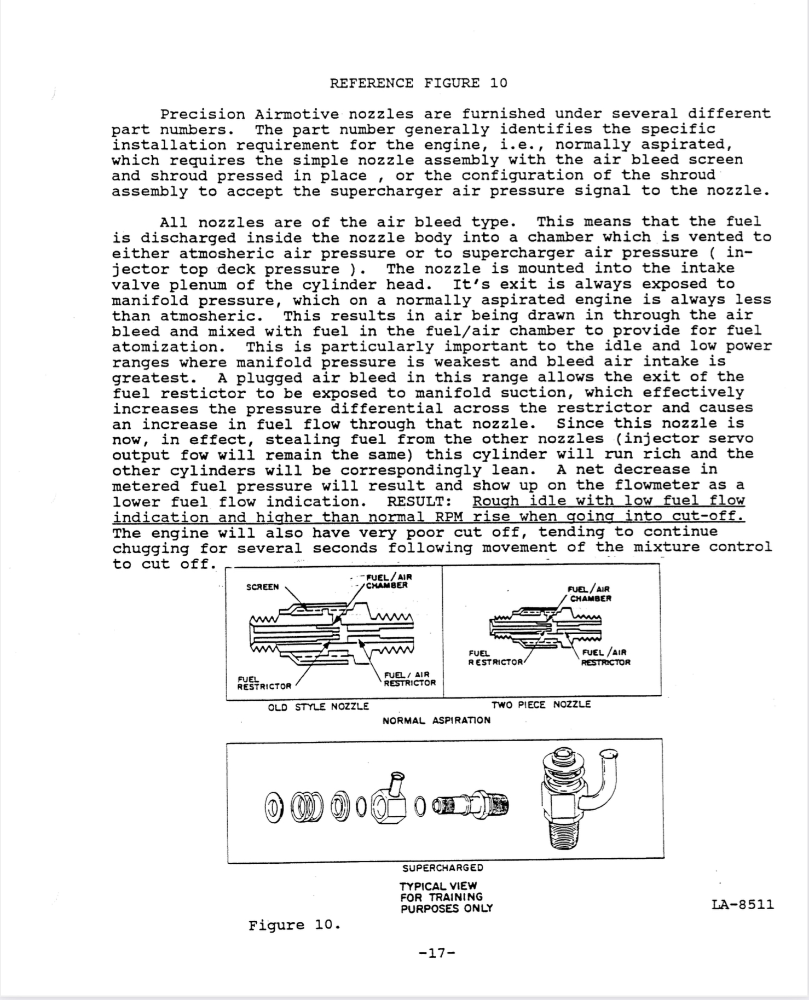

The servo meters fuel to the flow divider and the divider is supposed to send equal amounts to the cylinders. The restrictors in the nozzles are what control the flow division. Usually what happens is that one nozzle gets plugged and then all the fuel goes to the other four making them rich. But, if somehow the flow were slightly restricted to three nozzles, the fourth would run rich. I'd probably just clean the plugs and the nozzles and see if it ever repeats. -

Help Troubleshooting Fluctuating Fuel Pressure

PT20J replied to Ragsf15e's topic in General Mooney Talk

I put an Omega Engineering PS-8E snubber ahead of the transducer. It reduced the peaks but did not completely eliminate the variations. -

Help Troubleshooting Fluctuating Fuel Pressure

PT20J replied to Ragsf15e's topic in General Mooney Talk

If it didn't do this with the factory gauge, and it just started doing it after the installation of the Garmin gauge, and the plumbing hasn’t changed except for the transducer, and the engine runs normally, I’d just ignore it. It has probably always done that except that the variations were outside the bandwidth of the old mechanical gauge. The variation frequency is also outside the servo’s response, so as long as the average pressure is in the green, the servo won’t care. Skip -

https://aeromotors.azurewebsites.net/