-

Posts

9,836 -

Joined

-

Last visited

-

Days Won

218

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Store

Everything posted by PT20J

-

That looks like a very poorly done repair. I don’t think that grounding strap is original either. I’d remove the hinge and take it to a machine shop and see if they can duplicate it. Mooney won’t release drawings, but you can call a MSC and get a quote on price and delivery for a new one. Probably a lot more than the use one at BAS.

-

If it’s a bad bulb, search eBay for a Whelen H35W28V.

-

That looks like the bi-pin bulb/socket which is obsolete. There are no LED replacements. The porcelain socket looks discolored. Did it get glue or something in/on it. That metal clip should have .020 safety wire through the holes tightened just enough to hold the bulb without cracking the glass. If the socket or wiring is bad, best to replace it with the newer wedge base bulb/socket which may still be available.

-

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

I looked it up and according to FAR 145.219, repair stations are only required to keep records for two years. It might be a good idea to request copies whenever major work is done for your own file. I’m going to do that from now on -

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

Have you contacted Penn Yan? It’s a Part 145 repair station, so I would think it should have good parts traceability documentation. -

I got the RAM RAM-B-408-75-1U handlebar ball mount and mounted it ball down at the base of the yoke. This connects to a RAM-B-201-C-KRU long double socket arm mounted under the yoke. This connects to an EZ Roll'r mount with a RAP-B-202U ball mounted low on the backplate. Mounting the arm under the yoke lowers the iPad so it does not obstruct the instruments. Take the bulb out of the yoke map light because the arm will interfere with it and break it.

-

Funny, my shop talked me out of an overhaul. Said once he got it apart he could convert it to an overhaul if it warranted.

-

I contacted RAM and they said from the specs it should work but they have not verified it yet. They advised to check the website frequently or sign up for product announcements.

-

The airframe manufacturer gets to set limitations for the engine as installed because the airframe manufacturer designs the fuel, induction, exhaust and mounting systems. Of course the airframe manufacturer will have coordinated the design and limitations with the engine manufacturer. Section II of the POH constitutes the FAA-approved Airplane Flight Manual and the limitations therein are approved by the FAA and legally binding.

-

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

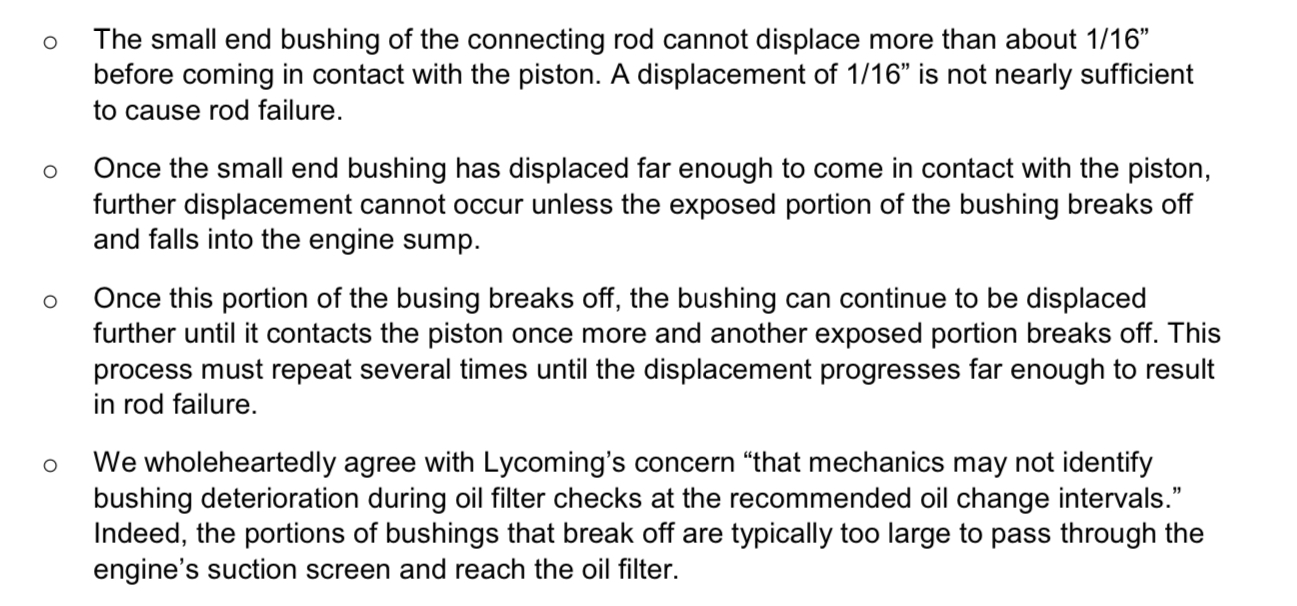

Here is the independent analysis of the failure mode taken from the 2017 letter to the FAA signed by Mike Busch and others. (I posted the entire letter earlier in this thread). I don’t know much about bronze bushings except that I tried to ream one once for a non-aviation project and it broke into little pieces, so I gather it’s a pretty brittle material. -

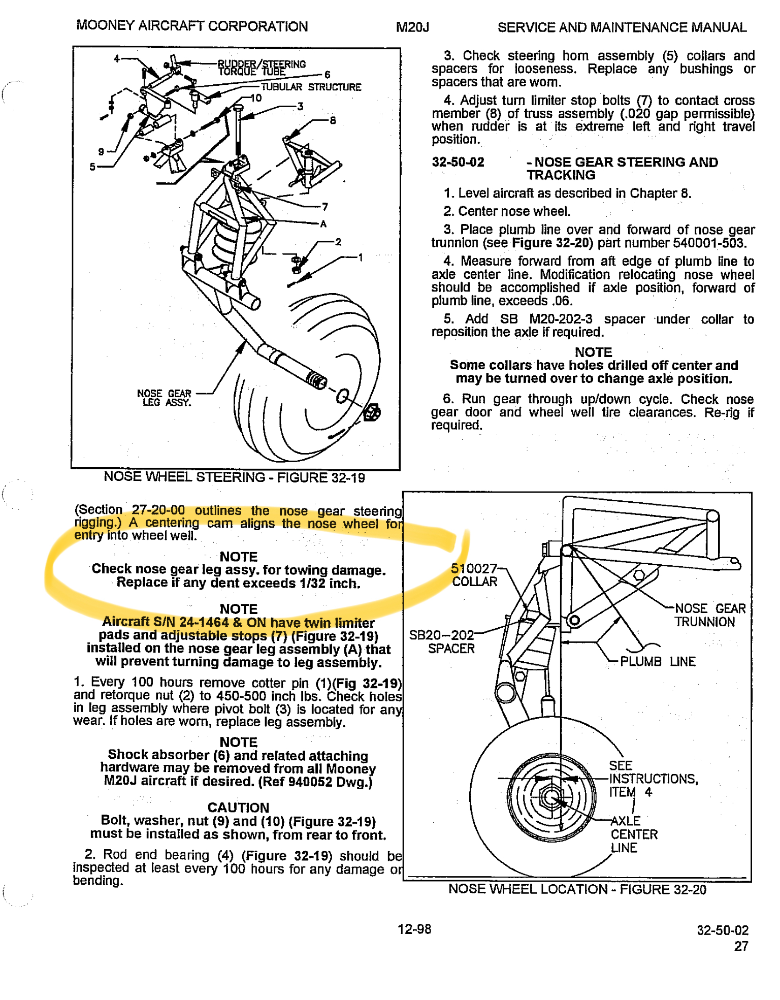

In the first picture, the badly damaged tube on the right is actually the gear leg and the part it hit on the left that shows missing paint is the truss. Usually only the leg gets damaged because it has the smaller tube. But, with that much damage to the leg, be sure that the truss tube isn’t also deformed. Also, check the rudder push pull tubes and the stops (in the tail) for damage because it will have hit the rudder stops well before the tubes on the nose gear touched.

-

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

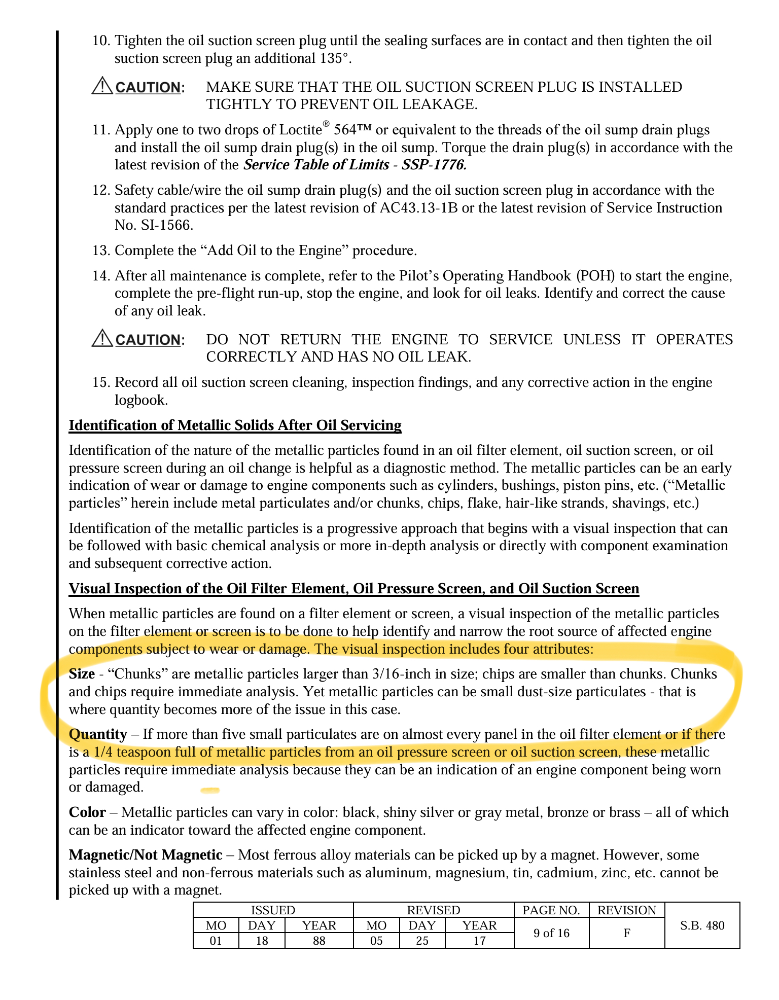

The SB does not define the size of chips other than to say they are smaller than chunks. The first entry in Table 3 that you quote is for metal in general, but later in the table it specifically indicates that finding any bronze in the screen or specified number of chips in the filter leads to corrective action 6 or 7 which is removing cylinders. -

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

From SB 480F, chunks are 3/16” or greater; chips are smaller. -

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

The way I read SB 480F Table 3 it’s required to remove cylinders to inspect the connecting rod bushings if any bronze chips are found in the suction screen, or more than 5 bronze chips are found in the filter, or more than three bronze chips and more than three aluminum chips are found in the filter. -

Fly the airplane at cruise speed. Set the prop control to 2700 rpm. Land without adjusting prop. Turn the governor stop screw CW until it just touches the control arm. The screw is safetied with .020 lock wire and a jam nut. You might remove the lock wire before flight to avoid accidentally bumping the control arm. McCauley governors adjust about 25 rpm with each turn of the screw.

-

My A&P tried to buy a throttle cable from Beechcraft for a Sundowner and was quoted just shy of $10,000.

-

Is that the one that covers the jack screw on the tail? I think some have fabricated replacements using SCEET ducting.

-

The drain valve is a Mooney custom part. It comprises a machined body that is riveted to the skin and threaded to accept a fitting to connect the static line. The actual valve is a clevis pin with an o-ring and a coil spring. I wonder what this mash up costs from Mooney? Maybe a used one from a salvage yard?

-

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

Apparently the bad bushings can shed chunks and that's the reason for including inspection of the suction screen in the AD. The original 2017 AD required removing the cylinders to test the bushings for fit. It was simple to determine if you needed to comply if you had a Lycoming-assembled (new, rebuilt, overhauled) engine because all the affected serial numbers were listed. If new rods had been installed in the field, it wasn't so simple because the bad rods were identified only by the date they were shipped from Lycoming. So, whoever installed them would have to have kept records showing when they were shipped. The 2024 AD doesn't list affected Lycoming-assembled engine serial numbers but it is easy to get the engine ship date from Lycoming and determine if the AD applies. But, again, it's harder to tell with field-assembled engines. The 2024 AD isn't difficult to comply with except for the fact that the suction screen is a bit of a pain to get to and many don't inspect it at every oil change. Personally, I have found that the screen gets easier to remove and safety wire (the hardest part) the more times I do it. -

The NTSB involvement probably didn't have anything to do with the pilot's statement. The NTSB investigates accidents which definition includes substantial damage. Note that the report lists the aircraft damage as substantial. A similar occurrence happened in June 2022 (Accident number ERA22LA319) where a M20J landed gear up in Charleston, SC due to a broken torsion spring in a Plessey actuator. The damage was classified as substantial because it ground through a structural tube in the belly much like this accident. The report picture of the damaged tube has the caption: "View depicting the damage to a tubular steel truss primary structure which required major repair and classification as an accident."

-

Lycoming Connecting Rod Bushing AD 2024-21-02

PT20J replied to MikeOH's topic in General Mooney Talk

I received confirmation from Lycoming that an engine assembled by Lycoming that contains an affected connecting rod assembly is only subject to the AD if the engine ship date falls within the connecting rod assembly date range listed in the AD. Ship dates for Lycoming assembled engines can be found here https://www.lycoming.com/core-history-search This, of course, doesn't help with engines assembled outside Lycoming. That will require some research and hopefully the assembler saved the packing slips for the parts with the ship dates. My Lycoming field rep sent me the attached letter. Response to Inquiry - AD 2024-10-02_FINAL.pdf -

As @kortopates pointed out above, if you push on the pins with the door open but the handle in the locked position, some will spring open with little force. Some I have checked take a lot of pressure. So, there is variation between airplanes and the mechanism has no adjustments. There is a spring the holds the pins either closed or open depending on the position of the handle and perhaps some springs are weak. It's also good to lube the piano hinge occasionally. Otherwise it will wear and be more likely to fail if the door does somehow open in flight.