-

Posts

922 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Stephen

-

Don really has a nice setup; have a look, it is worth your while!

-

I was just slow motion on my samsung galaxy S9.

-

Vortex generators on an Ovation?

Stephen replied to ilovecornfields's topic in Modern Mooney Discussion

I installed a set on a C414A back in the 90's when I was doing A&P stuff. As I recall, they were quite trivial to install as well. I think there was a roll-on paper template with cutouts for the VG's and special glue. Cleaned the surface per recommendation. Rolled on included paper template indexing to specific reference points. Took the VG's out, applied glue, applied and let cure. Then went to test fly..lowered stall by several KTS and also made it handle less mushy. I think even for that aircraft the things only weighed several ounces so added weight was absolutely negligible. -

Thought you guys might enjoy this video effect of one of the Jewell mechanics looking for an oil leak coming out of overhaul (turned out to be a bad filter). This is actually at high rpm. slow_mo.mp4

-

IO-360-A1A overhaul, what (else) do to?

Stephen replied to chrixxer's topic in Vintage Mooneys (pre-J models)

Jewell put in DLC on mine. I would recommend David to anyone if you haven't gotten an overhaul shop yet. -

IO-360-A1A overhaul, what (else) do to?

Stephen replied to chrixxer's topic in Vintage Mooneys (pre-J models)

I just got my plane back from Jewell today. Consider overhauling the fuel delivery components if they haven't been touched in a long time. -

-

Have used spray paint as well

-

+ 1 on grips... I've heard of using it as a spray on lure fish attractant

-

Another IO360 with hosed Lifters/CAM

Stephen replied to Stephen's topic in Vintage Mooneys (pre-J models)

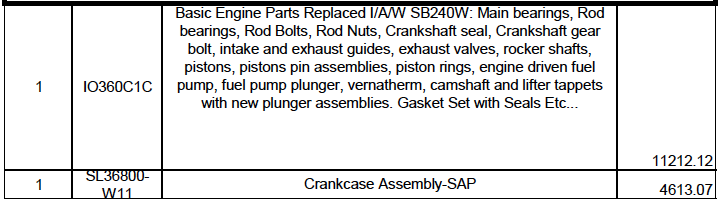

I am having some other work done that totals out the 23K, including airframe annual and replacing nose gear due to being bent by towing (again) -

Another IO360 with hosed Lifters/CAM

Stephen replied to Stephen's topic in Vintage Mooneys (pre-J models)

-

Another IO360 with hosed Lifters/CAM

Stephen replied to Stephen's topic in Vintage Mooneys (pre-J models)

I think we are about at 23K currently -

Another IO360 with hosed Lifters/CAM

Stephen replied to Stephen's topic in Vintage Mooneys (pre-J models)

-

Another IO360 with hosed Lifters/CAM

Stephen replied to Stephen's topic in Vintage Mooneys (pre-J models)

-

Nice, see what ya did there Mike! S.H... ah "ME" too.

-

The QC35s seem to work in my "F" just fine; I think they are as effective and way more comfortable than my Bose aviation headset. That said, (again) I think my problem was tons of use daily mostly due to my work (not aviation) use of the units.. But, if I want to try life minus ANR, that is going to mean passive protection and that probably means HALO's for me because I don't like the weight of the STD aviation units. .

-

Done

-

Fuel Sender (Transmitter) Question - M20C

Stephen replied to Toothdok50's topic in Vintage Mooneys (pre-J models)

I gave mine away too, I think if people asked when they need them there are quite a few of us that have converted. -

If the approaches in your area have a frequent drop-in aspect to them, might be a good case to call Precise Flight https://www.preciseflight.com/general-aviation/shop/speedbrakes/products/speedbrakes-mooney/ (if not already equipped).

-

^^^ This, Also, you can try the 20 minute method: Plan your decent to initiate at 20 minutes to your ETA at the pattern or IAF...whatever you are aiming for as a position target. Works as a general strategy on Cessna 150's, Mooneys, to the big planes because using time instead of a distance generally compensates for different aircraft speeds. When you nose over and pick up speed, the 20 minutes to your position target will drop down to a new ETA of (roughly) 15-17 or so minutes +/- due to your increased speed. Next check that using a 500 FPM descent, that you will arrive at altitude safely before the pattern (so you can slow down). Your present altitude in thousands above your target altitude x 2 will tell you how many minutes it will take at 500 FPM to hit your target altitude. If heading into a pattern make sure your ETA on altitude is < ETA at the airport pattern by a few minutes so you can slow down to pattern speed. If you work it a few times you will get a general pattern. Obvious adjustments/amendments are required for coordinating with ATC. Even then, using the 20 minute method, you can tell if ATC is holding you too high for too long, or conversely know at 25 minutes ahead that you need to request your descent to help them not forget.

-

Nearly Gave up General Aviation Flying After this Incident

Stephen replied to Mooney_Allegro's topic in General Mooney Talk

Kind of related discussions: -

Preventing Maintenance Accidents?

Stephen replied to 201er's topic in Mooney Safety & Accident Discussion

Well, perhaps one could take a systems approach to this and, as a pilot, deep-dive inspect, say the "fuel system" as a critical system. Maybe something like this for a deep review. (this is not a comprehensive list, just ideating here): Great call @mike_elliott, retuning the list: 0. Check Pilot as the most important critical system. IMSAFE (Illness, Meds, Stress, Alcohol, Fatigue, Emotion) , WX, how willing am I to do due diligence with MX, WX, Currency (IFR, Medical, BFR) , Competency (rusty?, should I plan ahead to take a few solo hops / circuits before I take the trip with PAX), learning my aircraft systems, reviewing emergency checklists etc? Can I plan ahead, make a calendar of regularized practice as a reminder to keep proficient? AMISAFE? 1. Purchase the MX and parts manuals for your aircraft, get a good flashlight and inspection mirror..also some inspectors paint (https://www.aircraftspruce.com/catalog/cspages/crosschecktorqueseal.php?gclid=Cj0KCQjwgezoBRDNARIsAGzEfe62MiGRRFz-WqqKs6eek8PWajrSiW5tqj29XafWmhUjUKFGUbtnlE4aAkC7EALw_wcB ) 2. Remove side and top cowling on the engine 3. Review manuals on all elements of the fuel system from tank to injector with an eye to understanding the complete fuel schematic and the purpose of every component in it. 4. Locate all referenced the fuel hoses, lines, junctions on your aircraft follow the fuel lines (review manuals for access panel removal). Inspect all junctions and clamps etc for tightness, clamp security, safety wiring, check for chafing, fuel stains/odor etc. 5. Once a fitting has been verified for security/torque, mark it with torque seal, ideally in a way that allows potential for visual inspection during a preflight. 6. Review your engine logs, when was the last time your fuel system screens were serviced? Fuel control / injection system rebuild? Injectors cleaned? Verify with your mechanic. 7. Have your (assumed Mooney literate) A&P show you how/where he checks filter/strainer conditions and review replacement schedule. 8. Remove your side walls covers in your interior and inspect the inboard fuel sending units. Check for leads/odor. 9. Review any outstanding questions, concerns with your mechanic and learn your airframe. 10. When MX is to be performed discuss what areas of the aircraft will be worked on , observe if you can, and put a second set of eyes on the work area to validate critical systems...even on systems that were not (theoretically) part of the work. (Found a nice snap-on ratchet that way....). 11. Make a MX calendar for your plane and check time/tach state. Put your next upcoming tach/time based MX items in a place you will notice. Put time based items in your email calendar as a reminder. All the above as supplemental to your annual inspections and other MX activity and inspections... just creating knowledge here and a second "thin blue line" to catch those finger tight fuel fittings and other unhelpful surprises so we don't find them in flight. This type of thing could be done for other critical and support systems. Flight Controls. Electric. Landing Gear. Propeller. Engine Cooling etc, but special attention on anything that would make the propeller stop turning in flight. -

Fuel Sender (Transmitter) Question - M20C

Stephen replied to Toothdok50's topic in Vintage Mooneys (pre-J models)

also consider CIES digital units as replacement if you are pulling senders out anyway.... https://ciescorp.net -

Many moons ago, which I used to do the MX stuff, we put all the tires, mains or nose, on a balancer and used adhesive backed weights. They have the low friction bearings on them which can help you get the weight right. https://aircraft-tool.com/shop/detail.aspx?id=AS01&AspxAutoDetectCookieSupport=1 DIY Option: http://ronkilber.tripod.com/balancer/balancer.htm

-

Thanks Paul!! I will, I think I have a line on some but will call out well before the show. Thanks again, very much appreciate the offer!