-

Posts

1,395 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Vance Harral

-

Emergency Gear Down Procedure - Practice

Vance Harral replied to Mark942's topic in Vintage Mooneys (pre-J models)

There may be enough electrons in the battery to continue illuminating the light (low amps) even after it can no longer drive the motor (high amps). But that's beside the point in this particular thread, because the OP said he doesn't turn the crank to the green light even under test conditions on jacks at the annual with a good battery. The assertion that "if the green strips line up, the gear is down regardless of the light", is an oversimplification - one that assumes perfect rigging of the both the gear system and the indicators. The strict definition of "gear down and locked" is when the preload torque on the over-center locks is within the tolerances specified in the service manual. In a perfect world, the green light would illuminate and the floor indicator would exactly align, when the preload torque is precisely in the dead center of its range. In the real world there can be differences, and it sounds like that's the case in the OP's airplane (and likely all of our airplanes, to some degree). If you read the service manual for electric gear rigging, preload torque is checked on the basis of the green light, *not* the floor indicator. This is because the switch that illuminates the green light is part of a two-pole switch, with the other pole being the switch that actually turns off the motor. Assuming the OP's gear is correctly rigged, it sounds like the floor indicator is slightly "off", such that it appears aligned when the preload torque is a little shy of the recommended range. It may also be that the floor indicator is good, but the gear is mis-rigged such that it slightly overdrives past the recommended preload torque. Suggest at the next annual, the OP crank the hand-crank until the floor indicator is aligned but the green light is not on per his usual practice, and check the preload torque there; then continue cranking until the green light is on, and check the preload torque again. If both values are within the service manual tolerance range, then either indicator is "good enough", despite the fact they're associated with two slightly different preload torques. If not, then the gear needs to be re-rigged and/or the floor indicator needs to be adjusted. -

Emergency Gear Down Procedure - Practice

Vance Harral replied to Mark942's topic in Vintage Mooneys (pre-J models)

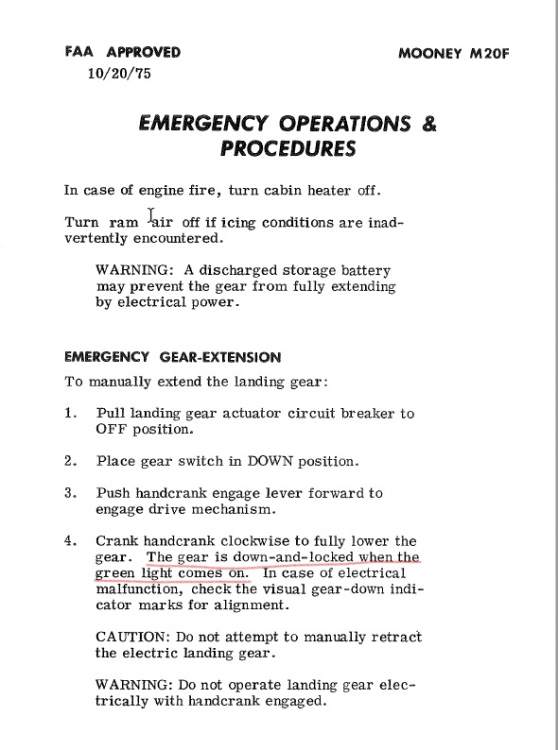

Seconded. The POH (for my make and model at least) explicitly says the green light should come on with manual cranking, see below. It sounds to me like you're not actually cranking the gear into the fully locked position. The crank does get harder to turn at the end of the cycle, as the over-center locks are going over-center. But this is not a bad thing, or a reason to stop cranking - you're supposed to keep going until the green light comes on. If pushing the breaker in after you stop cranking results in the motor running a little bit and lighting the green light as you describe, it likely means you didn't crank all the way to the locked position in the first place. -

If it were me, and I was evaluating a new mechanic, I might not give him the details up front, even if he hasn't performed this particular adjustment before. The learning curve is only a few minutes of leafing through a service manual he should already have and be pretty familiar with, considering he "maintains a couple of J models". It's a good test of whether he has and uses the factory manuals to maintain the airplane, vs. winging it.

-

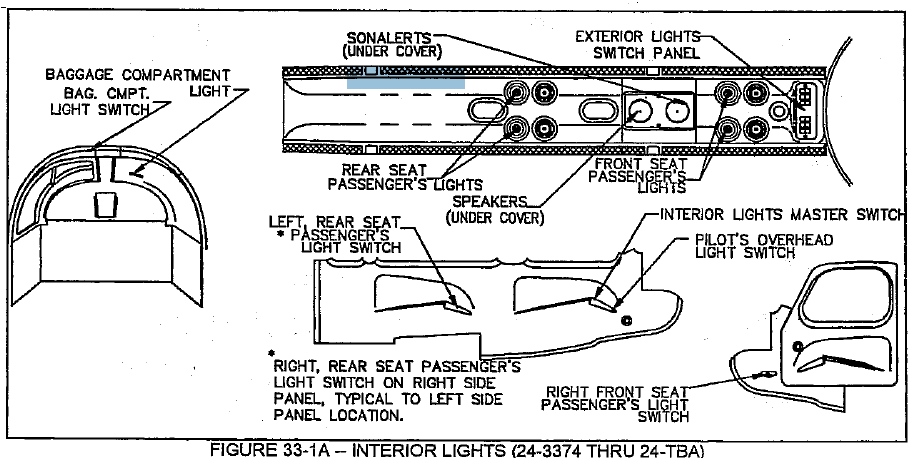

From the M20J Service Manual: The landing gear warning system provides the pilot with an audible warning that the landing gear is not down and locked when the throttle is retarded to within 1/4 to 3/8 in. throttle position. [...] This warning switch is mounted on the throttle housing forward of the instrument panel, and can be adjusted for the proper setting by loosening the screw and repositioning the switch. The system isn't connected to the manifold pressure gauge in any way, and doesn't "know" the MP setting at which it actuates. With trial and error, you can get it to actuate at a particular MP value on a particular day at a particular altitude, but the actual MP it switches at on other days will vary, depending on altitude and atmospheric conditions. When deciding where to set it, one consideration is how often you land at high- vs. low-density altitude airports. The MP you get at a particular throttle position can vary quite a bit at different altitudes. The beeping noise triggered by the gear warning system is sounded by a Mallory Sonalert installed in the ceiling. It's a little black round thing, slightly bigger in diameter than a quarter. It is unrelated to the overhead speaker that broadcasts audio from the radios. Below is a picture from the M20J service manual identifying the gear and stall warning Sonalerts relative to the overhead lights and other things in the overhead panel.

-

If you find one, let us know. That would be the holy grail.

-

Good luck with your purchase, Stig. Say hi to Juliana for me, and come show off your Mooney at KLMO some time.

-

So one interesting thing about our bird is that when it was re-imported back to the states, it got a "scuff and shoot" paint job, not a full strip and repaint. When it's washed and waxed to maximum shiny-ness (which still doesn't make it a looker, but it's a workhorse, not a show plane), you can actually see the contours of the old "DR" registration identifier on the wing. Thanks for the translations, folks. I can figure most of it out from context, but never bothered to look line-by-line. As one might expect with a brand new airplane, there is nothing really of note in those early logs: just oil changes, air filters, and normal inspections.

-

The 1976 F model is the finest Mooney ever produced. Ask me how I know.

-

Portable oxygen practical questions

Vance Harral replied to flynboy's topic in Modern Mooney Discussion

Same as Ron, my portable rig goes in a carry bag that straps to the front seats (I choose to hang it over the co-pilot seat, as it makes it easier to reach from the pilot seat). Quick Google search turns up this: https://www.aircraftspruce.com/catalog/pspages/aeroxcase.php Mine is similar, though it has clip-in straps that can be used to pretty securely strap the case to the seat. The one I linked to doesn't seem to have as elaborate a strap setup. -

This is already happening - occasionally - at KBJC. "Nxxxx, you up on my frequency?" Nothing official about it yet, but happening just the same.

-

-

preheat with a heat gun?

Vance Harral replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Please consider an arrangement that keeps the gun itself outside the cowl, and directs the hot air it blows up through the cowl flap. For one thing, hot air rises, so blowing hot air along the top of the engine is not going to be very effective in heating it. More importantly, though, a number of things can go wrong with the arrangement you propose. Some are admittedly small risks, like accidentally catching the frame of the gun or its power cord on your fuel injector lines and bending/breaking them. But some are potentially catastrophic, like the heating element or the temp controller malfunctioning, and starting a fire while unsupervised. When it comes to inexpensive DIY heating solutions, there just a lot of good, common-sense risk mitigation in keeping the thing that is generating the heat outside the engine compartment. -

How much it matters is an interesting question. We actually have the basemap turned off in our regular map view, because we find it distracting. More importantly, the AFMS limitations specifically reference the navigation database, but not any other databases. The conclusion I drew for our own operations is that the basemap has essentially zero impact on our operations. But we still keep it up to date.

-

Earlier this year, Garmin released a new version of the basemap database for GTN series navigators, version 20M1. That database version had a bug, see https://s23634.pcdn.co/en-US/aviationalerts/wp-content/uploads/2020/08/BasemapDataAlert_2020_08_14_basemap20m1_2092.pdf If you updated to 20M1, you were advised to revert back to 19M1. We got advance wind of this and never updated to 20M1. More recently, basemap 20M2 was released to fix the bug in 20M1, but turns out there's a lesser issue with version 20M2 as well. You can download 20M2 to an SD card, upload it to the GTN, and fly a flight with no problem. But the next time you power cycle the unit, it will fail the database verification step on the basemap database. I wrote Garmin about this problem and received an immediate response with a pointer to a recently released "knowledge base article" on the issue at https://support.garmin.com/en-US/aviation/faq/h4EcVRF0Nz0y2EEfl0IrT8/ That article describes a process by which you can upload the even older version 18M1 basemap to your GTN, then update to 20M2 from 18M1. Those of you with a little bit of computer savvy may speculate as I do that "verification" of GTN databases at boot-up is simply a checksum process, wherin the unit checksums the databases and compares the computed checksum against a known good signature. The nature of this bug suggests the known-good-signature checksum somehow depends on the previous version of the database from which the current database was upgraded. I can't imagine why the software engineers would design it to work that way, but my speculation may be way off base - I freely admit I lack any low-level knowledge of how GTN database verification works. Anyway, posting this here for others who may be struggling with this, and wondered like me if their SD card(s) and/or GTN unit might be faulty. It's not pilot error - it's the software.

-

Today's flight in the year 2020

Vance Harral replied to bonal's topic in Miscellaneous Aviation Talk

Not many chances to fly IMC in a piston single around here (Colorado). But coming home from Texas yesterday afternoon, I cruised over an undercast for more than an hour. And with the sun at just the right angle for it, I saw for the first time ever in my Mooney, glory. -

Here's a good article on LP+V. Note the "smoking hole" illustration: https://www.planeandpilotmag.com/article/tripped-up-by-stepdowns/

-

Peoples' experiences with headsets are deeply personal, based on personal preference and head/ear anatomy. So you're not going to be able to tell which one is best for you based on what others' say about them. As a simple example of that, I have absolutely no doubt that Niko182 is telling the truth when he says his QT halos are quieter than his over-the-ear Bose ANR headset. But I promise I'm telling the truth too, when I say I've had exactly the opposite experience with QT halos vs. over-the ear ANR (and yes, I insert the QT plugs all the way into the ear canal). To be clear, I really enjoy wearing the QT halos when flight instructing in 172s, but they're just not viable for me in the higher noise environment of my M20F. I may eventually try some custom ear molds based on comments from others, but it's not a priority. Anyway... the good news is that most/all of the manufacturers have no-cost return policies. Rather than asking for opinions on the internet, suggest you pick two or three options, order one of each, fly with all of 'em, and send back all but your favorite.

-

Panel adventure - what would you do?

Vance Harral replied to JamesMooney's topic in General Mooney Talk

Mechanically and electrically? Yes. Legally? No. There is no certified drawing that authorizes this, therefore no qualified avionics shop will do so. -

Panel adventure - what would you do?

Vance Harral replied to JamesMooney's topic in General Mooney Talk

As a huge fan of the Brittain autopilot installed in our airplane, but having spent 15 years working on and maintaining it, I just want to add a dose of reality for the OP to consider about starting with a Brittain wing leveler and crafting an autopilot solution. First, the Brittain factory is - and has been for some time - in "hibernation", much like Mooney has been in recent times. Jerry Walters, the principal owner/operator, passed away in December 2017, and the business subsequently lost both its brick-and-mortar shop, and its repair certificate. Brittain still returns calls, can sometimes help you with technical questions, etc. But they are not staffed or equipped to service or repair any existing parts, nor do they have any parts to sell. Sure, there are parts to be had on the used market, but these are all sold "as is". That's fine for mechanical parts like the servo jar/boots that can be worked on by any A&P with a modicum of street smarts (whether this is strictly legal is murky, but that's a separate question). Not so for complex parts such as the electronic head unit, or even the turn coordinator with integrated shuttle valve. At a certain point you run into dead ends. We're all rooting for Brittain to come out of hibernation, of course, and I don't rule out their doing so. But they've been laying low for almost 3 years now, and the longer that situation drags on, the less likely they are to return as an active concern. Second, lots of people are suggesting dual G5s for an integrated AI/DG/HSI solution. And a great solution that is. But you cannot legally connect a Brittain autopilot to a G5 for CDI left/right information, because the draft drawing from Jerry to do so has never been FAA approved. Therefore, legally flying an approach or even just tracking an enroute course with the Brittain requires a conventional CDI separate from the G5 DG/HSI, which has conventional left/right outputs. If the OP already has such a CDI attached to a radio they intend to keep, that may not be an issue. But you'd always have to use that #2 CDI for the autopilot, never the #1 G5 CDI/HSI . Finally, just make sure you have reasonable expectations of the system. The accuracy of Brittain's heading hold mechanism is difficult to tune to better than 5-10 degrees; its course tracking tolerates at least 1 "dot" of deviation and requires slight tweaking of the heading select; and altitude hold if you have it is only good to within +/- 200' in moderate turbulence (i.e. when you'd really like to have altitude hold in the first place). With all that said, do I still love the B5 in our airplane? Absolutely! Least expensive solution available by an order of magnitude, and most (not all) of the system can be maintained at your local shop by your local A&P. For Mooneys with a Brittain already installed, no reason not to keep using and trying to maintain it. And I'll keep rooting for Cecelia to find a new investor and bring the company back to active status. But I'm hesitant to encourage someone to embark on a quest to acquire and install an Accu-track or B5/B6/etc from scratch. I think it's likely to be a significant project, with a significant chance of simply running into a dead end until someone totals a Mooney with a working system. Whether that work and frustration is worth the many AMUs of savings vs. any other autopilot solution is up to the OP. But it's not the no-brainer it's sometimes made out to be here on Mooneyspace. Caveat emptor and all that. -

If your filter has a vertical orientation when installed, it's ten-thousand-percent easier!

-

I keep hearing about this trick, and the claims there "won't be a drop left in the filter". But it just doesn't make any sense. Look at the picture of a Champion CH48110-1 filter that goes on a Lycoming IO-360, attached below. The filter spins on to the engine in a horizontal orientation, like the image on the right. There's about a half inch of distance between the filter case and the lowest hole in the filter. No matter how many holes you punch in the filter or how many days you wait for it to drain, there's still going to be several tablespoons of oil in the filter when you remove it. As you rotate the filter to unscrew it, that oil tends to ooze out the holes. Certainly if you rotate the filter very slowly, and/or if you're lucky enough to have a slight rearward cant in the mount, not much (or any) will spill out. But claims that you can completely drain the filter by simply waiting long enough are at odds with gravity.

-

Everyone in this thread who tells you they can consistently change their oil without spilling a drop is a liar. We've been doing our own oil changes 2-3x year for the last 14 years. I have all the contraptions for dealing with the filter: the v-shaped piece of angle iron, the diagonally cut oil bottle, the rags, the bags, all of it. I've tried all the gimmicks, too: waiting two days after draining the oil to pull the filter, punching a hole in the filter, etc. And with dozens of oil change iterations under my belt I've finally reached the point where I only make a gargantuan mess pulling the filter every 2nd or 3rd time. It's just the way it is. Expect and plan for a mess. You won't feel disappointed or rushed when it happens, and you'll feel great on those occasions when it doesn't.

-

Teach me about audio panels

Vance Harral replied to ragedracer1977's topic in Avionics/Panel Discussion

Concur. -

'67 M20F Gear Horn Wiring Question

Vance Harral replied to SLOWR426's topic in Vintage Mooneys (pre-J models)

Most obvious thing is the (-) terminal of the "gear" connection on that terminal block appears to have nothing at all connected to it. That would be consistent with the gear horn not sounding. -

Teach me about audio panels

Vance Harral replied to ragedracer1977's topic in Avionics/Panel Discussion

It's likely Tahir's '66 M20E is wired similarly to my '76 M20F. If so, the attached schematic which depicts how we wired our gear warning system to an AV-17 voice annunciator may be of use. In our airplane, the factory-installed, "old school", simple sonalert for the gear warning has one terminal tied to ground. The other terminal is floating until both the "gear down" and "throttle low" logic switches close, at which point +12V is applied to the sonalert terminal, causing it to sound. We attached an additional wire to that sonalert terminal to drive the AV-17 voice annunciator trigger input. The AV-17 requires logic signals to be switched to ground to actuate warnings, so the additional complexity of an inverting circuit is required. In contrast, the PMA450B has an active-high audio alert trigger input on pin J2-17, so the inverter would not be necessary if that input is used. But as the attached schematic shows, we also added a voice trigger for the ram air warning light, which is also active high, and therefore required a second inverter. Unless the PMA450B inputs are programmable, it appears only one of the trigger inputs is active high. If you want a voice alert triggered by the stall warning, that sonalert is wired in such a way as to be active low. No inverter required to connect to an active-low input. In summary, and to repeat... the relationship of a old-school sonalert in a vintage Mooney to a voice annunicator such as the AV-17 or PMA450B, is just that the terminals of the sonalert provide a convenient location to connect to the trigger logic. Based on jcovington's responses above, it looks like newer Mooneys have additional hardware/integrated sonalert devices that have their own audio out line. But... and I'm guessing here... I think the only audio signal they output is a simple tone. If you want an actual "Bitchin' Betty" voice alert that speaks English words, you need a box that synthesizes that... such as an AV-17, or the PMA450B itself. system-p1.bmp