-

Posts

1,508 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Store

Everything posted by Vance Harral

-

Pitot static cert voided after avionics mods?

Vance Harral replied to FlyingDude's topic in Avionics/Panel Discussion

Maybe there's just a misunderstanding of language here. FlyingDude originally asked, "is my 24 monthly test void?", and Shadrach references "IFR certification". But those terms are not mentioned in the actual regulation. There is not a single "24 monthly test", or "IFR certification" that can become invalid. There are instead three separate testing requirements in the regulation, involving three separate systems. Per 91.411, each static pressure system, each altimeter instrument, and each automatic pressure altitude reporting system must be tested and inspected. Per 91.411(2), opening the static system requires a re-test of the static system. I think we all agree that event doesn't trigger a required re-test of the altimeter(s) or transponder(s), but I hope we all agree it triggers a re-test of the static system, because the regulation is plain as day on that point. Per part 43 Appendix E, that static system test must be in a manner "acceptable to the administrator". My interpretation is that a simple A&P/owner-assist leak check done with something like a handheld vacuum pump, stopwatch, and VSI doesn't meet that standard. I think the standard requires specific training and equipment that the average A&P doesn't have, e.g. equipment like this. I understand others may disagree. I agree with Shadrach that the altimeter in a G5 is not a primary, certified altimeter, and does not require altimeter testing per 91.411; but that's orthogonal to the OP's question. -

Pitot static cert voided after avionics mods?

Vance Harral replied to FlyingDude's topic in Avionics/Panel Discussion

OK, I'll play. If your point is that opening the static system doesn't void the altimeter or transponder checks described in FAR 43 Appendix E paragraphs (b) and (c), sure. But it does require the static system checks described in paragraph (a), particularly clause (2). The sub-clause about part 25 certification doesn't apply to Mooneys, but one must "Perform a proof test to demonstrate the integrity of the static pressure system in a manner acceptable to the Administrator". I suppose one can envision all kinds of methods that might accomplish this, but the FAA literature - including specifically AC 43-6D - makes reference to the kind of equipment and trained personnel that only repair shops which provide full 91.411 certification have on hand. If you are proposing there is some other "proof test", that your are confident is "acceptable to the Administrator", which requires only equipment and training the average A&P has in their shop, I'm all ears. My basic point is, you can't just install a G5 or GI-275 and say, "the installer was careful when they tightened up the static system connections, and that's good enough". The static system must be tested, using equipment designed to do so. -

Pitot static cert voided after avionics mods?

Vance Harral replied to FlyingDude's topic in Avionics/Panel Discussion

Do you intend to operate under IFR? If so, I think the 91.411 requirement is pretty clear: Per 91.411(2): Except for the use of system drain and alternate static pressure valves, following any opening and closing of the static pressure system, that system has been tested and inspected and found to comply with paragraph (a), appendix E, of part 43 of this chapter; Connecting a G5 to the static system certainly involves opening the static pressure system. If you want to be strictly legal, a re-test is required. -

You don't say what year model your 201 is (this matters), but it sounds like you're looking for the engraved plastic cover that snaps on to the Klixon breaker switches installed in Mooneys in the mid-60s to late 70s. The bad news is, you simply can't buy just a new, engraved switch cover. These are effectively Mooney-specific parts, and the factory doesn't offer them for sale. The factory might be able to sell you a whole switch (not just the plastic cover) for a hefty price. But they may not have any in stock. It seems that any time someone looks into it, the factory says they are simply not in a position to make a bulk order from Klixon (Sensata) for these parts. Your options are to search the salvage yards (Wentworth, Beegles, etc.) for a donor part from a totaled aircraft, or engage with one of the several enterprising Mooneyspacers who have developed 3D-printed replacements. There is a lengthy thread about that here:

-

The OEM CHT probe on vintage Mooneys is a thermistor, not a thermocouple like modern engine monitors use. It does not generate a voltage when heated, but rather varies its resistance in response to heat. You can still check it with a multi-meter, but you want to measure resistance as you heat the probe, not voltage. The usual failure mode is that the insulated positive lead at the top of the unit twists, and breaks the resistive connection internal to the probe. Sometimes this can happen from vibration, but it's equally common for the little nut that connects the wire to be overtorqued by ham-fisted repairmen, who wind up twisting the lead instead of just snugging up the connection. Aircraft Spruce carries the probe, but it is irritatingly expensive for what it is, and frequently out of stock: https://www.aircraftspruce.com/catalog/inpages/rochcht.php

-

This idea of "taking your aircraft into the Experimental category" comes up from time to time. It sounds like Anzaldi01 understands the implications, but for others who may be thinking about this, understand that there are multiple sub-categories of Experimental, most of which don't enjoy the broad freedoms afforded the Experimental Amateur Built category most pilots associate with the word "Experimental". If you're really serious, you can surrender the Normal category airworthiness certificate for your Mooney in exchange for, say, Experimental Research and Development or Experimental Showing Compliance with Regulations. However, once you do that, you may only operate the aircraft for those purposes. i.e. you can conduct test flights in a limited, local area; but you can't go for a $100 hamburger or take the family to visit Grandma. To use the airplane for recreational/business purposes, you have to put it back in the Normal category, which will require removing whatever gizmos caused you to go Experimental in the first place.

-

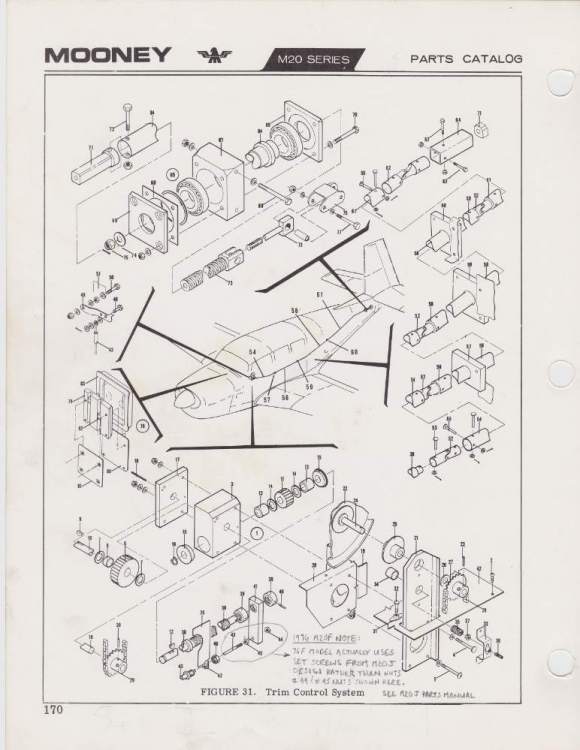

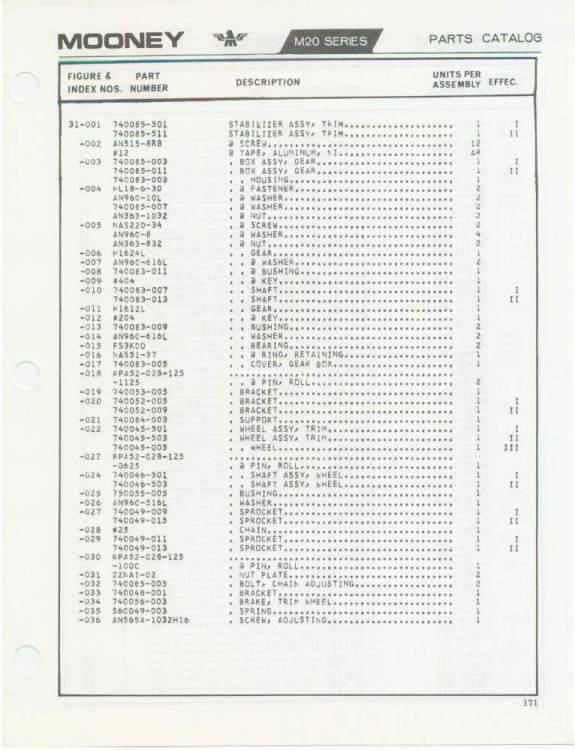

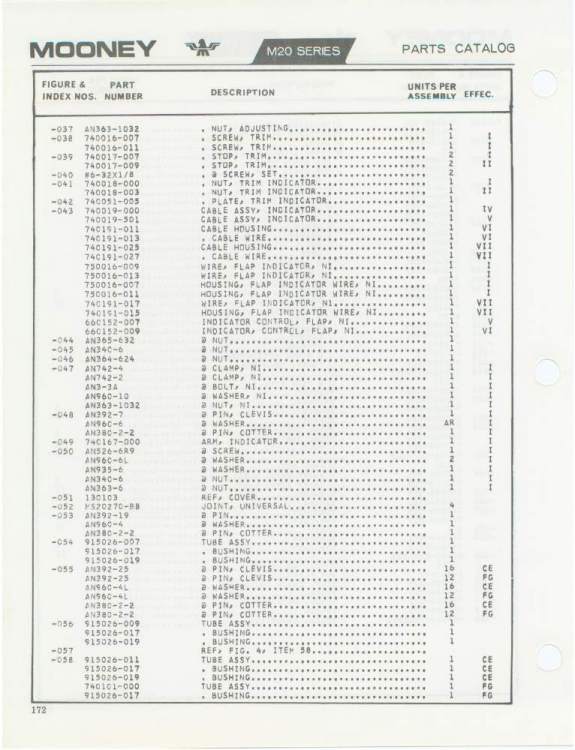

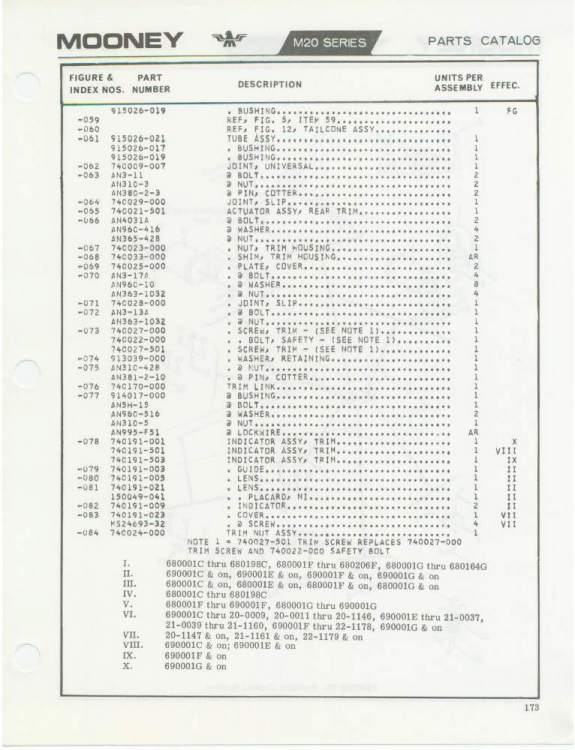

M20C Trim Jack Screw Issues

Vance Harral replied to Mx_edge's topic in Vintage Mooneys (pre-J models)

Allowable empennage slop is spec'd in Mooney Service Bulletin M20-62: https://mooney.com/wp-content/uploads/2020/12/SBM20-62.pdf With respect to the fore/aft play involving the trim system, the spec is 5/16" movement as measured at the bottom of the rudder trailing edge. When we purchased our airplane in 2004, the play in this area was a little under 1/4". Over the course of 14 years, it came to exceed the 5/16" spec. I admit we let is slide a few years when it was really a tad over spec. After LASAR overhauled our jackscrew assembly in 2018, and we re-installed the overhauled unit with new AN hardware, it's back well under 1/4". LASAR installed new bearings and a new shim set, but the jack screw itself and the threaded structure that receives it did not need to be replaced. -

M20C Trim Jack Screw Issues

Vance Harral replied to Mx_edge's topic in Vintage Mooneys (pre-J models)

Obligatory pedantry: you really need to get your own copy of the official parts manual, and your A&P isn't technically allowed to work on the airplane without owning or having access to that manual. Turning to something more helpful... the tail trim mechanism does indeed include a jack screw assembly, but it is a complex assembly of multiple parts, and it is not necessarily the screw itself that causes play. Attached to this post are pages from my copy of Mooney MAN 205, the "M20 series parts catalog issues 1976 revised June 1977", detailing the trim mechanism. Make sure you map your specific serial number to the applicability list on the last of these pages. There is also an extensive thread here on Mooneyspace about the jack screw assembly, in which both binding and play in the trim mechanism are discussed: Working on your jack screw assembly will require removing it from the airplane, which is discussed in the above thread. Once it's out, some mechanics are brave enough to open up the assembly and perform their own overhaul using parts sourced from a Mooney MSC. Others who are more chicken (like me) pack up the assembly and send it to an MSC for mechanics experienced with the mechanism to perform an overhaul. We had our jackscrew assembly overhauled by LASAR in 2018, it's holding up well 3 years later. -

Interesting, particularly this quote: "ANR is only effective in the low frequency range, below 500 Hz, because of physical limitation whose examination goes beyond the scope of this paper." A little more digging turns up this Avweb tutorial which says typical aviation ANR headsets only cancel low-frequency sound, and actually "overboost" noise a few dB in a small region around that. So I think I stand corrected: ANR has important limitations on protection, despite how good it sounds perceptually. What's unclear to me is how much cockpit noise occurs that is actually outside the range where ANR is effective. I found one paper here that suggests intensity doesn't roll off below 85db until about 1000 Hz: https://www.faa.gov/data_research/research/med_humanfacs/oamtechreports/1960s/media/AM68-21.pdf

-

I've seen this claim in several places. I'm trying to keep an open mind, but I'm having a hard time understanding the claim from a physics standpoint. Sound is just waves of air pressure. The higher the amplitude of those waves, the more your body (eardrums in particular) is affected by them, and the greater the potential for damage from long-term exposure. By definition, ANR reduces the amplitude of the original pressure waves, by broadcasting pressure waves that are out of phase with the original sound. It's not a perfect match, but the net result is always lower amplitude of pressure waves. Statements that "the sound/pressure is there but you don't detect it" are tough for me to reconcile with the physics as I understand them. The only way I think this claim could be true is if the ANR were frequency shifting the original sound to a very high/low frequency that cannot be heard by the average human, rather than decreasing its amplitude. Anything is possible - maybe there is some harmonic effect - but frequency shifting is certainly not what ANR systems are designed to do. None of this is meant to suggest that good passive protection and/or "double bagging" isn't the best belt-and-suspenders approach. I just don't get the skepticism about ANR being effective in preventing long-term hearing damage.

-

Fastest M20F ever....

Vance Harral replied to blaine beaven's topic in Mooney Safety & Accident Discussion

I don't know the answer to that question, but I do know the one airplane I've seen subject to an over-G condition (a high wing Cessna) had misaligned wing halves and oil canning on the wing skins. The damage wasn't so significant as to be grossly obvious to a casual observer, but it wasn't difficult to see if you just stood about 20 feet away from the airplane and gave it a decent eyeball look. The lesson I took away from that is, make sure your pre-flight inspections include "big picture" looks at the airframe. I see a lot of pilots get so focused on inspecting individual nuts and bolts that they could easily miss the entire empennage or wing structure being bent. -

If multiple avionics devices on multiple different circuits are all glitching at the same time, with no breakers popping, that sounds like a problem with the avionics bus voltage, not a problem with any individual device or circuit breaker affecting others. First order of business is to determine whether the affected devices are all on the avionics bus (do they all turn off when you turn off the avionics master?) If so, it's likely something is drawing a heavy load on the avionics bus, and yes it could be a short directly on that bus due to water or a loose wire. If not, then it's likely still the same sort of issue, except it's affecting the main bus (which drives the avionics bus when the avionics master is on). These busses are physically implemented by bus bars behind the circuit breaker panel, so I'd look back there for moisture or loose wires. As for why some devices shut down and others didn't, most modern electronics will automatically shut down if their input voltage falls below a certain threshold, but that threshold varies from device to device. A "lightweight" intermittent short on a main bus can therefore glitch some devices and not others that are all on the same bus.

-

It wouldn't matter except for the regulatory framework regarding who can disassemble a unit for maintenance and repair.

-

Fair enough, but when I say our airplane is rigged correctly, I don't just mean the preload torque; I mean the full procedure described in the maintenance manual, last performed when we removed the main gear to install new pivot link bushings from LASAR. I think the only thing that can be said is either some airplanes which flex the floor pan are operating as designed by the factory, or that the gear rigging procedure can be correctly followed and still "overdrive" the system by your standards.

-

That $25K settlement would be perfectly acceptable to me if: 1) My wife/child's life insurance company has already paid me directly for the full value of the financial loss, and the $25K in question is only going to my insurance company, not me. This is a somewhat common scenario. 2) I am only interested in actual financial damages, not punitive damages. I concede this is much rarer. Not everyone carries adequate insurance for themselves, of course, and their financial straits in the event of a loss is high motivation for them to retain an attorney and sue. But a lot of people do carry adequate insurance for themselves, and have no motivation to personally sue anyone after they've already been adequately compensated by their own insurer. How likely you think this scenario is, is part of the calculus of selecting the limit you're willing to pay for. Issue (2) is very tricky, of course, because the need for vengeance is a common human emotion. If Jeff Bezos mows down my infant child in a botched Blue Origin Shepherd landing, I'm going to want every penny of his billions, despite the fact that the financial impact to me is actually positive since I no longer have a child to raise. But the ugly part of this calculus is, just because I tell my lawyer I want every penny doesn't mean Jeff is actually at much risk of losing his fortune. More importantly, the need for vengeance is dependent on the actual incident. Again, if his Amazon-ness kills my infant child, I might spend the rest of my life pursuing him in court. But if all he did was knock the bumper off my 2007 Suburban, I wouldn't go looking for millions just because he's a rich guy. I concede others would, but their likelihood of success is low, and almost all attorneys they might retain know that in the first place. Anyway... I don't think there's actually much disagreement between us. Again, I just get a little tired of the implication that accepting $100K passenger sub-limits is foolish. It may or may not be foolish, but it depends on the insured party's particulars and risk tolerance. It is also the case that in some scenarios one simply cannot get any kind of aircraft liability insurance without $100K sub-limits: low experience, aircraft is in a partnership, etc. Accepting $100K sub-limits is certainly a financial gamble, but arguably no worse a financial gamble than flying a small airplane and thereby becoming an attractive target in the first place. And again, if $100K sub-limits aren't acceptable, what is? Pretty much every argument that applies to $100K limits also applies to $1M limits. As Mike noted, you can easily burn through $1M of damage, health care, etc.

-

That makes absolutely no sense to me, unless a "pin" is installed somewhere that prevents the landing gear from retracting at all. AD 75-23-04 makes Mooney Service Bulletin M20-190 mandatory. That SB requires removing and inspecting the landing gear actuator for worn internal gears. There is no "pin" involved, and I'm extremely skeptical that AD 75-23-04 is actually N/A to your airplane. Strongly suggest you have your mechanic research the AD and SB in detail.

-

I'm trying to understand why you would say this. Both the mains and the nose gear linkages in these systems incorporate heavy springs, which get compressed when the gear pivot links pass over center. The gear rigging checks effectively measure the spring compression force in the locked position, and there is a minimum standard below which is unsafe. Therefore, it is completely normal to have transitory loads during the time the pivots are going over center, which put the entire linkage system in compression, and therefore induce some amount of flex in the connections to the airframe. It is not true that these compressive loads and flex in the system mean the actuator is being driven beyond normal limits. It is true that excessive loads and flex indicate a problem, perhaps that's what you're getting at. But as we see from the postings here, multiple owners with correctly rigged gear report this "butt bump" in the seat pan when the gear transitions.

-

Electronically, this is true. Mechanically, the switch that engages the altitude hold is mounted in the BI-601 head unit. If the switch itself has an issue, repair will require opening the BI-601 unit for service. To my knowledge, only Brittain can legally do this, and they're not accepting work. I'm not trying to discourage the OP from working on their autopilot. It is certainly true that the B6 system consists of multiple sub-systems, and even just getting some of them to work is nice. We have a B-5 in our airplane, which was inop at the time of purchase. We got the wing-leveler (PC) component working fairly easily and quickly. Heading hold came later, though we never have gotten it to be quite as precise as we'd like. Nav tracking came even later, and we didn't get the altitude hold working until about 8 years into ownership.

-

I'm not disagreeing with your point. But everyone accepts some policy limit, and hopes the insurance company's duty to defend eliminates or at least mitigates any damage beyond that limit. $1M is also a "drop in the bucket" if a high net worth individual is killed. What makes $100K an unacceptable limit, and $1M acceptable? Why not $2M or $5M or $10M? The answer lies in the net worth of the individual purchasing the insurance. No matter how good a shark the damaged party's attorney is, they're not going to spend time pursuing a $10M judgement against an individual whose net worth consists of a Cessna 150, eighteen dollars in a checking account, and stack of pizza coupons. I grow tired of the accusation that pilots who accept $100K sublimits are cheap and naive. $100K sublimits are completely reasonable for a large percentage of aircraft owners.

-

Bear in mind that the "claimant" is often not the inured party themselves, but rather the injured party's own insurance company, who has already paid the injured party the full $1M, and is only attempting to subrogate against your insurer. The odds the injured party's insurance company will accept a $100K payout from your insurance company in the settlement, even though they just paid their own client $1M, are actually pretty decent. The $1M they paid their client is presumably already built into their own actuarial bets, and they're just trying to move the balance needle a little toward the side of profitability. Given a "take $100K right now or pay your own attorneys to fight us in court for a long time" offer, the injured party's insurance company is quite likely to take the settlement offer from your insurance company, even though it's only a fraction of what they paid out. None of this settlement negotiation involves either you or the injured party. It's just a dispassionate business discussion between two insurance companies, both of whom would like to avoid a court case. To be clear, you might be unlucky enough to injure someone who has absolutely no insurance of their own but subsequently hires a shark of an attorney; or the injured party's insurance company might be willing to go fight your insurance company in court, and win. But in most cases there are incentives not to press an individual for more than the limits of their policy. Interesting data point: during an insurance webinar given by Avemco, I asked why Avemco doesn't offer "smooth" insurance. The person on webinar claimed that industry-wide knowledge Avemco doesn't write smooth insurance and aggressively defends per-passenger sublimits, has resulted in a history of essentially every claim they process being settled for said sublimits. I have no way of verifying this is true, but it's interesting to think about.

-

The bracket on the airframe which your gear actuator mounts to, is in turn mounted to the floor pan directly under the pilot's seat. As the gear goes over center, compression of the springs in the system cause the rods to compress against the actuator on both the fore (nose gear) and aft (main gear) ends. This compression, combined with the aluminum floor pan not being perfectly rigid, will cause a "bump" under your butt in the left seat. Our 1976 M20F has consistently done this for the last 16 years, through numerous gear rigging checks, with no long-term ill effects. I've come to think of it as an additional "gear is down and locked" indicator. When I put the gear down, in addition to looking for the green light on the panel and checking the floor indicator alignment bars, I expect to feel a kick in the butt. On edit: if your log books indicate recent completion of Mooney Service Bulletin M20-190 (the AD that @Ron McBride refers to), I would not do anything at this time. If there is no record of this inspection being done recently, then yes, you ought to have the gear actuator checked out. But that is true independent of the "bump in the butt" observation. For further info, see https://www.donmaxwell.com/ad-75-23-04-sb-m20-190

-

Careful. The OP didn't say he had a "PC" system. He said he had a Brittain B6. That is a three-axis Brittain autopilot capable of nav tracking and altitude hold. In addition to the T&B and servos everyone correctly describes as simple, the B6 also has a control head unit full of electronics (not modern ones) with a complex rotary mode switch, as well as a complex altitude control unit, and the associated vacuum switches and relays required to make it work. Our own @211º has been through the Brittain saga, and was kind enough to collect a bunch of information from a bunch of different sources, and organize it at https://www.windfield.farm/brittain-autopilot. It's the best reference I know of on this class of Brittain autopilot. TLDR summary: it is feasible - if a little gray from a legal perspective - to patch cracked vacuum lines, re-seal servo boots, etc. But if there's an issue with the control head unit or the altitude control box, you're effectively out of luck. It is extremely difficult to get service for these modules, and any service you could actually get is one-hundred-percent not legal. Only Brittain holds the legal authority to do this work, and they're not taking any customers.

-

This is the best advice in the thread, and I'd add that it's true any time of year, not just in the summer. No matter how many weather sites, Foreflight features, etc. you find that promise "5 day" or "10 day" forecasts, none of them can help you make a strategic go/no-go decision a week in advance. Any weather forecast more than a couple of days in the future is for entertainment purposes only. I spent years agonizing over this sort of stuff, but I've stopped. My dispatch rate is just as good, and I sleep better at night, by simply ignoring weather planning until 24-48 hours before intended departure. This means I sometimes have to move departure dates, cancel trips, or go via last-minute expensive airline tickets. But that was true when I used to agonize over the weather days in advance, too. Such is the nature of GA travel. The sooner you accept that reality, the more you can actually enjoy it.

-

If $7500 for an engine monitor causes you to balk, suggest you install a much less expensive engine monitor, and consider working with an A&P to do some/all of the work yourself to save on labor cost. I am not claiming a JPI EDM 700 or EI UBG-16 is just as good as an EDM950/MVP-50. But those choices are literally thousands of dollars cheaper, still well supported, and still provide all the basic functionality you need for good engine management. Very reasonable in any airplane, especially one in which the owner is reasonably choosing not to turn it into a $100K glass panel beast.