Aerodon

Supporter-

Posts

1,293 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Aerodon

-

By the Mooneyspace definition, modern.

-

After years of following this site, adding a contribution or two, and selling bits and pieces, I am now a Mooney owner. Hope to take delivery next week. Now let's have a competition - ask 20 indirect questions and guess what model it is. Winner gets $200 off best advertised street price of a JPI system. Aerodon

-

To Powerflow or not to Powerflow - That is the question

Aerodon replied to Bart Chilcott's topic in General Mooney Talk

I installed a PF on a 180hp floatplane where we really needed the extra 100rpm it would provide on the slide. I did not care for the extra noise it makes or for the extra annual expenses. At one stage I had an extra PF exhaust, and I think PF wanted $300 or 500 to transfer the STC. Too high in my opinion, sometimes things change and you have to move a product from one plane to another. They also play ridiculous games with pricing and delivery schedules. This is not an airline ticket where you need to pay a premium for delivery next week. For these reasons alone, I probably will not install another one. Aerodon -

Larry, pg 3.3 & 3.4 deal with the specs for non-Garmin antennas. The GPS needs 1-25dB 40 max gain. The XM says 24dB max, with a note to add attenuation for each dB above this. I had a CI401-460 on the shelf (A $900 antenna) which has 27-35dB GPS gain and 26-30 dB XM gain. So with about 3dB loss in the cable and connectors, I added a 3dB attenuator. It's a special kind that allows the 5v to pass through, and cost $104. Aerodon

-

Do you have pictures of your Mooney blank panel please?

-

you mean 115 cu ft system?

- 1 reply

-

- 1

-

-

I bought both a GDL52 and GDL52R to play around with. (Can't help myself sometimes). For some reason my 660 does not 'auto connect' even though I have that option ticked in the setup. Have to go to BT every time to do it. I had a combined GPS/XM antenna on the shelf, but it needed an antennuator to get the output specs to match the GDL52R requirement. I used on the the 'cats whisker' antennas (slightly different length to transponder antenna). Thanks to Dave Medin for all his pre-made antenna cables and antenna advice. He's my 'go to guy' for pre-made antenna cables at very reasonable prices. PM for details. There are several reasons for the 52R over the 52: 1) get the cables out the cockpit and obstacles off the glare shield. 2) better reception with top and bottom mount antennas 3) solid base for AHARS I tried the BT around the house, and it works well (even at 40'), so I suspect that if you mount it on the rear avionics shelf 'looking through' plastic, it should be fine. But I'm hardwiring to audio panel, and 660 / 796. I love my XM music subscription, can't do without it. So far, no regrets. You could of course 'hard mount' the 52, and run inexpensive antennas to suitable locations. Aerodon

-

JPI 900 Installation Costs for 76 M20F

Aerodon replied to jerrodmonaghan's topic in Avionics/Panel Discussion

No, you are perpetuating a myth, I've researched this and: 1) The Cies frequency based transducers have 2000 steps, and will require a $3-400 'upgrade' from JPI. That is 0.025G increments in the average 50G tank. 2) The resistive or voltage Cies transducers have 500 steps, or 0.1G increments. Cies charge an extra $100 per pair, so this is the more economical way to go. Either way, accuracy is the same. I used the voltage output version, straight into a standard EDM, without the JPI 'black box' Voltage converter. I did not use the Cies connector option (too bulky). I ran 3 new wires to each side (power, ground, signal). Power from the original FQ CB. You can ground the transducers at the tank, but I grounded at the JPI. Aerodon -

JPI 900 Installation Costs for 76 M20F

Aerodon replied to jerrodmonaghan's topic in Avionics/Panel Discussion

Jerry, I would say 40 hours plus or minus 10. Why such a big range you might ask. If you are really organized, have the new hoses and other parts on hand, don't need to do any panel cutting and do it at annual when everything is open, its very different to taking it in just for an EDM900 upgrade. And panel creep.... Aerodon -

Comant CI-505 Triplexer -- Potentially Bad?

Aerodon replied to MisfitSELF's topic in General Mooney Talk

Too little information: 1) what antenna do you have on the tail - towel bar, two blades or cat's whiskers? There's lots of room for antenna failure, balun failure, bad terminals, combiner failure etc. 2) then probably have RG142 Co-ax - time to upgrade to RG400. 3) what radios do you have? Some have separate ILS and VOR RF connectors (KX155) and others have internal splitters and 1 RF connector (SL30). If you've had any sort of upgrade, I would check that you still have the right splitter installed. Needs to be an exact match, antenna to splitter, ILS to ILS, VOR to VOR and no empty ports. My bet is on #1 above, easy enough to get all this checked out by an avionics shop. Don -

I have several news ones for you, Aerodon

-

Pricing a charitable sightseeing flight

Aerodon replied to Robert C.'s topic in Miscellaneous Aviation Talk

I listed a sightseeing flight at a charity auction a long time ago. No minimum, what difference does it make to you whether the charity gets a small or large amount? The top bids were all really good, so I told the organizers to accept the top three. Everyone wins. -

Spend my money for me - new panel dreaming

Aerodon replied to Rick Junkin's topic in Avionics/Panel Discussion

There's a Mooney M20M on Controller with a made over panel. Some ideas to transfer: 1) The TKS is in the centre stack, looks good. 2) There are three rows of switches on the LHS - move the ones that make sense over there. 3) I'd go remote transponder or remote audio, before moving stuff to the second column. 4) Things like the GFC500 controller, Annunciatior panel, TKS panel are generally quite 'shallow' so fit better at the top or bottom the panel. 5) I still like the EDM900 on RHS 6) Start lining things up - nothing like a good horizontal line through the screens, including iPad Aerodon -

Spend my money for me - new panel dreaming

Aerodon replied to Rick Junkin's topic in Avionics/Panel Discussion

Rick, Your last iteration is getting better, but it still hurts my OCD a bit. I prefer the GFC500 at the top of the stack, like corporate aircraft and airliners. I'm taking the plunge and going both remote transponder and remote audio panel. There is a way to make the GNC255 the 'failsafe com'. And I did a C172 panel with the EDM900 down near the controls - it works well, and then your copilot can see the engine parameters. Don -

Thanks, updated. I got a 'Notification' from the above reply, but nothing from the replies to my original posting. My apologies. But when I'm serious about buying something - PM or email to the seller with questions, best way to get a reply. Aerodon

-

-

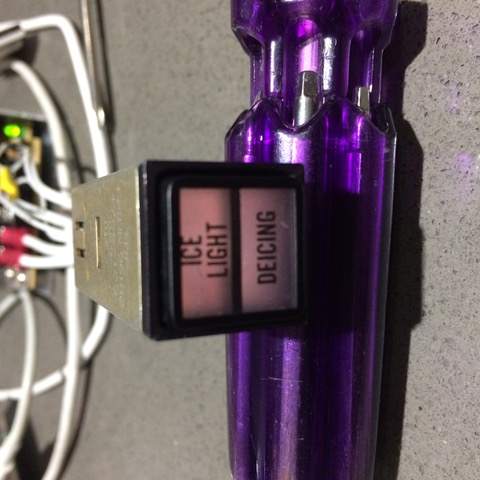

The landing gear unsafe light has 4 bulbs, how is that for redundancy. The deice light is a switch to turn the ice light on (to view ice on the boots on the wing) and the lower two bulbs light up when the deicing cycle is in progress. Cost me $70 for each 'capsule' (display) and the body is about $350. I bought a boxful of new surplus 'TAWS' annunciators, so have a stock to supply to my panel customers. A much less expensive option is to use the dialight LED panel lights (above the ELT switch). JPI have a neat one that does amber or red, but I have not found a source yet. Don

-

I'm replacing the OEM annunciators with Eaton annunciators. Quite expensive, especially when you are doing 8. But sure looks good. Custom graphics, and various switch options. I have one for 'ice light' to switch on the ice light as well as annunciate. Others have a non-latching switch (push to test?). Don

-

G5 install in the home stretch. GMU11 question

Aerodon replied to ragedracer1977's topic in Avionics/Panel Discussion

LED's are not going to help, just sort your grounds out. -

G5 install in the home stretch. GMU11 question

Aerodon replied to ragedracer1977's topic in Avionics/Panel Discussion

I was advised to run new grounds from my tail nav and tail beacon to 'in front' of the GMU11. I pre-emptively replaced the Cessna 'flasher' with one on the Whelen 'integrated flasher' because I just knew that was going to be a problem. Passed the GMU11 test with nothing more than 15% of the limit first time. Don -

OK I pulled the trigger on a GTN750. Have the following for sale: 1) GNS480, excellent low time unit, up to date software. $ traded 2) GTX33ES fresh back from Garmin for ES update $1800 available 3) GTX345 - new unit with encoder option $old supercub180@gmail.com Don

-

Like new JPI EDM 830 for sale - SOLD

Aerodon replied to JohnB's topic in Avionics / Parts Classifieds

John, OK here's the retail price for a head only, I'll take it for half of that, Don TRADE-IN EDM 700/800/760 to EDM-730/830/and the new 790 ( Use existing system wire harness, probes and Transducers). Indicator only. $1350. -

sorry sold and updated

-

The roll problem in my Seneca was much worse in the climb. Also, if the FD bars are leading the turn, is that not an indicator that the servo is not keeping up? Seems to me trying another servo is a quicker ‘plug and play’ option the the FD. I have a FD for you, just send me an email. Supercub180@gmail.com. Aerodon

-

So I did the 5.7 software upgrade and both units rebooted ok. On the next power up the HSI g5 failed to come on, tried 2 or 3 times. Then powered on while holding the power button down and it came to life. Can’t remember if it was setup mode or not. But it now it works.