-

Posts

6,403 -

Joined

-

Last visited

-

Days Won

33

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Ragsf15e

-

CO2 detectors the "Good The Bad and The Ugly

Ragsf15e replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

That seems like it would be ok, but the readout/sensitivity on the sensorcon is really nice. The guardian doesn’t go off until 50ppm and you don’t know what the actual level is. If I see 20+ on the ground, I already know I have a problem. More than about 5 in the air, same. I’m just hoping the sensorcon company isn’t defunct. -

There’s also a ring you can wear to continually monitor it. That’s a nice addition. Sorry, I don’t have a link. I use oxygen on all flights above 8k now and feel so much better for it.

-

You guys are making it a lot more palatable for me to freeze my ass off in Washington all winter just to enjoy our nice summer temperatures!

-

You can do a full power run up without overheating. You probably don’t want to run for an extended time like that, but a runup is fine. Also be careful that the ramp is clean (to save paint dings and your prop). One thing to be cautious of is setting “max rpm”. You’re looking for max power yes, but with enough ROP to provide some cooling from the extra fuel. If you do your max power runup, set around 50rop and then takeoff with the thin air and slow climb, you’ll quickly have very high chts. You need to be well rich of peak egt. Personally I like the target egt method and it works pretty well at higher altitudes, but a full power runup is certainly another option. I set my target egt (egt from a full rich sea level takeoff) during the takeoff roll, but it requires knowing the egt, having an engine monitor, and doing it during the takeoff.

-

Exactly. Just be very careful about the water…

-

On my ice unit, the condensation drips back into the ice chest which was pretty secure. I just wouldn’t want your condensation in a pan made to be stable, sloshing all over the place as you’re flying. In Florida humidity, you’re going to make water and put it somewhere.

-

Maybe be careful where the water goes if there’s some type of collection pan. You don’t want to drench what’s under your back seat…

-

The M20F Performance Benchmark thread.

Ragsf15e replied to Shadrach's topic in Vintage Mooneys (pre-J models)

We’ll have to try to get a few different altitudes. I usually fly 8-10k up here but I’ve seen the best speeds around 6,000’. -

The M20F Performance Benchmark thread.

Ragsf15e replied to Shadrach's topic in Vintage Mooneys (pre-J models)

I have class C above me too, but I can almost always get cleared through it before I have to level off to stay below. So I did one a few months ago at published Vy and now I’ve done it twice at 105mph which is about 5mph slower and my rate is better. My engine temps have been fine, but it’s pretty cold up here still. -

So here's a plot from right after my previous oil change (Nov of 2023) and then one from a flight from the recent one. Looking at them, the oil pressure is only about 3psi average higher, but I have never seen it in the 80s before which is why I noticed it. Oil temps appear the same on both flights and both pressure and temp are pretty stable for long periods (both of these flights are 2-4 hours). Weird, but probably nothing... This is the recent one below:

-

The M20F Performance Benchmark thread.

Ragsf15e replied to Shadrach's topic in Vintage Mooneys (pre-J models)

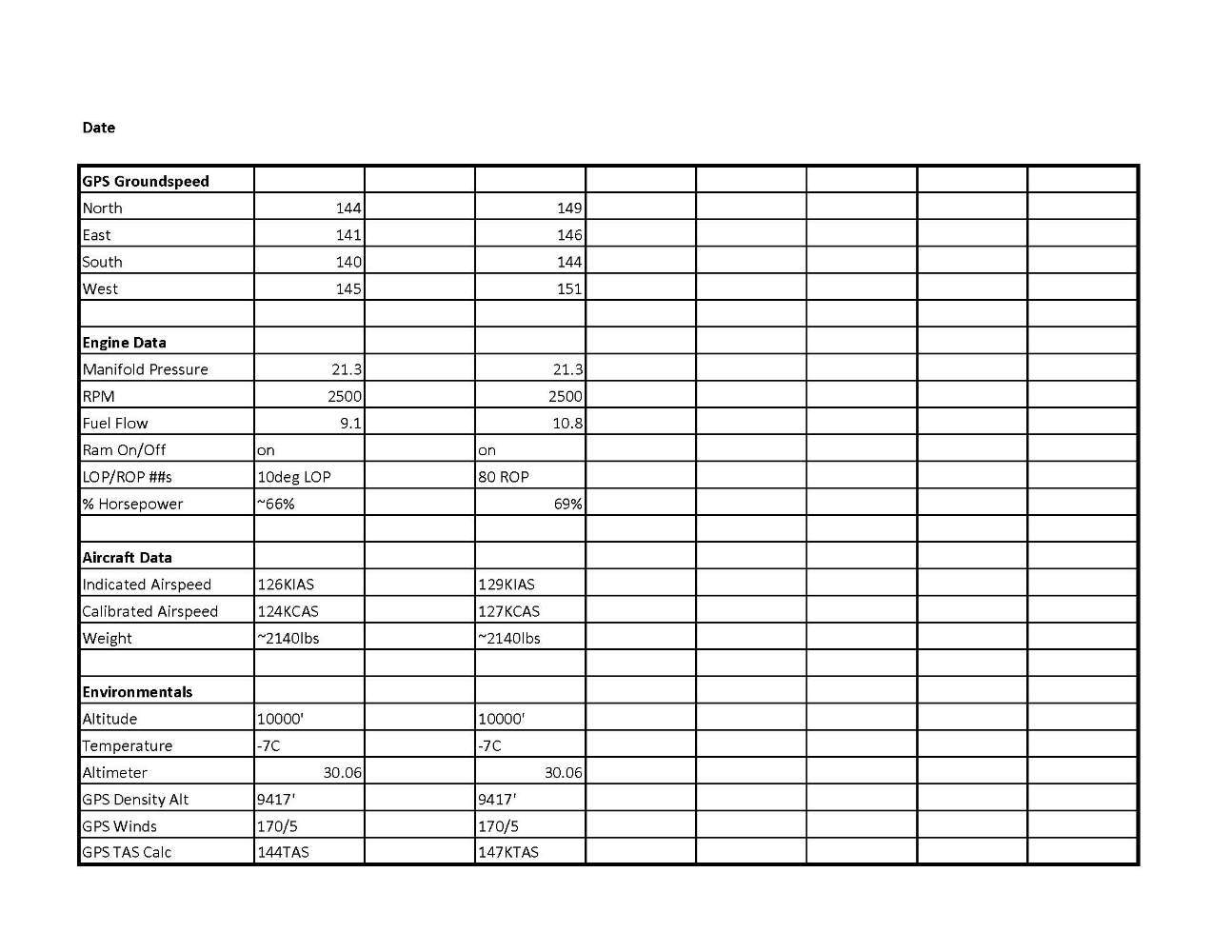

https://globe.adsbexchange.com/?icao=a4be6e&lat=47.625&lon=-117.353&zoom=11.8&showTrace=2024-05-03×tamp=1714757520 That should link to the flight. I did a timed climb at 105 mph indicated from 2000' field elevation to 10,000'. DA at takeoff was 3121'. Weight was 600lbs below MGW, about 2140lbs (pilot, some junk in the back and 30 gallons fuel). Initial climb was ~1100fpm, 2000-6000' in 4:20" (~925fpm average). 6-8000 in 2:15 (~890 fpm). 8-10,000 in 2:50 (705 fpm). Overall, 2000'-10000', ~850fpm. I have a 3 blade prop and a 201 windshield, but otherwise stock. Having owned it for 10 years, it's always been a bit slower than I see others claim, so it won't surprise me to see climb a bit less than others. Although I started from 3000' DA instead of sea level like @Shadrach, so I lost out on the higher climb rates down low helping my average. Then I did LOP and ROP speed runs at 10,000'. Here's the chart I use. I get groundspeed in each cardinal direction and then put that into a TAS computer when I get back home (https://www.eaa62.org/technotes/speed.htm). You can just take the average of the 4 way and get close, but it won't be correct as it will always indicate slightly higher than truth based on the wind drift (headwind and tailwind are taken out with the average but sideways isn't). Depending on winds, average of the 4 directions is within about 1 knot (it will always be higher than truth). These are 10,000', -7C, light airplane, relatively forward CG: So LOP, I get 142.5 KTAS And ROP, I get 147.5 KTAS -

The M20F Performance Benchmark thread.

Ragsf15e replied to Shadrach's topic in Vintage Mooneys (pre-J models)

How's you get the pretty table for your climb? Did you make it yourself or is there some way to export off adsb exchange? -

Alright, here's my Chicago shot... it's summer 2003. If you look very close at the bottom left, I think that's Meigs. We were flying the Gary airshow that weekend, but the runway there was 500' too short for us, so we flew out of O'hare! Was so much fun. Held over the lake (dumping gas because we'd be too heavy to land after the flyby) and then formation approach back into O'hare. I loved taxiing there - there was a taxiway bridge over a highway! We went over it and people were hanging out their windows waving at us. It was a good time to be a fighter pilot. Funny story from the actual airshow flybys... we were to go North to South down the runway at 500' and 500kts in fingertip formation and start a climb past the end of the runway. We had comms with the airshow coordinator who actually cleared us into the show box. After us, was the Red Baron pizza biplanes (Stearmans?) going by in a 6 ship formation at about 80kts but from the opposite direction. Anyway, at the pilot briefing, the Red Baron guy says to my WSO, "if it all goes bad, make sure you're at 500', we'll definitely be below that." So day one, pass one, holding over the lake, the coordinator gives us our time over target and the Red Barons theirs (about 1 minute after us). Well, I swear to god we were exactly on time, but at 80 knots, the Red Baron guy was also on time which put him about the South end of the runway. We were at 500' and, as he said, he was definitely lower, but the airshow coordinator got a surprise as 8 aircraft merged with something like 580kts closure pretty close to show center. I swear I didn't see them until they were about 500' in front of my nose and just below which is about a half second before we passed. They spread out the timing a bit for the next day.

- 177 replies

-

- 11

-

-

-

S-TEC 55x software / hardware mod for integration with G1000

Ragsf15e replied to dvk's topic in Avionics/Panel Discussion

Bob, that’s awesome, thanks for helping people out! -

Ha! Yeah, our Meridian (work plane) uses a ~$5k concorde!

-

My IA has an (older) legit load tester. It runs for an hour or more each time and has programs for the specific battery type/capacity. Other than that, I don’t have specifics. They are a flight school and Cirrus Service Center, and they test their own 12v Cessna batteries and 24v Cirrus, so I think it’s done correctly, but electricity is close to magic for me.

-

Still, needing a new battery every 1-2 seems odd. My lowly 12v concorde is load tested every year and it’s through 5 so far…

-

That’s true, but it seems very stable for an electrical “change” to have happened. I flew it again today and was seeing 80-81 very stable still. I’m going to download the data and compare it to last time I had the oil changed. I’ll post that this weekend.

-

Upgrade Questions M20E to Encore/Or Encore Conversion

Ragsf15e replied to mooneydemi's topic in General Mooney Talk

Well said. -

I did ohare once (not in a Mooney). I’ll try to dig up a picture, but I might get heckled for putting up a 20year old pic on “today’s flight”. Anyway, loved the Chicago controllers too! Very good, professional, but also, a good sense of business (no messing around)! Views of the skyline and lake were amazing.

-

My 20/1 gears failed the AD in 2015 at a major MSC. Luckily, they were available from laser at the time, so I have “new” 40 to 1 gears in there. I don’t know what the maintenance on them was like before that, because that was my first annual. However, they will eventually wear out. Especially the 20 to 1 gears.

-

Yeah I’ve been waiting for this one to crop up… Do you currently have a set of 20:1 that is worn out? If they are serviceable, you can keep using them. If not, you might look at salvage yards for a set of serviceable gears (either old or new). Even with the new ones (which makes moving the gear more gentle/slower), you still have the recurring AD for inspection and lube.

-

Hard / no start discussion - SOS Problems?

Ragsf15e replied to 33UM20C's topic in Vintage Mooneys (pre-J models)

Since you have an E, I’ll throw this out there (but we have plenty of threads on it already)… is it specifically “hot” starts your airplane struggles with? If so, what is your hot start technique? There are lots of ideas and techniques, but I personally will use my hot start technique anytime the airplane has already been run that day - ie, taxi to fuel, shutdown, restart = hot start technique. Injected airplane engines are notorious for being finicky to start when “hot”. They will start just fine, but may need a different technique than the first start of the day. -

A question of winds, geometry, TAS vs GS, and the G1000

Ragsf15e replied to Ragsf15e's topic in Avionics/Panel Discussion

Yes, they are perfect when more aligned with the track. The IAS does have a small correction, but it’s basically unnoticeable clean/cruise. It’s only when there’s a large crosswind component that this becomes noticeable. I think @EricJ had it right in the way garmin does the trigonometry doesn’t necessarily work out well between the heading, course, and wind components with a perfect crosswind. -

A question of winds, geometry, TAS vs GS, and the G1000

Ragsf15e replied to Ragsf15e's topic in Avionics/Panel Discussion

Maybe there’s something to your “tacking into the wind”… with this one I’ve got a headwind that’s giving me added groundspeed?? Since when does a 7kt hw component net a 10kt increase in groundspeed??