All Activity

- Past hour

-

Anything going on? Have the problems stopped? Are they selling fuel still? I would have thought by now I would have heard something, but it seems to have gone away, where I would have thought with time things would have worsened.

-

Fine wires I think should be good, I’ve never done it but feel sure you can check resistance without pulling the plugs, would of course have to remove the wire, but I’m afraid that’s honestly not it. If you swapped them from another cylinder, and the problem reoccurred in the same cylinder, there is an almost zero chance that’s it’s plugs. If your sure it’s not valves, then the only other likely possibility that jumps out is Injection or ignition, might not hurt to do a flow test and possibly clean that injector, very unlikely I know, but I like to troubleshoot with the free stuff, then the easy stuff before I start spending money myself. If nothing else you eliminate systems. It could be an ignition wire or even cap. If it happens to you again if you can do a mag check looking for increased EGT on the “bad” cylinder, if a plug isn’t firing then of course you won’t get a rise when you turn off that plug in that cylinder but will of course on the others whether the cause be the cap, plug or wire. I’m afraid that testing when it’s running fine won’t show anything, because it’s not “broke” then. Call Lycoming’s help desk, they are very knowledgeable and they don’t cost anything.

-

They might depends entirely on insured hull value, but if they do I’d love to have it, it would be a cheap and easy fix to resell.

-

ahhhh thats too bad. I wonder how bad the damage is. either way insurance will prob scrap it if that prop hit which I imagine it would. since I joined this website I have been so diligent about gear down I must check it at least 3x it starts and ends my landing checklist and then I check again for good measure.

-

I agree with the reamer suggestion as a matter of good practice and I may come back to it later. I could not give them a quick check because I don't have the correct size reamer. Mcfarland is out of stock of the guided reamers so I chose to put her back together. I'll have the correct reamer in a couple of weeks and after feeling the guides I'm confident they won't stick open or closed in the interim. Tried plug swapping. I did bench test all the plugs (fine wire) under pressure but I did not check resistance. Good suggestion, thanks! I'll be doing an inflight ignition test this afternoon.

-

I did all of that.....there is no way to get GP to boot up so I can see the downloads....I cannot get past this screen......

-

I did, see my previous post.

-

I like the KISS method, thanks Keith!

- Today

-

-

I wish that was still the case. I moved from North Dakota to San Antonio 35 years ago this month. Then it was amazing to me since it was a big city and you could get anywhere you wanted in 15 minutes. Now you can be stuck at a standstill in traffic without moving for 15 minutes in just about any part of San Antonio. Almost nine years ago I moved an hour or so North of San Antonio up to the Texas Hill Country, to an airpark in between Fredericksburg and Kerrville. For a big city an hour away I still like San Antonio and I still go there a couple times a month, but I plan when I get there and when I leave around traffic. It's quickly becoming a metroplex all of its own. I'm glad I got out while I could.

-

Understood, my main point is to keep looking. However if the reamer is of the right size and the guide is also correctly sized the reamer won’t do anything, it will only remove metal if the guide is undersized, but I understand if it ain’t broke, don’t fix it. Try this, exchange the plugs with another cylinder, it’s rare but sometimes you just get a “bad” plug, one that fires correctly when hot but not so much when cold, if it’s a bad plug then the problem will move to the other cylinder. This is unlikely, but it costs no money, is easy and does no harm, so eliminate plugs as a possibility. Oh and check the plug resistance when you have them out especially if the are Champion’s, many say resistance doesn’t matter but by definition high resistance resists electrical flow wasting some energy as heat, the result is less current to the electrodes

-

IFR avionics panel planning - need for VOR /LOC/GS?

Z W replied to AJ88V's topic in Miscellaneous Aviation Talk

I had two vacuum failures before we went all glass. The attitude indicator slowly drifted off both times. The first was the vacuum pump itself, so I did get a warning light on the panel for low vac. The second was the attitude indicator failing internally, so no warning lights, just an instrument that would have put the plane into a steep nose up climbing right turn until the pilot figured it out. Luckily I was VMC for both events. I'll take a big X failure display on a G5 every time. -

Louis Colantuoni joined the community

-

mach joined the community

-

Actually his oil temp is pretty standard for a K. I agree with you that around 180 is a good temp for the oil, but the primary oil temp sensor location on the tsio-360 is immediately after the oil cooler. In fact, it’s basically attached to the cooler. You kind of have to assume that the oil is much warmer (and thus above 180) elsewhere in the engine. However, his reading is pretty close to the average for this engine type.

-

The G3x is customizable. It is very easy to rearrange the screen and move the engine instruments to the other side. In that particular layout it only shows the temperature of the highest cylinder. If you touch the engine monitor screen it shows everything in detail for all 6 cylinders. I was running a fuel flow of 10.2 GPH. The entire trip only took 30.2 gallons which includes climbing to 15,000’.

-

Read the mil spec 193-2 306-2 milh5593 not for fuel and oil Safety is inexpensive.

-

We mfg molded silicone for various autos , were the only mfg that does the matte fabric finish. mbz 190-300 Toyota Tundra Vw water various Mk platforms Bus / Vanagon Porsche turbo intercooler Chevy SRS Seadoo models Husaberg / Ktm Ducati last week the new stark varg , ordered two of those one arrived today. You will find me each year at Sema with one of my classics and beautiful Columbian wife .

-

193-2 is listed in Mooney parts manual. -2 is easy to assemble, light weight and meets minimum bend radius requirements for easy install. Hose specifications has me concerned also so it’s on a replacement schedule.

-

Curious question about Charlie Weights in long bodies

cliffy replied to cliffy's topic in Modern Mooney Discussion

Kind of what I was thinking from memory. From number crunching 19 pounds in the rear moves my CG aft 1.2 inches at gross weight. -

I will 2nd that. Not meaning to scare away potential useful suppliers, but this company has repeatedly come to these forums with blatant advertising and not even trying to make it Mooney connected. It doesn't really worry me, but we do have the LHS company who have been respectful, helpful and friendly. Out of principle I will support the nice guys because I hate seeing people getting an unfair advantage because they are breaking the rules. I support the idea, but the wired in LHS ones which can be turned off quickly when not wanted sound like a way better idea. Good for night and for a gear alert, but yeah, no need on a normal day.

-

Wish you could make the hyd hoses for my Rolls Royce :-) The colors would look cool at the car show :-) As you can tell I'm not a purist in the car world

-

toto started following Garmin pilot stuck

-

I had this happen one time in the plane and it was super frustrating. Apparently the app had auto-updated overnight and required a new set of required downloads before it would work. Once it downloads the required files it should be fine - looks like you’re in WiFi range now. If the app is hung, just kill it with a double click on your home button followed by a swipe up on the app tile. Or just reboot the iPad.

-

IFR avionics panel planning - need for VOR /LOC/GS?

Vance Harral replied to AJ88V's topic in Miscellaneous Aviation Talk

Agree with @kortopates that you're over-simplifying a complex question, though the conclusions I draw are somewhat different than his. Within the realm of my experience (lots of steam and glass in piston aircraft, very little turboprop and zero jet time), I just don't care much whether information is displayed as pixels on a screen driven by a digital computer, or plastic and metal needles and rings driven by analog op-amps. i.e. I don't care about "glass", i.e. I agree with you. But if you start looking at reliability and redundancy, things get more complicated as Paul notes. One aspect of this is the power source, which is typically singular for a vacuum-powered instrument (one vacuum pump), but typically triple redundant for a glass instrument (alternator + ship's battery + internal backup battery). In this respect, glass is better than steam not because of pixels, but because you'd need a second steam instrument and/or a standby vacuum system to achieve the same level of power backup with steam gauges. If you actually have that power redundancy in your steam gauge setup, then I'm back to not caring. But standby vacuum and/or a spare electric-powered mechanical AI is not very common in the airplanes I fly. It's more expensive and more invasive to install than a second G5 or GI-275, and therefore the market dynamics just make it unlikely to be there. Another aspect is how different your scan has to be when primary attitude fails. If, say, a G5 ADI fails, and you have a G5 HSI right below it, the HSI can be reverted to an ADI and the location where you look for attitude information doesn't change much. However, the loss of the HSI means navigation "needles" are only available on the EFIS, which most people aren't used to looking at. Backup mechanical AIs are usually located somewhere outside the basic 6-pack layout, so the scan changes a bit more, but the needles on your vintage CDI/HSI are right where they've always been. The worst case, arguably, is big-screen PFD/MFDs, where you now have to look all the way on the other side of the panel for backup. It's hard to say which of these is the most distracting, but see my note about training below. Regarding the reliability of the instruments themselves, I'm a bit of a contrarian about this idea of replacing "unreliable" vacuum pumps with "reliable" electronics. First, I work in the electronics and software industry and I know all kinds of ways a supposedly reliable electronic system can fail, so this gives me a sense of paranoia others lack. I'm not sure why people assume electronic instruments won't fail, and I've never actually seen statistical data on it. Anecdotally, I'll point out that I fly half a dozen heavily used flight school airplanes with dual G5 setups, and I've seen as many failures in these systems as I've seen failed vacuum pumps in steam gauge panels. The failures mostly have to do with heading data on the G5 briefly going yellow due to what I assume is vibration-induced inaccuracy, but in one case the magnetometer in the wing came loose, rendering heading data completely incorrect despite the displayed heading not going yellow or red. it's also worth pointing out that the wires which connect the output of a GPS/NAV radio to an indicator are equally likely to break or burn up, regardless of whether that indicator is steam or glass. But I think the real bottom line is this: anything that changes the critical information displayed or the place it's shown, is extraordinarily distracting if you've never seen it before. The only fix for this is training for likely failures. People that fly instruments in steam gauge airplanes are somewhat likely to seek out "classic partial panel" training using needle/ball/airspeed to keep the greasy side down, and if you actually practice this intensively, it just doesn't seem that hard to me, though I admit I've never had a real vacuum instrument failure in actual IMC. Conversely, people that fly glass panels seem less likely to train for various failure modes, because they seem more sure that failures are a theoretical bogeyman rather than a real possibility. They also seem to assume things like automatic reversion of an HSI to an ADI, or the use of an iPad to get attitude information will be inherently manageable, and underestimate just how distracting it actually is the first time. To that end, I won't sign off someone for an instrument ride without a couple of hours flying in some sort of non-standard redundant mode, be it steam or glass-based. Pilots that get this kind of training during pursuit of the rating, and who keep it up in safety pilot sessions and IPCs, tend to do well, regardless of steam vs. glass. Pilots that don't, don't. -

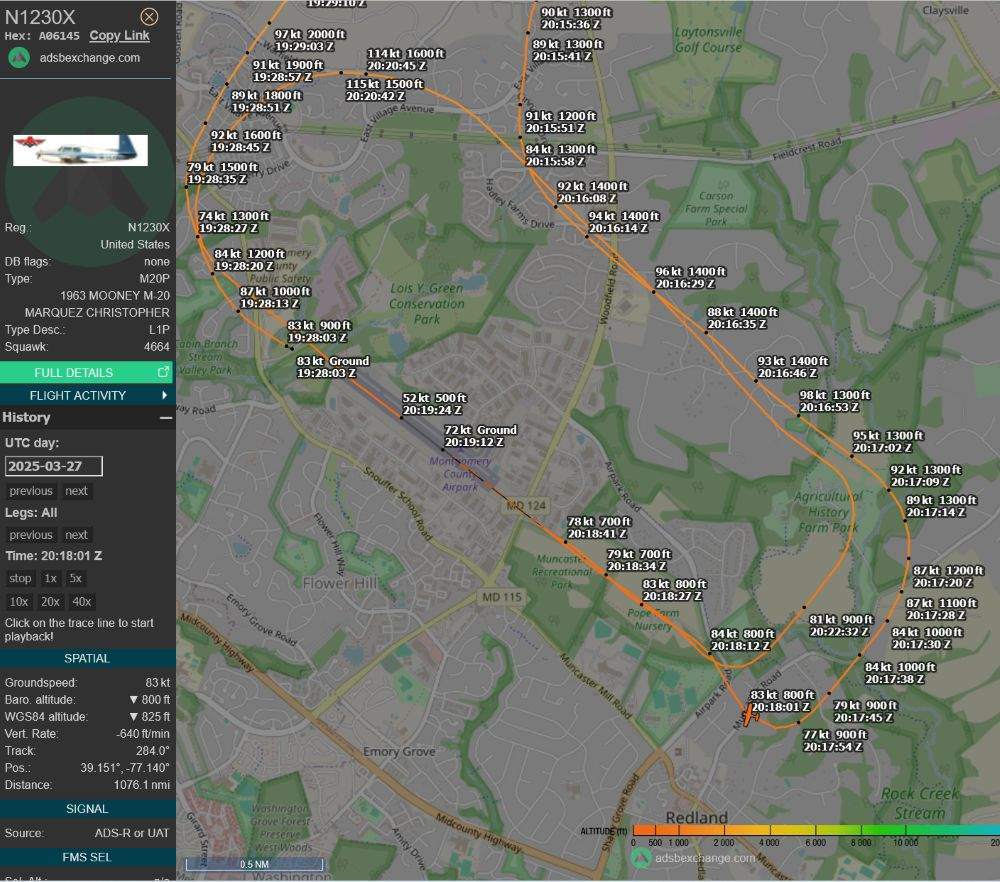

Well even "proficient" pilots can be distracted at the wrong time. But this apparently is an unfortunate case a new pilot in a newly purchased plane. Gear-up landing Incident Mooney M20E Super 21 N1230X, Thursday 27 March 2025 https://indyairsales.com/__resources/webdata/files/specsheets/1716_N1230X Info Spec Sheet Rev 2.pdf https://www.flightaware.com/live/flight/N1230X This is a 1964 M20E Super 21 with a J-Bar manual landing gear. The owner registered N1230X on November 12, 2024. ADSB-Exchange history shows that the plane showed up at the owner's home drome on October 30, 2024. It appears that the owner is a newly minted pilot, age 47 per the internet : Certificate: PRIVATE PILOT Date of Issue: 10/20/2024 His photo on LinkedIn shows him standing in front a C-172 holding his certificate. The owner came to MooneySpace once. On October 31, 2024 he posted a topic looking for a "Complex Mooney Instructor". He said "Recently bought a Mooney M20E, and need to find a CFI to complete my complex rating." and "My insurance requires that I have 10 hours dual time with an instructor and 10 takeoffs at landings. I've completed 4 hours and 4 takeoff and landings this past week with an instructor who helped me fly the plane home." He got some recommendations for the remaining 6 hours dual and 6 take-offs/landings and never came back to MS. His speed and glide slope/rate of descent don't look terrible. I can't find the METAR for KGAI that day but winds at Dulles were variable and not more than 5 mph. However, his Base to Final was sloppy. He busted the Final and he blew past the centerline before turning back approx. 110 degrees to Final. https://globe.adsbexchange.com/?icao=a06145&lat=39.168&lon=-77.145&zoom=14.3&showTrace=2025-03-27&trackLabels×tamp=1743106682 Perhaps he got flustered with the mistake. (or worrying about not banking too much in the correction) Perhaps he was debating balking the landing and going around resulting in a loss of focus on the landing configuration and getting "behind the plane". Perhaps that is why he didn't have the gear down in time well before the flare but put the gear down after "kissing the tarmac" and climbing out. Perhaps his J-Bar is out of rig or bent, like some comment here, and requires tremendous force or binds which hinders his smooth operation (But you would think if that was the problem, his instructor or ferry pilot would have highlighted it as a squawk that needed immediate repair)