Search the Community

Showing results for 'bleeding'.

-

I agree with the emotional stampede but strongly disagree with getting out of the way. One cannot reason someone out of a position they have been driven in a panic into. One can only work within the political and legal system to win. I’m deeply involved in one of the great and current civil rights policy debates, and I used to engage with the other side in describing how the existing laws function in legal commerce. No more. We now fight in court, where we win with the facts and reason. And we win. I am far from fluent on environmental law and the regulatory state, but the 100LL thing will ultimately be decided there. I hope Million Dollar Mark has his experts queued up to push back against preposterous “studies” showing abnormal and elevated lead levels in children residing near GA airports, but I fear he hasn’t. If the AOPA’s leadership wishes to stop the bleeding of membership and re-establish its relevance to grassroots GA, it has a window here to take an aggressive stand against the emotional tidal wave by side-stepping into the legal realm to protect our ability to fly. Else they will feed off the corpse of a once-great association while somebody else carries the fight. Don’t fold. -dan

-

Hi guys, I wanted to reach out and see if any one has ran across this issue before. I have put some time into diagnosing and repairing the issue but have not found the correct fix yet. 1993 M20J serial number 24-3xxx range area after flying 5 minutes the landing gear warning horn sounds in flight with normal flight speeds way above stall. Pulling the gear warning breaker quiets the alarm. It is not the stall horn coming over the overhead speaker, as it has a different tone. We can duplicate this on the ground on jacks at the same outside ambient temperature and the alarm will sound after 5 minutes with ground power applied and landing gear retracted. I believe it is temperature sensitive. The flight was at 72 degrees F and it took 5 minutes for the alarm to sound. We later tested again on a cold day 50 degrees F and it took 13 minutes to sound the alarm. Then again on a 40 degree day it took 23 minutes for the alarm to sound. The alarm starts out with a slow growl that gets louder and then grows into the full alternating tone. If you retard the throttle or cycle the breaker the alarm will stop for a few moments then start back again. This seems like either something is getting hot from the avionics , power being on and warming up, or electricity bleeding off from another source. We have disconnected the pitot pressure switch to eliminate that input. We have replaced and adjusted the throttle switch. We have replaced the alarm audio control box above the pilots rudder petals. The only other limit switches I can seem to find in the system are the up and down limit switches that tell the gear motor when to turn off and not over extend. I am scared to disconnect one of those for test purposes and to damage from over extension. The serial number 24-3xxx range area TBA manuals and schematics are a bit hard to navigate around this concern. Any of you guys have any suggestions? Thanks

-

Looking for tips on bleeding dual brake system. My 75 M20F has 4 master cylinders, I repacked all 4, blew brake lines from master cylinders to calipers out with shop air, wanted a clean start. Reinstall master cylinders, hooked up pressure pot (max 15 psi, i did not carbonate fluid, been using pressure pot very long time…) and as per manual depressed the pedals I wanted to bleed. Worked fine on pilots side. Manual say to depress CP pedals to sequence shuttle valve,,,, so I depressed CP pedals and bled both sides again, nothing… dead pedals on CP side, GTG on pilots side. I tried it with about a gallon of fluid. I believe there is an issue with my shuttle valve. I didn’t see it as I removed every belly panel (location?). Help please… thanks, Paul

-

I realize this may have been covered a number of times before but I cannot find it. Having trouble bleeding the brakes on a 68 F. Tried the bottom up using oil can to push upwards. pressure pot didn't work. Tried the top down as per bleeding car brakes. Get a good pedal but 10 minutes later pedal goes to the floor. no leaks out the bottom anywhere. Other than this the plane is ready to sell.

-

yep, it is that time of the year, if running an entire tank on high through the system on the ground while squeezing a copious amount of fluid into the non-flowing panel does not fix it a purging pot is required, might be best to contact CAV aerospace to find a shop that has one, nothing but a brake bleeding pot hoked up tho that particular panel, but have to find a panel connector, if you are anywhere close to CAV aerospace, let's say within non stop range the simplest way to fix this might just be going there and let them check out the entire system, most likely the membrane in this panel is just dried out and you need to run and squeeze in lots of fluid to make that panel flow again, then running each pump for 5 min on the ground on high will keep the membrane moist and all panels will kick in with 3 min when you need them

-

4 weeks of trying to bleed. Rebuilt master cylinders, calipers, park brakes, replaced as braided lines, and gone thru gallons of fluid. Bleed up and back. Pressure from the caliper nipples (15 psi) back through the system. Also raised the nose and bleed both ways. Currently have a vaccum pump running. What next? Oh it's a single station pedal brakes.

-

Hi Everyone. I purchased a 2003 Mooney M20R last April and during the pre-buy, we noticed mushy left brake pedal on the pilot side. The issue was fixed by bleeding the brakes bottom-up and then at every fitting under the belly where small amounts of air bubbled out. Since then the problem slowly got worse and this annual we decided to figure out the root-cause. Here's a list of what we have performed: 1. Identified that Swagelok B-400-7-2 fitting that connects the plastic tubing coming from the reservoir to the T that feeds to the low side of the Pilot master cylinders. Replaced the fitting and the leak stopped. Flushed caliper up and problem persisted. This probably was a problem but not the root-cause. 2. Removed all 4 master cylinders (pilot and co-pilot) and re-sealed them. Although some seals were worn out the inspection before and after revealed no external or internal leaks. We re-sealed anyway. Flushed the system caliper up both sides but the problem persisted. 3. Checked the calipers, lines, fittings and flushed the system reservoir down, caliper up, applied vacuum at the reservoir many-many times. Problem remained. 4. We noticed that the maintenance manual has different bleeding instructions for a/c with pedals on both sides. We blocked the reservoir, pushed fluid up the calipers with a high-flow fitting and cracked open the fittings at the parking brake manifold to see minimal amount of bubbles. I heard from a hangar buddy that when he replaced his a/c's tire, the two parts of the rim didn't fit perfectly because the valve stem could only fit in 1 of 3 positions. This caused the caliper to be pushed back enough during taxi that the first pump pushed the pads close to the disk and the second press held perfectly, unless he was taxiing faster. There are no visible leaks at all and we're kind of lost here. Any help is greatly appreciated. Thanks

-

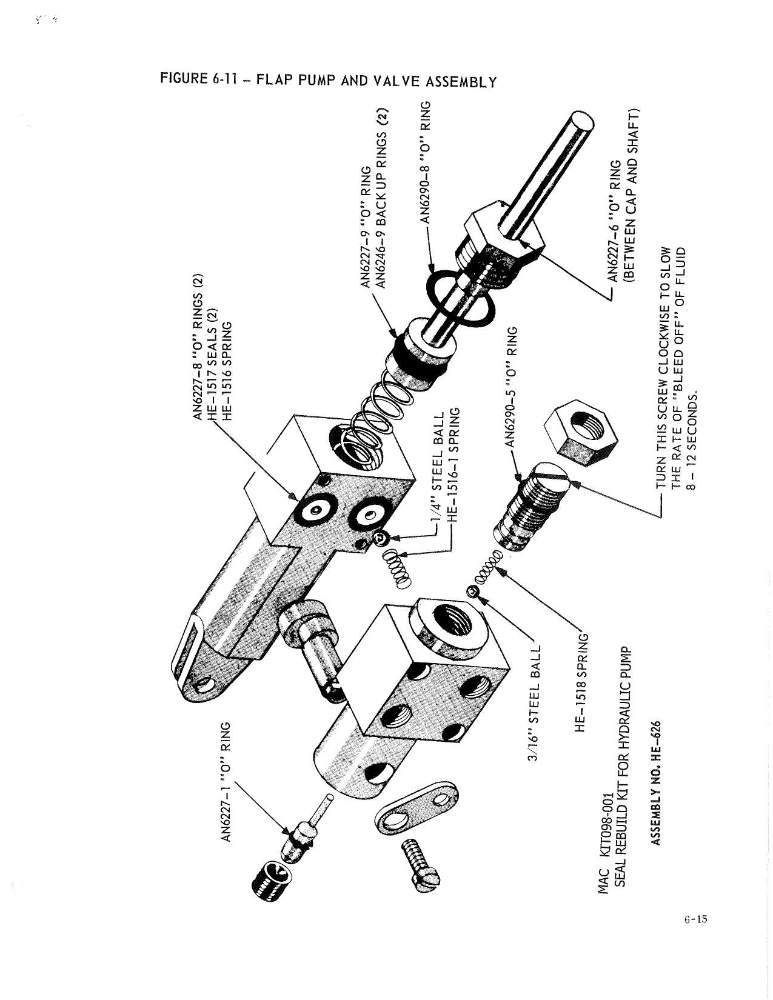

I know there are many threads out there for bleeding the flaps but I'm wondering what people have used to pump fluid when doing a bottom-up bleed. I assume top-down will not get them good enough. I've only ever bled brakes and either used a hand pump with vinyl tubing or the ATS bleeder that has a connection for the caliper bleeder screws. When people say they are using a pressure pot, what are they actually connecting to on the actuator and how?

-

Hello all. For the past few years I have had intermittent issues with flaps on my 65 M20C. We have been in 2 different mechanic shops and worked on it countless hours at home. A few years ago, the pump was serviced at LASAR and seals replaced, pressure check normal on bench (sent there twice). Most recently, we had big actuator leak. That was replaced with a rebuilt actuator and flaps did not function well thereafter. Replaced with a newer used pump. We bled the system multiple times and tried to adjust, then replaced a fatigued spring at the ball valve. Function was improved for a short time thereafter. After a few weeks, regressed to a place where she was holding full flaps, but bleeding up at any partial flap position. At annual this year, we tried to flush and re-bleed the system. Tried suction technique from the back, then pressure pod from the back - even positive pressure at the back and suction from the reservoir side. We never felt as though we were able to get all air bubbles from the system…. When we would work the pump, we just kept getting more and more air. In addition, even in the flaps down position, fluid will transit back to front at a similar rate to the flaps up position. Currently, flaps will go down with a variable number of pumps (5-7) and will bleed up even from the full down position. So now unsure if ball valve is not seating and/or if there is some leak in the system allowing ingress of air (although we dont see a significant visible outward hydraulic fluid leak). Is anyone pressure testing or vacuum testing this system to make sure not a small leak before just exhaustive bleeding? Is there anyone with a deep love and expertise on these hydraulic systems in Florida area who’d be interested to have a crack at it? I know that previous threads have talked about the simplicity and beauty of this manual system, but I am getting frustrated enough with the chronic problems and lack of readily available parts, that also starting to entertain the idea of an electrical conversion. Does anyone have experience or suggestions on a kit for conversion from hydraulic to electric? Many thanks in advance for any help!

-

Help with chronic issues on hydraulic flaps, 65 M20C…

Shadrach replied to Weston's topic in General Mooney Talk

I’m really sorry to learn that you’re still dealing with this.I am baffled. I sent them a working pump which they disassembled and then used parts from both the original pump in your plane and the one that I sent them to get what they told me was a working pump. I logged a few phone calls and several texts walking their tech through trouble shooting and bleeding. He told me the problem was sorted during our final conversation. There are two probable scenarios that explain the symptoms you are experiencing: 1) The hydraulic fluid is contaminated with debris that are preventing the check valves from sealing and fluid Is flowing the wrong direction through the check valves 2) all of the check valve seats need to be recoined to prevent fluid from backflowIng through the check valves. The first thing I would do is tighten the retraction speed screw all the way down. If the flaps stay down under those circumstances, your problem is almost certainly with the retraction circuit valve. If they bleed back up, then fluid is flowing the wrong way through the pump check valves. Feel free to DM me. I am dismayed that you’re still dealing with this.. -

Slow fluid loss at slave cylinder. Air in system. No flap actuation. What is the best method to bleed system? We have sent master cylinder of to LASAR twice.

-

Halos and other visual phenomena sometimes occur with IOLs. The key is to ignore them, as concentrating on the illusions will make your brain perceive them forever. I've been out of IOL manufacturing for a decade now, so am not up to speed on the different makes and models, just know that new versions are introduced frequently. Avoid getting a lens on the bleeding edge of technology. I worked for Alcon, and back then the progressive lenses had up to 13 different zones. Check with your surgeon, as there were two classes of people that were generally not good matches with progressive lenses: pilots and engineers (I'm both!). This is due to high expectations, but like with an airplane, there are tradeoffs--multifocal lenses do not produce as crisp of an image as monofocal lenses. But I've yet to talk to anyone who does not enjoy the tremendous improvement to their sight, which happens instantaneously when the new lens is put in.

-

Last year my brakes needed "pumped up" prior to departure and landing, as they were feeling spongy. So, during my last annual maintenance/inspection I had the brakes bled and fluid replaced. Well, this only worked for a couple of months before the brakes once again needed "pumped" on a regular basis. NOTE: My parking brake neve failed and always held solid. Now my brakes are worse than ever, but I can't find any leaks nor does the reservoir loose any fluid. I was told the seals in the master cylinder may need replaced, but I would appreciate other's thoughts. Thanks. 1988 M20J

-

The left master cylinder on my 1994 M20J was seeping a bit of fluid. I removed both cylinders and had my IA (Scott) inspect them and install new O-rings. I also replaced the hoses to both brake calipers and a hose between the left master cylinder and the parking brake valve, and installed new brake linings. When reassembling, I used a pump oil can to fill the lines and master cylinders with brake fluid. Now it was with some trepidation that I faced bleeding the brakes because I've never done it before and there are multiple threads on MS about how difficult this is. It turned out to be a nonevent. Scott suggested opening the bleeders and allowing the fluid to gravity drip. I ran a quart of fluid through the system this way to thoroughly flush it. Scott recommended stopping several times and closing the bleeders and slowly moving the pedals through complete strokes several times. He cautioned to move the pedals slowly to avoid aerating the fluid. After doing this we let it sit for a day and then did the standard bottoms up bleeding. Because the feed line from the reservoir to the master cylinders is clear, it's easy to see when all the bubbles are out. It worked great. Brakes are nice and solid. Skip

-

I’m interested in learning more about bleeding the flap system. I’ve done the brakes before and have a good feel for that but at my last annual the IA noted there was a hydraulic hose for the flaps in the belly area of my plane that looked worn and the plan is to fix it at the next annual. We will obviously introduce a lot of air into the system when that hose is removed and replaced. Without actually hearing from someone with experience I am thinking the way to do it would be to apply vacuum to the system to suck the air back up into the reservoir? What have you all done to bleed the flaps??

-

Bleeding dual brake systems

Fly Boomer replied to Buckblaster's topic in Vintage Mooneys (pre-J models)

I don't have any suggestions, but I have read several topics here on bleeding. If you want to try to track those down, try using the search engine in your favorite browser. You can restrict a search to a single website like this: site:mooneyspace.com x y It will search for x and y, but only on mooneyspace.com. The search function using the forum search engine is pretty weak, and it's amazing how quickly my browser's search engine spider has crawled mooneyspace and picked up new topics and new posts within topics. -

Actually, I'm not boring cylinders I'm bleeding brakes and changing o-ring on caliper

-

I was initially given 85KIAS on final during transition training. Reviewing Don Kaye's video course and reference materials, I have been transitioning to 70-75KIAS on short final, based on weight, aiming to enter the round-out phase at this speed. Tried 1. trim-back-and-push-forward early on, 2. don't use much additional trim, and 3. trim to maintain light forces into the flare to better control height below a few feet, which usually wants a bit more aft trim vs. the above, once the plane is in ground effect and bleeding off energy. Sounds like different planes have different trim appetites, though...

-

I capacity tested my 5 year old RG35AXC in June and it was just over 90% which translates to 29.7 Ahr. Nearly twice that of a BRAND NEW EarthX. While lithium may not age the same as lead-acid batteries it would be pretty naive to think that a 5 year old EarthX is going to maintain 100% of its new capacity. No, I do not know the exact capacity of my stone-age Concorde nor does anyone know the exact capacity of their bleeding-edge EarthX. But I'd bet you real money that my 5 year old battery will last longer in the clouds than a brand new EarthX. And by a significant amount. As a career engineer it just amazes me the lengths that people will go to defend a new technology (yes, aviation approved lithium batteries are new) in the face of demonstrable shortcomings by merely ignoring them! I'll repeat my list of FACTS posted much earlier before EarthX came here to 'answer questions' (IOW, advertise): 1) Concorde $500, EarthX $700 2) Concorde 440 CCA, EarthX 390 CCA 3) Concorde 33 Amp-Hour, EarthX 15.6 Amp-Hour 4) Concorde Ipp=800 A at -18C, EarthX Ipp=390 A at -18C 5) EarthX weighs 27 pounds less So, you have no issue with 1 through 4, just ignore them, because, by god you're going to save 27 pounds!! Joy to the World. And act like 1/2 the time in the clouds is okay because I can't tell you how close to double my Concorde is today? GMAB

-

Takeoff Trim Setting - New to me 1970 M20F

MikeOH replied to ProtoFly's topic in Vintage Mooneys (pre-J models)

WARNING! Thread creep: All this talk of flaps...my favorite was the M20B I used to rent: mechanical flaps No motors, wiring, limit switches, fuses, hydraulic pump, leaky seals, valves, bleeding air, jackscrews.... Just reach over and put the flaps where you want them as fast as your hand can move!! Mooney should have just left them that way, IMHO. But I guess customers wanted complexity and gadgets.... -

Why you can’t land a Mooney until it’s ready

1980Mooney replied to mooneyflyfast's topic in General Mooney Talk

Good question. 25 years ago, on a 8,000 ft Towered runway, my original Mooney instructor had me touch the mains down on the numbers holding the nose off and then gently adding a little power and pulling it off into ground effect. Then followed by pulling power/bleeding energy, landing again, touching the mains down with the nose held up followed by a little power and back up into ground effect. I "landed" consecutively four (4) times, touching the mains, adding power, pulling up into ground effect with the last a full power take off. The Tower was not amused. -

What made a huge difference in my landings is to naturally be aware of speed control, but also have a solid appreciation of your vertical descent, particularly objectively knowing when you are 1-2 feet above the runway. I installed the LHS lasar system, and the 2-foot and 1-foot call-outs are a great help. Come over the numbers at 70 kts. Bleed off speed. Generally use full flaps unless there is a reason not to do so. Once in the mid-60's speed range, keep bleeding off speed, and when you hear 2-foot and 1-foot you can comfortably pull the nose up further, and slow further. The stall warning generally will go off in the 1-2-foot warning range. The airplane will then no longer be carrying excessive energy and will settle in upon landing. With strong crosswinds, I will sometimes land with speed brakes. The same airspeeds are used, but the airplane feels heavier and more stable. I do not do this often, but some of my best landings have been with speedbrakes deployed. John Breda

-

Both brake cylinders were rebuilt prior to this refill. I don’t think it’s the Paramount cylinders so much as how they are oriented as well as the plumbing. There are nearly flat, lateral bends in the plumbing which make bleeding a challenge. if there’s air in the flap system, I think it is harder to evacuate with the return adjusted for an 8-12 second retraction. The fluid needs to move with some velocity to take air up stream.

-

Was one of the master cylinders leaking? We're trying a vacuum bleed which some users on here recommended since we got barely passable results through traditional methods (pressure bleed bottom-up 20-30 PSI, constant shaking of the cylinders, gallons of fluid, bench bleeding cylinders with caps on to just have the line off for a split second while fluid was pumped from below so minimal air was introduced). Not a big fan of the Paramount cylinders in general, but since it bench bled fine I still don't think it's the seals. If it's getting worse over time it's probably something in the system, but I've only ever had air introduced from bad cylinders, never seen any problems even from very leaky calipers since they're at the bottom of the system.