-

Posts

1,586 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by larryb

-

It’s faster and easier for me to do the oil change in my own hangar than fly to the shop and have them do it. Plus I really like to put eyes on everything under the cowl every 25 hours and make sure everything is ok. I almost always find something like chafing or a missing screw. On my last oil change I found something more serious, a cracked spinner backplate. Fortunately the crack was small and I was able to get it replaced before more damage happened.

-

Head porosity found during annual

larryb replied to Cruiser73's topic in Vintage Mooneys (pre-J models)

I had a cylinder head separation event in my IO-360. Fortunately on the takeoff roll so no emergency. If I saw anything that made me question the structural integrity of my cylinders I would want them replaced. And I’d replace with new ones. I don’t want somebody else’s old welded and ready to fail again cylinders. -

ANOTHER PATTERN COLLISION - NOT M20

larryb replied to DCarlton's topic in Mooney Safety & Accident Discussion

My observation at uncontrolled fields is that pilots often talk at each other but not with each other. Each one dutifully announces their intentions. And when a conflict develops they keep announcing their intentions rather than calling up the conflicting aircraft by N-number and mutually working out a plan. -

Do you always believe your ground speed?

larryb replied to Joe Larussa's topic in General Mooney Talk

I find forecast winds quite inaccurate. I always subtract 20kt from whatever GP says and am happy if it’s not that bad. If they say expect 10 kt tailwind I’m happy if I have better than a 10 kt headwind. So I’d be very happy with an unexpected 40 mph tailwind! -

I wish our POH had separate speeds for take off flaps vs full down. If it did I’m sure the take off position would have a much higher speed.

-

I really like the EZ Breath that attaches to the headset. It is much more comfortable on long trips than the regular over-the-ear cannulas. The foam tape provided on the mount didn't last that long in the heat. I used some JB weld and it is solid. As far as the regulators, I have a built-in oxygen system. That is 2 regulators at the tank, a high pressure regulator followed by the altitude compensating regulator. I bought the EDS-ILR Regulator from Mountain High. It goes between the altitude compensating regulator and the O2D2. The in-line regulator can handle whatever the altitude compensating regulator is putting out. It has worked well for me.

-

When I bought my Encore there was another almost-identical Encore, but without TKS for basically the same price. So in that instance, the TKS was basically free. Every airplane is so unique now days it's kind of hard to compare. On average I would think it would add something but not a lot, since a lot of people would not buy a plane with TKS.

-

Flying up front or riding in the back on an airliner? While flying up front, especially after a visit to the engine shop, I think my entertainment screen would be the engine monitor. For flying in back I download shows and movies on Netflix, prime, etc using their app.

-

I designed it and printed it on a 3D printer. I then tested it to failure, it withstands 700lb pull. My Encore uses little aluminum blocks and bolts as seat rail stops. It does not use the cotter pin like older Moonys do. These plastic clamps replace the factory aluminum stops.

-

I have this seat rail clamp I designed for a cargo net. That said I don’t think the idea will work well. It will be very hard to get a mount stiff enough to provide a stable writing platform. And if you did you might damage the rail if you bump it getting in and out of the seat. I use a small 6x9 clipboard for IFR clearances. Otherwise I don’t do any writing in the plane.

-

I agree getting rid of sunlight is best. I designed and printed this mount for my mini6 because Ram didn’t have the model yet. I added dual fans and risers to direct the airflow. So far so good.

-

Perhaps you could add some washers so the nut grabs on the threads near the top of the stud which still look OK. New studs would be preferred of course but if it takes too long to get them this could work temporarily. And use new a new nut of course.

-

If the flaps stick and then spring forward giving a jolt, it doesn't sound like a relay to me. It sounds mechanical. The day after I bought my J, with my instructor doing transition training, I experienced an asymetric flap retraction. Retracting from take-off flap position I felt a strong pull to one side. I looked down at the flaps, and one was up and one was not fully up. Instructor said it was impossible, yet here we are. To shorten the story, the skin on one flap was slightly elevated and catching on a piece of wing skin near the wing root. The fault would not present itself on the ground but finally a mechanic pulled really hard on the flap to simulate the air load and got it to catch. It was fixed by bending down the offending piece of wing flap skin and adding some teflon tape to prevent if from catching. Larry

-

I have the O2D2 and feel it's worth every penny. I started out with a SkyOx system with a 24 cu-ft tank. A tank would last 3-4 hours for two people at 12,000 feet. The problem with that is that every trip needs to start with a full tank, so you're filling a lot of half-empty tanks. That's when I bought the transfill system, I don't remember exactly, but I'm sure I have invested over $1000 in the transfill system between the hose hookup and the 3 125 cu-ft industrial tanks. That's when I updated to the O2D2. I use about 1 cu-ft per hour for two people at 12k ft. So 24 hours from a portable tank. Now I don't have to fill nearly as often, and I don't have to fill nearly as many half-empty tanks. Then I bought the Encore with a built-in 115 cu-ft tank. The O2D2 combined with the big tank allows me to fly a full year on a fill-up. Now I don't really need the trans-fill system anymore, I could just have my shop fill it at annual and I'd be all set. I feel it's all about the convenience, and not so much about the cost. But lets look at the cost. $50/fill, 3 fills per year with O2D2 and 12 fills per year without. So $450 per year in fill savings if you are using it a lot. Larry

-

What does skipping mean?

-

First ever aborted landing, in an airliner

larryb replied to larryb's topic in Miscellaneous Aviation Talk

Yes I was in back. I don’t fly an airbus 321ER. Only a Mooney for me. They diverted to Terceira and we all waited a few hours before being flown on ATR’s to our proper destination. That was a week ago, on Pico now. It was was the hardest hit I’ve ever experienced in an airliner. It was windy, but not that windy. -

SATA Airlines into Ponta Delgada. What surprised me was after this event they diverted to another island, which caused its own set of problems. https://share.icloud.com/photos/0418YlWS2aomWKuBlCWNsxwNQ

-

I pretty much only read the forum via TT. I wish the “recent activity” option on the web site listed by thread and not every individual post. TT does this and therefore is much easier to use.

-

M20R / M20S Boost Pump Regulator Voltages

larryb replied to kinser's topic in Modern Mooney Discussion

The same guy must have designed the other little boxes like the LED bar graph indicators and the flap relay board. All have the same look and feel. My understanding is that the regulator is for low-boost. In high boost the pump gets full 28V and in low-boost the pump gets a lower regulated voltage. So the question is, what is the proper voltage for low boost? Somebody would probably have to measure it. What is odd about the picture is I don't see any typical larger power handling transistors with heat sinks that you would typically use in this application. Larry -

When I bought my plane I spent a couple of hours and scanned every logbook page into a pdf file for each logbook. After each annual inspection I sit down for 5 minutes and scan all new pages since the previous annual. I store all of these, and all of my other computer files for that matter, in dropbox in the cloud. For those not familiar, for around $100 / year dropbox keeps all of your files safe in the cloud and also syncs the files between all of your computers. If I update a single file on one computer, within seconds that file is replicated on all of the 10 or so computers I own and use. You never have to worry about a hard disk or computer failure again.

-

So my Encore is in annual, and somehow the shop has manage to bend the shaft on the Stec yaw damper servo. This happened while repositioning the aircraft with a tug. They promise to make me good, and are working on having it repaired. But just in case they have difficulty getting the repair done, does anybody have one of these sitting on the shelf in their hangar after replacing it with a Garmin autopilot? The Mooney factory installed the KFC-150 auto pilot and also an Stec yaw damper. I don't have a PN at the moment. It's a 28V aircraft. If you have one of these that you are willing to sell, please PM me. I don't yet know for-sure if I need this, but I'm reaching out just in case. Thanks, Larry

-

When I owned my J I had the engine mounts replaced. They were old and the engine was sagging a bit. There was a very noticeable reduction in vibration after the swap. Same thing with landing gear pucks. I had them replaced and taxiing was much smoother as well. These rubber parts deteriorate slowly so we don't notice it. But you sure notice the improvement when fixed. These parts were all changed at my direction. They were not deteriorated enough for the shop to notice and say we had to do it at annual. Larry

-

Budget vs. capability. How much do you have to spend? E is capable and will get you there 80% of the time. A FIKI Bravo is more capable and will get you there 90% of the time. Only you can decide if it's worth it to you or not. For me it was, I had a J for 5 years but eventually tired of cancelling flights due to the threat of icing. I felt I couldn't touch a cloud below freezing. So I traded it for a FIKI Encore about 5 years ago. It was a great decision, and the Encore is only a little bit more expensive to operate than the J was. In those 5 years I've only used the FIKI a handful of times. But just having it there and ready makes some trips do-able where I would have cancelled in the J.

-

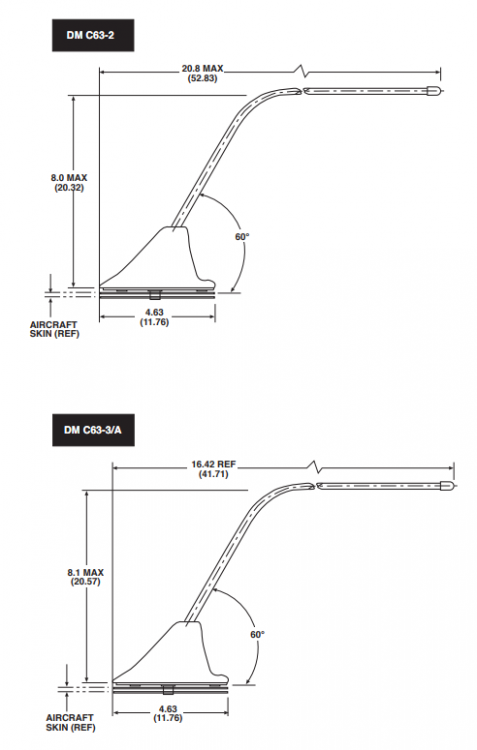

Back to original question #1. You don't want a rod and ball antenna if the antenna is in the slipstream. They have a surprising amount of drag. You want a transponder blade antenna such as the Commant CI-105. If the antenna is behind the fiberglass belly pan then you can use a rod and ball antenna such as the Ted. I have a Ted antenna mounted where the marker beacon antenna used to be feeding a GDL-52R. It works very well in that location. https://www.aircraftspruce.com/catalog/avpages/ted_transponder.php https://www.aircraftspruce.com/catalog/avpages/comant105.php

-

The 138 Mhz antenna is basically the same height as the 118mhz one. The difference in size is the length of the whip after the bend, about 4.4" shorter. I don't see the shorter horizontal section of whip being an advantage in any aircraft belly mounting situation. FWIW I have the CI-122 bent whip on the belly of my Mooney. The shop had to move one of my comm antennas off of the roof to make enough room for the 2 Aspen RSM's and the garmin GPS anntenna and meet all of the separation rules. Spruce sells a number of antenna's that are not used in standard aircraft communications, such as these. At least in the AV-14 the text tells you it's not intended for the aviation comm band. It is up to the user to buy the proper antenna for their application. https://www.aircraftspruce.com/catalog/avpages/av14.php The AV-14 is similar to the AV-10 using the same 4-bolt mounting base except it has a shorter radiating whip element. The antenna is designed to operate in the Public Service and Business Bands 138-174 MHz. https://www.aircraftspruce.com/pages/av/antenna_uhf/comantuhf200.php UHF 450 - 470 Mhz