-

Posts

12,585 -

Joined

-

Days Won

112

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by jetdriven

-

M20J nose wheel collapse at KHEF

jetdriven replied to Mooney in Oz's topic in Mooney Safety & Accident Discussion

The owner is gonna have an issue seeing as how there is no piston maintenance shop at HEF. There is a school that only works on their own planes -

48108 is also approved for replacement of the 48109

-

I put two desser retreads and two desser tubes on our plane a few years ago, one was flat when we let it off the jacks the next day, we took it off, and I was seeping out of one of those mold line seams. They sent me another one, I put that in. The other one, a year later, failed when I took a customer over to Dugosh to pick up his plane. I literally landed, after a half hour, I taxied over to the fuel pump, and it was flat when I got out of the plane. I haven't used one since.

-

If it is not torqued to spec, or not torqued at all, it has low or no preload on it, it will fail in cyclic fatigue. That looks like maybe what we have here.

-

Thats astounding, the KZ1000 had a reputation as a death machine, like the Porsche 930 Turbo, back in the day.

-

The state has been making the case for 13 years now that forfeiture is "required" So the man was convicted of importing alcohol into a dry village, which has its own set of problems. Chiefly, that a city can make an ordinance banning alcohol completely. And then second, the guy was convicted of doing something that did not happen, he never took off from Fairbanks. Intent is one thing, commission is another. And then he was fined $1500 a, and his his company was too, and he spent three days in jail. But then the state appealed the court's ruling, saying that forfeiture was mandated. https://law.justia.com/cases/alaska/supreme-court/2025/s-17593.html

-

**UPDATE** 40:1 Actuator Gearsets (LASAR)

jetdriven replied to Matthew P's topic in Vintage Mooneys (pre-J models)

you are underestimating the barriers to entry -

G3X Touch + EIS Owners - How is your tach wired?

jetdriven replied to Ryan ORL's topic in Avionics/Panel Discussion

We have the 275 EIS, but the JPI style Hall-effect magneto sensor works great with the system. It even reads Rpm with the key off. -

Based on the G100UL fuel leak thread what's your position?

jetdriven replied to gabez's topic in General Mooney Talk

That "for the children" study was that kids who lived within 500 meters of an airport had blood lead levels slightly higher than normal. -

Looks like a sellers annual. Did the shop know the seller?

-

Engine Monitor Recommendations

jetdriven replied to gwav8or's topic in Vintage Mooneys (pre-J models)

If you have the stock fuel senders cleaned up and IRAN'd, it's just as accurate as the CIES senders. they are infinitely variable 0-32ohm resistance, but in series, so 0-64. Ours rounds to the nearest gallon but the ipad shows .1 gallon resolution. -

Engine Monitor Recommendations

jetdriven replied to gwav8or's topic in Vintage Mooneys (pre-J models)

We had a SL30 connected to the bottom GI275, it was connected with RS 232. But it also has HSDB from the top one which is forwarded through from the GTN750XI, so you could display NAV one or two on the bottom GI275. Your G500 will have HSDB but it's not allowed to have any parallel legs, and they want it to go from the navigator to the 500 and then from there to the back up. But the problem is if the 500 quits, the backup won't get the HSDB data....and Trek Lawler said on Beechtalk that this STC tells you to find VFR if that happens. Some of the people have wired HSD from the navigator straight to the back up and then you get that data if your primary screen quits. -

Engine Monitor Recommendations

jetdriven replied to gwav8or's topic in Vintage Mooneys (pre-J models)

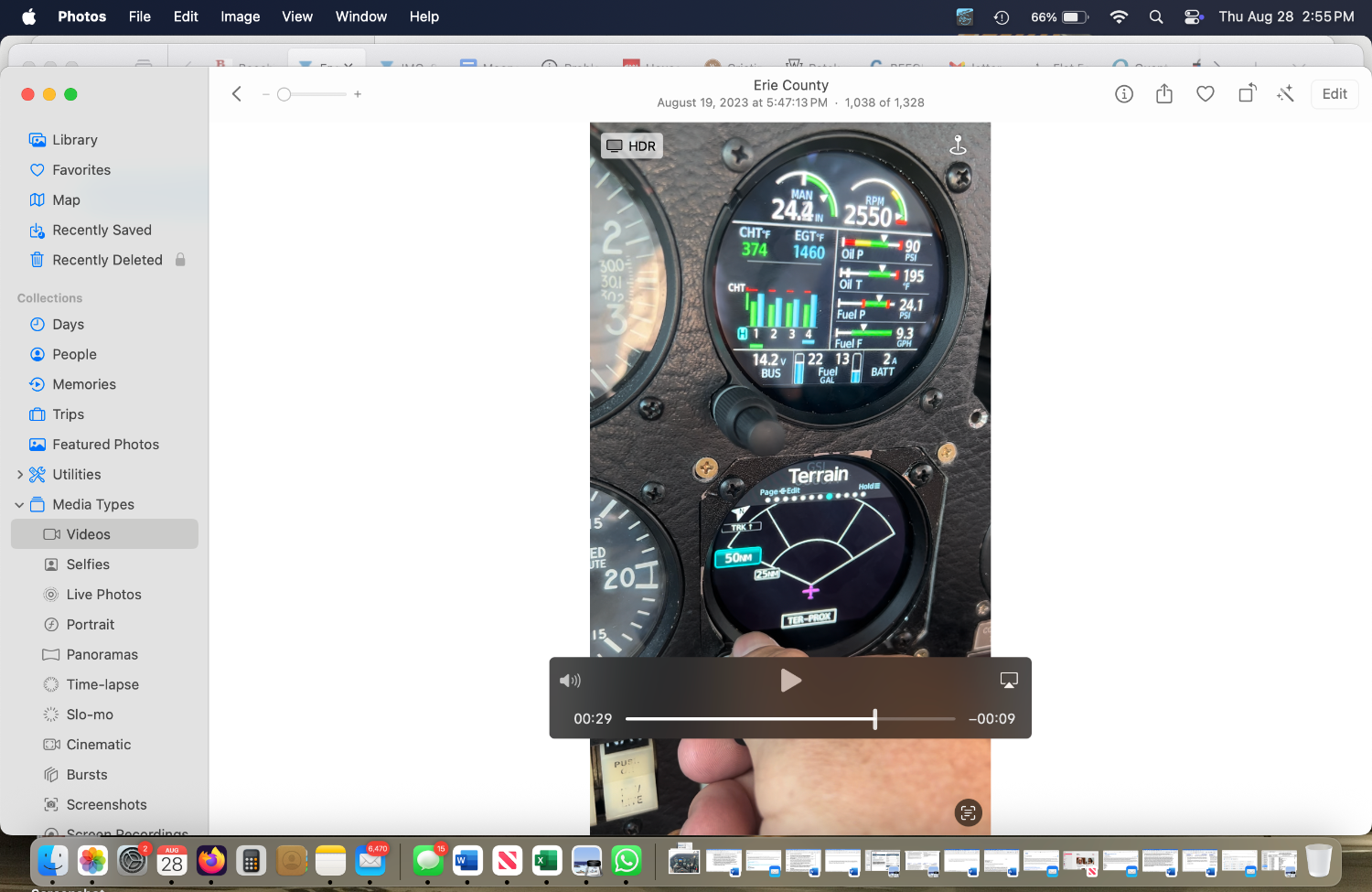

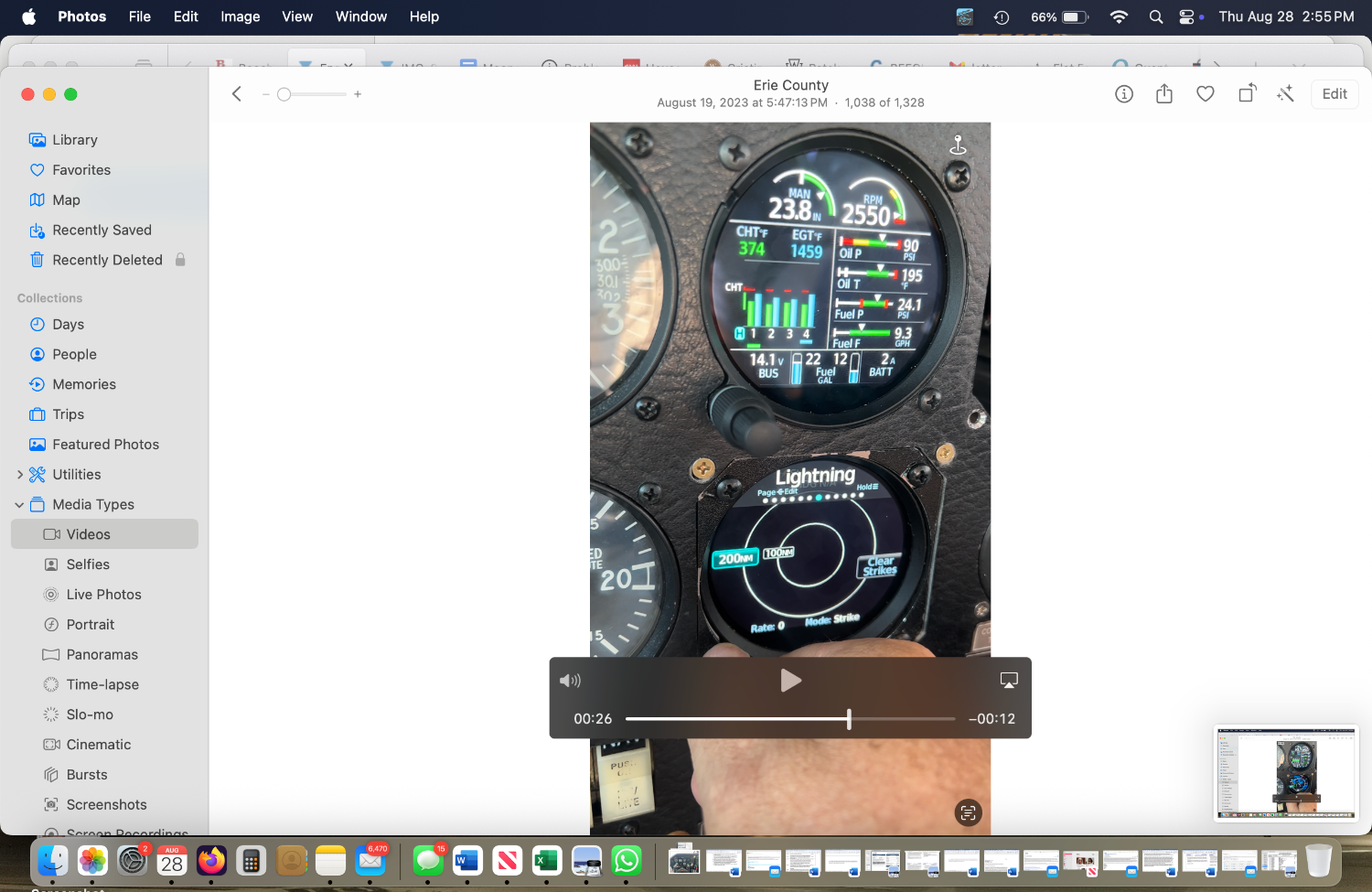

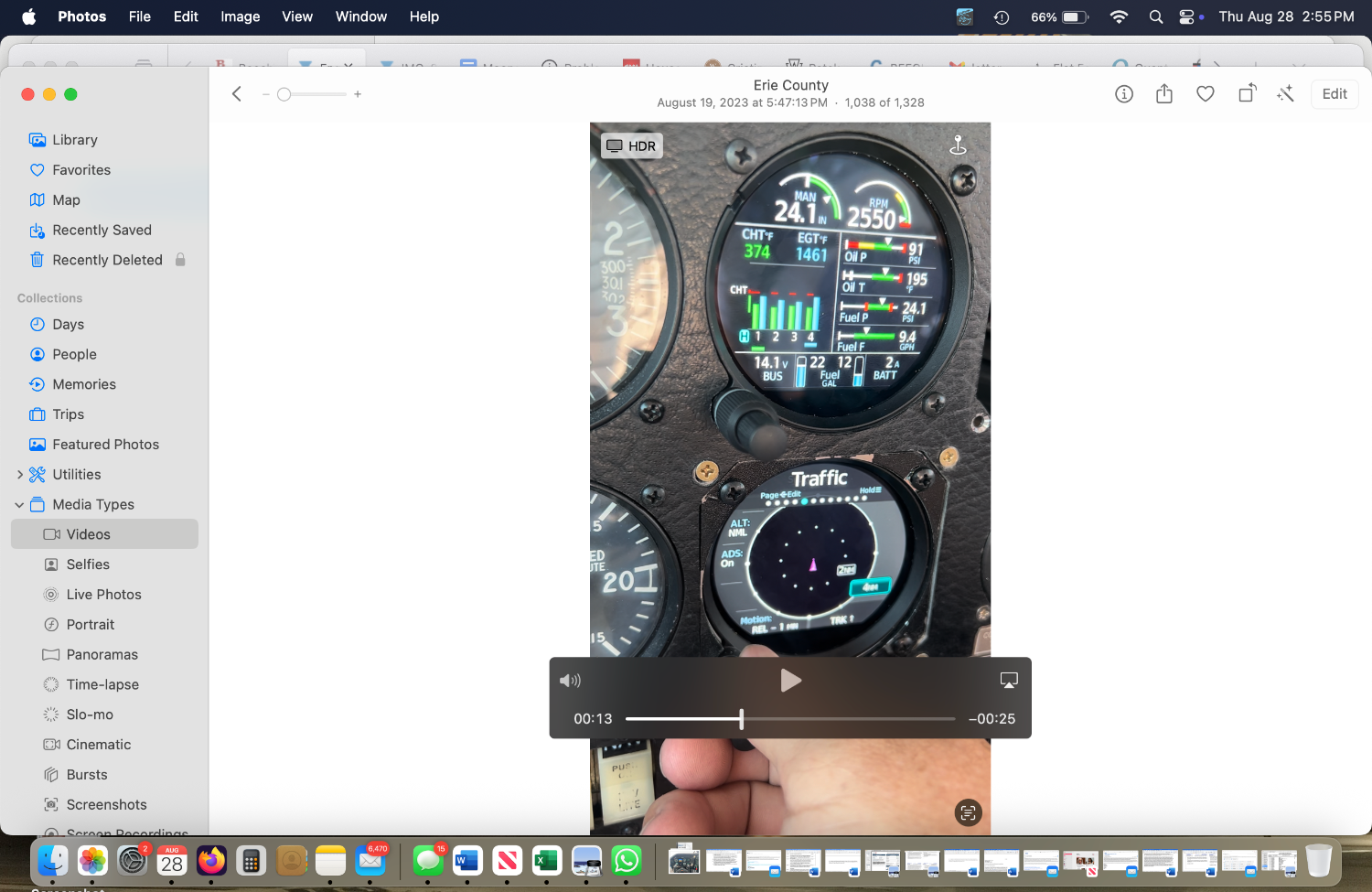

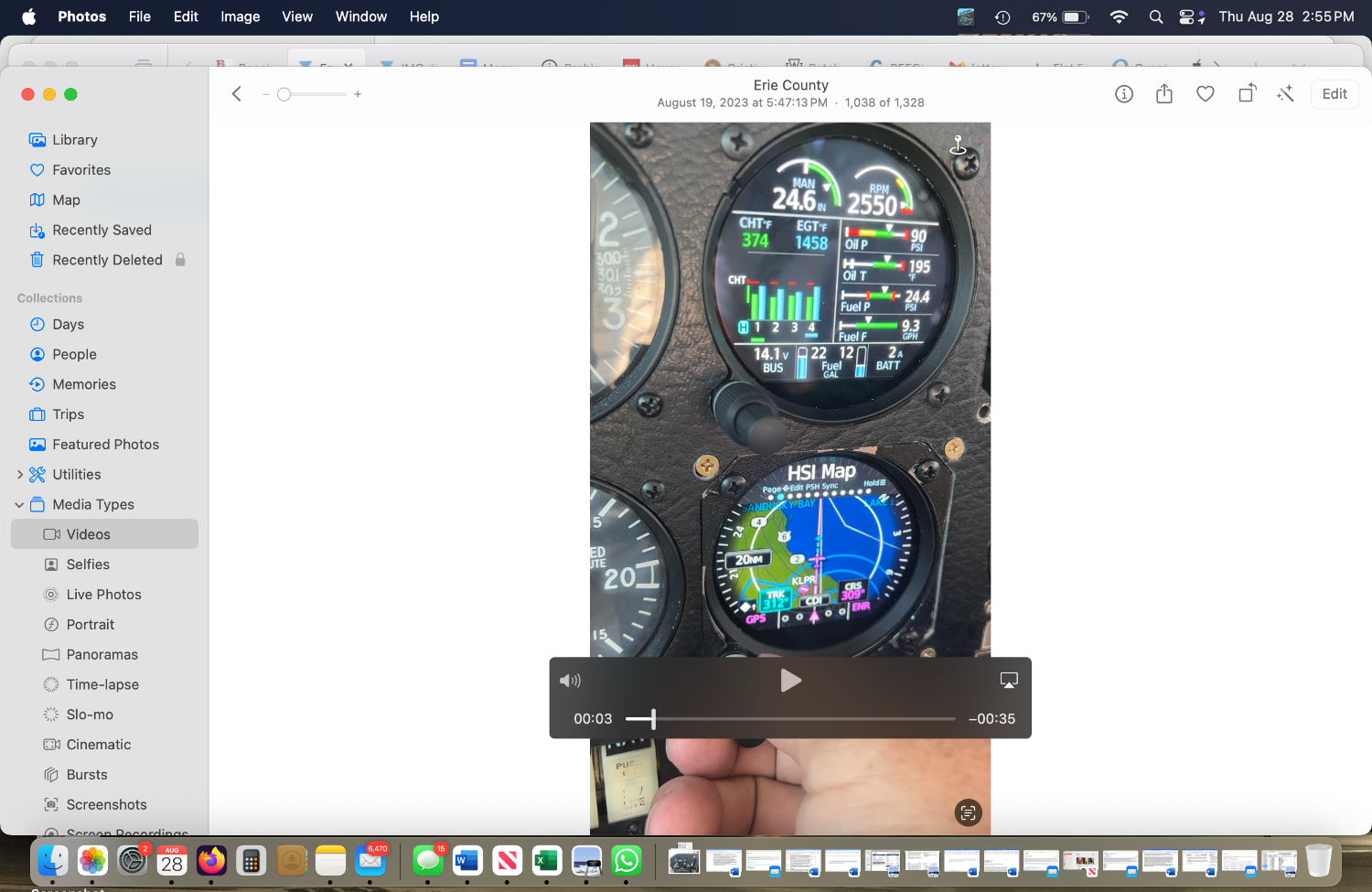

The second GI275 is actually an MFD, although it will display all the Engine monitor pages. It also has a HSI map page, a lightning page, a terrain page and a bunch of other stuff. It gets the data from HSDB piped in from the top unit, but if you pull the breaker on the top unit, the bottom one goes all X's. It doesn't forward the data through it. This is common with HSDB actually. But it's nice because you can have the leaning page on the bottom like that is and then leave the other one at the top with all the other gauges. STC says 2700 but I might have mistyped 2730 in there, but it hardly goes red now at 2710. -

SureFly with EAREM37HE plugs? Slick failure?

jetdriven replied to John Mininger's topic in General Mooney Talk

Iver seen this before. A member had his Surefly installed at 25 degrees, and had the DIP set to 25 also. After he put the gear up, the CHT continued to 600 degrees which was the gauge limit. He barely got back. It can get you killed. -

Engine Monitor Recommendations

jetdriven replied to gwav8or's topic in Vintage Mooneys (pre-J models)

The 275 engine monitor is the best one out there right now. And since it's primary, you can throw everything else away. We've done three of them and it really takes about 80 or 90 hours to get it all done when you add up the fuel quantity and everything else. It takes 6 hours to swap the senders, and calibrate the fuel, for example. You've got to get rid of the engine strip gauge, and then figure out what to do with the hole. And then all of the wiring to that strip gauge that goes through the firewall canon plug. All of the wiring harnesses are built just like avionics, it all gets pulled to the firewall and goes to the GEA24. -

We have a 1987 M20J here with 2700 hours on it. It's never had a cylinder off. It still looks good on the borescope and the compression test and it doesn't use too much oil so I don't know where the end is, but it's not there yet.

-

It must be going on everywhere then, because the local airport down the street, Manassas, has 300 piston airplanes based there and no piston airplane maintenance shop. And it's a similar situation at the other of the three big GA airports in the DC area too. I don't know how people are doing, maybe they're going out of state now for maintenance.

-

Insane impulse coupling issues AGAIN, seeking theories

jetdriven replied to Ryan ORL's topic in General Mooney Talk

We have a few clients with a Surefly/Bendix combo, including me. Slick magnetos on these planes are more expensive and not as good. QAA doesn't have the best reputation and neither does the 4000 series slick mag. But over hauling them, Kelly, for example, wrote into their manual, they don't have to replace anything and they can call it overhauled. -

If you call Continental or Lycoming and tell them it ran with no oil pressure, they will tell you to tear it apart. Because the hydrodynamic wedge has been compromised, and you can’t guarantee that the engine will not fail later. I can’t believe anybody with the professional license would tell you it was OK to continue with an engine that has been treated like that.

-

If it was 4 psi it needs to come off and be taken apart

-

201 Gear Up at KDWH

jetdriven replied to Mooney in Oz's topic in Mooney Safety & Accident Discussion

After finally seeing the video, I don’t think that Pilot deliberately stopped the prop, he may have pulled the mixture, however. -

Yes, it’s quite normal. Some airplanes over speed pretty badly and some don’t seem to be bothered by it. But your first instinct ought to be to bring the throttle back to about half, and then switch tanks and then after it stabilizes then bring the power back on. The prop goes to low pitch to try to maintain on speed, and in a Mooney, for example, it won’t maintain on speed so it goes to full flat pitch, and then, as soon as the power comes on, the torque rises so fast the governor can’t react soon enough. Go to any airport and listen to airplanes takeoff, it seems to be exclusively serious guys, but some Bonanza guys will do this too, they the firewall the throttle so fast that it overspeeds and surges on the takeoff roll. What do you think it does when you’re traveling 150 miles an hour. It could be a lot worse.

-

201 Gear Up at KDWH

jetdriven replied to Mooney in Oz's topic in Mooney Safety & Accident Discussion

The problem with stopping the prop is that you have to fool around with the starter to bump it enough to get it to be horizontal. And doing all this while you’re in an extremely critical phase of flight, and you also gave away your ability to go around in case you get a little too slow and slam it in which damages the airplane more. I just don’t think the perceived upside is gonna be nearly as good as the downside. There was a guy that did this I think with a traveler, and he was fooling around on the flare, bumping the prop trying to get it to stop horizontal, and it kept windmilling past that back to something not horizontal, and then he ended up hitting both props on the ground anyway, but he made it really hard landing because he stalled it because he was distracted. Don’t forget the potential for severe back injuries, because the seat frames in older planes are not designed to crush down like far part 23 seats are. There’s no shock absorbing system because the gear is up. I think the only upside here is that you might say the insurance company about $20,000. But you’re still going to have a claim, and they’re still going to raise your rates, and the additional part of the claim is gonna be more than the money you saved them, so I don’t think it really moves the needle all that much in the regard of upside.