-

Posts

12,475 -

Joined

-

Days Won

108

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by jetdriven

-

If you guys would put those cells in series and parallel and get 30 amp hours out of a 12 V battery you would sell a heck of a lot more of those things.

-

0 is empty

-

0-32 OHM. but they are in series so, as installed, its 0-64 OHM.

-

then the autopilot breaker will still kill it.

-

M20J Main Gear Tire and Tube Recommendations

jetdriven replied to SARNorm's topic in General Mooney Talk

That also brings up a another point. Transition to a different airplane. Rarely will you only fly this exact airplane the rest of your flying career. So you get into a piper arrow, or a Bonanza, and since your SOP is to put the flaps up to get weight on the wheels, you try that. -

M20J Main Gear Tire and Tube Recommendations

jetdriven replied to SARNorm's topic in General Mooney Talk

It’s a really great design and a really great idea, and the switch placement is ideal, but it still happens. -

The glue isn’t as strong as the Velcro and when you pull the two Velcro pieces apart on one side of the other of the glue comes off of the part. And whatever they make that glue out of is impossible to remove later, so you have these little squares of glue instead of fuzzy velcro on the end of your glare shield

-

M20J Main Gear Tire and Tube Recommendations

jetdriven replied to SARNorm's topic in General Mooney Talk

You would think that shape coding would eliminate gear retraction on rollout, but in fact, it happens quite often. And the results are pretty devastating. But if you don’t start grabbing stuff without actually paying attention and looking at it, you can’t put the gear up on the runway. But runway ops are the definition of a critical phase of flight. The first Culver cadet delivered from the factory had an interlock to where if the gear wasn’t down, The throttle could not be pulled back less than 1/3, and the factory pilot came in and realized that he couldn’t pull the throttle back far enough, so he turned the key on and geared up the first one. And we’ve still haven’t invented anything that’s idiot proof yet. -

Major versus minor alteration; voltage regulator

jetdriven replied to Jetrn's topic in Modern Mooney Discussion

What’s the far part 1 definition of a major alteration? -

M20J Main Gear Tire and Tube Recommendations

jetdriven replied to SARNorm's topic in General Mooney Talk

The tires are 125$ but the tubes are 200$. So changing them twice as often is false economy. -

If it comes from Kelly Aerospace or Hartzell, it ain’t gonna be quality.. that’s one thing to think about.

-

Cowl flaps : Landings and go-arounds

jetdriven replied to AJ88V's topic in Vintage Mooneys (pre-J models)

I used to fly with a guy that would do that…. He would put the gear down at the outer marker, and then he would add half flaps, and then full flaps while going down the glideslope, and then he would open the cowl flaps and mess with the prop and the mixture and everything. I mean, he made it work out OK but there were a lot of distractions inside the marker where it really all you wanna do is keep the needles centered and the airspeed where you want it. but one thing I did notice was that the CHT’s would crash. Can’t be good for it. The sole purpose of the cowl flaps is to manage engine temperature, so open at high power and low speed, and closed for the opposite. -

A Problem with hiring a local mechanic is he’s likely inside the sphere of influence of the seller and if he blows up the deal, he pisses off the seller and it’s his local reputation so I don’t think you can get a totally unbiased honest evaluation that way.

-

The annual was about six weeks ago and we have flown it about 25 hours since then, so I bet it’s still 95%. And yes, we’re required to test them at annual according to Concorde, but all the pre-buys and all the logs and all the previous owners and all the planes I’ve worked on I’ve almost never seen a capacity test written down in the book. And all the talk of the airport restaurant is the guy was flying along and the alternator off light popped on, and then four minutes later everything in the plane went dark and they cranked the gear down. But it does not have to be that way.

-

Did you notice if it cooled better?

-

I know what mine is, it’s about 95% of 33 amp hours. We test them all every year.

-

We had an alternator failure on the way to Oshkosh this year. Somehow, the damn shot that did the last annual didn’t inspect the output wire of the alternator, all all that well and the wire arch and burned off of the end of the terminal which killed the alternator. We flew about 18 more minutes and landed. But anyway, here’s the deal. Its electrical load is about 17 A in cruise and you can load shed it down to about 13. Now in that configuration you could fly it probably almost 3 hours. And not so with the Earthx. So when we got to Chicago executive, I took a Uber to the harbor freight and got a ring terminal and a hydraulic crimper and I stripped the wire and I fixed the airplane, or at least I think I did. I wasn’t really sure. But Oshkosh is an hour and 15 minutes away and my battery was probably about 80% charged. So I got the cowl back on, one man style, and I went inside and washed up and then the line guy is like I’ll walk you out. He said well if you start up and it’s charging what are you gonna do and I said I’m going to Oshkosh. He said if you start up and it’s not charging what are you gonna do, I said I’m going to Oshkosh. I cranked it up, it’s charging, I went. But VFR you can go a long way to someplace more conducive to get some repairs than Chicago PWK executive signature at 5 PM on a Sunday.

-

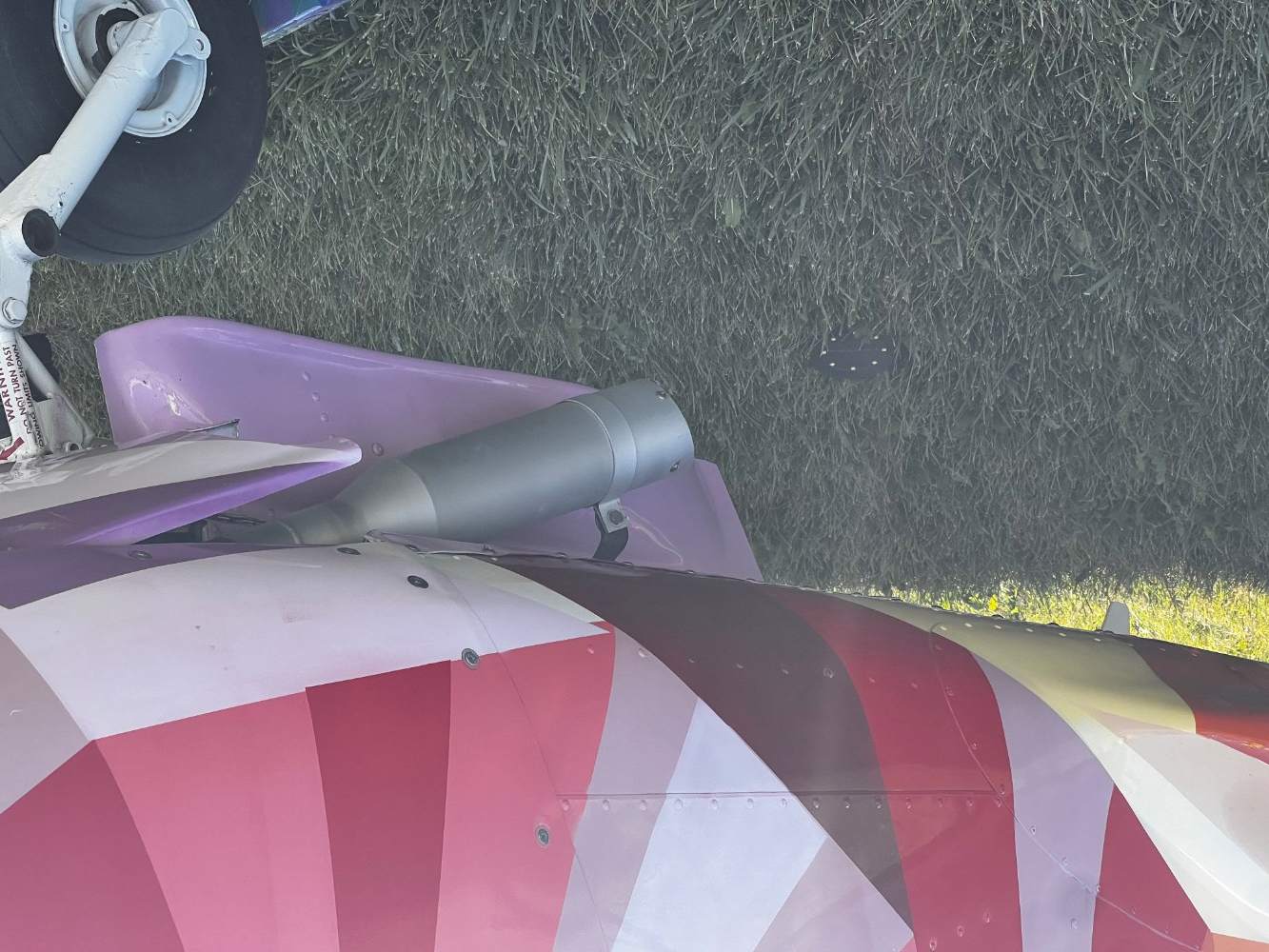

I visited these guys at Oshkosh a couple of times and I’m just kind of shocked at how far down the tailpipe sticks out. Now I think the reason for it is that it comes straight out the side of the muffler and it’s bent one time 90° and that’s the angle it’s going to exit at. If you look at a stock M20J tailpipe it has two bends in it. It has one bend that turns it aft and has another bend that turns it down. But anyway, I’m like the thing hangs out as far down as the gear door. He said well it doesn’t hang down below the airplane , but when the gear is up it hangs down 6 inches. Then he wants to claim that it’s so the carbon monoxide can’t find its way into the cabin inlet ob the side, which I don’t understand but anyway, I just can’t get over the tailpipe hanging down that far .

-

I’m a fan of lighter weight planes but I don’t skimp on batteries, starters, alternators, or magnetos. Compromise elsewhere.

-

Garmin EIS Fuel Pressure Wild Fluctuations

jetdriven replied to PeytonM's topic in Engine Monitor Discussion

Ours is pretty steady. It has a PS8E snubber on it. -

Medical Special Issuance Policy Changes??

jetdriven replied to MikeOH's topic in Miscellaneous Aviation Talk

One thing to consider is who the AME is. If you use a Senior AME with HIMS, they have a lot more sway with OKC. In my case, a phone call got me recertified under a CACI worksheet. -

M20S (or M20R) Rear Window Replacement

jetdriven replied to kinser's topic in Modern Mooney Discussion

thats it! -

Depends on who did the paint and how good that is. The engine is a narrow-deck and depends again, if it it has a reground cam and lifters or new, and new or rebuilt cylinders. it only has one nav, and that’s GPS only. Deficient for a plane in this price range. the interior looks good but cheap, like, vinyl and cloth Airtex. Fine for a flight school 172 but this is an expensive plane.

-

The gear walks all over the crank gear and trashes that and you have to remove the crank from the engine to change that ring gear plus it puts any pieces of metal into the engine as well, but yeah, it trashes the engine and people have taken to inspecting these things every 500 hours, but it needs to be good when it goes on as well. You can’t just slap it on there.

-

I hope somebody checked the alternator coupler per a bunch of service bulletins because if that fails, it trashes your entire engine. I’ve seen it happen.