-

Posts

6,461 -

Joined

-

Last visited

-

Days Won

73

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by kortopates

-

six gear collapses & gear ups in one week

kortopates replied to philiplane's topic in Mooney Safety & Accident Discussion

I wish they did, but perhaps the real value in something like the P2, that I own, is that it will save me from a gear up incident which in this current insurance climate could well result in making me uninsurable for a number of years. So even without a discount, that makes the P2 audio advisory system extremely valuable to me seeing first hand as a CFI others suffer the consequences of "insurance hell" after a gear up. -

Ferry pilot needed from Houston to SF Bay Area

kortopates replied to binkata's topic in General Mooney Talk

You'd be a slam dunk as a K owner. The process does take a couple days. The Broker will want you to fill out a full pilot history form like any Pilot applying for insurance before they present you to the underwriter for coverage. Then these days they are more often charging to add on a pilot even when the additional insured is much more experienced in type than the owner is. -

Ferry pilot needed from Houston to SF Bay Area

kortopates replied to binkata's topic in General Mooney Talk

I personally don't think a knowledgeable experienced pilot would do it without being an additional insured with a waiver of subrogation- so the 50 hrs of K time is mute and you'll simply want to add the ferry pilot to the policy; where lack of time may effect the rate but not make it impossible. Without the pilot being a names insured, I hope whomever realizes that your insurance won't cover them. Instead your insurance company could subrogate against the pilot to cover their losses if something did happen. Hopefully nothing will. Good luck with your new bird! -

Yes, but the letter specifically allows that the clock not be the sole function: For the reasons set out below, the required clock must be an installed appliance, but an installed appliance with a permanent clock presentation which means the requirements of § 91.205(d)(6) will suffice - it is not necessary that the appliance's sole function be time keeping. As previously mentioned that leaves a lot of interpretation between "Permanent display" and not sole function, but IMO it at least includes something like this of any appliance where the default mode is to display time. But it seems to leave out a lot of appliances where a clock isn't always being displayed and you have to go searching for it - but that's only my interpretation.

-

Agree with 99% of that Paul and 110% on the practicality of any of those satisfying the regs. Where I diverge a bit is that the letter of interpretation specifically says the appliance doesn't have to entirely dedicated to the clock and than multiple functions are allowed. That's leaves room for a lot of interpretation, but when we include the "permanent display" reference that suggest to me at least that time display should be main display or default which is not the case with many of the GPS examples where you may need to go find the time. That leaves seconds display that most of these multi-function clocks don't provide in the clock mode. This is the most glaring example as you well point out that these don't meet. I can't explain that except that its pretty clear the FAA over looks this as well. Maybe we need another letter of interpretation just on the missing seconds display for them to come out an accept that - or not. Personally I don't think we'd have this nebulous issue of what meets the clock requirements if there was a true TSO standard for an IFR Clock. But all the clocks that are TSO'd are TSO'd for something other than the clock function like the USB port DC-DC conversion C71. There is no standard for a clock that I am aware. In terms of practicality in the cockpit, in truth I use my wristwatch for current time, as primary which is accurate to the second since its also GPS based. For all timing functions, I my GTN provides all of those including time between checking tanks, timing flight duration and especially time to waypoint and length of legs in holding pattern. Those things are entirely automated. The egg timer we used as IFR students became obsolete with GPS IMO.

-

How to Lose Your License

kortopates replied to cliffy's topic in Mooney Safety & Accident Discussion

True, but I did think the controllers have some discretion as to what gets reported to the FSDO within limits, such as a loss of separation being a mandatory report. But glad to hear it was sent on to the FSDO. Although I am very familiar with the Compliance program where most deviations are dealt with by remedial training, I would have really thought that if an inspector has good cause to determine a deviation was beyond remedial training, this had to be a good example of one because of the pilots Anti-Authority hazardous attitude clearly portrayed on the tape recording. However, we may not know all the details of what happened between Inspector and Pilot. -

I am sure that's acceptable. The GTN's can do the same thing, but to be permanent it has to be an installation without all the options like an integrated Transponder code. But for many of us, myself included, I wouldn't use up a field for Zulu time unless I really needed too.

-

Paul, All Mooney's left the factory with a clock. The IPC for our K's lists many different possibilities that range by year of production. Per the IPC was even some options for Mid-Continent and Davtron clocks. When I got my 252, the clock was an Astrotech, a similar digital quartz clock, which I assume was a replacement clock. I now have a Guardian Aero-553 combination clock, CO monitor multi-function unit that fits in my old clock position. https://www.guardianavionics.com/aero-553-panel-digital-display-multi-function-co-detector-tso-certified-aircraft I always felt in Turbo's a CO monitor was vital and wanted the additional reliability of one installed in the panel. It too doesn't show seconds continuously - which is what I assume you are getting at. But the main thing I believe the FAA is trying to enforce is that something is dedicated to displaying time full time. But like Rich said above, which I agree with, you'd really have to piss off someone at the FAA to be cited for not having a permanent clock. But since the legal enforcement that was cited at the beginning of this thread for flying IFR without one was with a hangar neighbor of mine that was flying for hire I'll have to ask to get the rest of the story.

-

How to Lose Your License

kortopates replied to cliffy's topic in Mooney Safety & Accident Discussion

Doesn't sound like the supervisor was going to recommend an enforcement action or followup with the FAA, which seems like a shame to me. But don't really know if its up to him. I believe it automatically goes to the FAA regardless of their opinion. -

The primary problem with a GPS clock is that for it to meet the requirements stated in the letter it must provide a permanent clock display: "Another installed appliance with a permanent clock display that meets the requirements of§ 91.205(d)(6) that displays "hours, minutes, and seconds with a sweep-second pointer or digital presentation," is adequate for the purposes of this regulation. So unless GPS clock time is being displaying somewhere "permanently", the GPS clock isn't going to be meet the requirement. With only a few data fields to display on the main GPS screens, typically time is pretty far down on our list compared to the importance of fields like TRK, DTK, GS, ETE, DST, and many others would get higher importance IMO before clock time. "Permanent Clock display" I believe means its not adequate that we can turn to the satellite page and see exact Z time, but I would love to see evidence of the contrary because in practical terms it seems sufficient enough to me.

-

Pretty Amazing!! He doesn't even have the Mooney step to help get down! I visited one of the historic Chinese strips of the flying tigers while I was in China with Mooney and saw a lot of Flying Tigers memorable photo's of the young American pilots and their planes. In China the young pilots were considered big heroes and still are revered today. Capt Moyer has been keen on keeping the special bond that formed during that time alive. Here is an article from last year when Capt Moyer attended an event in Las Vegas to celebrate those memories: http://www.ecns.cn/news/feature/2020-11-02/detail-ihacnaey6712185-p2.shtml While I was there, they were building a new concrete runway where the old dirt strip had been getting ready for an airshow. We were there to see if we wanted to fly in a new Acclaim in support of the show. Unfortunately the short runway in the bottom of the valley with utility wires across each end of the runway posed many hazards and I campaigned not to fly in our Mooney's. As it turned out, others show participants of similar sized aircraft followed suit and only LSA type of aircraft flew into their new runway; which was a disappointment to many officials.

-

For 252's, Its as easy as spending the $12K+ for one! That price was from 5-6+ years ago, no idea what the price tag today is. I am just thankful they didn't make it required part of the drawing to go from the 252 to Encore conversion.

-

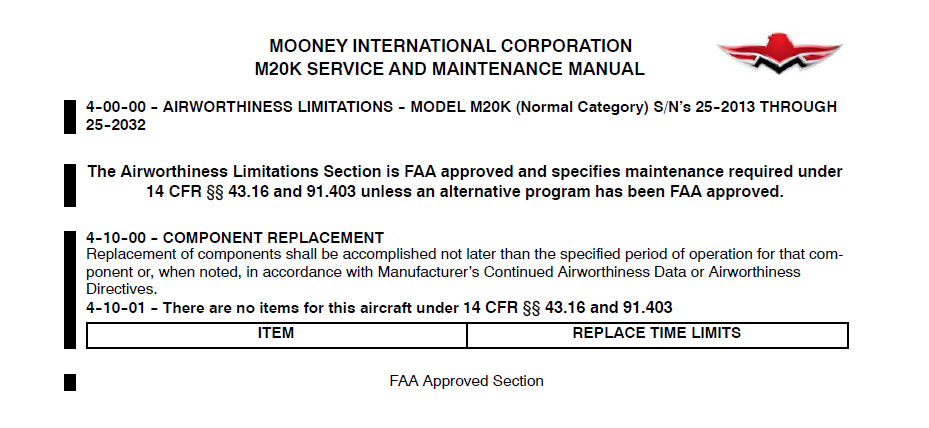

Yes - there is much confusion on this topic because only the FAA Approved section listed under "Airworthiness Limitations Section" also referred to as the ALS specifies maintenance required under 14 CFR § 43.16 and § 91.403 unless an alternate program has been FAA approved. So I'll try to boil it down so that its clear what part of an ICA is mandatory and what isn't since their is a lot of confusion on this. The rules for ICA are precisely the same as the rules for maintenance manuals. Specifically, if an ICA has a clearly identified "Airworthiness Limitations section" (ALS) then everything in that section (and ONLY that section) must be complied with, precisely as if it were in an AD. Such a section will also show "FAA Approved". For example, most of the Mooney Maintenance Manuals were updated a few years ago to include the FAA Approved ALS. Here is an example of the M20K Maintenance Manual update for this section: Notice there isn't a single required FAA Approved Airworthiness Limitation on any of the K's and FAA requirements for incorporating this section didn't even start till the Encores. Longbody's are similar. More commonly, to day we see lots of ICA's associated with STC'd appliances such as Avionics. But the only section of an ICA that is mandatory is the FAA approved ALS. With respect to anything in any other section of ICA, there is no requirement for a Part 91 operator to perform any of the inspection or maintenance items prescribed therein. But if the operator elects to do any of those items, then they must be performed using the methods, techniques and practices prescribed in the ICA. In general, a Part 91 operator of a small piston or single-engine turbine airplane is never required to comply with either the manufacturer’s inspection program or the manufacturer’s maintenance program. Such an operator is required only to perform a generic (Appendix D) annual inspection, and is not required to comply with any particular maintenance program (other than Airworthiness Limitations and ADs). A Part 91 operator of a multiengine turbine or a large airplane >12,500 lbs. must comply with the manufacturer’s inspection program (or AAIP) but not with any particular maintenance program (other than Airworthiness Limitations and ADs). A Part 135 or 121 operator is required to comply with both the mfr’s inspection and maintenance programs.

-

There is no right or wrong answer, when choosing to go IFR or VFR, just priorities and tradeoffs. I personally don't care about taking a few minutes to get an IFR release and very few IFR routing add much distance to my trip. But what I really value is a low stress trip through the SOCAL Bravo which is extremely busy when flying under and around the fringes. So I personally prefer IFR since it makes it far easier than VFR - most of the time. And the same hold true most of the time on long cross countries since being turbo equipped we'll fly high enough to get direct routes most anywhere once we're in Center airspace. But here is a video on Rod Machado explaining why he prefers to fly VFR on long cross countries whenever the weather allows. He gave this talk to out San Diego pilots earlier this month. https://cccconfer.zoom.us/rec/share/qBvW7QfIhxJicMcvCWn_I8tfoEtBWYW6Sv_WbCFFOuVK9iBowiyOLkBrDVtAq08U.uEULeRFxBChf2PzC?startTime=1601604084000

-

I think you're right about the culture. I've been flying long enough to see ATC cultures change. Further south where I fly under the largest TRACON in the country we had very similar issues. Many of little guys got to the point they would avoid talking to ATC. But ATC was smart enough to recognize that's not in anyone best interest and really took to heart how they could get local pilot support. This led to the TRACON appointing a senior controller to spend a portion of his time doing pilot outreach. This is when things finally got started in the right direction. As a Lead FASSTeam rep, we worked with him to understand our needs so that they would get what they needed in much greater pilot participation. Our controller rep, who joined the FAASTeam to work with us, really came around and sold his fellow controllers, with the help of his management, that they really needed to be there for us consistently and make it easier for us to access the airspace. And to give you an idea how much things have improved we can now get a VFR Flight following clearance and code from most of our ground controllers in SOCAL before departure so that once airborne they're expecting us just like an IFR departure. Very rarely is anyone dropped now, but it can still happen, but its far easier to get a flight following on the ground before departure than try to get it in the air in the busiest sectors. Overall they have been great and we all know what to expect for common routes through the Bravo. So I would encourage you to get involved with your local FAASTeam, if not already, and make this a priority to work with them. Hopefully you'll be well rewarded for the effort. Its going to take some time but it can really pay dividends for all with both much greater pilot participation and controllers trained to help with our VFR and IFR needs as well.

-

Like all Mooney parts, I got mine from the factory via a MSC (LASAR). There are also salvage sources include Paul Loewen https://www.loewensmooneysalvage.com/

- 1 reply

-

- 1

-

-

If you got the motor overhauled by Globe, it will be to the newer spec and the shaft will have larger holes. You’ll have to drill out an older assembly to match the larger holes. Too bad it’s missing because after drilling out the holes to the larger size it cleans out the elongated holes like new. Sent from my iPhone using Tapatalk

-

What's wrong with it? Are you replacing the cowl flap motor with new or OH unit too? If so you likely won't need this part.

-

Yes, but they don't really seem comparable. WRT to GA technology the information is generally available to pilot and the learning the system and failure modes is the responsibility of the pilot, but the pilots of the MAX crashes where not only victims of unanticipated single source of failure but also were not afforded training on the new system due to no fault of their own but of the manufacturer - at least as best as I recall.

-

Wow, that's a hell of a check ride! Double AHRS failures with (I assume) both check pilot and FAA guy onboard! That must have been intimidating to begin with but I guess you were too busy dealing with the issues to worry about them much I hear you on the "It just needs to work" statement. I felt very much the same way about the GFC-500 AP when we learned it was dependent on GPS to fly approaches. I very much would prefer the GFC-600 solution (pretty much the retrofit version of the 700) but that is both much more expensive and not available (yet). I still don't know but have warmed up considerably to the limitations of the GFC based on the probabilities. These are not easy tradeoff's give the $.

-

Obviously staged, but just tying what appears to be a couple overhand knots of rope to his belt?? As if that would actually hold? And even if it did he could still fall out of reach of the plane. Pretty crazy stunt. A future Darwin Award recipient?

-

Absolutely it can happen and does happen and Fred does an awesome job of going through the G1000 failure modes. And shortly after posting I did hear from another G1000 pilot whom told me about their personal AHRS failure so I won't disagree that total AHRS failures probably do happen more than we would expect. But we know its rare since its takes a lot before we entirely lose a Garmin AHRS unlike some of the less robust early GA offerings out there - but yes the doomsday scenario is still possible and much more so in a single engine GA aircraft like our Mooney's. But we can and should incorporate partial panel training in our currency training. But if I could, I would reference statistical odds of failures in our GA aircraft and would expect this is pretty far down the list but unfortunately we really only have reliable statistics from those failures that make the NTSB files. The good thing is that you do understand the failure modes and how it effects your panel capabilities, given your professional pilot background. The unfortunate thing as glass and avionics has evolved into what the FAA refers to as Technically Advanced Airplanes, fewer and fewer GA pilots really do understand their own aircraft specific system dependencies and failure modes until they experience one.

-

I would also point out that if we could equate the realistic failure statistics to the 3 scenarios @GeeBee outlined, Scenario 1, where a full AHRS failure is considered is not going to be the failure mode to be concerned with. It is the worst case scenario of the that configuration but but less likely that the others. First off, the Stec Turn-coordinator has a far greater chance of failing before a complete G1000 AHRS does. Now if our AHRS was a first generation Aspen AHRS I probably would have used the same failure scenarios. But the G1000 is AHRS is not vulnerable to a single input going bad which brings down your entire AHRS like the original Aspen did such as a loss of Air Data. To bring down the entire Garmin AHRS its takes total loss of both Air Data and both GPS's (see emergency procedures in the G1000 AFMS.) With any one individual loss we'll see degraded or partial AHRS capability. And with at least 1 GPS we will still have ground track information for heading and desired track to to steer with out needing to resort to the compass. Buts its because of the more advanced Garmin AHRS that fails gradually that Garmin doesn't really need a second AHRS. But still, in the vast majority of G1000 installations, you will have a GTX-345 that provide backup AHRS for your doomsday failure mode. It won't provide it to the panel or GFC700 but it will to your iPad and that along with a backup portable GPS can get you down. Chances of needing that capability in low IMC conditions is pretty minute since it will require both a loss of Air Data, such as a pitot heat failure in icing conditions, and loss of both GPS's from perhaps jamming or interference testing. I've experienced loss from jamming 3 times now and every case it lasted no more than 20 minutes - thankfully only once was in IMC. Reversionary mode is a really slick and automatic with the Mooney G1000 implementation. For example with PFD failure, it automatically goes into the reversionary mode bringing up the PFD on the MFD. The downside of this though is that when you loose either the PFD or MFD you loose the GIA-63(w) associated with that screen - you're down to one even though it none actually failed - so just one Nav Com to work with. But there are far better backup options for the g1000 today rather than the limited Attitude gyro with Altimeter and Airspeed such as the ESI-500 which is like a mini Garmin or Aspen and includes navigation. I'd rate that as a better option over a G5. So as much as I like the STEC AP's independence on a traditional 6 pack panel, I'll happily keep that GFC700 on a G1000 panel.

-

You’re probably thinking of the smaller foot print EI R1's I believe that were used in all the G1000's before the O3 s/w. Still used on the TNs I believe. Never seen a Horizons in longbody but I am sure it's possible but popular with the vintage Mooney's because their size matched the Vintage tach/rpm gauge. Sent from my iPhone using Tapatalk

-

That wire goes through the rear baffling bottom, under the cylinders, and terminates at the forward lower baffling. It's purpose is the pull the front and rear lower baffling against the cylinders so that airflow around those front and rear cylinders is forced through the cylinder fins. There should be a spring on the wire where it inserts into the rear baffling to keep it tight with the spring compressing when the hooked and is hooked into the front baffling hole. Looks like neither of yours is fully functional. This is a TCM baffling part, you can look up any TCM part number on TCM's web site. I'd expect to fix this you'll need a new hole in the rear baffling since the old hole is probably cracked it thus no longer able to hold it in place - which is common including several holes in the rear baffling after several cracks/breaks.