-

Posts

132 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Guillaume

-

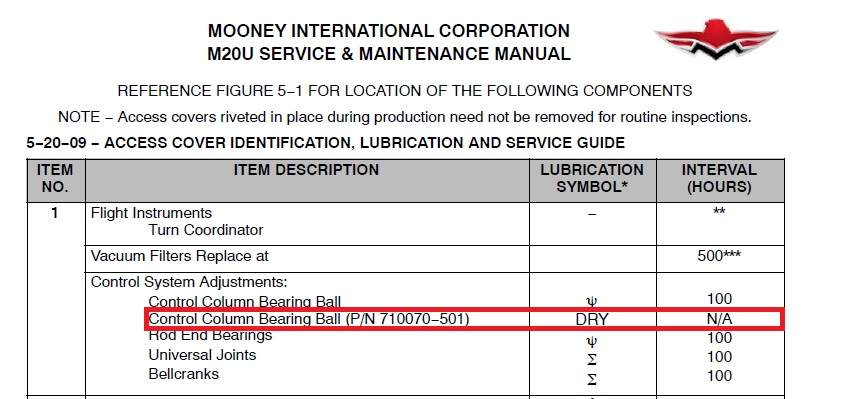

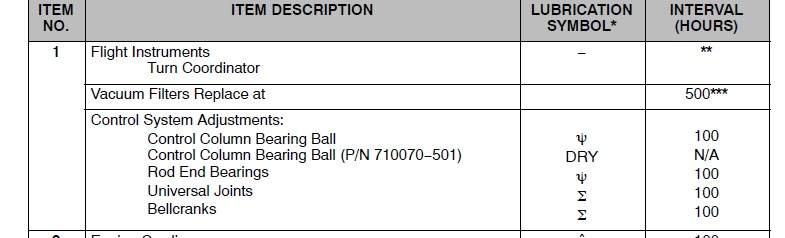

The new maintenance manuals are quite clear regarding 710070-501 lubrication. Unfortunately for me, this piece of information is still not in the latest M20J Maintenance manual (although aircraft are equipped with it). Mooney doesn't care.

-

Indeed, it was.

-

- I purchased them from LASAR. Aprox 2 weeks lead time during Christmas 2018 (Mooney had it in stock back then). - Wiring is the hardest part. There are many cables (yoke lighting, PTT, AP disconnect, CWS, Speedbrakes, possibly trim switch if equipped). Wires were cut behind the yoke tube (approx a good meter behind). New wire splices were installed (most of the wires already had a splice anyway). Disconnecting the wire at switch end is another option but it will require welding inside the aircraft for reinstall. Welding is a precision task and I felt that I might not be able to make a good welding job in the aircraft cockpit. I just wasn't confortable with that. Carefull cable routing after reinstall is an important task too. You don't want to mess with your flightcontrols. - When the yokes were off, I wanted to have a new part. I wasn't sure I would be able to clean the old ones back then. I installed the new parts right away. Although the old eyeballs were way smoother after cleaning, they were not as smooth as the new ones. Hope that helps. Good luck !

-

With EASA Part-M light, you can now run "on condition".

-

POH & Maintenance Manuals for M20V

Guillaume replied to Daneshgari's topic in Modern Mooney Discussion

Are you interested by M20U manuals ? -

SB M20-201 (still looking for a spinner aft bulkhead)

-

I'm looking for a reasonably priced M20J spinner bulkhead if someone happen to have one in stock (p/n : 680031-017) . I got mine repaired but I would prefer to have a spare one in case it cracks again.

-

I replaced my 17 years old Lords with Barrys last month. They work as expected.

-

Indeed, my profile is for the J.

-

Indeed I had to change a ST microelectronics transistor on my lighting box (M20J) few years ago. Total cost 2$.

-

This G1000 panel would require (at least !) welding of a new part (340304-501) to the cabin primary tubular structure (if that's even possible) and a new glareshield if your M20J is below s/n 24-3374. I'm not sure how you would deal with that with your aviation authority wth that, but on this side of the pound it would be rather complex. Dual 10'6" G3X is not an approved configuration per Garmin STC. Only a 10'6" + 7' is approved. Remote com does not exist for G3X touch certified. Only for experimental as of today The AoA feature does not exsit for G3X certified . Only for experimental as of today Remote audio panel does not exist for G3X touch certified. Only for experimental as of today Well...

-

Advice for installing LED Wing Tip lights in europe

Guillaume replied to Philip France 13's topic in Modern Mooney Discussion

EASA minor mod approval http://www.aveoengineering.com/downloads/10068162_CERT_REV_0_20181220.pdf -

Changing the eyeballs (both sides, pilot and copilot) really improved the yoke sliding. But now I have to wait for warmer temperature in order to check that the stiffness is totally gone. My point was, despite what is written above by other posters, this eyeball should not be lubed. Actually lubing this eyeball may damage it but only newer maintenance manuals mention it.

-

I ran through the same issue as @Danb . My elevator control was slightly stiff, especially when outside temperature was above 80°F or so. The old eyeballs were almost stuck even though I lubed them at every annual (per Maintenance manual MN123). (MN123 rev 12/98) I replaced the old eyeballs with new ones (P/N 710070-501, real PIA to do...). I also noticed that new aircraft (M20U / M20V) still use the same 710070-501 eyeballs. But their maintenance manual comes with an extra line in the chapter 5 : P/N 710070-501 must stay dry. It makes sense as it as made of nylon and not metal unlike other eyeballs. (MN 165 rev A) Although some of the M20J (s/n 24-0901+ ) and M20K are equipped with the same P/N 710070-501 eyeball, the fact that it must stay dry is absent from their maintenance manual. I e-mailed Mooney factory support about that, they couldn't care less... I'm writing this here hoping it can help someone.

-

Not to mention that for the 430 -> 430w upgrade you have to purchase an individual EASA STC. There is no « free of charge » EASA STC for this upgrade (contrary to GTN650 or IFD 440 upgrades)

-

I understand you did ask MSC's but did you ask your FSDO ? We also have MSC arround here and our CAA's (Civil aviation authority, our FAA equivalent) really don't care what MSC opinion's is on the regulations. During ramp checks or airworthiness review, the CAA opinion is the one that matters. I'm surprised that in the US you can install/replace any parts which is not listed in the TCDS but then, did you update the POH pages yourself without any approval (to reflect the new engine configuration) ? Everytime Mooney has released a SB for a new prop, engine, they would provide POH replacement pages for the aircraft updated configuration.

-

In europe, each certified aircraft like the M20J has to comply with the design approval holder parts catalog. For the engine, the M20J parts catalog says : A1B6D for aircraft s/n from 24-0002 to 24-0377 excluding 24-0084 A3B6D for aircraft s/n from 24-0378+ A3B6 for aircraft s/n 24-3374+ It also says that A1B6D engines can be converted to A3B6D by complying with Mooney SB M20-206. Mooney also says you can replace the old C212 (square tip) prop by the C214 (round tip) by complying with SB M20-214. But I'm not aware of a Mooney SB providing the instructions to convert an aircraft equipped with an A3B6D to an A3B6 (ie replacement of prop governor bracket, change of hoses...) . I'm surprised that in the US, you can install an engine not listed for your aircraft serial number (in the parts catalog) without any further approval . In Europe, this wouldn't be possible for a type certified aircraft without a manufacturer SB, third party STC or major modification approval.

-

I don't think there is one. I have the installation manual for the 2000 series and it just says : 4.4 MAINTENANCE INSTRUCTIONS Maintain aircraft structure, and wiring in accordance with aircraft maintenance manual, and FAA AC 43.13. INSTRUCTIONS FOR CONTINUED AIRWORTHINESS are listed in the install manual

-

Mine (2000 series electric, installed in 2001) had less than 600 hours TTIS. I was quoted 3361 USD (!!!) to overhaul them last month. I ended with a standard exchange for 3200 USD. Needless to say that I spent more $$$ than expected...

-

When Mooney tested the MT prop in the late 90's it was the old blades design. The new scimitar blades design release in the early 00's supposedly improved overall performance.

-

Yes, because the Ovation 2 (280 hp) is EASA certified. If your aircraft is EASA registered, you should contact your local CAA to get a noise certificate. If it's N-reg, check this.

-

There is no european noise restrictions as such. It varies from country to country. However we do have european noise certificate. Most noise restrictions are in Germany / Austria where usually a quiet aircraft get a cheap landing fee. A noisy aircraft is going to get an expensive landing fee. In France we have some restrictions at few airfields for noise abatment purposes (ie no VFR traffic pattern during the weekend, airport closes between 2300 and 0600 local...) You obviously can't change the way a Mooney operates (as it was certificated with POH data) so there is no actual change in power / noise level. On a Mooney, the only way to improve the noise level is by changing the prop (per STC). On the M20J, the mt-prop with new blades is supposed to give you better or equal performance. That's why you find a lot of Mooney in Germany with a mt-propeller.

-

For your option 2 I would try to contact this company : http://sega-aero.fr/ I have no personal experience with them but they have the proper approval and are located in the east part ou France.

-

@Hyett6420 I'm ATC in France and I can tell you for sure that I don't work for eurocontrol . In the UK, the biggest ANSP is NATS which is half public / private (according to wikipedia : the UK government holds 49% and a golden share, with 42% held by the Airline Group, 5% by NATS staff, and 4% by UK airport operator LHR Airports Limited) But the rest of your post is correct