-

Posts

9,512 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

I have a yoke mounted iPad running ForeFlight. With the G3X and GTN 650Xi, it is superfluous, but adds redundancy and I like the user interface. It happily keeps track of local time, so I set the panel avionics to UTC.

-

It's not a very smart clock. It doesn't change when flying across time zones either. I just set it to UTC. Done. I have a wristwatch for local time.

-

Where is the leak? If it is at the outboard end of the tank, I would first check the fuel sender.

-

A pot is a mechanical device, so it is subject to wear, especially in an environment where the wiper frequently rests on one location and there is vibration. But if both are doing it, I'd still look for something common to them. On the other hand, the pot is only about $30 to replace, so it's probably easier to replace it than to spend a lot of time troubleshooting unless inspection finds a loose connection or something obvious. Looks like someone has new/old stock on eBay for $27.50 https://www.ebay.com/itm/153892538415?hash=item23d4b5c82f:g:eL8AAOSw4A9ejyQe&amdata=enc%3AAQAIAAAAwBYA%2FsyYnycHBB74s6awH4oNvoZdB%2BtMMX2AI8zmYzY59zSvGRoSm9C6L70n23W7ZFJv7iLDsgbktElPa4GJyCoJ1N5E8BZ%2BqNLytOR5tXcjjz%2FZ%2B4OCQW%2BI5JD6A%2F6SDak8T8ROv4njhQk63zCzqwSv0MLcpT7l2O9wo2aPgcg4lydfQlgIUP0A2QZdu4ZAi3lmlfcPJv4XYPsUb25EJNf0Y520xehsWDrOUOzC0ky%2FoIpZ06hEf4nbw9O3YtJFQQ%3D%3D|tkp%3ABk9SR8rO2oX-Yg Skip

-

If they are both jumpy, I'd look for a common power or ground connection problem rather than assume two pots went bad.

-

I like 3M Dual Lock tape. Holds better than Velcro. I've used double sided carpet tape, but it takes a lot of it to hold the panels down. I don't want to glue them because sometimes I have to remove them to get the side panels off.

-

Sometimes it's something simple

-

What year and serial number do you have? The 1977 M20Js are a little different because, except for the aerodynamic mods, they are essentially M20Fs. Mooney made a lot of changes to the M20J in 1978. I have owned a 1978 J and a 1994 J. Both describe flashing for low voltage and steady for high voltage in the POH. The flasher circuitry is within the annunciator panel and the voltage regulator has an overvoltage output that sends a signal to activate the flashing circuit. I don't know if the 1977 is different. I suppose it is also possible that the flashing circuit has failed causing a steady annunciation during low voltage. Skip

-

If the annunciator light is now on steadily when you turn the master on and the engine is not running, it sounds like the OVP has failed and will not reset.

-

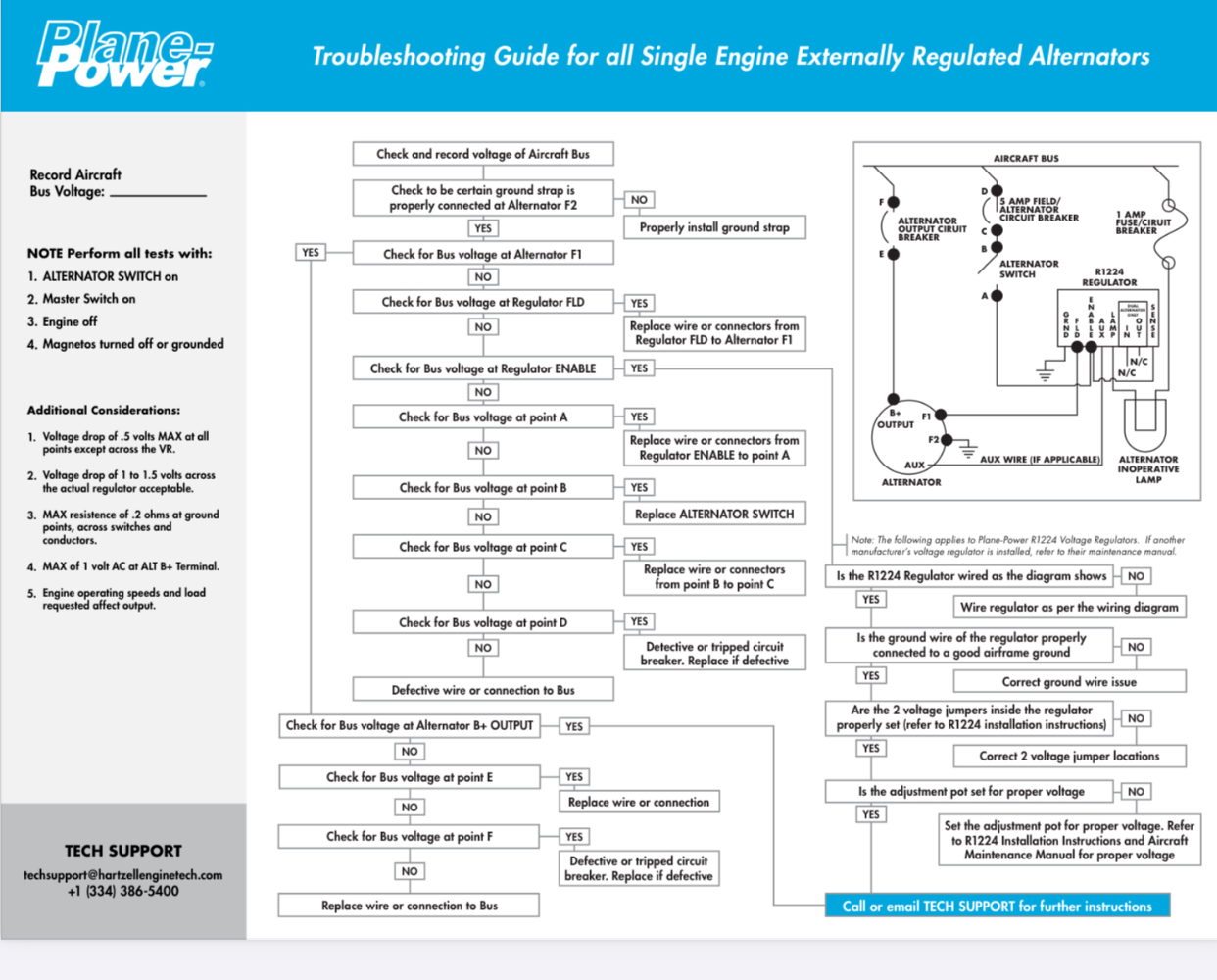

There are two types of over voltage protectors (OVP). Some just remove the field current to shut down the alternator and some “crowbar” (short) the field circuit to trip the field breaker to shut down the alternator. A flashing annunciator indicates low voltage and a steady annunciator means the OVP tripped. If the OVP trips the field breaker, I believe the correct procedure is to cycle the master switch to reset the OVP as well as resetting the field breaker. Resetting the field breaker alone probably isn’t sufficient. Check the emergency procedures section of your POH. Lot’s of things can cause no output from the charging system (most common failure mode), but about the only things that can cause over voltage are a regulator failure or the field wire being shorted to the battery bus. From the PlanePower website:

-

I’d call Frank Crawford at Mooney.

-

Did you try calling Dan at LASAR? He works out of his home and he’s answered the phone the last few times I’ve called.

-

@Kerrville is correct. The firewall isn't used and the airplane has to be levelled.

-

GFC 500 "Fail / System not usable"

PT20J replied to Rick Junkin's topic in Avionics/Panel Discussion

I've never had it fail, but I have had three or four random disconnects that Garmin couldn't explain. -

Suspected Broken Oil control ring

PT20J replied to Greg Ellis's topic in Vintage Mooneys (pre-J models)

Clearly the rings weren't sealing well but it may not be the ring's fault (at least before they lost their temper); it's probably that the barrel is just worn out and maybe out of round. The rings are at the top of the cylinder when you do the compression test, but most of the oil loss would be as the piston travels up and down the barrel. Also, an oily cylinder will often have great compression because the oil seals the ring barrel interface during the test. It's just another reason why compression tests are not a definitive indication of overall cylinder health. -

If the weights are correct, there is no need to reweigh it. Just level it and measure the gear positions per the Mooney procedure.

-

All speed brake installations are by STC. When Mooney installs them at the factory, they still use the STC.

-

That is impossible. The forward limit on a J is 41. My empty CG is 46. If it was reweighed, someone screwed up the calculation. (Because of the trailing link landing gear, you cannot use standard positions for the gear -- you have to use the procedure in the POH which is also in the Service and Maintenance Manual when weighing the aircraft). If the CG was calculated, you'll have to go all the way back to the factory CG and recheck all the intervening calculations (assuming that all the changes were kept) to find the error.

-

Keep in mind that they are the only ones that have seen your airplane and they might have noticed something not obvious from the pictures. Beegles has an excellent reputation for quality sheet metal work. That said, Maxwell also has a good sheet metal guy and the factory should be able to do a good job. But you'll have to talk to them. The repair I quoted was out at the wing tip (last two ribs) and may have been simpler to repair. No two are the quite the same and repairs on airplanes are expensive.

- 75 replies

-

- 1

-

-

Lexan (i.e. polycarbonate) is more flexible and less brittle than acrylic so it’s less likely to crack. I’ve found step drill bits to be the best for drilling holes in all plastics. Seems like you would still need to get the curve as the lens in the picture appears slightly convex. You could make a cast of the underside with plaster of Paris and then heat a piece of Lexan over it with a heat gun and then trim it to size.

-

I once brushed that switch while reaching to change the heading bug while making a 180 to extricate myself from icing. I immediately retracted them, but the left brake had collected enough ice to not fully retract. I now pull the speed brake CB if there is any chance of entering icing conditions.

-

If you have the yoke-mounted speed brake switch, it is very easy to brush against it with your left arm when you reach around the yoke and this will extend the speed brakes without you knowing it. When you turn off the master, the brakes free-fall with a loud clunk. Scared the heck out of me the first time it happened. Skip

-

It was the previous owner so I wasn’t involved. I would get your local maintainer to work out what needs to be done to get a ferry permit. I once helped get a Beech 18 ready to ferry after it ran off the runway and hit a sign when a brake failed. We got some sheet aluminum and wrapped it around the leading edge to reform the airfoil shape and pop riveted it to the skin and sealed the edges with duct tape.

- 75 replies

-

Don Maxwell is the owner of Don Maxwell Aviation Services in Longview, TX (KGGG). Maxwell is one of the oldest and best known Mooney Service Centers. https://www.donmaxwell.com/ The factory in Kerrville operates a service center: Mooney Factory Repair (Maintenance & Repair Only - No Part Sales) 165 Al Mooney Road North Kerrville, TEXAS 78028 United States Email: fsc@mooney.com Phone: 830.792.2052 Skip

- 75 replies