-

Posts

9,512 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

Should be the same. The logic was the same on my 200 and 150. GPSS is completely external to the autopilot and is just a converter to translate digital roll steering commands from a GPS navigator to analog heading for the autopilot.

-

With my Aspen/KAP 150/GNS 450W I used HDG for heading, HDG + GPSS for GPS Nav, NAV for VOR nav (rarely), and APR for approaches regardless of nav source.

-

An engine overhaul is only as good as the person doing the work. There has been a lot of turnover in most every industry during recent years. If I were going to have an engine overhauled, I would ask hard questions about who is going to do the work, and what their experience is, and how their work is inspected, and how the engine will be run in. And, I would visit the facility to see all this first hand. It's a lot of money. When I attended the Lycoming factory class last year we got a tour of the factory. Lycoming currently assembles all engines on the same AS9100-certified assembly line. That means that new, overhauled and rebuilt engines are all assembled by the same persons using the same procedures, and there is an inspection at every step. The engines are run in in a computerized test cell with a dynamometer rather than a test club and you get a printout of the results with your engine. This means that it is mostly broken in when you take delivery. Since all engines are assembled on the same line with the same process, the only difference between new and rebuilt is the parts. New is new. Rebuilt engine parts come from a stock of used parts that meet new tolerances harvested from returned cores. Cylinders are scrapped. Camshafts are scrapped. The main parts that get reused are crankshafts and cases because these usually have little wear. They always use new cylinders and pistons. I went with a factory rebuilt for three reasons: 1) At the time I did it (October 2018), it was the fastest option. 2) I wanted roller lifters and Lycoming now ships all non-turbo engines with roller lifters. 3) I felt that the AS9100 certification would reduce the risk of issues due to assembly variations. BTW, a rebuilt engine is zero time because Lycoming disassembles cores and puts all the reusable parts in stock and destroys the unusable parts. When a rebuilt engine is assembled, they pull all the parts from this stock plus whatever new parts are needed and there is no way to reconstruct any meaningful total time on the rebuilt engine. Since it meets new specs, it gets a new serial number (which indicates that it was rebuilt) and a new logbook. This means that your zero time rebuilt engine could theoretically have a crankshaft that has several thousand hours on it. This bothers some people. But I've never seen any evidence that rebuilt engines have a higher failure rate than new engines. Skip

-

Not sure about the non-Xi version. There was a software release a while back for the GTN Xi to allow it to show fuel data from the G3X. It also required changing a setting for a connection between the G3X and GTN. I’d check with your Garmin dealer.

-

Agree. My 78 J had it screwed to the firewall, up high under the windshield combing. It was an OECO and looked like this.

-

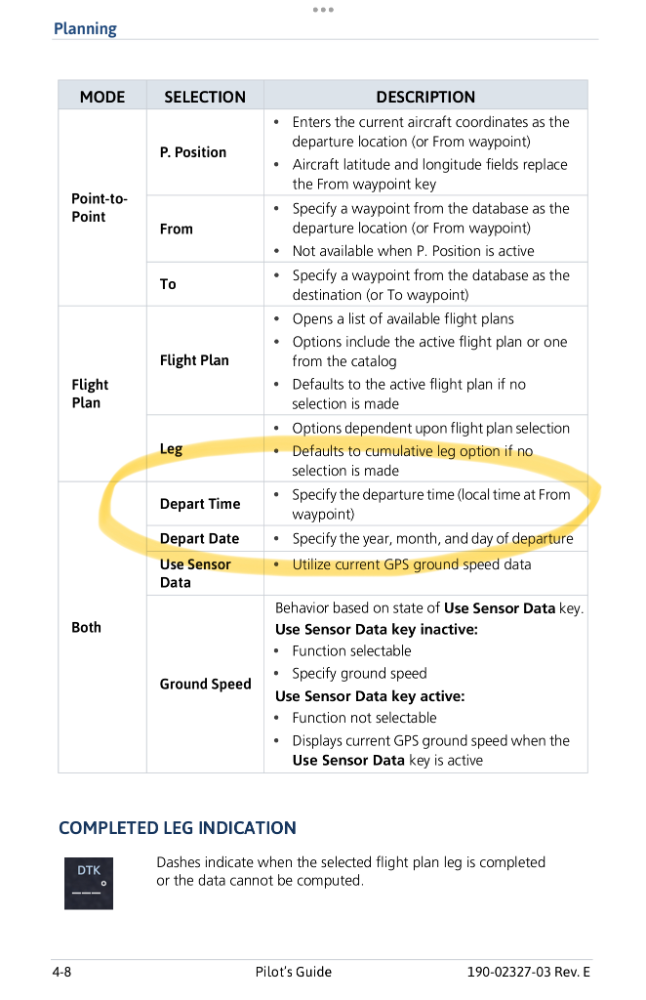

The manual isn’t terribly clear. It says ETA = Current Time + ETE … It doesn’t say that you have to enter the current time except for the sentence that says, “Departure date and time and ground speed data are required independent of mode selection.” Also, the table says it’s a manual entry. I agree it could be better designed, and it certainly could better described in the manual, but I believe it works as designed. Skip

-

Mine in a 1994 J are extrusions.

-

On mine the installer ordered some material that the vertical rails are made from, cut new rails to length, drilled them for the new trays, riveted the trays into the rails on the bench and installed the entire stack in the panel.

-

I like the flight plan page also on the GTN. It gives quick access if I need to change something. I have a G3X and have the map page up on that and I have a yoke mounted iPad running ForeFlight and I have the approach plate on that.

-

Time to buy new material and start fresh. That's what we did.

-

Tanis Cabin/ Avionics Pre-Heater?

PT20J replied to William Munney's topic in Modern Mooney Discussion

It probably depends on the insulation. Mooney long ago went to aluminized Mylar foam on the side panels to prevent moisture retention and corrosion of the tubular structure, but at least into the 1990s, it still used fiberglass elsewhere. I replaced all the fiberglass with the same material used on the side panels and it made it cozier in the cockpit. -

Tanis Cabin/ Avionics Pre-Heater?

PT20J replied to William Munney's topic in Modern Mooney Discussion

I keep a West Marine boat air dryer in the baggage compartment running continuously during the winter/rainy season in the Seattle area. It puts out a very small amount of heat. https://www.westmarine.com/west-marine-air-dryer-with-fan-dehumidifier-120v-ac-7867518.html?&utm_medium=cpc&utm_source=google&utm_campaign=PMax: GSC>Smart_Shopping>Plumbing & Ventilation2023&gad_source=1&gclid=CjwKCAiAjfyqBhAsEiwA-UdzJIgMRohFHXuGmp0j485jgUi6-W_5v5XRpUdxvM62pvVVFjjRqgcyBhoC4q4QAvD_BwE -

Tanis Cabin/ Avionics Pre-Heater?

PT20J replied to William Munney's topic in Modern Mooney Discussion

How cold? I have a 1500W ceramic heater that will heat the interior toasty warm on low in a few minutes in a 30 deg F hangar. I often use it on cold days to warm up the cabin while pre-flighting. It also works well on high with a piece of aluminized flexible duct attached and blasting up through a cowl flap to preheat the engine in about an hour. Skip -

If the GI 275 works like the G3X, the GPS bearing pointers will only point to the next waypoint on an active flight plan.

-

Interesting. I didn’t know that. Thanks!

-

For reference, the low voltage annunciator on a M20J is set to flash at 26.5 volts for a 28v system, so 13.25 for a 14v. The overvoltage relay is set to trip at 16v.

-

Soft Spongy Brakes - even after bleeding brakes

PT20J replied to LemansJeff's topic in Modern Mooney Discussion

@EricJ makes a good point. I believe letting the pressure pot sit after filling is in the M20J Service Manual bleeding procedure. My IA claims that rapidly pumping the pedals can aerate the fluid if there is any air in the master cylinders and it can take a while for the air to bubble up out of the fluid. It seems to me that spongy brakes would be due to air in the system and that the fact that bleeding fixed it, but it came back would imply a small leak in the system somewhere, probably on the low pressure side between the reservoir and master cylinders. If the O-rings in the master cylinder piston were leaking I would expect the pedal to just slowly go to the stop when constant pressure was applied. But as noted above, it seems unlikely that both master cylinders would develop this issue at the same time. Skio -

Mooney used different regulators and mounted them in different locations over the years. My 1978 J had a giant OECO regulator mounted in a place almost impossible to get out. It might help if you could take some pictures. Then perhaps someone might recognize your installation as similar to theirs.

-

The wings lift the fuselage. The more weight in the fuselage, the greater the bending moment where the wings attach. Large aircraft with a lot of useful load have a zero fuel weight limitation to avoid loadings that over-stress the wing/fuselage connection.

-

You can load a new approach anytime after the MAP. So, if you execute the missed early, you need to fly past the MAP before loading another approach.

-

Do you have a GTN 650 or a GTN 650Xi? On the Xi, the Depart Time isn’t hard coded. It must be manually set to the correct time depending on the calculation you want it to make before you press Compute Data. If you are calculating from present position, you would set it to current time. I haven’t tried it on a non-Xi EDIT: Here are a couple of screen shots from the Xi simulator app. The first shows the Depart Time button on the Trip Planning Page, and the second shows the data entry screen after pressing the Depart Time button. Skip

-

RPM and Manifold Pressure violent fluctuations

PT20J replied to Jrags's topic in Engine Monitor Discussion

What kind of gauges do you have? Original mechanical? Replacement electric? An engine monitor? -

My iPad or iPhone knows GPS time and position, so it calculates proper local time accounting for DST and time zone. I'm not seeing your issue. The Departure Time is a user entered field. I believe the planner does fill it with actual departure time when you begin a flight, but thereafter, you need to enter it manually. So, if you are planning from P.POS to some waypoint it uses your GPS position as the start point and if you select Use Sensor Data it uses your GPS groundspeed, but you have to change the Depart Time manually. I believe that this is because it is a general purpose planner that can be used both in the air and on the ground and you might be planning some future flight. So, it has user entries for date and time. The Pilot's Guide pretty clearly states "Depart Time - Specify the departure time (local time at From waypoint)" in table that describes the modes.