-

Posts

10,085 -

Joined

-

Last visited

-

Days Won

229

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PT20J

-

-

One more thing. The 2700/2800 studs can be used with two types of retainer washers. The star washer holds the stud firmly against the panel -- it's the type used on the tail cone access panel. The cowling uses the split washer that allows the studs to be pulled away from the sockets. Some people prefer not using any washers so that the studs can be removed like screws making the upper cowling easier to remove and install. The smaller studs can be installed without special tools but it is difficult to install the larger 4002 studs without a special pliers made for that purpose. Get one -- it's inexpensive and makes the job easy and avoids risk of slipping with makeshift tools and damaging the paint.

-

Path forward for return to flying/aircraft ownership?

PT20J replied to Wing Nut's topic in General Mooney Talk

All you need is time and financial resources. Getting a commercial certificate is a good thing because the training is structured and you have to meet a defined level of proficiency. But, you need to do it intensively which will also protect you, somewhat, from instructor turnover. When I was actively teaching (I'm a CFII SMEL), pilots that took forever and often quit were the ones that had busy schedules and could only fly a few times a month. Block off some time and get 'er done. A new to you 40+ year-old airplane can be expensive the first year or two of ownership and can spend a lot of down time in the shop. Most people that sell airplanes do not wake up one morning and decide to sell their meticulously maintained airplane. They have usually been thinking about it for some time and deferring maintenance during that time, perhaps because they really could not afford to own it. Or, they decide to sell when something expensive rears its head like tanks needing resealing. So, you want to pick your airplane very carefully which takes time. Even then there will be surprises. Insurance will be expensive the first year or two or three. Heck, I've got loads of time in all kinds of airplanes from a Piper Cub to a DC-3 and all kinds of ratings and no accidents and mine is still expensive. Probably the best thing you can do is fly a lot and get an instrument rating.- 22 replies

-

- 3

-

-

- insurance cost

- 201

-

(and 1 more)

Tagged with:

-

If there were good news, we’d hear about it. The fact that Jonny is silent means that there is no good news to share. Do you really need the details?

-

At the Lycoming factory class it was pointed out that higher is always better and anything below 100 psi (115 during start, warm up, takeoff) is fine. Lycoming considers 160 F to 210 F to be the normal range with 180 F nominal. The lubrication system will begin to drop pressure when the oil temperature reaches 220 F.

-

No, there is extra stiffening for the right wing walk. You can see it if you look in the right wheel well and compare it with the left.

-

The original fasteners are Camloc 2700 (small) and 4002 (large). Often, if you want the best fit, you have to try different lengths in different holes because the cowlings vary slightly in thickness. Camlocs are available in Cad plated steel or stainless steel. Skybolt makes identical parts in stainless and Skytanium (lightweight). The flange on the 2700 studs is 0.390" diameter. It works fine if the holes in the cowling are not augured out. Skybolt also makes a 2800 stud that has a 0.500" flange - not as finished looking but saves you if you have enlarged holes. (If you use the 2800 with a standard hole, you might have to ream it to 0.310 to get the flange to lay flat). The studs are all available in slot or Phillips head. Phillips is less likely to have a screwdriver slip and scratch the paint. Slot makes it easy to check alignment of the heads during preflight to make sure all are fully seated.

-

You might want to check around. When I bought mine last year, Mooney had them in stock. LASAR didn't but was willing to order it. I got it from a MSC closer to me at a significantly lower price than LASAR quoted. Mooney sells to all the MSCs at the same price, but each MSC sets its own markup. Since its latest move, I notice that LASAR has raised its parts prices. I'm not knocking them, but it may pay to shop around on an expensive part. Also, the part comes primed so it has to be painted. I ordered mine through a MSC and had it drop shipped to me and then had it painted at a local paint shop.

-

In general, it depends on the AD wording, the serial number of your airplane, and what has been previously done and logged. Specifically for AD 85-24-03, the text requires one time inspection and repair of fuel tanks on airplanes within a specific serial number range that may have left the factory with drain holes plugged with sealant. It also requires the same inspection and repair if the tanks have been resealed in the field. It further requires annual inspection of the Shaw fuel caps.

-

What I believe @cliffy was alluding to in the original post is that CG is only one parameter. Moment of inertia is also a consideration. A bowling ball and a bowling ball cut in half with each half mounted to opposite ends of a three foot pipe both have that same CG but very different moments of inertia. Once the second object begins spinning about it's CG, it will resist attempts to stop the spin.

-

I would take it to a place that does a lot of GFC 500 installs. Garmin copied the Bendix-King installation, so those shops have experience with the setup. I’m told a shop can replace a Garmin Mooney roll servo in less than a day, so I would think it should be the same for the KS-178. I just sold all my B-K autopilot parts to www.skymanavionics.com so you might check with him if you haven’t located a servo.

-

I just screwed a large plastic-coated hook in the wall and hang it from the drill handle so it hangs conveniently right side up.

-

According to the note STUD LENGTH MAY VARY WITH MATERIAL BUILDUP.

-

Do this in the proper order 1. Get it rigged correctly 2. Remove any excessive control friction 3. Make sure there are no static leaks 4. Then if there are still issues try the new gains. If you do this first, you may be masking other issues.

-

Part number is for a 50A bridge rectifier. I cannot see all the wires in the picture, but it looks like Mooney just wired it to use one diode. Clever way to get a high current diode with a mounting means.

- 22 replies

-

- 1

-

-

- electric heat

- pitot

-

(and 2 more)

Tagged with:

-

Because I am a curious sort, I called Rochester Sensors (current company name for Rochester Gauges) and spoke with Cheryl Manning who told me that Rochester doesn't sell retail and I would need to contact one of the companies on a list which she then sent me (attached). Next, I called Air Dallas and the gentleman there told me that he thought that this part was discontinued, but to be certain he would need the part number. Apparently, the 5- number on the dial is not the actual part number. The actual part number is much longer and located on the back of the dial. So, if anyone has a removed or new dial, perhaps you could look on the back and find the part number and determine if it is possible to order these. Referral List.pdf

-

If you are calling around asking about parts, be sure to ask for the right thing. The nose gear has three main components. The truss attaches to the airframe, the leg attaches to the truss, and the spindle attaches to the leg. When oversteered, a tube on the leg hits a tube on the truss but the truss tube is beefier than the leg tube, so it is usually the leg that gets damaged, not the truss.

-

I own a 2009 Subaru Outback. It has a seeping power steering hose. Subaru no longer makes the part and there are no aftermarket replacements. Last I checked, Subaru was a going concern. When Clarence used to post here, he pointed out that some Cirrus parts have very long lead times. Beechcraft owners waited years to finally get some magnesium control surfaces made. I was pleased that Mooney could provide me with a new nose gear leg when an FBO damaged mine. Personally, I can live without a redundant fuel gauge. I understand that some of you cannot.

-

If you call Frank Crawford at Mooney, he can look up the drawing and tell you if there is anything special about it. Mooney sometimes modifies standard AN fittings (for example to add a flow restriction for instrument connections or to make a right angle sniffle valve). I don’t see why a mod would be needed here, but the drawing will tell.

-

Had a friend that had a Mercedes 300 SL. It needed a new fuel injector body. Mercedes agreed to allow Bosch to sell directly to owners. Bosch agreed to build a minimum order of ten for $10K each. That was 40 years ago, so $10K then would be about $30K today. My friend got 9 others together and they bought the parts. So it’s possible to do this sort of thing, but it might be expensive. How many Mooneys have the wing gauges and how many would buy spares and at what price?

-

I know for a fact that Mooney manufactured ten nose gear legs a little over a year ago, so they are making more than just sheet metal. Custom parts made outside likely have a minimum order and perhaps a setup charge and that ties up cash needed for things that are more immediately important like payroll, taxes, rent. Also, the previous owners may have left some unpaid bills which vendors will want paid before accepting new orders. Another cash drain. Been there. It's a tough situation.

-

There is nothing wrong with 5606 and it has the advantage of being universally available. However, it does thicken with age and especially heat from the brakes. I still use it, but I drain some from the wheel cylinder bleeders every year until the discolored fluid is running pure red. Then I top off the reservoir.

-

Landing gear bushing/bearing alloy

PT20J replied to Hradec's topic in Vintage Mooneys (pre-J models)

I would consult with Frank Crawrord at Mooney to see how the factory would advise making such a repair. He could tell you how much you can ream the leg and you’d have documentation from the factory for the acceptable method of repairing the leg which whoever signs it off might want. The gear legs are heat treated. -

It’s because the airplane sits on the ground at a positive angle of attack, so it’s light on the gear at landing speed. The flaps increase the effective angle of attack and exacerbate the effect. That’s why a lot of us raise the flaps after touchdown.

-

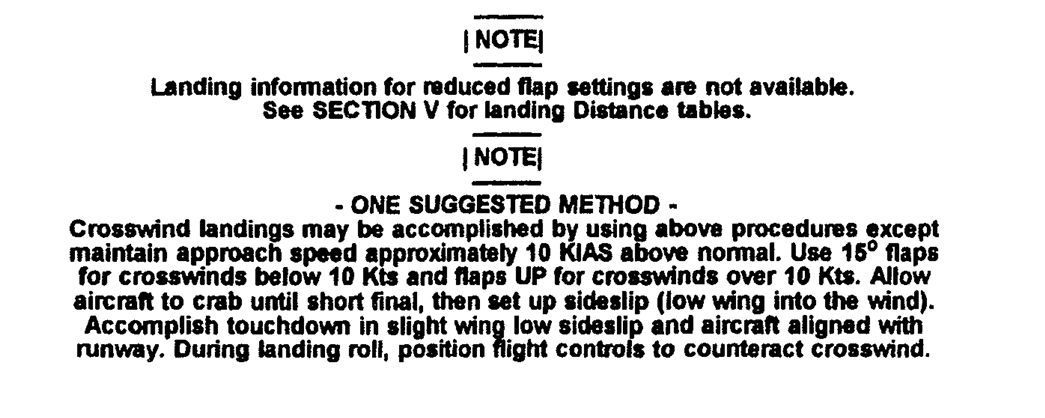

The certification basis for the M20 series is Civil Aviation Regulation 3 which states “There shall be no uncontrollable looping tendency in 90-degree cross winds up to a velocity equal to 0.2 Vso at any speed at which the aircraft may be expected to be operated upon the ground or water.” Aircraft delivered after 1975 generarally come with a Pilot’s Operating Handbook (POH). The POH is non-regulatory (except for the FAA-approved limitations chapter). There will not be a cross wind limitation. Instead there will be a maximum demonstrated crosswind velocity defined in the General Aviation Manufacturers Assoc. specification 1 (which defines the contents and structure of the POH) as “The demonstrated crosswind velocity is the velocity of the crosswind component for which adequate control of the airplane during takeoff and landing was actually demonstrated during certification tests. The value shown may or may not be limiting. (Whether or not the value shown is limiting should be stated.)” The M20J POH lists a relatively low demonstrated cross wind velocity of 11 kts. I asked Bob Kromer (former Mooney test pilot) and he said that he had personally tested a M20J to a 18 kt, 90 degree cross wind. But, Mooney has always been conservative to account for the skill level of the average pilot. Most pilots don’t practice crosswinds often and Mooneys tend to float. Higher approach speeds to perhaps compensate for gusts increase the float and it is during the float that the inexperienced pilot has ample opportunity to lose control. The 1996 M20J POH contains the following advice