-

Posts

9,508 -

Joined

-

Last visited

-

Days Won

206

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by PT20J

-

M20J - All Annunciators Illuminated

PT20J replied to WheelPantsOff's topic in Modern Mooney Discussion

The TEST+ circuit is what illuminates all the lamps when energized by the TEST button. There is a diode that isolates TEST+ from the GEAR DN light. If this diode is shorted, it will cause the gear down indication to energize the TEST+ circuit. -

Freshly overhauled IO-360-A3B6 - max fuel flow too high?

PT20J replied to Ryan ORL's topic in General Mooney Talk

I assume that the engine shop had the servo overhauled or supplied an overhauled servo. Perhaps it was set up incorrectly. The servo needs to be set to Lycoming specs on a flow bench - there isn't a field adjustment. I usually see about 18.5 gph. on my A3B6. -

I don't see anywhere where Mooney calls out heat treating for the horn. The gear legs are called out as being heat treated.

-

The steering horn looks to me like a part that any good machine shop could easily rebuild.

-

Worn steering parts just make taxiing straight take a lot if pedal work, but it’s not dangerous. If the gear is properly set up, there is enough caster to keep it going straight at landing speeds. I’ve been told by a couple of well known MSC owners that the Mooney steering is kind of sloppy even when new. There are lots of places that wear and cause slop as you noted. In my case, replacing a rod end and shimming the steering horn took out most of it. One problem with the newer horns is that they are hollow and it takes a lot of grease to get it to the bushings and the bushings will wear if not lubed. MSCs have access to more parts info than is in the IPC. They can get the correct bushings if that’s what you need.

-

Garmin 530 ARINC settings with G5

PT20J replied to TuomoMooneyFlying's topic in Avionics/Panel Discussion

The G5 installation manual is available on the Garmin website. It contains all the settings for the GNS. -

I believe the GI 106A is has been replaced by the GI 106B. Are you purchasing a used GI 106A or did you find a new one on the shelf somewhere?

-

If everything is running well, a single gauge reading should always be verified before taking other action, so your mechanic's suggestion is a good idea. Ideally, I would tap the mechanical gauge in as close to the transducer for the engine monitor as possible so both are measuring at the same point. If you eyeball the plumbing, it will become obvious what fittings and hoses you need. But first, I might check for restrictions that could increase pressure. Have you checked the fuel screen at the carburetor inlet? Also, you might inspect the hose between the fuel pump and carburetor to be sure it isn't deteriorating.

-

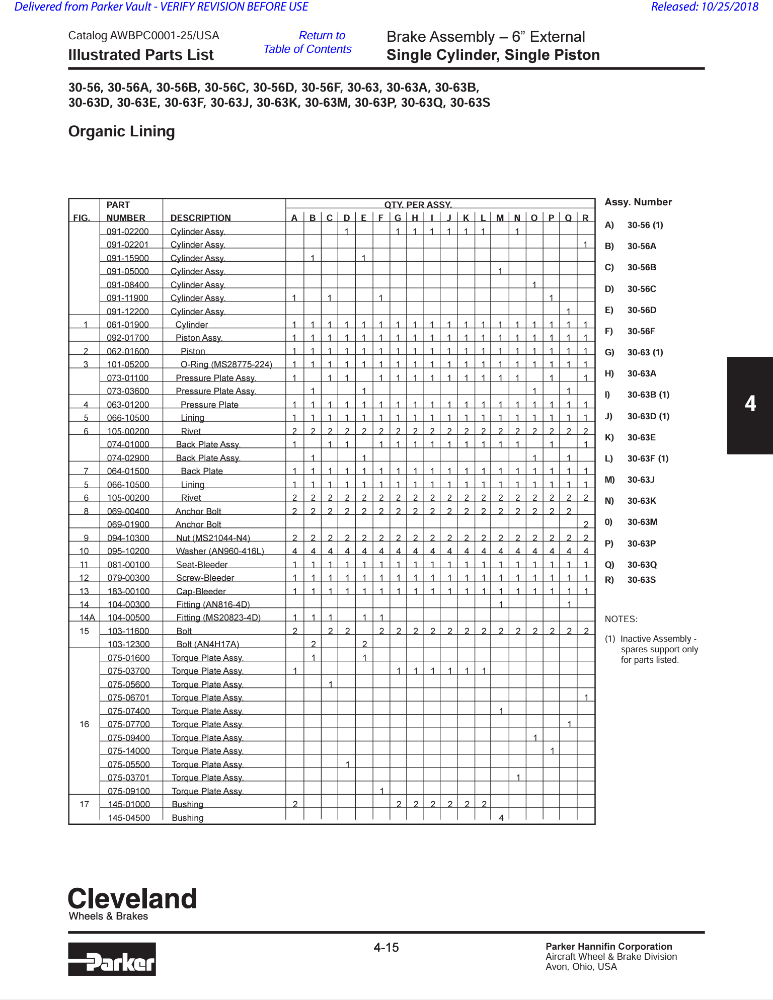

I have contracted with Skyman Avionics to sell my used avionics and instruments removed from my 1994 M20J 28V. Please contact Skyman directly at www.skymanavionics.com, 541-604-9573.

-

I used to do it from underneath with an acid brush attached to a dowel for length. But I discovered it's easier to lube them from the top by lifting the blades to get access. All you need is a little dab of grease on the worm gear. Too much grease just makes a mess and attracts dirt.

-

That's not per the drawing. I suspect that the spring broke and someone jury rigged this to make a shorter spring fit. _ 000S001D_Rev B_Drawing Package_08_14_2014.pdf

-

What is the original shock panel angel/tilt in degrees?

PT20J replied to Zippy_Bird's topic in Vintage Mooneys (pre-J models)

Why not just measure it? It’s easy to do with an inclinometer (you can get a fancy digital one, a cheap mechanical one, or use your iPhone). Measure the panel angle on the ground and then subtract the airplane angle measured at the leveling points. Most Mooney’s sit about 5-6 deg nose up on the ground, so maybe that’s why some say 8 and some say 14. -

If they do both for $2K it’s reasonable since they charged me almost that much to do one a couple of years ago. They told me at the time that they replace the switches, clutch and motor because they are not hermetically sealed and fail due to moisture. They also replaced the springs which had some light corrosion. They did not paint them or repair stripped screw holes on the frame even though I asked.

-

And, don’t expect them to repaint your chipped blades. That’s not included. I had to do my own after overhaul.

-

I gave this more thought and reread the documentation. I think the logic is pretty simple: The Go Around button activates GFC Go Around mode (wings level, pitch up). If connected to the GTN, it also activates the missed approach per the GTN Pilot's Guide. Auto Switch ONLY works on an ILS; not a VOR or LOC approach. The GTN knows it is set for an ILS. The GFC normally reverts to ROL when the CDI source is changed. The reason you need to arm APR is that this is what tells the GFC that you shooting an approach with vertical guidance and then the logic prevents it from reverting to ROL. This implies that it should also not revert to ROL if you switch manually when the CDI is within the localizer capture range since the GFC doesn't know about GTN settings.

-

Pull circuit breakers until it stops. That should help identify it. Can you hear it in headphones, or is it a sonalert? Mooney uses an intermittent tone for the gear warning to distinguish it from the stall warning. You might heck the throttle switch adjustment.

-

Then I would replace the jacks. They are inexpensive.

-

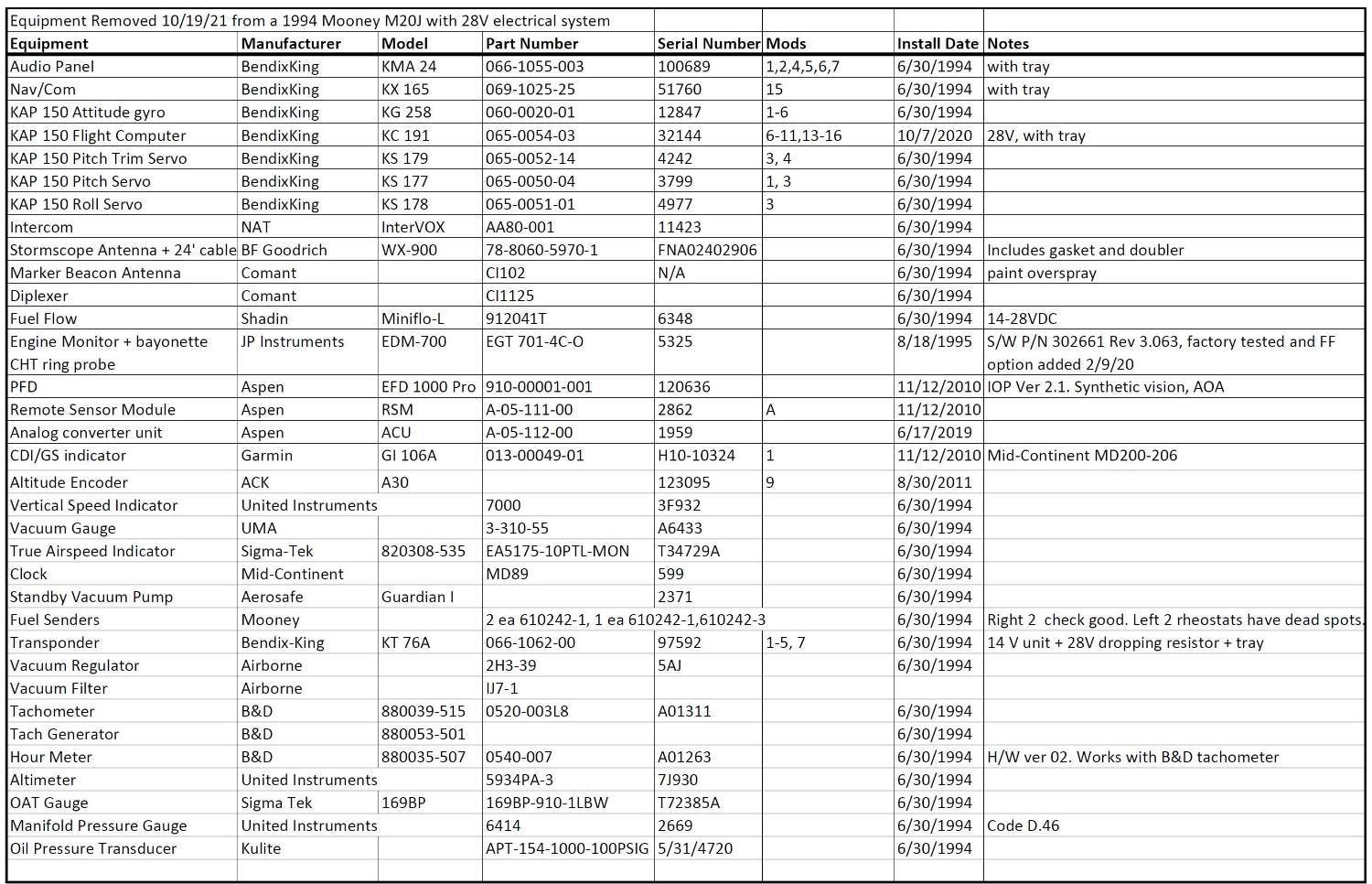

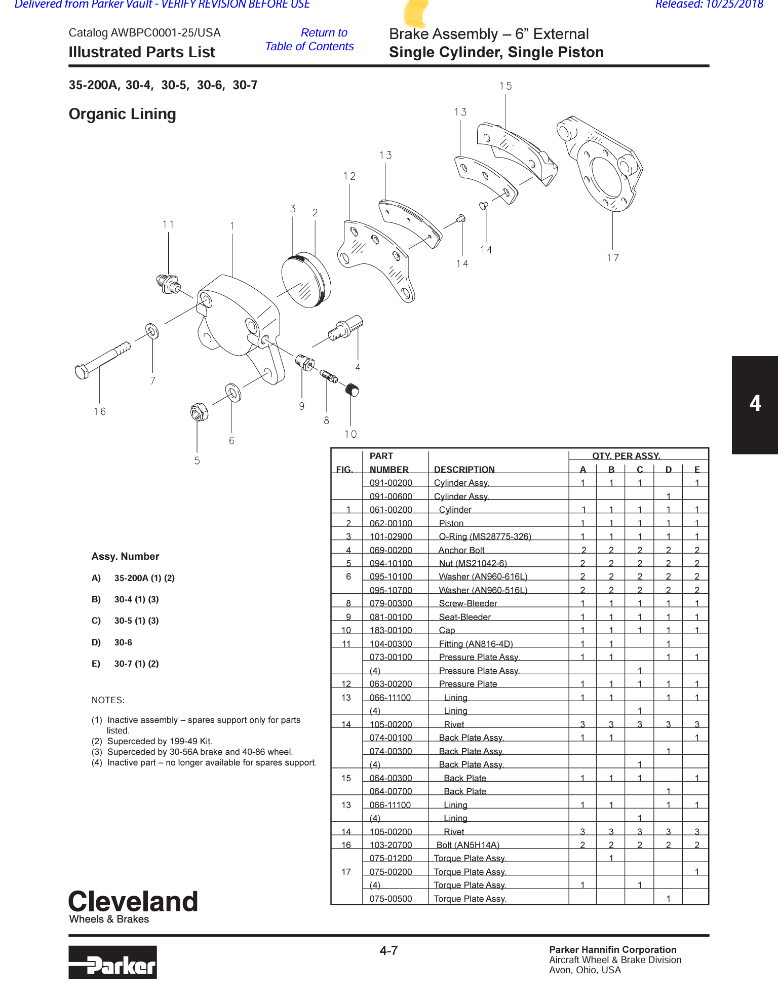

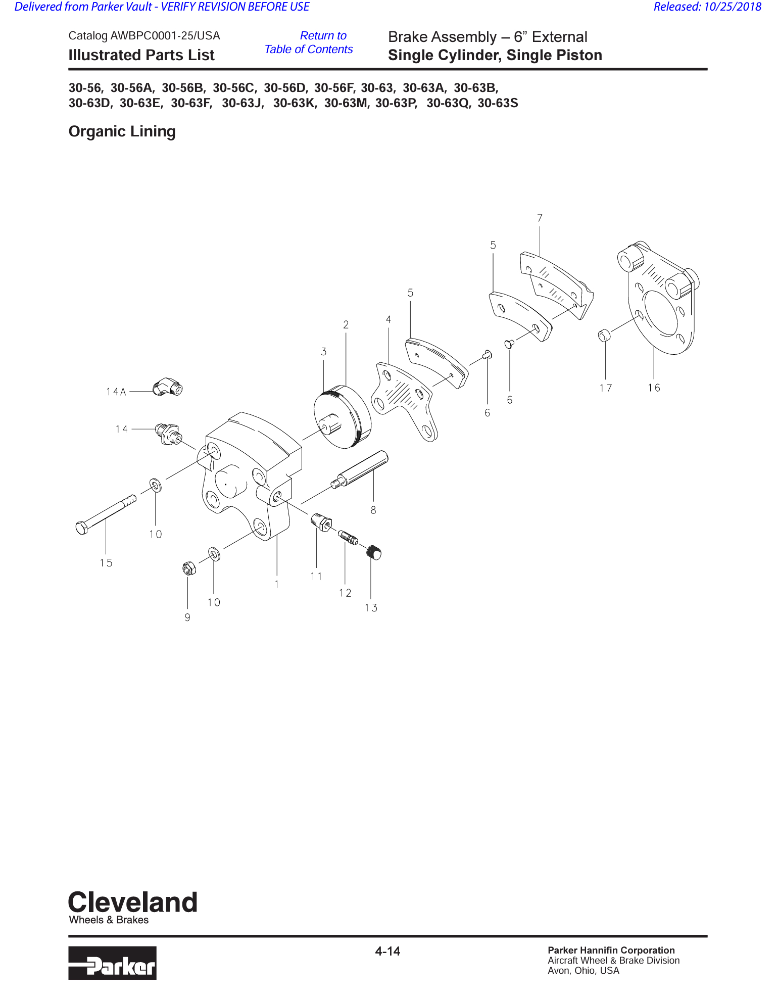

According to the Parker Cleveland Product Catalog, the 30-5 is obsolete and replaced by the 30-56A. If it were mine, I’d look for a used serviceable 30-56A.

-

The gear leg is heat treated so the repair is a little more complicated. I replaced one about a year ago and at that time Mooney had just made a lot of eight. This was for an M20J so you would have to check the part number to see if they are the same as yours. Frank Crawford at Mooney can verify part numbers and inform you of Mooney stock but cannot quote prices since each MSC sets its own markup (LASAR was not the best price when I ordered mine through another MSC). Mooney won't know what MSCs have in stock and so you will have to call around to see if anyone has one sitting in inventory. The gear legs come primed and ready to paint.

-

The IPC you posted lists the brake cylinder assy as a 30-5 or a 30-56A depending on aircraft serial number. The 30-5 uses three rivet linings and the 30-56A uses two revet linings. Mooney often only shows one variation in IPC drawings. You really shouldn't have two different brakes installed on the same airplane.

-

Let’s make sure we are talking about the same part. The steering horn is not the same as the gear leg (the latter being the part that gets dented by oversteering with a tug). The steering horn does have shims that can be adjusted to remove some play. LASAR no longer makes the PMA horn. They used to rebuild worn factory horns before they moved out of Lakeport, but I don’t know if they do that anymore or not.

-

I use Auto Switch, but my SOP is to always verify that I have the appropriate nav source as soon as I am established on the final approach course. That’s good to do whether you use Auto Switch or not.

-

Can you describe the “interference”? Are the jacks tight when you plug the headset in? Does it do this with another headset? Have you tried cleaning the headset plugs? I’d clean everything and try bending the jack contact that contacts the plug tip a bit to get a better connection.

-

Part numbers for prop/throttle controls (63C)

PT20J replied to phxcobraz's topic in Vintage Mooneys (pre-J models)

If you cannot access the nut on the back with an open end wrench, McFarlane has a tool for that. -

OK, but try this Auto Switch off. Be on a feeder route headed to an IAF in NAV with the CDI on GPS. Hit APR. Switch the CDI to VLOC. The CDI is off scale. What can the autopilot reasonably do? It’s got to go to ROL. Only if you wait until you are within a dot of centered on the localizer will it capture.