-

Posts

932 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by skydvrboy

-

I have no where near the experience level of most on here, so my achievements were a bit less lofty. 2018: My goals at the start of the year were to take a vacation with the plane (Oshkosh), and to fly 100 hours (117.8). Other accomplishments that weren't on the goal list: learned formation flying, joined Mooney Caravan to Oshkosh, set new CC distance record (496 NM), learned to change my own oil, got an AWESOME picture of my plane by the St. Louis Arch! 2019 Goals: 100+ hrs, IFR rating, Oshkosh/Caravan again, family vacation, new distance record, install engine monitor & ADS-B, mountain flying training, get a picture of @Junkman by the arch to return the favor!

-

That looks like exactly what I want to do with my panel. Did you have the JPI installed by itself? If so, how many AMU’s was the install cost? @Marauder thanks for posting the pic of the racking. Looks like if I want to move the audio panel I’ll need to have the rack rebuilt. @Andy95W I love the six (8) pack configuration. Are you recommending that I just put patches over the holes in my existing panel?

-

Weather permitting, I’ll be there.

-

Great responses and advice so far that I am very grateful for. A couple more questions though if I may. I see several of your panels have a left and right panel instead of one piece. This makes a lot of sense to me, making it modular (left, center, & right), so I'll follow suit. Can you elaborate on this? I can certainly see the advantages of cutting a new panel for the left side especially, since I will be considering it done once the JPI is installed. However, it seems it would be a nice to have rather than a need. Does the panel have to come out to install the JPI 900 or could it be added without removing the panel? Bottom line, what would the price delta be for cutting and installing a new left side panel in both parts and labor? I could see how the upcharge for replacing the panel could be less than the hit one would take on the value for having a franken-panel. As for the right side, I still have more I'd like to do to it, so I think cover plates would be the way to go until I'm ready to make the rest of the changes. I'm also still unclear on what everything attaches to for support. I'm pretty sure all the switches, gauges, warning lights, etc. just attach directly to the panel, correct?. But what about the racking for the radio stack? Does that also attach directly to the panel or is there some kind of support behind the panel for the radio racks?

-

I'm not familiar with this particular gauge, but the engineer in me says pushing the button opens the circuit via a momentary off switch in order to read the potential difference. When you push the button, do the ammeters drop to zero? If so, I'm pretty sure this is what's happening. It's like trying to read the voltage at a light switch. When the light is on, you get 0 volts, turn it off and you read 120 volts (+/-).

-

Paul, I thought you abandoned the GUMPS check for the new and improved GEAR check? G - Gear E - Everything Else A - As R - Required

-

Fair question and the answer is I don't really know. It is my first plane and I bought it thinking I would just fly it until I figured out what kind of plane I really wanted and then trade. However, the more I fly it and learn about it, it seems an F would make a pretty decent forever plane. I almost never fly solo, in fact, I fly with all four seats full more often than I fly solo, so I don't think I'd ever want to trade it for a C or E model. Currently, a 6-seat aircraft would make some sense, as I sometimes want to take my parents with my family of 4. However, my youngest will head off to college in just under 5 years, so I don't see myself getting a 6 seat. I like the idea of back country flying, but living in the middle of Kansas any true back country is quite a distance away. Bottom line, I'm trying to treat it as a temporary plane and only upgrade what I will use right now and might get something out of when/if I sell it. Hence the EDM and ADS-B and not paint and interior. As for instrument flying, I don't foresee doing any real hard IMC flying. I don't fly for work or ever "need" to get where I'm going when I take the plane. I want the instrument rating to give myself the option to bust up through the clouds and then back down to VFR weather on arrival instead of scud running. I also think the rating would improve my flying and weather decision making skills considerably, making me a safer pilot whether I ever use the rating or not. I got one about this time last year after my wife and I both got headaches on the same flight. No CO found, but after that, I refused to fly it again until the detector arrived. I "installed" it on that blank below the CDI with sticky velcro, so I'll need to find a new home for if I go with the proposed layout. I've pretty much ruled out putting in on the right side unless I run into something that will cost me a couple AMU's more to put it on the left. I already know my aging eyes are getting worse, I don't need an eye chart on the right side to prove it. Plus, what else is there to do in cruise other than monitor your engine and listen for your call sign?

-

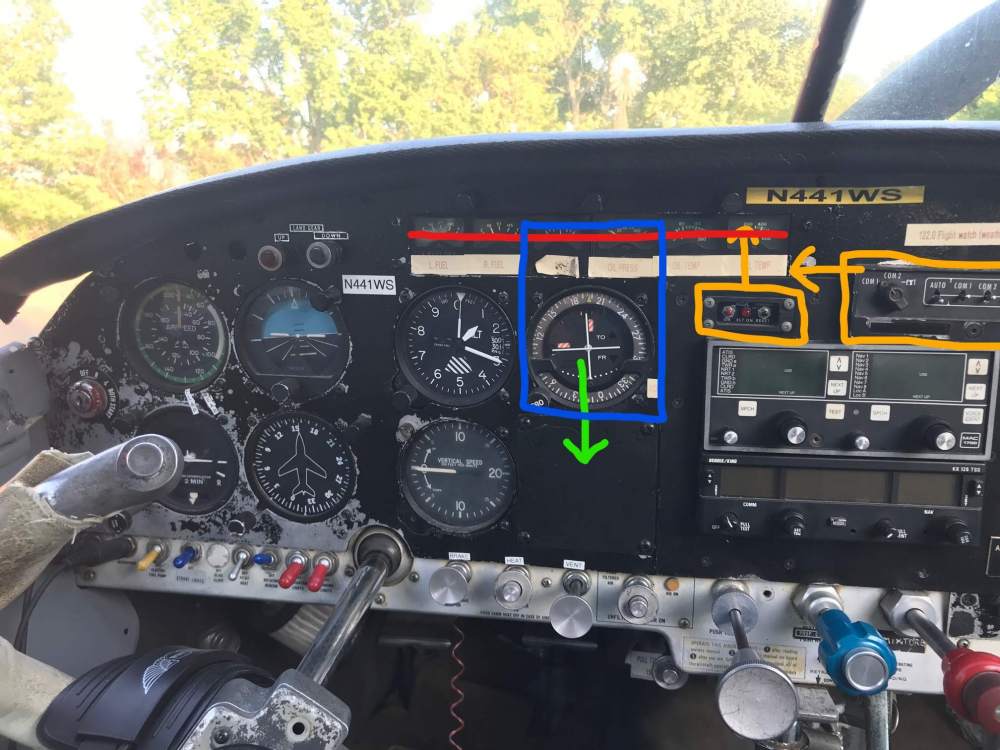

OK, I don't currently have an engine monitor and I'd like to add one. I know there are a lot cheaper alternatives, but I feel that I'd be wasting my money if I went with anything other than a primary replacement unit once a few legacy gauges start failing. One of my big pet peeves is spending money on the same thing twice. A little background, I'm currently only VFR rated but plan to get my IR during 2019. That said, here is my current panel with some drawing I will explain. Green = move, blue = new, red = remove, orange = ??? To the left of the picture is a standard 6-pack configuration. I'm pretty sure I want to move the CDI down and install the JPI 900 in its place mounted portrait style. Removing all the primary instruments above would allow enough room for it to fit there and I'd have it on the left side of the panel eliminating the need for the remote warning light install. My OCD makes me want to move the ELT switch out of the way and align the audio panel with the radios. However, I don't know how much work or expense that would entail as I'm completely unfamiliar with how the trays are supported. Along those same lines, I'd like to have the transponder aligned as well, but I'm still contemplating whether to keep it and get a SkyBeacon or swap it out for a Stratus ESG for the 1090 ES as I'd like to be able to fly internationally. I'm kind of leaning toward wait and align them all when I do the ADS-B. Thoughts? I know I need to keep the vacuum gauge, but do I leave it there or move it somewhere else? Similarly, do I keep the RPM, MAP, FP gauges as backup or remove them? The Apollo GPS has a dead back light on the display. I just don't see any point in getting it fixed. Is there anything it can provide that I don't already get from my iPad and portable GPS receiver? My panel is currently a single piece of aluminum all the way across. Does it make sense to split it in half and have a left and right panel? Once I put the engine monitor in the left side, I would consider it done as I don't see myself making any other changes over there. I could cut a new piece for the left side, but I think other changes might be coming for the right side, so I'd probably just cover any holes with plates. Is there support behind the panel to attach to if I split the panel or does this need to be added in? I know it can be done as I've seen others with two piece panels. Any affect on resale value either way? Finally, how much of this can realistically be done by the owner under the supervision of an A&P/IA to save cost? I'm an engineer and pretty mechanically inclined. I also have a good friend who was an A&P (15 years ago) and another who was an avionics tech (20 years ago). I doubt either would help me with the whole project, but they'd certainly come out for an afternoon to help out me out of a bind or answer my near endless questions. I know that's a lot of questions, but nothing that the group here can't handle. THANKS!!!

-

I'm in the exact same boat here. I'll be in Cozumel on the 4th.

-

Ram Air Door Opens On Its Own At Cruise

skydvrboy replied to apenney's topic in Vintage Mooneys (pre-J models)

@Shadrach You are spot on. Here is a pic of mine. I think that the push button that locks the cable slips when pressure is applied to the door itself. It does open and close all the way when the lever is pushed/pulled. I'll check that the cable ends are secured and don't slip next time I'm at the plane. If the locking mechanism is slipping, is there any way to adjust that or does that mean it's time to replace? -

Good luck! I would guess that 90% or more of the people on this site would say you have a good list. However, 90% or more of us are flying a plane that wouldn't meet your requirements. If you do find one, jump on it QUICK or it will be gone.

-

Ram Air Door Opens On Its Own At Cruise

skydvrboy replied to apenney's topic in Vintage Mooneys (pre-J models)

I'm also interested in the cause of this, as mine will slowly creep open when the air pressure on it is high. I have to be up closer to 140 mph airspeed before mine will open and then just a bit. It's enough that if I cruise with it closed, the warning light comes on when the gear goes down, but not so much that you would notice by looking at the lever. I think the push button locking mechanism just isn't holding well enough, but I'll see what others have to say. -

You should try it while skydiving. Indy car effect without the car!

-

I’ve never flown a 182. How fast do they fly on 8 gallons an hour? My F does about 165 mph at that fuel flow.

-

Kansas - $0 registration, $0 license, & 0$ tax.

-

Wow, form follows function!!!

-

Wow, I never imagined this topic would generate so much discussion. I thought I'd get one or two answers like "heat management" or "nothing". Turns out, it seems like I could have went and got my high performance endorsement in less time than it took to read all the replies.

-

Hmm. Well the atmosphere is saturated up to about 17000 ft with the temp and dew point running together below that. The temperature inversion briefly goes above freezing, but that's clear up at 5000' or more. That's too far to fall through freezing air to not refreeze before hitting the surface, so no freezing rain. I'm saying sleet.

-

As @kpaul said, get your replacements from OSUAV8TER and do it yourself. The first one took me about 45 minutes. I took it apart, replaced the inside o-ring, put everything back together and didn't get the nut tight enough. Take out the cotter pin, redo everything and now it's too tight. Take out the cotter pin, think this is stupid, why don't I adjust the nut before I put the cotter pin. The second one took about 10 minutes. When I pay a pro to do it, I expect them to know how and not go through the stupid mistakes that a first timer would. So, to me the hour is to high even though it took me that long to bumble my way through it!

-

This is what we had discussed doing, but will both still need to meet any time in type requirements. Transition would be into a Cherokee 6 with a 300 hp engine, so no turbo, no O2, etc. I did my primary training in the same Cherokee Warrior that the Cherokee 6 owner learned in and he claims it was a pretty easy transition.

-

Good point about the insurance thing. I have a good friend a few hangars down who flies a Cherokee 6, often solo for work. Meanwhile, I occasionally want to take my parents along with my two kids for trips. We were kicking around the idea of swapping time in each other's planes when the mission dictates. He'll need the complex endorsement and I'll need the high performance. We discussed adding each other to our insurance, but didn't think about any insurance required dual time.

-

Catching fuel from gascolator drain

skydvrboy replied to ilovecornfields's topic in General Mooney Talk

The checklist that came with my plane (made by a previous owner) stated to pull the ring with the selector valve in both the left and right position. Is there any reason to do this or would just a single pull regardless of the valve position be sufficient? My POH doesn't mention anything about draining it on both tanks. -

So this may be a stupid question, but I haven't been able to find a good answer. Maybe one of the many CFI's on here can help me out. What training will be required to get a high performance rating endorsement? I know what the regs say "Receive and logged ground and flight training from an authorized instructor in a high performance airplane..." My question is more around what am I going to learn about operating a 210 or 230 hp engine that I don't already know from operating my 200 hp Mooney?