-

Posts

3,267 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 0TreeLemur

-

Mine too, but the paint on the logo is still crisp and shiny, making it "look" new!

-

Got this working today. I can now display traffic from the Stratus on the IFD540, which is what I really wanted. One weird thing is, I can download a flight plan from the IDF to Foreflight, but when I upload a flight plan from the iPad to the IFD it doesn't work. When I send the flight plan, a cyan dialog pops up in the lower right-hand side of the IFD saying something like "flight plan ready for upload". I click on that, and viola! Nothing happens. No other warnings or symptoms. Thanks to all for contributing to the discussion!

-

This is the first time I'm learning about this. Makes sense. Good to know. I'd nominate this piece of information for a MS FAQ. Is it controversial? Seems not.

-

I ordered a 6" Air Stop tube from AS a few months ago as a precaution because one of the mains is leaking a few psi per week. It's been on back-order every since! Anybody have a good suggestion for another source having them in stock, or is this a widespread problem? I figured it was easier to ask this crowd than spend time bird-dogging. Thx. Fred

-

What is the useful load of your J?

0TreeLemur replied to 0TreeLemur's topic in Modern Mooney Discussion

Thanks for the data point. My J is 24-1402, and my UL is 880 according to the most recent W&B calcs. Looking at the low end of the distribution that my poll was designed to analyze, there is such a difference. Equipment? They are probably similarly equipped- mine has a KFC150 AP. The manual says that when they painted my J in 2019 they stripped it before painting, so that's not it. I've read that a paint job weighs at least 30 lb so if not stripped it goes on all the rides and eats UL. In an upgrade in March we installed a JPI EDM900 and removed all the legacy gauges and the ADF. It has a single Aspen PDF so it has vacuum pump, and legacy flight instruments required as backups but they don't weigh 10 lbs all together. When I bought it Jimmy G. told me that "in the early 80's J's started getting heavy". I didn't ask him for clarification as in "what changed"? Anybody know? Despite advice I give others, I'm starting to think about tempting fate and weighing it... Somebody STOP ME! -

Hot Air... Fixable or Expected?

0TreeLemur replied to Zippy_Bird's topic in Vintage Mooneys (pre-J models)

I've got the same issue. It's on my to-do list, but hasn't risen to the top yet. When I first flew my J in January, the heat was nice. That first flight I pulled the air on, with heat off, and the air was still warm. After five minutes or so, it cools down to "not hot, not cool". It seems that the hot air valve leaks pretty badly. Once an Alabama hangar once becomes a place where one can spend much time (latter half of Sept.) I'll take a look at that. -

What is the useful load of your J?

0TreeLemur replied to 0TreeLemur's topic in Modern Mooney Discussion

Thanks for posting. I'm ineligible by S/N. -

In the shaky video the aircraft appeared in a flat spin.

-

Is not missile. Is not bomb. Prigozhin simply fell.

-

What is the useful load of your J?

0TreeLemur replied to 0TreeLemur's topic in Modern Mooney Discussion

Curious- what makes one "2900 eligible"? I recall reading that the UL increase required redesign of the steel cage with some beefed up members. That sound muy expensivo as a retrofit. -

I've used them. They are quite affordable. I think the whole set for our C model was about $100 a few years ago. The C set seemed all inclusive with different styles for different model years included. Since then I've had them make some custom labels for me. They charge about $25 per sheet. E-mail them: aero@aerographics.com for current pricing.

-

I have read on these pages that there is a company called Belofram who makes parts for diaphragms for pneumatic actuators. I've also read that if you contact them with the correct information in terms of fold type and dimensions, they will sell you one to fix a piece of industrial or farm equipment. If you search MS for this topic you might find someone who knows more about it than I do. I kind of lost interest once I figured out how to patch the step actuator diaphragm on our previous C model and didn't follow up on it any more. I think that some have had luck with them, without using the word "airplane".

-

Well, thinking about it, I cut scotchbrite into 1/4" strips, and worked it around in the bottom of the contact well with a small flat-bladed screwdriver. Three times per plug seemed to do the trick. Measured resistance of all eight plugs as 1200-1300 ohms. That's a solution. Before cleaning the varnish off the contact surface, I couldn't get a reliable resistance measurement.

-

A question: I've got the Tempest fine wire plugs out of our IO-360 for cleaning. Doing the resistance check, I notice some tarnish down in the contact well. Anybody have a good method for cleaning that?

-

My attitude indicator is starting to fail

0TreeLemur replied to M20 Ogler's topic in General Mooney Talk

Folks are ditching their vacuum AI's like crazy for digital. I need a vacuum AI as a backup to the single Aspen PFD in my J. I bought a serviceable one off eBay and sent it to a shop for OH. Total cost $700 for a freshly overhauled Sigma Tech 5000-37, which has internal lighting. -

-

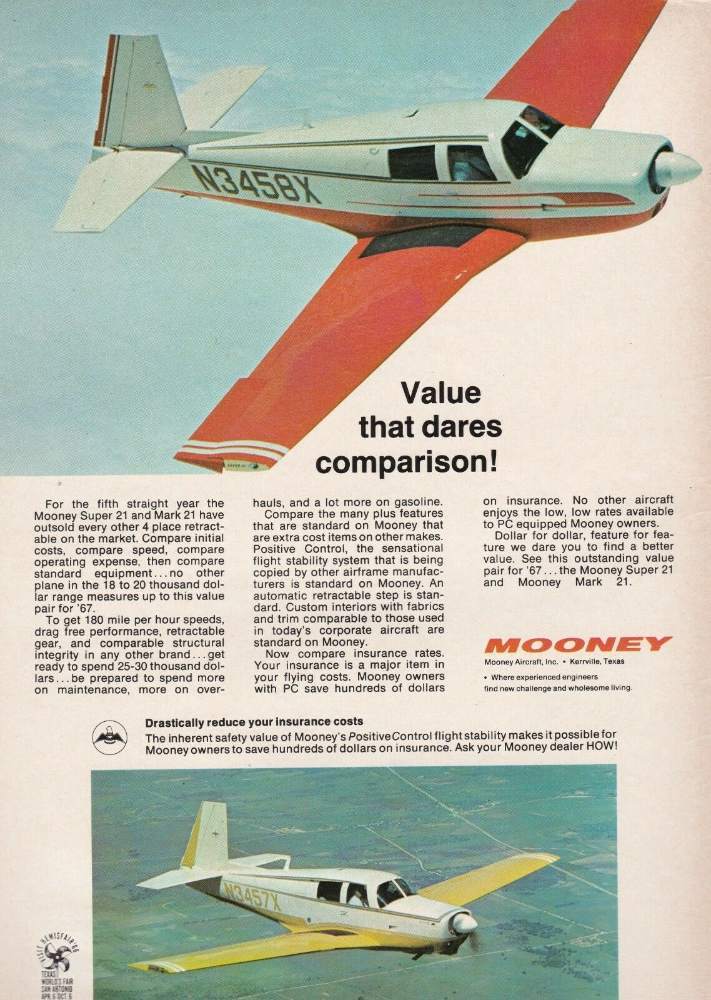

I just removed this from a frame and finished scanning it to post. Beat me by 30 seconds.

-

What is the useful load of your J?

0TreeLemur replied to 0TreeLemur's topic in Modern Mooney Discussion

Not at all. The top category is >939 lb, which lets you fly with full 64 gallon tanks plus at least 556 lb of other stuff. I'm more interested in the low end of the distribution. Note in my profile that I have an '83J, before the MGW increase. I'm trying to get a sense for how heavy my bird is. I hope that explains why the poll is set up the way it is. Thanks to everyone who replies. -

Interested to see what the range of UL for M20Js is. Please fill out the poll you own an M20J, or even if you used to own one.

-

What is your Useful Load in your M20E?

0TreeLemur replied to Echo's topic in Vintage Mooneys (pre-J models)

One thing to keep in mind when draining the fuel to weigh an older Mooney is this: The fuel drains screw into a steel gusseted receptacle that is riveted in the bottom of the fuel tank where water sometimes accumulates. They corrode. Removing the fuel drain can damage them so be gentle. You'll find that in this case after screwing the fuel drain back in it doesn't completely seal. We discovered that problem in our '67C, and they replaced that steel receptacle when we had the tank resealed. -

It depends on the location of the OAT probe. One well positioned probe is infinitely more valuable than a poorly positioned probe in the heatstream of the engine. My EDM-900 OAT probe is located maybe three inspection panels out on the left wing, way outside the heat influence of the engine. The magnetometer/temp sensor connected to the Aspen Pro is on the tail and consistently reads 4-5 degF higher then the wing mounted probe. It's not accurate, and throws off the TAS calcs done by the Aspen.

-

Calibration not necessary because ADS-B doesn't make the news, it just reports it. Then the FAA ignores it . I don't believe that the FAA software does anything with it automatically. I've read that controllers can access your extended squitter info, but generally don't. The only thing they get by default on their display is the good ol' mode C altitude readout, which was calibrated when you do your mandatory IFR Cert. test on the pitot-static system.

-

I heard this as: "A man with one watch always knows the exact time, right?"

-

The Hartzell Top Prop we bought a couple of years ago came with NYCO grease, and a nice big sticker on the hub saying that was the only acceptable grease. My A&P last annual said "What's NYCO grease?". Luckily I bought some and a grease gun before the annual and gave it to him. If only the paint would stay on the leading edge within 6" of the tip... That's another story. Some law firm could make coin organizing a class action on that one. I know of several people here on MS that have the same problem with the paint on Top Props.