TigerMooney

Basic Member-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Location

NC

-

Model

1981 M20J

Recent Profile Visitors

315 profile views

TigerMooney's Achievements

-

ELT Battery (am I getting ripped off?)

TigerMooney replied to TigerMooney's topic in Modern Mooney Discussion

Final outcome: I called the “service center” (will go un-named, but happens to be located in the middle of the United States). I directly asked if my airplane would be un-airworthy if they just replaced the battery. Lots of run around. He said he would only discuss it with my IA and not me. I told him to call the IA. Then he called me back. Said he couldn’t just change the battery. He had a very self righteous disposition. Then while on the phone with me he said he had my unit on the bench test and said it was testing at 63.9 standby current. The original quote said 42.7. I immediately called him out, and said I had a problem trusting him. He apolozoged and said he “had a different unit he was testing and mistook it for mine”. I then replied, “I guess that’s because every unit you receive tests high in standby current?” After that, he offered to “handle the repair charges” and only charge me $499(plus shipping) for the battery. Then said they barely make any profit. Lol, then had the audacity to say he wouldn’t cover these repairs next time, when it was due again. So of course I told him “you expect it to high for standby current again, even after you repair it this time? Anyway here I am…$499 later (plus shipping) with a fresh ELT battery. I’ll throw it in the garbage next time it’s due. Will not use that facility again or product again. -

My Kannad af compact ELT battery was due for replacement - and of course it has to be sent in to be replaced (the IA can’t just do it in the shop). So here’s the shocker… I get a quote back from the facility stating that additional work needs to be done in addition to the battery(!) and the stand-by current is “too high”. Of course he told me that the battery I sent in wasn’t dead…but that doesn’t mean the new one will last. He said there’s no way he would “certify” it. My question is does he need to “certify” it? Or is this the same circumstance of a “mandatory” service bulletin on a prop saying it has to be overhauled every 6 years…when in fact, that SB isn’t regulatory at all.

-

Thanks, That is some great info…and some math that would certainly made my brain hurt! While my plane is in for annual I think I’ll have the IA pull the tach and I can sent it to AQI in Missouri who said they can calibrate it for less than $200…but I know its a gamble with a 40 year old Stewart instrument…but I think a new one would be about $500 all together…hopefully after that, a prop governor adjustment I’m not too deep into this to restore full takeoff power.

-

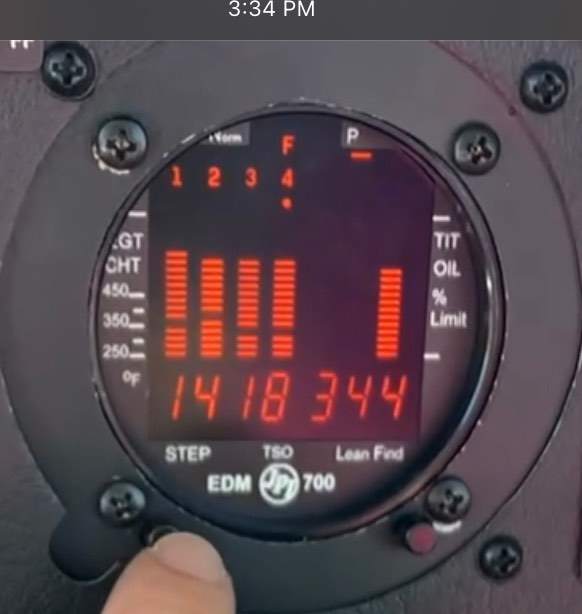

I made a previous post on this prior to signing up for savvy analysis, adjusting baffling, changing all 8 spark plugs and cleaning my injectors. I’m still seeing my #2 CHT shoot up close to 400 (and 35 degrees hotter than #4) when I run 20-25 LOP (before I intervene). My gami spread and ignition stress tests are all very acceptable, according to savvy. I’m putting my plane into annual this week and am out if ideas, but would like to equip my IA with as much info as possible. Aside from this one issue, I’m very pleased with the engine. It’s just over 500 hours from an overhaul by zypher, does not consume much oil (1 qt every 12-15 hours), and the engine compartment stays very dry. Should I have the cylinders and/or valves borescoped? I’m truly at a loss… The pictures are below from when I’m at 7k wide open throttle and as lean as I can get it before the engine runs too rough. If I were at a normal cruise setting, #2 would almost certainly settle above 400. And I’m pretty sure thats not acceptable for long term operations.

-

The main concern is after uploading engine data to savvy analysis pro, I’m making 2610 rpm on takeoff (according to JPI), and they recommend a prop governor adjustment. But I don’t know if 90 RPM is enough to necessitate a R2 of my analogue tach. Aircraft Quality Instruments in KS said they will adjust it for $185, plus an hour labor on each side of that. Once my IA shoots it with a laser during annual, I guess I’ll make a decision. Would you guys r2 the tach and adjust the prop governor if it’s just 90 off at takeoff power? Can anyone recommend Aircraft Quality Instruments, or have a recommendation for another shop?

-

Hottest cylinder CHT at cruise

TigerMooney replied to Wildhorsetrail's topic in Engine Monitor Discussion

Thanks for that tip. That may be my last option. Had baffling rechecked a second time, fuel injectors cleaned, and had the CHT probes checked….no spark plug gasket plug (same CHT probes all around). #2 still runs about 20 degrees hotter at times in cruise, while the other 3 are within 5 degrees of each other. Been uploading my JPI EDM 700 data to savvy analysis pro. They don’t seem alarmed, but it does say I’m in the high end of my cohort for CHTs. -

Looking for PIREP on Wet-Wingologist East

TigerMooney replied to FLYFST's topic in Modern Mooney Discussion

This is great news - 9 months in to owning an 81 M20J and I’ve started having a screw weep right by my entry door on the wing walk. Although my tanks were re sealed about 10 years ago by the previous owner, I’ve had no other issues *knocks on wood*. Hopefully this is an isolated incident, related to stress from walking on the wing. -

Thanks for all the tips! I actually have a third digital tach on my panel too…so three watches and I don’t really know what time it is Is it reasonable to ask my IA to calibrate my analogue tach an annual? Or is the original tach not able to be adjusted? if it’s indicating RPMs faster than actual, then it’s also running hours off my engine faster….

-

On takeoff and throughout cruise my JPI RPM indication disagrees with my analogue tach (JPI 50-80RPM less). Are there any simple initial thoughts on which one to trust and which one may be off? I just submitted my engine data to Savvy for analyzation and of course they came back saying my engine wasn’t making full power on takeoff…however I believe it is based on the analogue tach.

-

Lend or Sell your EDM 700 download kit?

TigerMooney replied to TigerMooney's topic in Engine Monitor Discussion

Do either of you have the box that goes with it, that plugs into the cigarette lighter adapter? -

TigerMooney started following Lend or Sell your EDM 700 download kit?

-

Wondering if anyone would let me borrow or purchase the JPI EDM 700 engine monitor download equipment? I’d like to avoid spending the $200 on the JPI website. I’m about 75 hours into the ownership of a 81 J model - reading Mike Busch’s book on engines and trying to track down why my #2 CHT runs 20+ hotter than all the others (mid 380s). It runs rough LOP, and I have to run it 200ROP (about a GPH more than needed) or partially open the cowl flaps to keep it below 380. Already replaced all 8 spark plugs, did an ignition stress test and a gami lean test. All those seem to be fine. Message me if you’re willing to lend or sell that download equipment. Thanks. I believe the port near the top right corner of the instrument is the data connection. Can someone please verify?

-

Hottest cylinder CHT at cruise

TigerMooney replied to Wildhorsetrail's topic in Engine Monitor Discussion

Interesting. I still have the ram air, however the rubber seal around the bottom is sort of chewed up and loose. Maybe that will help. It’s still really strange to me that I have to run it so rich to keep the temps down. I’ll keep trying one thing at a time until I get it right. -

Hottest cylinder CHT at cruise

TigerMooney replied to Wildhorsetrail's topic in Engine Monitor Discussion

First time poster here….This closely describes my 1981 M20J with an IO-360. I just bought it last week and have only put 7 hours on it. Has EDM 700, and in cruise #3 is hottest, with #2 sometimes being close. I have to go 150-200+ ROP to get the temps below 380 (and they’ll hang in the 370s). I sometimes will open the cowl flaps partially to get more air flow, while I’m trying to figure it all out. If I lean 50-100 ROP it gets in excess of 390 rather quick, but I also notice the fuel flow seems rather low for a given power setting per the book. Obviously I’m still very new to the plane, but it sounds like I should look at the baffling? The mechanic in the Pre Buy took both the top and bottom cowlings off - and maybe they were not seated properly when they were put back on? I’m not entirely sure what I’m looking for, if I were to look at it myself. I’m operating it in the warmer southeastern temps (mid 80s to mid 90s on the ground) so obviously its going to be hot anyway. Are there and specific Mooney tips for leaning on the ground/takeoff/climb? Also, is it general practice to use the electric fuel pump on every takeoff/landing? In other airframe types, it’s been recommended not to use them, as sometimes the fuel pump themself can break up and cause a fuel like blockage. Thanks in advance, and sorry for the long post!